How to Elevate Display Tech with QNED Modeling?

JUN 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QNED Display Evolution

QNED (Quantum Nano Emitting Diode) display technology has emerged as a promising advancement in the field of display technology, offering potential improvements in image quality, energy efficiency, and manufacturing processes. The evolution of QNED displays can be traced through several key stages, each marking significant progress in overcoming technical challenges and enhancing performance.

In its early stages, QNED technology focused on developing the fundamental principles of quantum dot light emission and nanorod structures. Researchers explored various materials and fabrication techniques to create nanoscale light-emitting diodes that could produce vibrant, precise colors. This phase laid the groundwork for understanding the quantum mechanical properties that govern QNED performance.

As the technology progressed, efforts shifted towards improving the efficiency and stability of QNED devices. Scientists worked on optimizing the quantum dot composition and nanorod architecture to enhance light output and reduce energy consumption. This period saw the introduction of advanced materials and novel manufacturing processes that allowed for better control over the nanoscale structures.

The next phase in QNED evolution concentrated on scaling up the technology for practical display applications. Engineers tackled challenges related to uniformity, yield, and integration with existing display manufacturing infrastructure. This stage was crucial in bridging the gap between laboratory prototypes and commercially viable products.

Recent developments in QNED technology have focused on enhancing color gamut, contrast ratio, and overall picture quality. Researchers have made significant strides in fine-tuning the spectral characteristics of QNED emitters, resulting in displays capable of reproducing a wider range of colors with greater accuracy. Additionally, advancements in light management and pixel design have led to improved contrast and black levels.

The current frontier of QNED evolution involves addressing remaining technical hurdles, such as long-term stability, color shift over time, and further improvements in energy efficiency. Ongoing research is exploring new materials, including perovskite quantum dots and advanced semiconductor alloys, to push the boundaries of QNED performance.

Looking ahead, the QNED display evolution is expected to continue with a focus on miniaturization, enabling higher pixel densities and potential applications in emerging fields like augmented and virtual reality. Furthermore, integration with flexible and transparent substrates may open up new possibilities for innovative display form factors and applications.

In its early stages, QNED technology focused on developing the fundamental principles of quantum dot light emission and nanorod structures. Researchers explored various materials and fabrication techniques to create nanoscale light-emitting diodes that could produce vibrant, precise colors. This phase laid the groundwork for understanding the quantum mechanical properties that govern QNED performance.

As the technology progressed, efforts shifted towards improving the efficiency and stability of QNED devices. Scientists worked on optimizing the quantum dot composition and nanorod architecture to enhance light output and reduce energy consumption. This period saw the introduction of advanced materials and novel manufacturing processes that allowed for better control over the nanoscale structures.

The next phase in QNED evolution concentrated on scaling up the technology for practical display applications. Engineers tackled challenges related to uniformity, yield, and integration with existing display manufacturing infrastructure. This stage was crucial in bridging the gap between laboratory prototypes and commercially viable products.

Recent developments in QNED technology have focused on enhancing color gamut, contrast ratio, and overall picture quality. Researchers have made significant strides in fine-tuning the spectral characteristics of QNED emitters, resulting in displays capable of reproducing a wider range of colors with greater accuracy. Additionally, advancements in light management and pixel design have led to improved contrast and black levels.

The current frontier of QNED evolution involves addressing remaining technical hurdles, such as long-term stability, color shift over time, and further improvements in energy efficiency. Ongoing research is exploring new materials, including perovskite quantum dots and advanced semiconductor alloys, to push the boundaries of QNED performance.

Looking ahead, the QNED display evolution is expected to continue with a focus on miniaturization, enabling higher pixel densities and potential applications in emerging fields like augmented and virtual reality. Furthermore, integration with flexible and transparent substrates may open up new possibilities for innovative display form factors and applications.

Market Demand Analysis

The market demand for QNED (Quantum Nano-Emitting Diode) display technology is rapidly growing as consumers and industries seek superior visual experiences. QNED combines the advantages of quantum dot and mini-LED technologies, offering enhanced color accuracy, brightness, and contrast ratios. This innovative display solution addresses the limitations of current LCD and OLED technologies, positioning itself as a potential game-changer in the display market.

The global display market is projected to expand significantly in the coming years, driven by increasing demand for high-quality displays in various sectors. QNED technology is poised to capture a substantial share of this growth, particularly in premium television and professional monitor segments. The technology's ability to deliver deeper blacks, wider color gamut, and improved energy efficiency aligns well with consumer preferences for immersive viewing experiences and eco-friendly products.

In the consumer electronics sector, there is a growing demand for larger screen sizes with higher resolutions. QNED displays are well-suited to meet this demand, offering superior picture quality even in large-format screens. The technology's potential to reduce power consumption while maintaining high brightness levels is particularly attractive to environmentally conscious consumers and businesses looking to reduce their carbon footprint.

The professional and commercial display markets also present significant opportunities for QNED technology. Industries such as healthcare, digital signage, and aerospace require displays with exceptional color accuracy and reliability. QNED's ability to provide consistent performance over extended periods makes it an attractive option for these sectors.

The automotive industry is another key market for QNED displays. As vehicles become more technologically advanced, there is an increasing need for high-quality, durable displays for infotainment systems and digital dashboards. QNED's resistance to image retention and its ability to perform well in varying light conditions make it well-suited for automotive applications.

Market trends indicate a shift towards more immersive and interactive display technologies. QNED's potential to support high refresh rates and low latency could make it an ideal choice for gaming and virtual reality applications, where visual quality and responsiveness are crucial.

As the display industry continues to evolve, there is a growing emphasis on sustainability and energy efficiency. QNED technology's potential to reduce power consumption while maintaining high performance aligns with these market trends, potentially driving adoption across various industries.

In conclusion, the market demand for QNED display technology is robust and diverse, spanning multiple sectors and applications. As the technology matures and production costs decrease, it is likely to gain significant market share, challenging existing display technologies and opening new possibilities for innovative products and solutions.

The global display market is projected to expand significantly in the coming years, driven by increasing demand for high-quality displays in various sectors. QNED technology is poised to capture a substantial share of this growth, particularly in premium television and professional monitor segments. The technology's ability to deliver deeper blacks, wider color gamut, and improved energy efficiency aligns well with consumer preferences for immersive viewing experiences and eco-friendly products.

In the consumer electronics sector, there is a growing demand for larger screen sizes with higher resolutions. QNED displays are well-suited to meet this demand, offering superior picture quality even in large-format screens. The technology's potential to reduce power consumption while maintaining high brightness levels is particularly attractive to environmentally conscious consumers and businesses looking to reduce their carbon footprint.

The professional and commercial display markets also present significant opportunities for QNED technology. Industries such as healthcare, digital signage, and aerospace require displays with exceptional color accuracy and reliability. QNED's ability to provide consistent performance over extended periods makes it an attractive option for these sectors.

The automotive industry is another key market for QNED displays. As vehicles become more technologically advanced, there is an increasing need for high-quality, durable displays for infotainment systems and digital dashboards. QNED's resistance to image retention and its ability to perform well in varying light conditions make it well-suited for automotive applications.

Market trends indicate a shift towards more immersive and interactive display technologies. QNED's potential to support high refresh rates and low latency could make it an ideal choice for gaming and virtual reality applications, where visual quality and responsiveness are crucial.

As the display industry continues to evolve, there is a growing emphasis on sustainability and energy efficiency. QNED technology's potential to reduce power consumption while maintaining high performance aligns with these market trends, potentially driving adoption across various industries.

In conclusion, the market demand for QNED display technology is robust and diverse, spanning multiple sectors and applications. As the technology matures and production costs decrease, it is likely to gain significant market share, challenging existing display technologies and opening new possibilities for innovative products and solutions.

QNED Tech Challenges

QNED (Quantum Nano-Emitting Diode) technology represents a significant advancement in display technology, but it also presents several technical challenges that need to be addressed for its successful implementation and widespread adoption. One of the primary challenges is achieving consistent and uniform quantum dot synthesis. The size and composition of quantum dots directly impact their emission properties, and maintaining precise control over these parameters during large-scale production is crucial for ensuring display quality and color accuracy.

Another significant challenge lies in the integration of quantum dots with existing LED structures. The interface between the quantum dot layer and the LED substrate must be carefully engineered to maximize energy transfer efficiency and minimize losses. This requires advanced materials science and nanofabrication techniques to create seamless and stable interfaces at the nanoscale.

Thermal management is a critical issue in QNED displays. Quantum dots are sensitive to temperature fluctuations, which can affect their emission properties and long-term stability. Developing effective heat dissipation mechanisms and thermal management strategies is essential for maintaining consistent performance and extending the lifespan of QNED displays.

Color purity and gamut expansion present additional challenges. While quantum dots offer the potential for wider color gamuts, achieving and maintaining precise color control across the entire display area requires sophisticated color management algorithms and calibration techniques. This is particularly important for high-end applications such as professional-grade monitors and high-fidelity video displays.

Longevity and degradation resistance are ongoing concerns for QNED technology. Quantum dots can be susceptible to photo-oxidation and other degradation mechanisms over time, potentially leading to shifts in color output or reduced efficiency. Developing robust encapsulation methods and materials that protect quantum dots from environmental factors without compromising their optical properties is a key area of research.

Manufacturing scalability poses another significant challenge. Transitioning from laboratory-scale production to large-scale, cost-effective manufacturing processes while maintaining the precise control required for QNED technology is a complex undertaking. This involves optimizing deposition techniques, developing new quality control methods, and establishing reliable supply chains for specialized materials.

Lastly, achieving high energy efficiency in QNED displays is crucial for their commercial viability. While quantum dots offer the potential for improved efficiency compared to traditional display technologies, further advancements are needed to minimize energy losses and maximize the conversion of electrical energy into light output. This requires ongoing research into quantum dot materials, device architectures, and driving electronics to push the boundaries of display efficiency.

Another significant challenge lies in the integration of quantum dots with existing LED structures. The interface between the quantum dot layer and the LED substrate must be carefully engineered to maximize energy transfer efficiency and minimize losses. This requires advanced materials science and nanofabrication techniques to create seamless and stable interfaces at the nanoscale.

Thermal management is a critical issue in QNED displays. Quantum dots are sensitive to temperature fluctuations, which can affect their emission properties and long-term stability. Developing effective heat dissipation mechanisms and thermal management strategies is essential for maintaining consistent performance and extending the lifespan of QNED displays.

Color purity and gamut expansion present additional challenges. While quantum dots offer the potential for wider color gamuts, achieving and maintaining precise color control across the entire display area requires sophisticated color management algorithms and calibration techniques. This is particularly important for high-end applications such as professional-grade monitors and high-fidelity video displays.

Longevity and degradation resistance are ongoing concerns for QNED technology. Quantum dots can be susceptible to photo-oxidation and other degradation mechanisms over time, potentially leading to shifts in color output or reduced efficiency. Developing robust encapsulation methods and materials that protect quantum dots from environmental factors without compromising their optical properties is a key area of research.

Manufacturing scalability poses another significant challenge. Transitioning from laboratory-scale production to large-scale, cost-effective manufacturing processes while maintaining the precise control required for QNED technology is a complex undertaking. This involves optimizing deposition techniques, developing new quality control methods, and establishing reliable supply chains for specialized materials.

Lastly, achieving high energy efficiency in QNED displays is crucial for their commercial viability. While quantum dots offer the potential for improved efficiency compared to traditional display technologies, further advancements are needed to minimize energy losses and maximize the conversion of electrical energy into light output. This requires ongoing research into quantum dot materials, device architectures, and driving electronics to push the boundaries of display efficiency.

Current QNED Solutions

01 QNED structure and composition

QNED technology utilizes quantum dots and nanorod emitters in its structure. The display incorporates a combination of quantum dots, nanorods, and LED backlighting to achieve improved color gamut, brightness, and energy efficiency. The unique structure allows for precise control of light emission and color reproduction.- QNED structure and composition: QNED technology utilizes quantum dots and nanorod emitters in a diode structure. The composition typically includes III-V semiconductor materials, enhancing light emission efficiency and color purity. This structure allows for improved brightness, contrast, and color gamut compared to traditional LED displays.

- Color enhancement and control: QNED displays achieve superior color performance through precise control of quantum dot size and composition. This enables a wider color gamut and more accurate color reproduction. Advanced color management systems and algorithms are employed to optimize color output and maintain consistency across the display.

- Brightness and contrast improvements: QNED technology offers enhanced brightness and contrast ratios compared to conventional displays. This is achieved through improved light emission efficiency of quantum dots and nanorods, as well as advanced backlight control techniques. The result is a display with deeper blacks, brighter whites, and improved overall picture quality.

- Energy efficiency and power management: QNED displays are designed to be more energy-efficient than traditional LED or OLED displays. This is accomplished through optimized quantum dot emission, improved electron injection and transport layers, and advanced power management systems. The technology allows for high-quality display performance with reduced power consumption.

- Durability and lifespan: QNED technology addresses issues of display longevity and durability. Innovations in quantum dot and nanorod stability, encapsulation techniques, and heat management contribute to extended display lifespan. This results in QNED displays maintaining their high-quality performance over longer periods compared to some other display technologies.

02 Color enhancement and gamut improvement

QNED displays offer enhanced color performance through the use of quantum dots and nanorods. These nanomaterials enable a wider color gamut, more accurate color reproduction, and improved color saturation compared to traditional LED displays. The technology allows for finer control over individual color channels, resulting in more vibrant and lifelike images.Expand Specific Solutions03 Brightness and contrast optimization

QNED technology enhances display brightness and contrast through improved light management. The quantum dots and nanorods enable more efficient light conversion and emission, resulting in higher peak brightness levels. Additionally, the technology allows for better local dimming control, leading to improved contrast ratios and deeper blacks.Expand Specific Solutions04 Energy efficiency and power consumption

QNED displays offer improved energy efficiency compared to traditional LED and OLED technologies. The quantum dot and nanorod emitters require less power to produce the same level of brightness, resulting in lower overall power consumption. This efficiency translates to longer battery life in portable devices and reduced energy costs for larger displays.Expand Specific Solutions05 Durability and lifespan

QNED technology addresses some of the longevity issues associated with other display technologies. The use of inorganic materials in quantum dots and nanorods contributes to improved stability and resistance to degradation over time. This results in displays that maintain their color accuracy and brightness levels for longer periods, potentially extending the overall lifespan of the display.Expand Specific Solutions

Key QNED Players

The QNED (Quantum Nano Emitting Diode) display technology market is in its early growth stage, with significant potential for expansion. The global market size for advanced display technologies is projected to reach billions of dollars in the coming years. QNED technology is still evolving, with varying levels of maturity among key players. Companies like BOE Technology Group, TCL China Star Optoelectronics, and Sharp Corp. are at the forefront of QNED development, investing heavily in research and production capabilities. Other players such as Applied Materials and Corning are contributing to the ecosystem with specialized components and materials. The competitive landscape is characterized by a mix of established display manufacturers and innovative startups, all vying to perfect QNED technology for mass-market adoption.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a QNED (Quantum Nano Emitting Diode) display technology that combines quantum dot and mini-LED technologies. Their approach involves using a blue mini-LED backlight to excite red and green quantum dots, resulting in a display with high brightness, wide color gamut, and improved contrast ratio. BOE's QNED panels utilize advanced quantum dot materials and precise light management techniques to achieve optimal color performance and energy efficiency. The company has also implemented AI-driven local dimming algorithms to enhance contrast and reduce blooming effects in their QNED displays.

Strengths: Superior color performance, high brightness, and improved contrast ratio. Weaknesses: Higher production costs compared to traditional LCD technologies and potential challenges in achieving uniform light distribution across large panel sizes.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has developed a QNED display technology that integrates quantum dot color conversion with mini-LED backlighting. Their approach focuses on optimizing the quantum dot layer to achieve precise color conversion and enhance overall display performance. TCL CSOT's QNED panels feature a high number of local dimming zones, allowing for improved contrast and HDR performance. The company has also implemented advanced optical designs to minimize light leakage and improve viewing angles in their QNED displays. Additionally, TCL CSOT has developed proprietary quantum dot materials that offer improved stability and longevity compared to traditional quantum dot solutions.

Strengths: High contrast ratio, wide color gamut, and improved HDR performance. Weaknesses: Potential challenges in mass production and maintaining consistent quality across large panel sizes.

QNED Modeling Patents

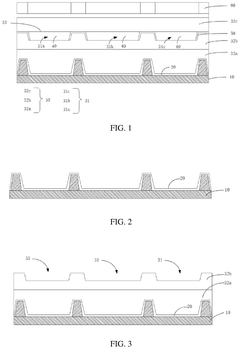

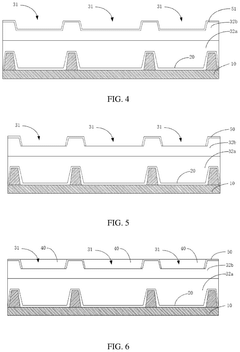

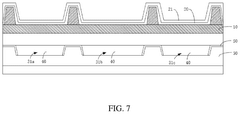

Method for preparing high-resolution quantum dot (QD) pixelated light-emitting film

PatentActiveUS12120941B1

Innovation

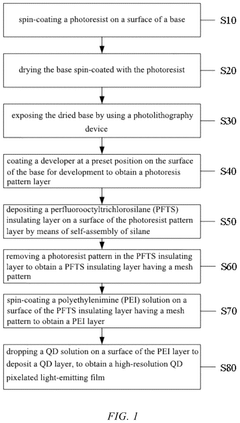

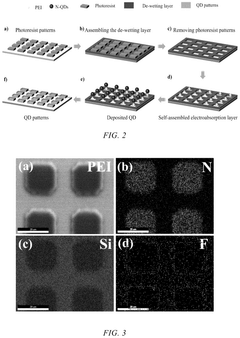

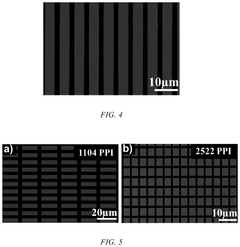

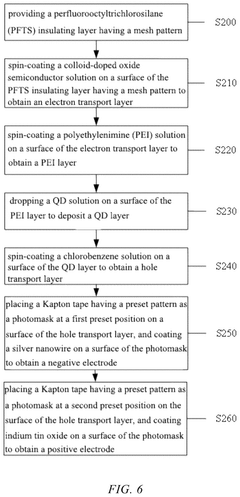

- A method involving spin-coating a photoresist, exposing, and developing to create a pattern, followed by depositing a perfluorooctyltrichlorosilane (PFTS) insulating layer, then a polyethylenimine (PEI) layer, and finally a QD layer, using self-assembly and electrostatic interactions to avoid direct photolithography on the QD layer, thereby preventing damage and improving film quality.

Quantum dot display panel and manufacturing method thereof and display device

PatentPendingUS20240407230A1

Innovation

- A quantum dot display panel design where the quantum dot light-emitting layer is integrated within a closed pixel definition region formed inside an encapsulation layer on the array substrate, reducing the impact of alignment deviations and omitting the need for an encapsulating film on the color filter cover, thereby simplifying the manufacturing process and enhancing light intensity by direct light emission.

QNED Manufacturing

QNED (Quantum Nano-Emitting Diode) manufacturing represents a critical aspect of advancing display technology. The process involves integrating quantum dots and nanorod LEDs to create highly efficient and color-accurate displays. Key steps in QNED manufacturing include quantum dot synthesis, nanorod LED fabrication, and precise integration of these components.

Quantum dot synthesis requires careful control of temperature, reaction time, and precursor concentrations to achieve uniform size distribution and optimal optical properties. Advanced techniques such as continuous flow reactors and microfluidic systems have been developed to enhance the consistency and scalability of quantum dot production.

Nanorod LED fabrication involves epitaxial growth of III-V semiconductor materials, typically using molecular beam epitaxy (MBE) or metal-organic chemical vapor deposition (MOCVD). These processes require ultra-high vacuum conditions and precise control of growth parameters to achieve the desired nanorod structures with optimal electronic and optical characteristics.

Integration of quantum dots and nanorod LEDs presents significant challenges in terms of alignment, electrical connectivity, and maintaining the integrity of both components. Advanced pick-and-place techniques, such as transfer printing and self-assembly methods, have been explored to achieve high-precision placement of nanoscale elements.

Encapsulation and packaging of QNED devices are crucial for protecting the sensitive quantum structures from environmental factors and ensuring long-term stability. Novel materials and deposition techniques are being developed to create effective barrier layers while maintaining optical transparency and electrical conductivity.

Scaling up QNED manufacturing for large-area displays requires overcoming several hurdles, including uniformity across large substrates, yield improvement, and cost reduction. Roll-to-roll processing and large-area printing techniques are being investigated as potential solutions for high-throughput production.

Quality control and characterization play vital roles in QNED manufacturing. Advanced imaging techniques, such as high-resolution transmission electron microscopy (TEM) and atomic force microscopy (AFM), are employed to analyze the structural properties of quantum dots and nanorods. Spectroscopic methods, including photoluminescence and electroluminescence measurements, are used to assess the optical performance of QNED devices.

Addressing these manufacturing challenges is essential for realizing the full potential of QNED technology in next-generation displays. Continued research and development efforts are focused on improving material synthesis, enhancing integration techniques, and optimizing large-scale production processes to bring QNED displays to commercial viability.

Quantum dot synthesis requires careful control of temperature, reaction time, and precursor concentrations to achieve uniform size distribution and optimal optical properties. Advanced techniques such as continuous flow reactors and microfluidic systems have been developed to enhance the consistency and scalability of quantum dot production.

Nanorod LED fabrication involves epitaxial growth of III-V semiconductor materials, typically using molecular beam epitaxy (MBE) or metal-organic chemical vapor deposition (MOCVD). These processes require ultra-high vacuum conditions and precise control of growth parameters to achieve the desired nanorod structures with optimal electronic and optical characteristics.

Integration of quantum dots and nanorod LEDs presents significant challenges in terms of alignment, electrical connectivity, and maintaining the integrity of both components. Advanced pick-and-place techniques, such as transfer printing and self-assembly methods, have been explored to achieve high-precision placement of nanoscale elements.

Encapsulation and packaging of QNED devices are crucial for protecting the sensitive quantum structures from environmental factors and ensuring long-term stability. Novel materials and deposition techniques are being developed to create effective barrier layers while maintaining optical transparency and electrical conductivity.

Scaling up QNED manufacturing for large-area displays requires overcoming several hurdles, including uniformity across large substrates, yield improvement, and cost reduction. Roll-to-roll processing and large-area printing techniques are being investigated as potential solutions for high-throughput production.

Quality control and characterization play vital roles in QNED manufacturing. Advanced imaging techniques, such as high-resolution transmission electron microscopy (TEM) and atomic force microscopy (AFM), are employed to analyze the structural properties of quantum dots and nanorods. Spectroscopic methods, including photoluminescence and electroluminescence measurements, are used to assess the optical performance of QNED devices.

Addressing these manufacturing challenges is essential for realizing the full potential of QNED technology in next-generation displays. Continued research and development efforts are focused on improving material synthesis, enhancing integration techniques, and optimizing large-scale production processes to bring QNED displays to commercial viability.

QNED Energy Efficiency

QNED (Quantum Nano-Emitting Diode) technology has emerged as a promising solution for enhancing display energy efficiency. By leveraging quantum dot technology and nanorod LEDs, QNED displays offer significant improvements in power consumption compared to traditional LCD and OLED displays.

The energy efficiency of QNED displays stems from their unique structure and operating principles. Unlike LCDs that require constant backlighting, QNED displays use self-emissive quantum dots, allowing for precise control of individual pixels. This results in better black levels and reduced power consumption in dark scenes. Additionally, the high quantum efficiency of QNED emitters translates to less energy wasted as heat, further improving overall efficiency.

QNED displays also benefit from improved color purity and brightness. The narrow emission spectra of quantum dots enable more accurate color reproduction with less energy input. This allows QNED displays to achieve higher peak brightness levels while consuming less power than conventional display technologies.

The use of nanorod LEDs in QNED displays contributes to their energy efficiency by providing better current spreading and reduced droop effect. This results in more uniform light emission and improved efficiency at higher current densities, allowing for brighter displays without proportional increases in power consumption.

Recent advancements in QNED technology have focused on optimizing the quantum dot and nanorod materials to further enhance energy efficiency. Researchers are exploring new compositions and structures to improve quantum yield and reduce energy losses due to non-radiative recombination processes. These efforts aim to push the theoretical limits of QNED efficiency closer to practical realization.

The potential for QNED displays to significantly reduce energy consumption in consumer electronics and large-format displays has attracted considerable attention from industry leaders. Major display manufacturers are investing in QNED research and development, recognizing its potential to address growing concerns about the energy footprint of display technologies in an increasingly screen-centric world.

As QNED technology continues to mature, it is expected to play a crucial role in the development of more energy-efficient display solutions. The combination of high brightness, excellent color performance, and low power consumption positions QNED as a compelling option for next-generation displays across various applications, from mobile devices to large-scale digital signage.

The energy efficiency of QNED displays stems from their unique structure and operating principles. Unlike LCDs that require constant backlighting, QNED displays use self-emissive quantum dots, allowing for precise control of individual pixels. This results in better black levels and reduced power consumption in dark scenes. Additionally, the high quantum efficiency of QNED emitters translates to less energy wasted as heat, further improving overall efficiency.

QNED displays also benefit from improved color purity and brightness. The narrow emission spectra of quantum dots enable more accurate color reproduction with less energy input. This allows QNED displays to achieve higher peak brightness levels while consuming less power than conventional display technologies.

The use of nanorod LEDs in QNED displays contributes to their energy efficiency by providing better current spreading and reduced droop effect. This results in more uniform light emission and improved efficiency at higher current densities, allowing for brighter displays without proportional increases in power consumption.

Recent advancements in QNED technology have focused on optimizing the quantum dot and nanorod materials to further enhance energy efficiency. Researchers are exploring new compositions and structures to improve quantum yield and reduce energy losses due to non-radiative recombination processes. These efforts aim to push the theoretical limits of QNED efficiency closer to practical realization.

The potential for QNED displays to significantly reduce energy consumption in consumer electronics and large-format displays has attracted considerable attention from industry leaders. Major display manufacturers are investing in QNED research and development, recognizing its potential to address growing concerns about the energy footprint of display technologies in an increasingly screen-centric world.

As QNED technology continues to mature, it is expected to play a crucial role in the development of more energy-efficient display solutions. The combination of high brightness, excellent color performance, and low power consumption positions QNED as a compelling option for next-generation displays across various applications, from mobile devices to large-scale digital signage.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!