Advanced QNED Techniques for Display Innovation

JUN 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QNED Display Evolution and Objectives

QNED (Quantum Nano Emitting Diode) display technology represents a significant leap forward in the evolution of display innovation. This cutting-edge technology combines the advantages of quantum dot and mini-LED technologies to create a new generation of displays with superior image quality, energy efficiency, and longevity.

The development of QNED technology can be traced back to the early 2010s when researchers began exploring ways to enhance the color performance and efficiency of LED displays. The integration of quantum dots into LED backlighting systems marked a crucial milestone in this journey, leading to the emergence of QLED (Quantum Dot LED) displays.

As the demand for higher resolution and better contrast in displays continued to grow, the industry saw the potential in combining quantum dot technology with mini-LED backlighting. This convergence gave birth to QNED displays, which offer significant improvements in brightness, contrast ratio, and color accuracy compared to traditional LCD and OLED technologies.

The primary objective of QNED research is to overcome the limitations of existing display technologies while leveraging the strengths of both quantum dots and mini-LEDs. Researchers aim to develop QNED displays that can deliver perfect blacks, vibrant colors, and high brightness levels without the drawbacks of image retention or burn-in associated with OLED displays.

Another key goal is to improve the energy efficiency of QNED displays, making them more sustainable and cost-effective for consumers. This involves optimizing the quantum dot materials and refining the mini-LED backlighting system to reduce power consumption without compromising on picture quality.

Durability and longevity are also critical objectives in QNED research. Scientists are working on enhancing the stability of quantum dot materials and developing protective layers to prevent degradation over time, ensuring that QNED displays maintain their performance characteristics throughout their lifespan.

The evolution of QNED technology is expected to continue, with researchers focusing on increasing the pixel density, improving color gamut coverage, and reducing production costs. These advancements aim to make QNED displays more competitive in various applications, from high-end televisions and monitors to automotive displays and professional-grade screens for content creation.

As QNED technology progresses, it is anticipated to play a crucial role in shaping the future of display innovation. The ongoing research and development efforts are directed towards creating displays that offer an unparalleled visual experience while addressing the growing demand for energy-efficient and long-lasting display solutions across multiple industries.

The development of QNED technology can be traced back to the early 2010s when researchers began exploring ways to enhance the color performance and efficiency of LED displays. The integration of quantum dots into LED backlighting systems marked a crucial milestone in this journey, leading to the emergence of QLED (Quantum Dot LED) displays.

As the demand for higher resolution and better contrast in displays continued to grow, the industry saw the potential in combining quantum dot technology with mini-LED backlighting. This convergence gave birth to QNED displays, which offer significant improvements in brightness, contrast ratio, and color accuracy compared to traditional LCD and OLED technologies.

The primary objective of QNED research is to overcome the limitations of existing display technologies while leveraging the strengths of both quantum dots and mini-LEDs. Researchers aim to develop QNED displays that can deliver perfect blacks, vibrant colors, and high brightness levels without the drawbacks of image retention or burn-in associated with OLED displays.

Another key goal is to improve the energy efficiency of QNED displays, making them more sustainable and cost-effective for consumers. This involves optimizing the quantum dot materials and refining the mini-LED backlighting system to reduce power consumption without compromising on picture quality.

Durability and longevity are also critical objectives in QNED research. Scientists are working on enhancing the stability of quantum dot materials and developing protective layers to prevent degradation over time, ensuring that QNED displays maintain their performance characteristics throughout their lifespan.

The evolution of QNED technology is expected to continue, with researchers focusing on increasing the pixel density, improving color gamut coverage, and reducing production costs. These advancements aim to make QNED displays more competitive in various applications, from high-end televisions and monitors to automotive displays and professional-grade screens for content creation.

As QNED technology progresses, it is anticipated to play a crucial role in shaping the future of display innovation. The ongoing research and development efforts are directed towards creating displays that offer an unparalleled visual experience while addressing the growing demand for energy-efficient and long-lasting display solutions across multiple industries.

Market Demand for QNED Displays

The market demand for QNED (Quantum Nano Emitting Diode) displays has been steadily growing as consumers and industries seek advanced display technologies that offer superior image quality, energy efficiency, and durability. QNED technology, which combines quantum dot and mini-LED technologies, has positioned itself as a promising contender in the high-end display market.

Consumer electronics, particularly in the television sector, have shown significant interest in QNED displays. The technology's ability to deliver enhanced brightness, deeper blacks, and more vibrant colors has resonated with consumers looking for premium viewing experiences. This demand is further fueled by the increasing consumption of high-quality content, including 4K and 8K resolution videos, HDR content, and immersive gaming experiences.

In the professional and commercial sectors, QNED displays are gaining traction for applications requiring high-quality visual output. Industries such as digital signage, control rooms, and medical imaging are exploring QNED technology for its superior color accuracy and contrast ratios. The automotive industry is also showing interest in QNED for in-vehicle displays, where high brightness and wide color gamut are crucial for visibility and user experience.

The market demand is also driven by the technology's potential to address some of the limitations of existing display technologies. QNED offers advantages over OLED in terms of brightness and longevity, while surpassing traditional LCD in color performance and contrast. This positioning makes QNED an attractive option for consumers and businesses looking for a balance between performance and cost.

Environmental considerations are playing a role in market demand as well. QNED displays are generally more energy-efficient than their predecessors, aligning with the growing consumer preference for eco-friendly technologies. This aspect is particularly appealing in regions with strict energy regulations and for businesses aiming to reduce their carbon footprint.

The global shift towards remote work and digital communication has also contributed to the demand for high-quality displays. As virtual meetings and remote collaboration become more prevalent, there is an increased need for displays that can accurately reproduce colors and details, making QNED technology relevant in both home and office environments.

While the market demand for QNED displays is growing, it is important to note that the technology is still relatively new and faces competition from established technologies like OLED and emerging ones like micro-LED. The adoption rate and market penetration will depend on factors such as manufacturing costs, technological advancements, and the ability to scale production to meet demand.

Consumer electronics, particularly in the television sector, have shown significant interest in QNED displays. The technology's ability to deliver enhanced brightness, deeper blacks, and more vibrant colors has resonated with consumers looking for premium viewing experiences. This demand is further fueled by the increasing consumption of high-quality content, including 4K and 8K resolution videos, HDR content, and immersive gaming experiences.

In the professional and commercial sectors, QNED displays are gaining traction for applications requiring high-quality visual output. Industries such as digital signage, control rooms, and medical imaging are exploring QNED technology for its superior color accuracy and contrast ratios. The automotive industry is also showing interest in QNED for in-vehicle displays, where high brightness and wide color gamut are crucial for visibility and user experience.

The market demand is also driven by the technology's potential to address some of the limitations of existing display technologies. QNED offers advantages over OLED in terms of brightness and longevity, while surpassing traditional LCD in color performance and contrast. This positioning makes QNED an attractive option for consumers and businesses looking for a balance between performance and cost.

Environmental considerations are playing a role in market demand as well. QNED displays are generally more energy-efficient than their predecessors, aligning with the growing consumer preference for eco-friendly technologies. This aspect is particularly appealing in regions with strict energy regulations and for businesses aiming to reduce their carbon footprint.

The global shift towards remote work and digital communication has also contributed to the demand for high-quality displays. As virtual meetings and remote collaboration become more prevalent, there is an increased need for displays that can accurately reproduce colors and details, making QNED technology relevant in both home and office environments.

While the market demand for QNED displays is growing, it is important to note that the technology is still relatively new and faces competition from established technologies like OLED and emerging ones like micro-LED. The adoption rate and market penetration will depend on factors such as manufacturing costs, technological advancements, and the ability to scale production to meet demand.

QNED Technology Challenges

QNED (Quantum Nano Emitting Diode) technology, while promising significant advancements in display innovation, faces several critical challenges that need to be addressed for its widespread adoption and commercialization. One of the primary hurdles is the complexity of manufacturing processes required to produce QNED displays at scale. The precise placement and alignment of nanoparticles demand highly sophisticated equipment and techniques, which currently limit production efficiency and yield rates.

Another significant challenge lies in the stability and longevity of QNED displays. The quantum dots used in these displays are susceptible to degradation over time, particularly when exposed to heat and oxygen. This degradation can lead to color shifts and reduced brightness, impacting the overall display quality and lifespan. Developing robust encapsulation methods to protect the quantum dots from environmental factors remains a crucial area of research.

Color accuracy and consistency pose additional challenges for QNED technology. While quantum dots offer the potential for a wider color gamut, achieving precise color control across the entire display and maintaining uniformity between different units is technically demanding. This challenge is further compounded by the need to balance color accuracy with energy efficiency, as driving the quantum dots to produce highly saturated colors can increase power consumption.

The integration of QNED technology with existing display architectures presents another set of challenges. Adapting current manufacturing processes and equipment to accommodate QNED production requires significant investment and retooling of production lines. Additionally, ensuring compatibility with various display drivers and control systems adds complexity to the development process.

Heat management is a critical concern in QNED displays. The high current densities required to excite the quantum dots can generate substantial heat, potentially affecting the display's performance and longevity. Developing effective thermal management solutions without compromising the display's form factor or increasing production costs is a significant engineering challenge.

Lastly, the cost of QNED technology remains a substantial barrier to widespread adoption. The materials used in QNED displays, particularly high-quality quantum dots, are currently expensive to produce at scale. Reducing production costs while maintaining performance standards is crucial for QNED to compete with established display technologies in the consumer market.

Overcoming these challenges requires concerted efforts in materials science, manufacturing processes, and display engineering. Advances in quantum dot synthesis, encapsulation techniques, and production methods are essential to address stability, uniformity, and cost issues. Furthermore, innovations in thermal management and color calibration technologies will be critical in realizing the full potential of QNED displays for next-generation visual experiences.

Another significant challenge lies in the stability and longevity of QNED displays. The quantum dots used in these displays are susceptible to degradation over time, particularly when exposed to heat and oxygen. This degradation can lead to color shifts and reduced brightness, impacting the overall display quality and lifespan. Developing robust encapsulation methods to protect the quantum dots from environmental factors remains a crucial area of research.

Color accuracy and consistency pose additional challenges for QNED technology. While quantum dots offer the potential for a wider color gamut, achieving precise color control across the entire display and maintaining uniformity between different units is technically demanding. This challenge is further compounded by the need to balance color accuracy with energy efficiency, as driving the quantum dots to produce highly saturated colors can increase power consumption.

The integration of QNED technology with existing display architectures presents another set of challenges. Adapting current manufacturing processes and equipment to accommodate QNED production requires significant investment and retooling of production lines. Additionally, ensuring compatibility with various display drivers and control systems adds complexity to the development process.

Heat management is a critical concern in QNED displays. The high current densities required to excite the quantum dots can generate substantial heat, potentially affecting the display's performance and longevity. Developing effective thermal management solutions without compromising the display's form factor or increasing production costs is a significant engineering challenge.

Lastly, the cost of QNED technology remains a substantial barrier to widespread adoption. The materials used in QNED displays, particularly high-quality quantum dots, are currently expensive to produce at scale. Reducing production costs while maintaining performance standards is crucial for QNED to compete with established display technologies in the consumer market.

Overcoming these challenges requires concerted efforts in materials science, manufacturing processes, and display engineering. Advances in quantum dot synthesis, encapsulation techniques, and production methods are essential to address stability, uniformity, and cost issues. Furthermore, innovations in thermal management and color calibration technologies will be critical in realizing the full potential of QNED displays for next-generation visual experiences.

Current QNED Solutions

01 Quantum dot structure and composition

QNED displays utilize advanced quantum dot structures and compositions to enhance display quality. These nanostructures are engineered to emit specific wavelengths of light, resulting in improved color accuracy and brightness. The composition of quantum dots, including core-shell structures and doping materials, plays a crucial role in determining the overall display performance.- Quantum dot structure and composition: QNED displays utilize advanced quantum dot structures and compositions to enhance display quality. These quantum dots are typically made of semiconductor materials and are engineered to emit specific wavelengths of light, resulting in improved color accuracy and brightness. The size, shape, and composition of quantum dots are crucial factors in determining the overall display performance.

- Light-emitting layer design: The design of the light-emitting layer in QNED displays plays a significant role in display quality. This includes the arrangement of quantum dots, the use of multiple layers, and the incorporation of other materials to enhance light emission and efficiency. Optimizing the light-emitting layer can lead to improved color gamut, contrast ratio, and overall visual performance.

- Electrode and substrate configuration: The configuration of electrodes and substrates in QNED displays affects the overall display quality. This includes the design of transparent electrodes, the use of flexible substrates, and the implementation of novel electrode structures to improve current distribution and light extraction. Proper electrode and substrate design can enhance display brightness, uniformity, and power efficiency.

- Color conversion and enhancement techniques: QNED displays employ various color conversion and enhancement techniques to improve display quality. These may include the use of color filters, phosphors, or other materials to convert and fine-tune the emitted light. Advanced color management algorithms and techniques are also implemented to optimize color accuracy, saturation, and overall visual experience.

- Manufacturing and fabrication processes: The manufacturing and fabrication processes of QNED displays significantly impact display quality. This includes techniques for precise deposition of quantum dots, patterning methods for creating pixel structures, and processes for integrating various display components. Advanced manufacturing techniques can lead to improved uniformity, yield, and overall display performance.

02 Light-emitting layer design

The design of the light-emitting layer in QNED displays is critical for achieving high display quality. This includes optimizing the arrangement of quantum dots, incorporating multiple emissive layers, and developing novel materials to enhance light output and efficiency. Advanced layer designs can lead to improved color gamut, contrast ratio, and overall visual performance.Expand Specific Solutions03 Quantum dot synthesis and deposition techniques

The methods used for synthesizing and depositing quantum dots significantly impact QNED display quality. Advanced techniques such as solution-based processing, inkjet printing, and vapor deposition are employed to create uniform and precise quantum dot layers. These methods aim to improve the consistency and stability of quantum dot emissions, resulting in better display performance.Expand Specific Solutions04 Backplane and driving technology

The backplane and driving technology used in QNED displays play a crucial role in display quality. This includes the development of high-performance thin-film transistors (TFTs), advanced pixel circuits, and efficient driving schemes. These technologies contribute to improved refresh rates, reduced motion blur, and enhanced overall image quality in QNED displays.Expand Specific Solutions05 Color management and image processing

Advanced color management and image processing techniques are essential for optimizing QNED display quality. This includes developing algorithms for color calibration, gamut mapping, and dynamic range enhancement. These techniques ensure accurate color reproduction, improved contrast, and enhanced overall visual experience in QNED displays.Expand Specific Solutions

Key QNED Industry Players

The research on Advanced QNED Techniques for Display Innovation is in its early stages, with the market still developing. Major players like BOE Technology Group, Samsung Electronics, and LG Display are investing heavily in this emerging technology. The market size is expected to grow significantly as QNED displays offer potential improvements in picture quality and energy efficiency. Technologically, QNED is still maturing, with companies like Sharp Corp. and TCL China Star Optoelectronics Technology Co., Ltd. making advancements in quantum dot and mini-LED integration. Universities such as The Hong Kong University of Science & Technology are contributing to fundamental research, while industry collaborations are accelerating practical applications.

BOE Technology Group Co., Ltd.

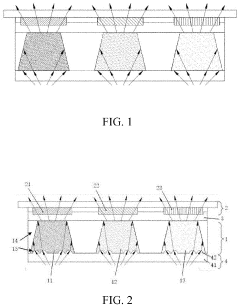

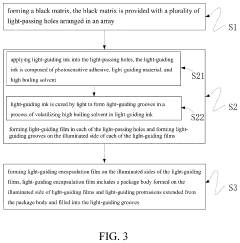

Technical Solution: BOE has developed advanced QNED (Quantum Nano Emitting Diode) technology for display innovation. Their approach combines quantum dot technology with mini-LED backlighting to achieve superior color performance and contrast ratios. BOE's QNED displays utilize a unique quantum dot film and precise light control algorithm to enhance color gamut and brightness. The company has also implemented advanced local dimming techniques to improve contrast and reduce blooming effects. BOE's QNED panels incorporate a specialized optical structure to minimize light leakage and maintain image quality at wide viewing angles.

Strengths: Superior color performance, high contrast ratios, and wide color gamut. Weaknesses: Higher production costs compared to traditional LCD technology, and potential challenges in achieving uniform brightness across large panel sizes.

Sharp Corp.

Technical Solution: Sharp has focused on developing QNED technology that leverages their expertise in LCD manufacturing. Their approach involves integrating quantum dot materials directly into the LCD cell structure, rather than using a separate quantum dot film. Sharp's QNED displays utilize a unique backlight design that combines mini-LED technology with quantum dot color conversion. The company has developed proprietary quantum dot materials optimized for stability and longevity in display applications. Sharp's QNED technology also incorporates advanced optical films to enhance light extraction efficiency and improve overall display brightness.

Strengths: Potential for lower production costs due to integration with existing LCD manufacturing processes, good color performance. Weaknesses: May face challenges in achieving the same level of contrast and black levels as other QNED approaches.

Core QNED Innovations

Quantum dot color filter substrate, fabricating method thereof, and display panel

PatentActiveUS20210336171A1

Innovation

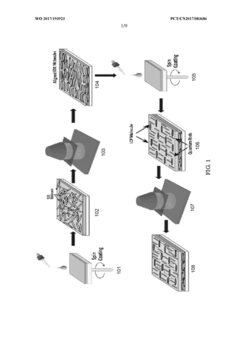

- A quantum dot color filter substrate with light-guiding grooves and protrusions on the surface of light-guiding films, which act as convex mirrors to increase the optical path of incident light, reducing absorption by the black matrix and enhancing light utilization efficiency without increasing the luminous intensity of the light-emitting device.

Photoaligned quantum rod enhancement films

PatentWO2017193923A1

Innovation

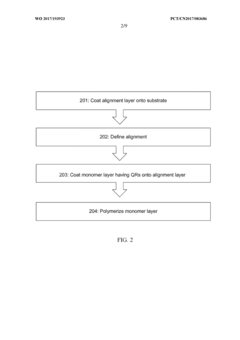

- Utilization of photoalignment technique to align quantum rods in a polymer layer, enabling precise control over the orientation of quantum rods.

- Integration of quantum rod enhancement film (QREF) into LCD displays to improve color gamut and optical efficiency.

- Development of a scalable method for producing QREF, involving coating and polymerization steps, suitable for large-scale fabrication of LCDs.

QNED Manufacturing Processes

QNED (Quantum Nano Emitting Diode) manufacturing processes represent a critical aspect of advancing display technology. The production of QNED displays involves several sophisticated steps, each requiring precise control and innovative techniques. The process begins with the preparation of quantum dots, typically composed of semiconductor materials such as indium phosphide or cadmium selenide. These quantum dots are synthesized using colloidal chemistry methods, allowing for precise control over their size and composition, which directly influences the color and efficiency of light emission.

Following quantum dot synthesis, the next crucial step is the integration of these nanoparticles into a suitable matrix. This often involves dispersing the quantum dots in a polymer or resin, which serves as a protective encapsulation and facilitates their incorporation into the display structure. The dispersion process must be carefully controlled to ensure uniform distribution and prevent aggregation of the quantum dots, which could lead to inconsistent color output.

The creation of the nano-LED structure is another key component of QNED manufacturing. This involves the deposition of multiple layers of semiconductor materials to form the LED structure, typically using techniques such as molecular beam epitaxy or metal-organic chemical vapor deposition. The precise control of layer thickness and composition is crucial for achieving the desired electrical and optical properties of the nano-LEDs.

Assembly of the QNED display panel requires the integration of the quantum dot-embedded layer with the nano-LED array. This process often involves advanced patterning techniques such as photolithography or inkjet printing to precisely position the quantum dots in alignment with the underlying LED structure. The alignment accuracy is critical for ensuring optimal color conversion and light output efficiency.

The final stages of QNED manufacturing involve the integration of driving electronics and the encapsulation of the display panel. This includes the deposition of transparent electrodes, typically using materials like indium tin oxide, and the integration of thin-film transistors for pixel addressing. Encapsulation is crucial for protecting the sensitive quantum dot and LED structures from environmental factors such as moisture and oxygen, which can degrade performance over time.

Throughout the manufacturing process, quality control and testing play a vital role. This includes spectroscopic analysis of quantum dot emissions, electrical characterization of nano-LEDs, and optical performance testing of the completed display panels. Advanced imaging techniques, such as atomic force microscopy and transmission electron microscopy, are often employed to verify the structural integrity and uniformity of the quantum dot and LED layers.

Following quantum dot synthesis, the next crucial step is the integration of these nanoparticles into a suitable matrix. This often involves dispersing the quantum dots in a polymer or resin, which serves as a protective encapsulation and facilitates their incorporation into the display structure. The dispersion process must be carefully controlled to ensure uniform distribution and prevent aggregation of the quantum dots, which could lead to inconsistent color output.

The creation of the nano-LED structure is another key component of QNED manufacturing. This involves the deposition of multiple layers of semiconductor materials to form the LED structure, typically using techniques such as molecular beam epitaxy or metal-organic chemical vapor deposition. The precise control of layer thickness and composition is crucial for achieving the desired electrical and optical properties of the nano-LEDs.

Assembly of the QNED display panel requires the integration of the quantum dot-embedded layer with the nano-LED array. This process often involves advanced patterning techniques such as photolithography or inkjet printing to precisely position the quantum dots in alignment with the underlying LED structure. The alignment accuracy is critical for ensuring optimal color conversion and light output efficiency.

The final stages of QNED manufacturing involve the integration of driving electronics and the encapsulation of the display panel. This includes the deposition of transparent electrodes, typically using materials like indium tin oxide, and the integration of thin-film transistors for pixel addressing. Encapsulation is crucial for protecting the sensitive quantum dot and LED structures from environmental factors such as moisture and oxygen, which can degrade performance over time.

Throughout the manufacturing process, quality control and testing play a vital role. This includes spectroscopic analysis of quantum dot emissions, electrical characterization of nano-LEDs, and optical performance testing of the completed display panels. Advanced imaging techniques, such as atomic force microscopy and transmission electron microscopy, are often employed to verify the structural integrity and uniformity of the quantum dot and LED layers.

QNED Environmental Impact

The environmental impact of QNED (Quantum Nano Emitting Diode) technology is an important consideration in the development and adoption of this innovative display technology. As QNED displays gain traction in the market, it is crucial to assess their ecological footprint throughout their lifecycle, from production to disposal.

In terms of manufacturing, QNED technology utilizes quantum dots and nanoparticles, which require specialized production processes. These processes may involve the use of rare earth elements and other materials that can have environmental implications if not properly managed. However, compared to traditional LCD and OLED manufacturing, QNED production has the potential to be more energy-efficient and require fewer toxic chemicals, potentially reducing overall environmental impact.

The energy consumption of QNED displays during operation is a key factor in their environmental performance. Initial studies suggest that QNED technology may offer improved energy efficiency compared to existing display technologies. This is primarily due to the high luminance efficiency of quantum dots and the precise control of light emission at the nanoscale level. As a result, QNED displays could contribute to reduced energy consumption in consumer electronics and commercial applications, leading to lower carbon emissions over their lifespan.

Durability and lifespan are also important considerations in assessing the environmental impact of QNED displays. If QNED technology proves to be more durable and long-lasting than current display technologies, it could lead to a reduction in electronic waste. This would be particularly significant given the growing concern over e-waste and its impact on the environment.

The end-of-life management of QNED displays is an area that requires careful consideration. The presence of nanoparticles and quantum dots in these displays necessitates the development of specialized recycling processes to ensure proper handling and disposal. Research into effective recycling methods for QNED components is ongoing, with the aim of maximizing material recovery and minimizing environmental harm.

As QNED technology continues to evolve, there is a growing focus on developing more sustainable production methods and materials. This includes exploring bio-based quantum dots and environmentally friendly nanoparticles that could further reduce the ecological footprint of QNED displays. Additionally, efforts are being made to optimize the supply chain and reduce transportation-related emissions in the production and distribution of QNED components.

In conclusion, while QNED technology shows promise in terms of energy efficiency and potential durability, ongoing research and development efforts are crucial to fully understand and mitigate its environmental impact. As the technology matures, it will be essential to conduct comprehensive life cycle assessments to accurately compare QNED's environmental performance with that of other display technologies.

In terms of manufacturing, QNED technology utilizes quantum dots and nanoparticles, which require specialized production processes. These processes may involve the use of rare earth elements and other materials that can have environmental implications if not properly managed. However, compared to traditional LCD and OLED manufacturing, QNED production has the potential to be more energy-efficient and require fewer toxic chemicals, potentially reducing overall environmental impact.

The energy consumption of QNED displays during operation is a key factor in their environmental performance. Initial studies suggest that QNED technology may offer improved energy efficiency compared to existing display technologies. This is primarily due to the high luminance efficiency of quantum dots and the precise control of light emission at the nanoscale level. As a result, QNED displays could contribute to reduced energy consumption in consumer electronics and commercial applications, leading to lower carbon emissions over their lifespan.

Durability and lifespan are also important considerations in assessing the environmental impact of QNED displays. If QNED technology proves to be more durable and long-lasting than current display technologies, it could lead to a reduction in electronic waste. This would be particularly significant given the growing concern over e-waste and its impact on the environment.

The end-of-life management of QNED displays is an area that requires careful consideration. The presence of nanoparticles and quantum dots in these displays necessitates the development of specialized recycling processes to ensure proper handling and disposal. Research into effective recycling methods for QNED components is ongoing, with the aim of maximizing material recovery and minimizing environmental harm.

As QNED technology continues to evolve, there is a growing focus on developing more sustainable production methods and materials. This includes exploring bio-based quantum dots and environmentally friendly nanoparticles that could further reduce the ecological footprint of QNED displays. Additionally, efforts are being made to optimize the supply chain and reduce transportation-related emissions in the production and distribution of QNED components.

In conclusion, while QNED technology shows promise in terms of energy efficiency and potential durability, ongoing research and development efforts are crucial to fully understand and mitigate its environmental impact. As the technology matures, it will be essential to conduct comprehensive life cycle assessments to accurately compare QNED's environmental performance with that of other display technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!