How to Integrate QNED in Affordable Display Solutions?

JUN 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QNED Technology Evolution

QNED (Quantum Nano Emitting Diode) technology has undergone significant evolution since its inception, marking a transformative journey in the display industry. Initially conceptualized as a theoretical advancement in display technology, QNED has progressed from laboratory experiments to practical applications in a relatively short span of time.

The early stages of QNED development focused on overcoming the limitations of existing display technologies, particularly in terms of color accuracy, brightness, and energy efficiency. Researchers concentrated on refining the quantum dot materials and nanorod structures that form the core of QNED technology. This phase saw intensive efforts in material science and nanotechnology to create stable and efficient quantum emitters.

As the technology matured, the focus shifted towards scalability and manufacturing processes. Engineers worked on developing methods to precisely control the placement and orientation of quantum nanorods on large-scale substrates, a crucial step in making QNED viable for commercial production. This period also saw advancements in electron beam lithography and other nanofabrication techniques essential for QNED manufacturing.

The next significant milestone in QNED evolution was the integration of quantum dot color conversion layers with nanorod electron emitters. This integration allowed for improved color purity and efficiency, bringing QNED closer to real-world applications. Concurrently, efforts were made to enhance the longevity and stability of QNED displays, addressing issues such as degradation of quantum materials over time.

Recent years have witnessed a focus on optimizing QNED for different display sizes and applications. Researchers have explored ways to adapt QNED technology for various form factors, from large-scale televisions to smaller, high-resolution displays for mobile devices. This phase has also seen increased attention to reducing production costs, a critical factor in making QNED technology more accessible and competitive in the consumer market.

The latest developments in QNED evolution are centered on enhancing its affordability without compromising performance. This includes research into alternative materials that can replicate the optical properties of traditional quantum dots at lower costs, as well as improvements in manufacturing processes to increase yield and reduce production expenses. Additionally, there's ongoing work to integrate QNED with existing display technologies, creating hybrid solutions that leverage the strengths of multiple approaches.

As QNED technology continues to evolve, the focus remains on balancing superior display quality with cost-effectiveness, paving the way for its integration into a wider range of affordable display solutions. This ongoing evolution represents a significant step towards making advanced display technologies more accessible to a broader consumer base.

The early stages of QNED development focused on overcoming the limitations of existing display technologies, particularly in terms of color accuracy, brightness, and energy efficiency. Researchers concentrated on refining the quantum dot materials and nanorod structures that form the core of QNED technology. This phase saw intensive efforts in material science and nanotechnology to create stable and efficient quantum emitters.

As the technology matured, the focus shifted towards scalability and manufacturing processes. Engineers worked on developing methods to precisely control the placement and orientation of quantum nanorods on large-scale substrates, a crucial step in making QNED viable for commercial production. This period also saw advancements in electron beam lithography and other nanofabrication techniques essential for QNED manufacturing.

The next significant milestone in QNED evolution was the integration of quantum dot color conversion layers with nanorod electron emitters. This integration allowed for improved color purity and efficiency, bringing QNED closer to real-world applications. Concurrently, efforts were made to enhance the longevity and stability of QNED displays, addressing issues such as degradation of quantum materials over time.

Recent years have witnessed a focus on optimizing QNED for different display sizes and applications. Researchers have explored ways to adapt QNED technology for various form factors, from large-scale televisions to smaller, high-resolution displays for mobile devices. This phase has also seen increased attention to reducing production costs, a critical factor in making QNED technology more accessible and competitive in the consumer market.

The latest developments in QNED evolution are centered on enhancing its affordability without compromising performance. This includes research into alternative materials that can replicate the optical properties of traditional quantum dots at lower costs, as well as improvements in manufacturing processes to increase yield and reduce production expenses. Additionally, there's ongoing work to integrate QNED with existing display technologies, creating hybrid solutions that leverage the strengths of multiple approaches.

As QNED technology continues to evolve, the focus remains on balancing superior display quality with cost-effectiveness, paving the way for its integration into a wider range of affordable display solutions. This ongoing evolution represents a significant step towards making advanced display technologies more accessible to a broader consumer base.

Market Demand Analysis

The market demand for affordable display solutions incorporating QNED (Quantum Nano Emitting Diode) technology is rapidly growing, driven by the increasing consumer appetite for high-quality visual experiences across various devices. QNED displays offer superior color accuracy, brightness, and contrast compared to traditional LCD panels, while potentially being more cost-effective than OLED alternatives. This positions QNED as a promising technology for bridging the gap between premium and mid-range display markets.

Consumer electronics, particularly televisions and monitors, represent the primary market segment for QNED integration. As 4K and 8K resolutions become more prevalent, there is a growing need for display technologies that can fully leverage these high-resolution capabilities while remaining accessible to a broader consumer base. QNED's ability to deliver enhanced picture quality without the prohibitive costs associated with OLED panels makes it an attractive option for manufacturers looking to differentiate their products in the competitive mid-range market.

The automotive industry is another significant potential market for QNED technology. As vehicles become increasingly connected and autonomous, the demand for high-quality, durable, and energy-efficient displays for infotainment systems and digital dashboards is rising. QNED's advantages in brightness and longevity make it well-suited for automotive applications, where displays must perform reliably under varying light conditions and withstand extended use.

In the commercial and professional sectors, there is a growing demand for large-format displays with superior image quality for applications such as digital signage, control rooms, and collaborative workspaces. QNED's ability to produce vibrant, high-contrast images at scale could make it a compelling choice for these markets, especially if it can be offered at a more competitive price point than current premium display technologies.

The education sector also presents opportunities for QNED integration, as schools and universities seek to upgrade their audiovisual equipment to enhance remote and hybrid learning experiences. Affordable QNED displays could provide the visual clarity and color accuracy needed for effective digital content delivery without straining institutional budgets.

Market analysis indicates that the global demand for advanced display technologies is expected to grow significantly in the coming years. However, the success of QNED in capturing market share will depend on manufacturers' ability to scale production efficiently and reduce costs to a level that allows for integration into mid-range products. The technology's adoption rate will also be influenced by factors such as energy efficiency, durability, and compatibility with existing display manufacturing processes.

As consumers become more environmentally conscious, there is an increasing demand for sustainable display technologies. QNED's potential for improved energy efficiency and longer lifespan compared to some existing technologies could align well with this market trend, potentially driving adoption in eco-friendly product lines.

Consumer electronics, particularly televisions and monitors, represent the primary market segment for QNED integration. As 4K and 8K resolutions become more prevalent, there is a growing need for display technologies that can fully leverage these high-resolution capabilities while remaining accessible to a broader consumer base. QNED's ability to deliver enhanced picture quality without the prohibitive costs associated with OLED panels makes it an attractive option for manufacturers looking to differentiate their products in the competitive mid-range market.

The automotive industry is another significant potential market for QNED technology. As vehicles become increasingly connected and autonomous, the demand for high-quality, durable, and energy-efficient displays for infotainment systems and digital dashboards is rising. QNED's advantages in brightness and longevity make it well-suited for automotive applications, where displays must perform reliably under varying light conditions and withstand extended use.

In the commercial and professional sectors, there is a growing demand for large-format displays with superior image quality for applications such as digital signage, control rooms, and collaborative workspaces. QNED's ability to produce vibrant, high-contrast images at scale could make it a compelling choice for these markets, especially if it can be offered at a more competitive price point than current premium display technologies.

The education sector also presents opportunities for QNED integration, as schools and universities seek to upgrade their audiovisual equipment to enhance remote and hybrid learning experiences. Affordable QNED displays could provide the visual clarity and color accuracy needed for effective digital content delivery without straining institutional budgets.

Market analysis indicates that the global demand for advanced display technologies is expected to grow significantly in the coming years. However, the success of QNED in capturing market share will depend on manufacturers' ability to scale production efficiently and reduce costs to a level that allows for integration into mid-range products. The technology's adoption rate will also be influenced by factors such as energy efficiency, durability, and compatibility with existing display manufacturing processes.

As consumers become more environmentally conscious, there is an increasing demand for sustainable display technologies. QNED's potential for improved energy efficiency and longer lifespan compared to some existing technologies could align well with this market trend, potentially driving adoption in eco-friendly product lines.

QNED Integration Challenges

Integrating QNED (Quantum Nano Emitting Diode) technology into affordable display solutions presents several significant challenges that need to be addressed. One of the primary obstacles is the high production cost associated with QNED manufacturing processes. The intricate nature of quantum dot synthesis and precise placement of nanoparticles requires advanced equipment and specialized facilities, which currently contribute to elevated production expenses.

Another major challenge lies in scaling up QNED production to meet the demands of mass-market consumer electronics. The current manufacturing techniques are not yet optimized for high-volume production, leading to potential bottlenecks in the supply chain. This scalability issue needs to be resolved to make QNED integration economically viable for affordable display solutions.

The stability and longevity of QNED materials pose additional integration challenges. Quantum dots are sensitive to environmental factors such as heat, moisture, and oxygen, which can degrade their performance over time. Developing effective encapsulation methods and protective layers to shield the quantum dots from these external factors is crucial for ensuring the long-term reliability of QNED displays in consumer products.

Color accuracy and consistency across different batches of QNED displays represent another significant hurdle. Achieving uniform color reproduction and maintaining it throughout the production process requires precise control over quantum dot size and composition. Variations in these parameters can lead to inconsistencies in display quality, which is particularly problematic for affordable solutions where tight quality control is essential.

Power efficiency is a critical factor in integrating QNED into affordable display solutions. While QNED technology promises improved energy efficiency compared to traditional LED displays, further optimizations are necessary to reduce power consumption without compromising display performance. This challenge is particularly relevant for battery-powered devices where energy conservation is paramount.

The integration of QNED technology with existing display manufacturing infrastructure presents logistical and technical challenges. Adapting current production lines and processes to accommodate QNED components requires significant investment and retooling. Balancing the need for new equipment with the goal of maintaining affordability is a delicate task that manufacturers must navigate.

Lastly, the regulatory landscape surrounding QNED technology adds another layer of complexity to its integration. Ensuring compliance with safety standards, environmental regulations, and potential restrictions on nanomaterials in consumer products may require additional testing and certification processes. These regulatory hurdles could potentially impact the timeline and cost of bringing affordable QNED display solutions to market.

Another major challenge lies in scaling up QNED production to meet the demands of mass-market consumer electronics. The current manufacturing techniques are not yet optimized for high-volume production, leading to potential bottlenecks in the supply chain. This scalability issue needs to be resolved to make QNED integration economically viable for affordable display solutions.

The stability and longevity of QNED materials pose additional integration challenges. Quantum dots are sensitive to environmental factors such as heat, moisture, and oxygen, which can degrade their performance over time. Developing effective encapsulation methods and protective layers to shield the quantum dots from these external factors is crucial for ensuring the long-term reliability of QNED displays in consumer products.

Color accuracy and consistency across different batches of QNED displays represent another significant hurdle. Achieving uniform color reproduction and maintaining it throughout the production process requires precise control over quantum dot size and composition. Variations in these parameters can lead to inconsistencies in display quality, which is particularly problematic for affordable solutions where tight quality control is essential.

Power efficiency is a critical factor in integrating QNED into affordable display solutions. While QNED technology promises improved energy efficiency compared to traditional LED displays, further optimizations are necessary to reduce power consumption without compromising display performance. This challenge is particularly relevant for battery-powered devices where energy conservation is paramount.

The integration of QNED technology with existing display manufacturing infrastructure presents logistical and technical challenges. Adapting current production lines and processes to accommodate QNED components requires significant investment and retooling. Balancing the need for new equipment with the goal of maintaining affordability is a delicate task that manufacturers must navigate.

Lastly, the regulatory landscape surrounding QNED technology adds another layer of complexity to its integration. Ensuring compliance with safety standards, environmental regulations, and potential restrictions on nanomaterials in consumer products may require additional testing and certification processes. These regulatory hurdles could potentially impact the timeline and cost of bringing affordable QNED display solutions to market.

Current QNED Solutions

01 Cost-effective manufacturing processes

Developing efficient and scalable manufacturing processes for QNEDs can significantly reduce production costs. This includes optimizing material deposition techniques, improving yield rates, and streamlining assembly processes. By enhancing manufacturing efficiency, the overall cost of QNED displays can be reduced, making them more affordable for consumers.- Cost-effective manufacturing processes: Developing efficient and scalable manufacturing processes for QNEDs can significantly reduce production costs. This includes optimizing material deposition techniques, improving yield rates, and streamlining assembly processes. By enhancing manufacturing efficiency, the overall cost of QNED displays can be reduced, making them more affordable for consumers.

- Material innovations for cost reduction: Research into alternative materials for QNED components can lead to cost savings. This includes exploring cheaper quantum dot materials, developing more efficient electron transport layers, and finding alternatives to expensive rare earth elements. Innovations in material science can help reduce the overall cost of QNED production while maintaining or improving performance.

- Simplified device structures: Designing simpler QNED structures can reduce manufacturing complexity and costs. This may involve reducing the number of layers in the device, developing multi-functional materials that serve multiple purposes, or creating more efficient light-emitting structures. Simplified designs can lead to easier fabrication and lower production costs.

- Economies of scale and market adoption: As QNED technology gains wider adoption and production volumes increase, economies of scale can help reduce costs. This includes optimizing supply chains, increasing production capacity, and improving yield rates through experience. Greater market demand and competition among manufacturers can also drive down prices, making QNEDs more affordable over time.

- Integration with existing display technologies: Developing methods to integrate QNED technology with existing display manufacturing infrastructure can reduce implementation costs. This may involve creating hybrid display technologies or adapting QNED production processes to be compatible with current LCD or OLED manufacturing lines. Such integration can leverage existing investments and help bring down the overall cost of QNED displays.

02 Material innovations for cost reduction

Research into new materials and nanostructures for QNEDs can lead to more affordable components. This includes developing cheaper alternatives to traditional quantum dot materials, exploring novel semiconductor compositions, and optimizing the structure of nano-emitters. These material innovations can potentially lower the cost of key QNED components without compromising performance.Expand Specific Solutions03 Simplified device architecture

Designing QNEDs with simpler structures and fewer layers can reduce manufacturing complexity and cost. This approach focuses on minimizing the number of processing steps, using fewer materials, and creating more integrated device architectures. A simplified design can lead to more cost-effective production while maintaining the essential functionality of QNEDs.Expand Specific Solutions04 Integration with existing display technologies

Developing methods to integrate QNED technology with existing display manufacturing infrastructure can reduce implementation costs. This involves adapting QNED production to be compatible with current LCD or OLED production lines, leveraging existing equipment and processes where possible. Such integration can lower the barrier to entry for QNED technology in the display market.Expand Specific Solutions05 Economies of scale and market strategies

Increasing production volume and developing strategic market approaches can drive down the cost of QNED technology. This includes scaling up manufacturing capabilities, forming industry partnerships, and creating a roadmap for gradual market penetration. As production volumes increase and the technology matures, economies of scale can be achieved, leading to more affordable QNED displays for consumers.Expand Specific Solutions

Key QNED Industry Players

The integration of QNED in affordable display solutions is currently in an early development stage, with the market size still relatively small but showing significant growth potential. The technology maturity is progressing rapidly, driven by key players like BOE Technology Group, TCL China Star Optoelectronics, and Sharp Corp. These companies are investing heavily in R&D to overcome challenges in mass production and cost reduction. While QNED offers superior image quality and energy efficiency compared to traditional LCD and OLED technologies, its widespread adoption in affordable displays is still limited by production complexities and higher costs. However, collaborations between display manufacturers and research institutions like The Hong Kong University of Science & Technology are accelerating technological advancements, potentially leading to more cost-effective QNED solutions in the near future.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a QNED (Quantum Nano Emitting Diode) display technology that combines quantum dot and mini-LED technologies. Their approach involves using a blue mini-LED backlight with red and green quantum dots to achieve high color gamut and contrast. BOE's QNED panels utilize advanced quantum dot color conversion and precise light control to enhance color performance and energy efficiency. The company has also focused on improving the manufacturing process to reduce costs, making QNED more accessible for affordable display solutions.

Strengths: High color gamut, improved contrast, and energy efficiency. Weaknesses: Still relatively new technology with potential for further cost reduction and optimization.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has been actively researching and developing QNED technology as part of their next-generation display solutions. Their approach involves combining quantum dot technology with mini-LED backlighting to create high-performance, cost-effective displays. TCL CSOT's QNED panels aim to offer improved color gamut, contrast ratio, and energy efficiency compared to traditional LCD displays. The company is focusing on optimizing the quantum dot material and mini-LED array design to enhance overall performance while keeping production costs in check. TCL CSOT is also exploring ways to integrate QNED technology into various display sizes and applications, from TVs to mobile devices.

Strengths: Leveraging existing quantum dot and mini-LED expertise. Weaknesses: Balancing performance improvements with cost considerations for affordable solutions.

QNED Core Innovations

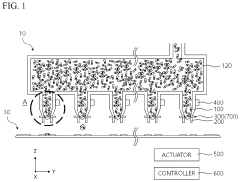

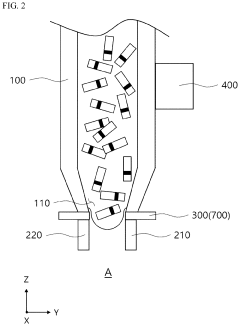

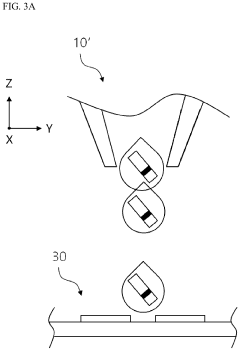

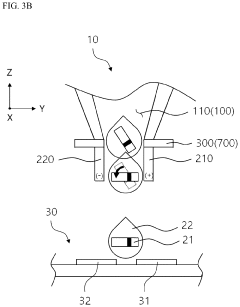

Inkjet head and method of ejecting ink using the same

PatentActiveUS11845276B2

Innovation

- An inkjet head with nozzles and pairs of electrodes that apply an electrode voltage to the light-emitting elements, including a first and second piezoelectric element, and a controller to independently control the electrode voltage, allowing for precise arrangement of light-emitting elements on a substrate with separate electrodes before and during the jetting process.

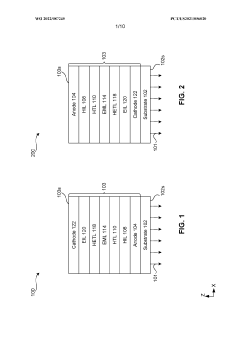

Electroluminescent devices with hybrid transport layers

PatentWO2022087245A1

Innovation

- The development of electroluminescent devices with hybrid transport layers, comprising an organic layer and inorganic nanostructures, where the luminescent nanostructures are separated by an organic layer, utilizing materials like (1,3,5-Triazine-2,4,6-triyl)tris(benzene-3,1-diyl)tris(diphenylphosphine oxide) and metal oxide nanostructures, to enhance light emission efficiency and reduce quenching effects.

Cost Reduction Strategies

To integrate QNED (Quantum Nano Emitting Diode) technology into affordable display solutions, several cost reduction strategies can be implemented. These strategies focus on optimizing manufacturing processes, leveraging economies of scale, and exploring alternative materials and components.

One key approach is to streamline the production process for QNED displays. This involves automating key manufacturing steps, such as the deposition of quantum dots and the assembly of display panels. By reducing manual labor and increasing production efficiency, manufacturers can significantly lower costs. Additionally, implementing advanced quality control systems can help minimize waste and improve yield rates, further reducing overall production expenses.

Economies of scale play a crucial role in cost reduction. As QNED technology becomes more widespread, manufacturers can benefit from bulk purchasing of raw materials and components. This increased purchasing power can lead to better negotiation leverage with suppliers, resulting in lower input costs. Furthermore, establishing long-term partnerships with key suppliers can help secure more favorable pricing and ensure a stable supply chain.

Exploring alternative materials and components is another vital strategy. Researchers and engineers should focus on developing cost-effective substitutes for expensive materials used in QNED displays without compromising performance. This may include investigating new quantum dot formulations or exploring alternative electrode materials that offer similar functionality at a lower cost.

Optimizing the display architecture can also contribute to cost reduction. By simplifying the layer structure of QNED displays or reducing the number of components required, manufacturers can decrease material costs and simplify the production process. This may involve redesigning the backplane or exploring new ways to integrate the quantum dot layer more efficiently.

Investing in research and development to improve QNED technology efficiency is crucial. By enhancing the quantum yield of the nano-emitters and optimizing the light extraction efficiency, manufacturers can potentially reduce the number of quantum dots required per display. This not only lowers material costs but also improves energy efficiency, making QNED displays more attractive for cost-conscious consumers.

Lastly, considering vertical integration strategies can help reduce costs across the supply chain. By bringing key component production in-house or forming strategic partnerships with suppliers, display manufacturers can have greater control over costs and quality. This approach can also lead to faster innovation cycles and more efficient product development processes.

One key approach is to streamline the production process for QNED displays. This involves automating key manufacturing steps, such as the deposition of quantum dots and the assembly of display panels. By reducing manual labor and increasing production efficiency, manufacturers can significantly lower costs. Additionally, implementing advanced quality control systems can help minimize waste and improve yield rates, further reducing overall production expenses.

Economies of scale play a crucial role in cost reduction. As QNED technology becomes more widespread, manufacturers can benefit from bulk purchasing of raw materials and components. This increased purchasing power can lead to better negotiation leverage with suppliers, resulting in lower input costs. Furthermore, establishing long-term partnerships with key suppliers can help secure more favorable pricing and ensure a stable supply chain.

Exploring alternative materials and components is another vital strategy. Researchers and engineers should focus on developing cost-effective substitutes for expensive materials used in QNED displays without compromising performance. This may include investigating new quantum dot formulations or exploring alternative electrode materials that offer similar functionality at a lower cost.

Optimizing the display architecture can also contribute to cost reduction. By simplifying the layer structure of QNED displays or reducing the number of components required, manufacturers can decrease material costs and simplify the production process. This may involve redesigning the backplane or exploring new ways to integrate the quantum dot layer more efficiently.

Investing in research and development to improve QNED technology efficiency is crucial. By enhancing the quantum yield of the nano-emitters and optimizing the light extraction efficiency, manufacturers can potentially reduce the number of quantum dots required per display. This not only lowers material costs but also improves energy efficiency, making QNED displays more attractive for cost-conscious consumers.

Lastly, considering vertical integration strategies can help reduce costs across the supply chain. By bringing key component production in-house or forming strategic partnerships with suppliers, display manufacturers can have greater control over costs and quality. This approach can also lead to faster innovation cycles and more efficient product development processes.

QNED Supply Chain Analysis

The QNED (Quantum Nano Emitting Diode) supply chain analysis reveals a complex ecosystem of manufacturers, suppliers, and technology providers working to integrate this innovative display technology into affordable solutions. The supply chain begins with raw material suppliers, primarily focused on providing high-quality quantum dots and nanorod materials essential for QNED production.

Key players in the QNED supply chain include major display manufacturers such as Samsung, LG, and TCL, who are investing heavily in research and development to commercialize QNED technology. These companies are partnering with specialized quantum dot suppliers like Nanosys and Nanoco to secure a stable supply of critical materials.

The production process involves several stages, starting with the synthesis of quantum dots and nanorods. These materials are then integrated into LED structures, which are subsequently incorporated into display panels. Each stage requires specialized equipment and expertise, creating opportunities for equipment manufacturers and process technology providers to contribute to the supply chain.

One of the main challenges in the QNED supply chain is scaling up production to meet potential demand while maintaining cost-effectiveness. This has led to increased collaboration between display manufacturers and material suppliers to optimize production processes and reduce costs. Additionally, efforts are being made to develop more efficient and environmentally friendly synthesis methods for quantum dots and nanorods.

The supply chain also extends to component manufacturers who produce drivers, backplanes, and other essential parts for QNED displays. These companies are adapting their existing technologies to meet the specific requirements of QNED displays, such as higher refresh rates and improved color accuracy.

To integrate QNED into affordable display solutions, the supply chain is focusing on several key areas. First, there is a push to increase the yield and efficiency of quantum dot and nanorod production, which will help reduce overall costs. Second, manufacturers are exploring ways to simplify the QNED panel structure, potentially reducing the number of components and assembly steps required.

Furthermore, the supply chain is leveraging existing LCD and OLED manufacturing infrastructure where possible to minimize capital expenditure. This approach allows for a more gradual transition to QNED technology while maintaining cost competitiveness.

As the QNED technology matures, the supply chain is expected to evolve, with new players entering the market and existing ones expanding their capabilities. This dynamic environment presents both challenges and opportunities for companies looking to establish a strong position in the QNED ecosystem.

Key players in the QNED supply chain include major display manufacturers such as Samsung, LG, and TCL, who are investing heavily in research and development to commercialize QNED technology. These companies are partnering with specialized quantum dot suppliers like Nanosys and Nanoco to secure a stable supply of critical materials.

The production process involves several stages, starting with the synthesis of quantum dots and nanorods. These materials are then integrated into LED structures, which are subsequently incorporated into display panels. Each stage requires specialized equipment and expertise, creating opportunities for equipment manufacturers and process technology providers to contribute to the supply chain.

One of the main challenges in the QNED supply chain is scaling up production to meet potential demand while maintaining cost-effectiveness. This has led to increased collaboration between display manufacturers and material suppliers to optimize production processes and reduce costs. Additionally, efforts are being made to develop more efficient and environmentally friendly synthesis methods for quantum dots and nanorods.

The supply chain also extends to component manufacturers who produce drivers, backplanes, and other essential parts for QNED displays. These companies are adapting their existing technologies to meet the specific requirements of QNED displays, such as higher refresh rates and improved color accuracy.

To integrate QNED into affordable display solutions, the supply chain is focusing on several key areas. First, there is a push to increase the yield and efficiency of quantum dot and nanorod production, which will help reduce overall costs. Second, manufacturers are exploring ways to simplify the QNED panel structure, potentially reducing the number of components and assembly steps required.

Furthermore, the supply chain is leveraging existing LCD and OLED manufacturing infrastructure where possible to minimize capital expenditure. This approach allows for a more gradual transition to QNED technology while maintaining cost competitiveness.

As the QNED technology matures, the supply chain is expected to evolve, with new players entering the market and existing ones expanding their capabilities. This dynamic environment presents both challenges and opportunities for companies looking to establish a strong position in the QNED ecosystem.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!