How to Optimize Screen Longevity with QNED?

JUN 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QNED Screen Tech Evolution

QNED (Quantum Nano Emitting Diode) technology has undergone significant evolution since its inception, marking a revolutionary advancement in display technology. This innovative approach combines quantum dot and mini-LED technologies to create screens with superior color accuracy, brightness, and contrast ratios.

The journey of QNED began with the development of quantum dot technology in the early 2000s. Initially used to enhance LCD displays, quantum dots provided a wider color gamut and improved energy efficiency. As research progressed, scientists explored ways to integrate quantum dots directly into LED structures, leading to the concept of QNED.

By 2015, major display manufacturers started investing heavily in QNED research, recognizing its potential to overcome limitations of existing technologies. The first breakthrough came in 2018 when researchers successfully demonstrated a prototype QNED display, showcasing its ability to produce deeper blacks and more vibrant colors than traditional LCD screens.

The years 2019-2021 saw rapid advancements in QNED manufacturing processes. Engineers focused on refining the quantum dot synthesis and integration techniques, resulting in more uniform and stable QNED arrays. This period also witnessed significant improvements in the miniaturization of LED components, enabling higher pixel densities and better control over local dimming.

In 2022, the first commercial QNED TVs hit the market, offering consumers a glimpse into the future of display technology. These early models demonstrated superior HDR performance and color accuracy compared to conventional LED-LCD and OLED displays. However, they also highlighted areas for improvement, particularly in terms of power efficiency and production costs.

Recent developments in QNED technology have focused on enhancing screen longevity. Researchers have been working on improving the stability of quantum dots and developing more robust encapsulation methods to protect them from environmental factors. These efforts aim to address concerns about color shift and brightness degradation over time, which are critical for the widespread adoption of QNED displays.

The evolution of QNED technology continues to accelerate, with ongoing research into new materials and manufacturing techniques. Scientists are exploring the use of perovskite quantum dots and investigating ways to further reduce the size of LED components. These advancements promise to deliver even more impressive visual experiences while addressing the challenges of durability and energy efficiency.

As QNED technology matures, it is poised to revolutionize not only the television market but also other display applications such as monitors, smartphones, and automotive displays. The ongoing evolution of QNED screens represents a significant step towards achieving the perfect balance of image quality, energy efficiency, and longevity in display technology.

The journey of QNED began with the development of quantum dot technology in the early 2000s. Initially used to enhance LCD displays, quantum dots provided a wider color gamut and improved energy efficiency. As research progressed, scientists explored ways to integrate quantum dots directly into LED structures, leading to the concept of QNED.

By 2015, major display manufacturers started investing heavily in QNED research, recognizing its potential to overcome limitations of existing technologies. The first breakthrough came in 2018 when researchers successfully demonstrated a prototype QNED display, showcasing its ability to produce deeper blacks and more vibrant colors than traditional LCD screens.

The years 2019-2021 saw rapid advancements in QNED manufacturing processes. Engineers focused on refining the quantum dot synthesis and integration techniques, resulting in more uniform and stable QNED arrays. This period also witnessed significant improvements in the miniaturization of LED components, enabling higher pixel densities and better control over local dimming.

In 2022, the first commercial QNED TVs hit the market, offering consumers a glimpse into the future of display technology. These early models demonstrated superior HDR performance and color accuracy compared to conventional LED-LCD and OLED displays. However, they also highlighted areas for improvement, particularly in terms of power efficiency and production costs.

Recent developments in QNED technology have focused on enhancing screen longevity. Researchers have been working on improving the stability of quantum dots and developing more robust encapsulation methods to protect them from environmental factors. These efforts aim to address concerns about color shift and brightness degradation over time, which are critical for the widespread adoption of QNED displays.

The evolution of QNED technology continues to accelerate, with ongoing research into new materials and manufacturing techniques. Scientists are exploring the use of perovskite quantum dots and investigating ways to further reduce the size of LED components. These advancements promise to deliver even more impressive visual experiences while addressing the challenges of durability and energy efficiency.

As QNED technology matures, it is poised to revolutionize not only the television market but also other display applications such as monitors, smartphones, and automotive displays. The ongoing evolution of QNED screens represents a significant step towards achieving the perfect balance of image quality, energy efficiency, and longevity in display technology.

Market Demand for QNED

The market demand for QNED (Quantum Nano Emitting Diode) technology is rapidly growing as consumers and industries seek advanced display solutions with enhanced longevity and performance. QNED combines the benefits of quantum dot and mini-LED technologies, offering superior color accuracy, brightness, and energy efficiency compared to traditional LCD and OLED displays.

In the consumer electronics sector, there is a strong demand for QNED in high-end televisions and monitors. As consumers increasingly prioritize picture quality and durability in their home entertainment systems, QNED's ability to deliver vibrant colors, deep blacks, and extended lifespan makes it an attractive option. Market research indicates that the premium TV segment, where QNED is positioned, is expected to grow significantly over the next five years.

The professional display market also shows substantial interest in QNED technology. Industries such as digital signage, control rooms, and medical imaging require displays with high reliability, color accuracy, and longevity. QNED's resistance to burn-in and its ability to maintain consistent performance over time make it particularly appealing for these applications.

In the automotive industry, QNED is gaining traction for in-vehicle infotainment systems and digital dashboards. The technology's high brightness and wide color gamut are well-suited for automotive environments where readability under various lighting conditions is crucial. As the trend towards larger and more sophisticated in-car displays continues, QNED is poised to capture a significant market share.

The mobile device market presents another potential growth area for QNED. While currently less prevalent in smartphones and tablets due to cost considerations, there is increasing interest in QNED for premium mobile devices where display quality is a key differentiator. As manufacturing processes improve and costs decrease, QNED could see wider adoption in the mobile sector.

From a geographical perspective, the demand for QNED is particularly strong in regions with mature consumer electronics markets, such as North America, Western Europe, and parts of Asia. These areas have a higher concentration of early adopters willing to invest in cutting-edge display technologies. However, as awareness grows and prices become more competitive, demand is expected to expand globally.

The market demand for QNED is closely tied to its ability to address the longevity concerns associated with other display technologies. As consumers and businesses seek displays that maintain their quality over extended periods, QNED's potential for optimizing screen longevity becomes a key selling point. This aspect of QNED technology aligns well with the growing emphasis on sustainability and reduced electronic waste in consumer and industrial markets.

In the consumer electronics sector, there is a strong demand for QNED in high-end televisions and monitors. As consumers increasingly prioritize picture quality and durability in their home entertainment systems, QNED's ability to deliver vibrant colors, deep blacks, and extended lifespan makes it an attractive option. Market research indicates that the premium TV segment, where QNED is positioned, is expected to grow significantly over the next five years.

The professional display market also shows substantial interest in QNED technology. Industries such as digital signage, control rooms, and medical imaging require displays with high reliability, color accuracy, and longevity. QNED's resistance to burn-in and its ability to maintain consistent performance over time make it particularly appealing for these applications.

In the automotive industry, QNED is gaining traction for in-vehicle infotainment systems and digital dashboards. The technology's high brightness and wide color gamut are well-suited for automotive environments where readability under various lighting conditions is crucial. As the trend towards larger and more sophisticated in-car displays continues, QNED is poised to capture a significant market share.

The mobile device market presents another potential growth area for QNED. While currently less prevalent in smartphones and tablets due to cost considerations, there is increasing interest in QNED for premium mobile devices where display quality is a key differentiator. As manufacturing processes improve and costs decrease, QNED could see wider adoption in the mobile sector.

From a geographical perspective, the demand for QNED is particularly strong in regions with mature consumer electronics markets, such as North America, Western Europe, and parts of Asia. These areas have a higher concentration of early adopters willing to invest in cutting-edge display technologies. However, as awareness grows and prices become more competitive, demand is expected to expand globally.

The market demand for QNED is closely tied to its ability to address the longevity concerns associated with other display technologies. As consumers and businesses seek displays that maintain their quality over extended periods, QNED's potential for optimizing screen longevity becomes a key selling point. This aspect of QNED technology aligns well with the growing emphasis on sustainability and reduced electronic waste in consumer and industrial markets.

QNED Challenges

QNED (Quantum Nano Emitting Diode) technology, while promising, faces several significant challenges in its development and implementation for optimizing screen longevity. One of the primary obstacles is the complexity of manufacturing processes required to produce QNED displays at scale. The precise placement and control of quantum dots and nanoparticles demand highly sophisticated and expensive equipment, which currently limits mass production capabilities.

Another major challenge lies in the stability and durability of QNED materials. Quantum dots are known to be sensitive to environmental factors such as heat, moisture, and oxygen, which can lead to degradation over time. This sensitivity poses a significant hurdle in ensuring long-term screen longevity, as the performance of QNED displays may deteriorate more rapidly than traditional LED or OLED technologies if not properly protected.

Color accuracy and consistency present additional challenges for QNED technology. While quantum dots offer the potential for a wider color gamut, achieving and maintaining precise color reproduction across the entire display and throughout the lifespan of the screen remains a complex task. Variations in quantum dot size and composition can lead to color shifts, affecting the overall image quality and user experience.

Power efficiency is another area of concern for QNED displays. Although quantum dots have the potential to improve energy efficiency, the current implementations still struggle to match the power consumption levels of OLED technology, particularly in displaying dark scenes. Balancing brightness, color accuracy, and power consumption continues to be a delicate challenge for QNED developers.

Thermal management poses yet another significant challenge in QNED technology. The heat generated during operation can affect the performance and lifespan of quantum dots, potentially leading to reduced screen longevity. Developing effective heat dissipation mechanisms without compromising the display's thinness and overall design aesthetics is crucial for the success of QNED screens.

Lastly, the cost of QNED technology remains a substantial barrier to widespread adoption. The expensive materials and complex manufacturing processes contribute to higher production costs compared to existing display technologies. Reducing these costs while maintaining performance and quality standards is essential for QNED to become a viable option for mainstream consumer electronics.

Addressing these challenges requires continued research and development efforts in materials science, manufacturing processes, and display engineering. Innovations in quantum dot encapsulation, more efficient production methods, and advanced thermal management techniques will be critical in overcoming these obstacles and realizing the full potential of QNED technology for optimizing screen longevity.

Another major challenge lies in the stability and durability of QNED materials. Quantum dots are known to be sensitive to environmental factors such as heat, moisture, and oxygen, which can lead to degradation over time. This sensitivity poses a significant hurdle in ensuring long-term screen longevity, as the performance of QNED displays may deteriorate more rapidly than traditional LED or OLED technologies if not properly protected.

Color accuracy and consistency present additional challenges for QNED technology. While quantum dots offer the potential for a wider color gamut, achieving and maintaining precise color reproduction across the entire display and throughout the lifespan of the screen remains a complex task. Variations in quantum dot size and composition can lead to color shifts, affecting the overall image quality and user experience.

Power efficiency is another area of concern for QNED displays. Although quantum dots have the potential to improve energy efficiency, the current implementations still struggle to match the power consumption levels of OLED technology, particularly in displaying dark scenes. Balancing brightness, color accuracy, and power consumption continues to be a delicate challenge for QNED developers.

Thermal management poses yet another significant challenge in QNED technology. The heat generated during operation can affect the performance and lifespan of quantum dots, potentially leading to reduced screen longevity. Developing effective heat dissipation mechanisms without compromising the display's thinness and overall design aesthetics is crucial for the success of QNED screens.

Lastly, the cost of QNED technology remains a substantial barrier to widespread adoption. The expensive materials and complex manufacturing processes contribute to higher production costs compared to existing display technologies. Reducing these costs while maintaining performance and quality standards is essential for QNED to become a viable option for mainstream consumer electronics.

Addressing these challenges requires continued research and development efforts in materials science, manufacturing processes, and display engineering. Innovations in quantum dot encapsulation, more efficient production methods, and advanced thermal management techniques will be critical in overcoming these obstacles and realizing the full potential of QNED technology for optimizing screen longevity.

QNED Longevity Solutions

01 Quantum dot and nanorod structures for improved longevity

QNED screens utilize quantum dot and nanorod structures to enhance longevity. These nanostructures are engineered to improve stability and reduce degradation over time, resulting in longer-lasting displays. The use of specific materials and fabrication techniques helps to maintain consistent light emission and color quality throughout the screen's lifespan.- Quantum dot enhancement for QNED displays: QNED screens utilize quantum dots to enhance color performance and efficiency. These nanoscale semiconductor particles are integrated into the display structure to improve light emission and color purity, potentially extending the longevity of the display by reducing power consumption and heat generation.

- Nano-emitting diode structure optimization: Advancements in nano-emitting diode structures focus on improving electron injection, light extraction, and overall efficiency. These optimizations can lead to reduced degradation of the emitting materials over time, thereby increasing the lifespan of QNED screens.

- Protective layers and encapsulation techniques: Implementing advanced protective layers and encapsulation methods helps shield the sensitive quantum nano-emitting components from environmental factors such as moisture and oxygen. This protection is crucial for maintaining the long-term stability and performance of QNED displays.

- Thermal management solutions: Effective thermal management is essential for prolonging the life of QNED screens. Innovative heat dissipation techniques and materials are employed to regulate operating temperatures, preventing premature aging and degradation of the quantum nano-emitting components.

- Advanced manufacturing processes: Refined manufacturing processes, including precision deposition techniques and quality control measures, contribute to the production of more durable and consistent QNED screens. These advancements in fabrication methods help to minimize defects and enhance the overall longevity of the displays.

02 Protective layers and encapsulation techniques

To increase the longevity of QNED screens, various protective layers and encapsulation methods are employed. These techniques shield the quantum nano-emitting diodes from environmental factors such as moisture and oxygen, which can degrade performance over time. Advanced barrier materials and multi-layer encapsulation designs contribute to extended screen life.Expand Specific Solutions03 Thermal management for improved durability

Effective thermal management is crucial for QNED screen longevity. Innovative heat dissipation techniques and materials are incorporated to prevent overheating, which can lead to premature aging of the quantum nano-emitting diodes. Improved thermal design helps maintain consistent performance and extends the overall lifespan of the display.Expand Specific Solutions04 Optimization of driving circuits and power management

Longevity of QNED screens is enhanced through optimized driving circuits and power management systems. These improvements help to reduce electrical stress on the quantum nano-emitting diodes, preventing premature degradation. Advanced control algorithms and efficient power distribution contribute to consistent performance and extended screen life.Expand Specific Solutions05 Self-healing and defect mitigation technologies

Emerging technologies for self-healing and defect mitigation are being developed to improve QNED screen longevity. These innovations aim to address pixel degradation and maintain uniform brightness across the display over time. Techniques may include adaptive compensation algorithms and materials that can recover from minor damage, ensuring prolonged screen quality and lifespan.Expand Specific Solutions

QNED Industry Leaders

The optimization of screen longevity using QNED technology is currently in its early development stage, with a growing market potential. The technology's maturity is still evolving, as evidenced by the involvement of major players like BOE Technology Group, TCL China Star Optoelectronics, and Samsung Display. These companies are investing in research and development to enhance QNED's durability and performance. The competitive landscape is characterized by a mix of established display manufacturers and emerging tech firms, such as Kateeva and Najing Technology, focusing on specific aspects of QNED implementation. As the technology progresses, we can expect increased competition and innovation in areas like quantum dot stability, nanorod alignment, and overall display lifespan improvement.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a QNED (Quantum Nano Emitting Diode) technology that combines quantum dot and mini-LED technologies. Their approach involves using a blue mini-LED backlight with red and green quantum dots to produce high-quality colors. To optimize screen longevity, BOE implements advanced thermal management systems, including heat dissipation materials and intelligent brightness control algorithms. They also use high-quality, stable quantum dot materials and protective encapsulation techniques to prevent degradation over time.

Strengths: High color gamut, excellent brightness, and energy efficiency. Weaknesses: Complexity in manufacturing process and potential cost implications.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has developed a QNED technology that utilizes a unique combination of quantum dots and nanorod LEDs. Their approach focuses on enhancing the stability of quantum dots through advanced encapsulation techniques and optimizing the nanorod LED structure for improved efficiency and longevity. They have implemented a sophisticated color management system that dynamically adjusts the output of different color channels to maintain color accuracy while reducing overall power consumption, thus extending the screen's lifespan.

Strengths: Advanced color management and power efficiency. Weaknesses: Relatively new technology with potential for further optimization.

QNED Lifespan Patents

QLED device based on gradient refractive index super-hydrophobic surface enhanced light extraction and preparation method thereof

PatentPendingCN117202691A

Innovation

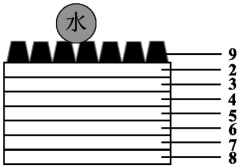

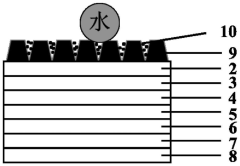

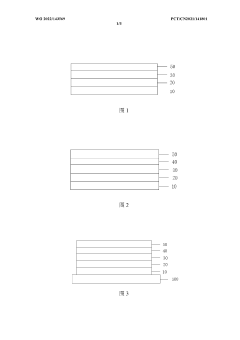

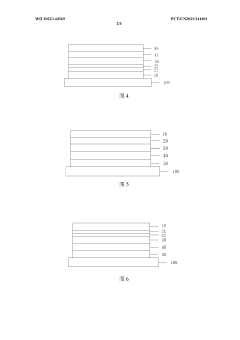

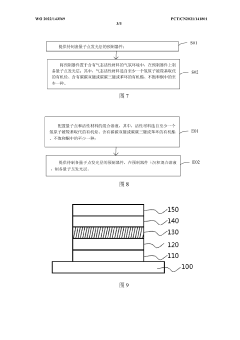

- Using a superhydrophobic surface based on a graded refractive index, the refractive index is controlled to enhance the light extraction efficiency through a superhydrophobic surface composed of polymers and nanoparticles, combined with a transparent substrate, a conductive layer, a hole injection layer, and a hole transport layer , the structure of the quantum dot luminescent layer and electrode, and the superhydrophobic surface with micro-nano structure is prepared using the sol-gel method, soft transfer technology and spraying method.

Quantum dot light-emitting diode and preparation method therefor

PatentWO2022143569A1

Innovation

- Introducing active materials into the quantum dot light-emitting layer, such as organic hydrocarbons in which hydrogen atoms are replaced by carboxyl groups, organic esters containing carbon-carbon double bonds or carbon-carbon triple bonds, or benzene rings, are prepared by gas phase methods or solution processing methods, and modified quantum dots and The electronic functional layer interface regulates the electron injection barrier and suppresses surface exciton quenching and charge accumulation.

QNED Manufacturing Process

The QNED (Quantum Nano Emitting Diode) manufacturing process is a complex and intricate procedure that combines advanced nanotechnology with traditional display manufacturing techniques. This process involves several key stages, each crucial for optimizing screen longevity and performance.

The first stage in QNED manufacturing is the preparation of the quantum dot material. This involves synthesizing nanocrystals of specific sizes and compositions to achieve the desired color output. The quantum dots are typically made from semiconductor materials such as indium phosphide or cadmium selenide, carefully engineered to emit precise wavelengths of light when excited.

Once the quantum dots are prepared, they are integrated into a matrix material, usually a polymer or resin. This matrix serves as a protective encapsulation for the quantum dots and helps distribute them evenly across the display panel. The integration process must be carefully controlled to prevent aggregation or degradation of the quantum dots, which could negatively impact screen performance and longevity.

The next critical step is the deposition of the quantum dot layer onto the display substrate. This is typically achieved through advanced printing techniques such as inkjet printing or photolithography. The precision of this step is paramount, as it directly affects the uniformity and consistency of the display's color output.

Following the quantum dot layer deposition, the manufacturing process incorporates the fabrication of the micro-LED backlight. This involves creating an array of miniature LEDs that will serve as the primary light source for the display. The micro-LEDs are manufactured using semiconductor fabrication techniques and must be precisely aligned with the quantum dot layer to ensure optimal light conversion and energy efficiency.

The integration of the quantum dot layer with the micro-LED backlight is a delicate process that requires precise alignment and bonding techniques. This step is crucial for achieving the desired color gamut and brightness while maintaining the display's overall thinness and energy efficiency.

Finally, the QNED panel undergoes a series of quality control tests and optimizations. This includes color calibration, uniformity adjustments, and stress testing to ensure the longevity of the display under various operating conditions. Advanced algorithms and software are employed to fine-tune the display's performance and maximize its lifespan.

Throughout the entire manufacturing process, strict environmental controls are maintained to prevent contamination and ensure the stability of the quantum dot materials. Factors such as temperature, humidity, and exposure to oxygen are carefully regulated to preserve the integrity of the quantum dots and other sensitive components.

The first stage in QNED manufacturing is the preparation of the quantum dot material. This involves synthesizing nanocrystals of specific sizes and compositions to achieve the desired color output. The quantum dots are typically made from semiconductor materials such as indium phosphide or cadmium selenide, carefully engineered to emit precise wavelengths of light when excited.

Once the quantum dots are prepared, they are integrated into a matrix material, usually a polymer or resin. This matrix serves as a protective encapsulation for the quantum dots and helps distribute them evenly across the display panel. The integration process must be carefully controlled to prevent aggregation or degradation of the quantum dots, which could negatively impact screen performance and longevity.

The next critical step is the deposition of the quantum dot layer onto the display substrate. This is typically achieved through advanced printing techniques such as inkjet printing or photolithography. The precision of this step is paramount, as it directly affects the uniformity and consistency of the display's color output.

Following the quantum dot layer deposition, the manufacturing process incorporates the fabrication of the micro-LED backlight. This involves creating an array of miniature LEDs that will serve as the primary light source for the display. The micro-LEDs are manufactured using semiconductor fabrication techniques and must be precisely aligned with the quantum dot layer to ensure optimal light conversion and energy efficiency.

The integration of the quantum dot layer with the micro-LED backlight is a delicate process that requires precise alignment and bonding techniques. This step is crucial for achieving the desired color gamut and brightness while maintaining the display's overall thinness and energy efficiency.

Finally, the QNED panel undergoes a series of quality control tests and optimizations. This includes color calibration, uniformity adjustments, and stress testing to ensure the longevity of the display under various operating conditions. Advanced algorithms and software are employed to fine-tune the display's performance and maximize its lifespan.

Throughout the entire manufacturing process, strict environmental controls are maintained to prevent contamination and ensure the stability of the quantum dot materials. Factors such as temperature, humidity, and exposure to oxygen are carefully regulated to preserve the integrity of the quantum dots and other sensitive components.

QNED vs. OLED Comparison

QNED (Quantum Nano Emitting Diode) and OLED (Organic Light Emitting Diode) are two advanced display technologies that have gained significant attention in recent years. While both offer superior picture quality compared to traditional LCD displays, they differ in several key aspects that impact their longevity and overall performance.

QNED technology utilizes quantum dots and mini-LED backlighting to produce vibrant colors and high contrast ratios. This combination allows for precise local dimming, resulting in deeper blacks and brighter highlights. The use of inorganic materials in QNED displays contributes to their enhanced durability and resistance to burn-in, a common issue with OLED screens.

OLED, on the other hand, employs organic compounds that emit light when an electric current is applied. This self-emissive nature allows for perfect blacks and infinite contrast ratios, as each pixel can be turned off completely. However, the organic materials used in OLED displays are more susceptible to degradation over time, potentially leading to reduced brightness and color accuracy.

In terms of longevity, QNED displays have a distinct advantage. The inorganic quantum dots used in QNED technology are inherently more stable than the organic compounds in OLED displays. This stability translates to a longer lifespan and reduced risk of image retention or burn-in, which can be particularly beneficial for devices that display static content for extended periods.

Energy efficiency is another area where QNED and OLED differ. OLED displays are generally more energy-efficient, especially when displaying darker content, as individual pixels can be turned off completely. QNED displays, while still energy-efficient, may consume slightly more power due to the mini-LED backlighting system.

When it comes to picture quality, both technologies offer exceptional performance. OLED displays excel in producing perfect blacks and wide viewing angles, while QNED displays can achieve higher peak brightness levels, making them ideal for HDR content and well-lit environments.

In conclusion, while both QNED and OLED technologies offer significant improvements over traditional displays, QNED holds an edge in terms of longevity and durability. Its resistance to burn-in and overall stability make it a compelling choice for applications where screen longevity is a critical factor. However, the choice between QNED and OLED ultimately depends on specific use cases and individual preferences, as both technologies continue to evolve and improve.

QNED technology utilizes quantum dots and mini-LED backlighting to produce vibrant colors and high contrast ratios. This combination allows for precise local dimming, resulting in deeper blacks and brighter highlights. The use of inorganic materials in QNED displays contributes to their enhanced durability and resistance to burn-in, a common issue with OLED screens.

OLED, on the other hand, employs organic compounds that emit light when an electric current is applied. This self-emissive nature allows for perfect blacks and infinite contrast ratios, as each pixel can be turned off completely. However, the organic materials used in OLED displays are more susceptible to degradation over time, potentially leading to reduced brightness and color accuracy.

In terms of longevity, QNED displays have a distinct advantage. The inorganic quantum dots used in QNED technology are inherently more stable than the organic compounds in OLED displays. This stability translates to a longer lifespan and reduced risk of image retention or burn-in, which can be particularly beneficial for devices that display static content for extended periods.

Energy efficiency is another area where QNED and OLED differ. OLED displays are generally more energy-efficient, especially when displaying darker content, as individual pixels can be turned off completely. QNED displays, while still energy-efficient, may consume slightly more power due to the mini-LED backlighting system.

When it comes to picture quality, both technologies offer exceptional performance. OLED displays excel in producing perfect blacks and wide viewing angles, while QNED displays can achieve higher peak brightness levels, making them ideal for HDR content and well-lit environments.

In conclusion, while both QNED and OLED technologies offer significant improvements over traditional displays, QNED holds an edge in terms of longevity and durability. Its resistance to burn-in and overall stability make it a compelling choice for applications where screen longevity is a critical factor. However, the choice between QNED and OLED ultimately depends on specific use cases and individual preferences, as both technologies continue to evolve and improve.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!