How to Implement QNED for Reducing Display Glare?

JUN 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QNED Technology Background and Objectives

QNED (Quantum Nano Emitting Diode) technology represents a significant advancement in display technology, combining the benefits of quantum dot and mini-LED technologies. The development of QNED stems from the continuous pursuit of improved display quality, energy efficiency, and reduced environmental impact in the display industry.

The evolution of display technology has progressed from CRT to LCD, OLED, and now to advanced technologies like QNED. Each iteration has aimed to address limitations of previous generations, with QNED specifically targeting issues such as display glare, color accuracy, and energy consumption. The primary objective of QNED technology in reducing display glare is to enhance visibility and user comfort, particularly in high-ambient light conditions.

QNED technology utilizes quantum dots, which are nanoscale semiconductor particles that emit light of specific wavelengths when excited. These quantum dots are combined with mini-LED backlighting to create a display that offers superior brightness, contrast, and color accuracy compared to traditional LCD displays. The nano-scale nature of quantum dots allows for precise control over light emission, which is crucial in managing and reducing glare.

The technical goals of QNED in glare reduction include achieving higher peak brightness without increasing power consumption, improving local dimming capabilities for enhanced contrast, and optimizing the light emission spectrum to minimize reflections. By attaining these objectives, QNED displays aim to maintain image quality and visibility even in challenging lighting environments, such as outdoor settings or brightly lit offices.

Another key aspect of QNED technology is its potential for energy efficiency. By combining the high efficiency of quantum dots with the precise control of mini-LED backlighting, QNED displays can potentially reduce power consumption while maintaining or even improving display performance. This aligns with the broader industry trend towards more sustainable and environmentally friendly display technologies.

The implementation of QNED for glare reduction also involves addressing challenges in manufacturing scalability, cost-effectiveness, and long-term stability of quantum dot materials. Overcoming these hurdles is essential for widespread adoption of QNED technology in consumer electronics and professional display applications.

As the display industry continues to evolve, QNED technology represents a promising direction for achieving superior visual performance while addressing practical concerns such as glare reduction. The ongoing research and development in this field aim to refine the technology further, potentially revolutionizing the way we interact with displays in various environments and applications.

The evolution of display technology has progressed from CRT to LCD, OLED, and now to advanced technologies like QNED. Each iteration has aimed to address limitations of previous generations, with QNED specifically targeting issues such as display glare, color accuracy, and energy consumption. The primary objective of QNED technology in reducing display glare is to enhance visibility and user comfort, particularly in high-ambient light conditions.

QNED technology utilizes quantum dots, which are nanoscale semiconductor particles that emit light of specific wavelengths when excited. These quantum dots are combined with mini-LED backlighting to create a display that offers superior brightness, contrast, and color accuracy compared to traditional LCD displays. The nano-scale nature of quantum dots allows for precise control over light emission, which is crucial in managing and reducing glare.

The technical goals of QNED in glare reduction include achieving higher peak brightness without increasing power consumption, improving local dimming capabilities for enhanced contrast, and optimizing the light emission spectrum to minimize reflections. By attaining these objectives, QNED displays aim to maintain image quality and visibility even in challenging lighting environments, such as outdoor settings or brightly lit offices.

Another key aspect of QNED technology is its potential for energy efficiency. By combining the high efficiency of quantum dots with the precise control of mini-LED backlighting, QNED displays can potentially reduce power consumption while maintaining or even improving display performance. This aligns with the broader industry trend towards more sustainable and environmentally friendly display technologies.

The implementation of QNED for glare reduction also involves addressing challenges in manufacturing scalability, cost-effectiveness, and long-term stability of quantum dot materials. Overcoming these hurdles is essential for widespread adoption of QNED technology in consumer electronics and professional display applications.

As the display industry continues to evolve, QNED technology represents a promising direction for achieving superior visual performance while addressing practical concerns such as glare reduction. The ongoing research and development in this field aim to refine the technology further, potentially revolutionizing the way we interact with displays in various environments and applications.

Market Demand for Glare-Free Displays

The demand for glare-free displays has been steadily increasing across various sectors, driven by the growing awareness of eye health and the need for improved visual experiences. In the consumer electronics market, smartphones, tablets, and laptops are primary targets for glare-reduction technologies. Users increasingly seek devices that offer comfortable viewing experiences in diverse lighting conditions, from bright outdoor environments to dimly lit indoor spaces.

The automotive industry represents another significant market for glare-free displays. As vehicles incorporate more digital interfaces and heads-up displays, the need for clear visibility in varying light conditions becomes crucial for both safety and user satisfaction. This demand extends to both personal vehicles and commercial fleets, where driver fatigue and eye strain are major concerns.

Professional sectors such as healthcare, aviation, and industrial control rooms also show a strong interest in glare-free display technologies. In medical settings, accurate image interpretation is critical, making glare-free monitors essential for diagnostics and surgical procedures. Similarly, in aviation and industrial control environments, where operators must maintain visual acuity for extended periods, the reduction of eye strain through glare-free displays is increasingly prioritized.

The education sector presents a growing market for glare-free displays as well. With the rise of digital learning platforms and smart classrooms, there is a heightened focus on creating comfortable viewing experiences for students and teachers alike. This trend has been further accelerated by the increase in remote and hybrid learning models.

Market research indicates that consumers are willing to pay a premium for devices with superior display quality, including glare reduction features. This willingness is particularly evident in high-end consumer electronics and professional-grade equipment. The global market for anti-glare coatings and technologies is expected to expand significantly in the coming years, driven by these diverse sector demands.

The push for energy efficiency also aligns with the demand for glare-free displays. As displays with reduced glare often require less brightness to maintain visibility, they can contribute to lower power consumption, appealing to both environmentally conscious consumers and organizations looking to reduce operational costs.

In summary, the market demand for glare-free displays spans multiple industries and is driven by factors including eye health concerns, improved user experience, safety considerations, and energy efficiency. As QNED technology offers promising solutions for glare reduction, it is well-positioned to address these growing market needs across various sectors.

The automotive industry represents another significant market for glare-free displays. As vehicles incorporate more digital interfaces and heads-up displays, the need for clear visibility in varying light conditions becomes crucial for both safety and user satisfaction. This demand extends to both personal vehicles and commercial fleets, where driver fatigue and eye strain are major concerns.

Professional sectors such as healthcare, aviation, and industrial control rooms also show a strong interest in glare-free display technologies. In medical settings, accurate image interpretation is critical, making glare-free monitors essential for diagnostics and surgical procedures. Similarly, in aviation and industrial control environments, where operators must maintain visual acuity for extended periods, the reduction of eye strain through glare-free displays is increasingly prioritized.

The education sector presents a growing market for glare-free displays as well. With the rise of digital learning platforms and smart classrooms, there is a heightened focus on creating comfortable viewing experiences for students and teachers alike. This trend has been further accelerated by the increase in remote and hybrid learning models.

Market research indicates that consumers are willing to pay a premium for devices with superior display quality, including glare reduction features. This willingness is particularly evident in high-end consumer electronics and professional-grade equipment. The global market for anti-glare coatings and technologies is expected to expand significantly in the coming years, driven by these diverse sector demands.

The push for energy efficiency also aligns with the demand for glare-free displays. As displays with reduced glare often require less brightness to maintain visibility, they can contribute to lower power consumption, appealing to both environmentally conscious consumers and organizations looking to reduce operational costs.

In summary, the market demand for glare-free displays spans multiple industries and is driven by factors including eye health concerns, improved user experience, safety considerations, and energy efficiency. As QNED technology offers promising solutions for glare reduction, it is well-positioned to address these growing market needs across various sectors.

Current Challenges in QNED Implementation

The implementation of Quantum Nano Emitting Diodes (QNED) for reducing display glare faces several significant challenges. One of the primary obstacles is the complexity of manufacturing processes required to produce QNED displays at scale. The precise control needed for quantum dot placement and alignment demands advanced fabrication techniques that are not yet fully developed for mass production.

Another challenge lies in the stability and longevity of QNED materials. Quantum dots are susceptible to degradation over time, particularly when exposed to heat and light. This can lead to color shifts and reduced brightness, potentially negating the glare-reduction benefits of QNED technology. Developing more robust quantum dot materials that maintain their optical properties over extended periods is crucial for widespread adoption.

The cost of QNED implementation remains a significant hurdle. The materials and manufacturing processes associated with QNED technology are currently more expensive than those used in traditional LED or OLED displays. This cost factor limits the technology's accessibility and makes it challenging to compete with established display technologies in the consumer market.

Power efficiency is another area of concern. While QNEDs have the potential to be more energy-efficient than some existing technologies, optimizing their power consumption while maintaining high brightness and color accuracy is an ongoing challenge. This is particularly important for mobile devices where battery life is a critical factor.

Color accuracy and consistency across different viewing angles present additional challenges. Ensuring that QNED displays maintain their color fidelity and glare-reduction properties from various perspectives requires sophisticated optical engineering and careful calibration.

The integration of QNED technology with existing display architectures poses its own set of challenges. Adapting current manufacturing lines and display designs to incorporate QNED elements without compromising other aspects of display performance requires significant research and development efforts.

Lastly, there are regulatory and environmental considerations. The use of certain materials in quantum dots, such as heavy metals, raises concerns about toxicity and disposal. Developing eco-friendly alternatives and ensuring compliance with evolving environmental regulations are essential for the long-term viability of QNED technology in display applications.

Another challenge lies in the stability and longevity of QNED materials. Quantum dots are susceptible to degradation over time, particularly when exposed to heat and light. This can lead to color shifts and reduced brightness, potentially negating the glare-reduction benefits of QNED technology. Developing more robust quantum dot materials that maintain their optical properties over extended periods is crucial for widespread adoption.

The cost of QNED implementation remains a significant hurdle. The materials and manufacturing processes associated with QNED technology are currently more expensive than those used in traditional LED or OLED displays. This cost factor limits the technology's accessibility and makes it challenging to compete with established display technologies in the consumer market.

Power efficiency is another area of concern. While QNEDs have the potential to be more energy-efficient than some existing technologies, optimizing their power consumption while maintaining high brightness and color accuracy is an ongoing challenge. This is particularly important for mobile devices where battery life is a critical factor.

Color accuracy and consistency across different viewing angles present additional challenges. Ensuring that QNED displays maintain their color fidelity and glare-reduction properties from various perspectives requires sophisticated optical engineering and careful calibration.

The integration of QNED technology with existing display architectures poses its own set of challenges. Adapting current manufacturing lines and display designs to incorporate QNED elements without compromising other aspects of display performance requires significant research and development efforts.

Lastly, there are regulatory and environmental considerations. The use of certain materials in quantum dots, such as heavy metals, raises concerns about toxicity and disposal. Developing eco-friendly alternatives and ensuring compliance with evolving environmental regulations are essential for the long-term viability of QNED technology in display applications.

Existing QNED Glare Reduction Solutions

01 QNED structure and composition

Quantum Nano Emitting Diodes (QNEDs) are composed of quantum dots or nanocrystals as the light-emitting material. The structure typically includes a substrate, electrodes, and multiple layers of quantum dot materials. These devices utilize quantum confinement effects to produce highly efficient and tunable light emission.- QNED structure and composition: QNED technology combines quantum dots with nano-scale LEDs to create a display with improved brightness and color accuracy. The structure typically includes a substrate, quantum dot layer, and nano-LED array. This configuration allows for precise control of light emission and reduces glare by enhancing contrast and color purity.

- Glare reduction techniques in QNED displays: Various methods are employed to reduce glare in QNED displays, including anti-reflective coatings, light-diffusing layers, and optimized pixel structures. These techniques help to minimize unwanted reflections and improve viewing experience in bright environments, while maintaining the high contrast and color accuracy of QNED technology.

- Quantum dot enhancement for QNED displays: Advancements in quantum dot technology play a crucial role in improving QNED display performance. This includes developing new quantum dot materials, optimizing their size and distribution, and enhancing their integration with nano-LEDs. These improvements contribute to better color gamut, increased brightness, and reduced power consumption, indirectly addressing glare issues.

- Nano-LED design for glare reduction: Innovative nano-LED designs focus on minimizing light scattering and improving directional emission. This includes developing specialized electrode structures, optimizing the shape and size of nano-LEDs, and implementing advanced packaging techniques. These enhancements contribute to better light control and reduced glare in QNED displays.

- Control systems for dynamic glare management: Advanced control systems are implemented in QNED displays to dynamically manage brightness and contrast levels. These systems can adjust the display output based on ambient light conditions, viewing angles, and content, effectively reducing perceived glare. This may include local dimming techniques and adaptive brightness control algorithms.

02 Glare reduction techniques in QNED displays

Various methods are employed to reduce glare in QNED displays. These include applying anti-reflective coatings, optimizing the arrangement of quantum dots, and implementing advanced light management structures. Some techniques involve manipulating the surface morphology of the display to scatter incident light and minimize specular reflections.Expand Specific Solutions03 Color enhancement and control in QNED technology

QNED technology allows for precise control over color output through the manipulation of quantum dot size and composition. This enables a wider color gamut and improved color accuracy compared to traditional LED displays. Advanced color management systems are implemented to optimize color reproduction and reduce unwanted color shifts or glare effects.Expand Specific Solutions04 Integration of QNED with other display technologies

QNED technology is being integrated with other display technologies to enhance overall performance. This includes combining QNED with Mini-LED backlighting systems, incorporating quantum dots into OLED structures, and developing hybrid display architectures. These integrations aim to leverage the strengths of multiple technologies while addressing limitations such as glare.Expand Specific Solutions05 Manufacturing processes for QNED displays

Advanced manufacturing processes are developed to produce QNED displays with improved performance and reduced glare. These include novel deposition techniques for quantum dot layers, precision patterning methods, and innovative encapsulation processes to protect the sensitive quantum dot materials. Emphasis is placed on achieving uniform light emission and minimizing defects that could contribute to glare.Expand Specific Solutions

Key Players in QNED Display Industry

The implementation of Quantum Nano Emitting Diode (QNED) technology for reducing display glare is in its early development stage, with a growing market potential due to increasing demand for high-quality displays. The technology's maturity is still evolving, with major players like BOE Technology Group, Samsung Display, and Sharp Corp. leading research and development efforts. Other companies such as TCL China Star Optoelectronics and Guangdong Juhua Printing Display Technology are also contributing to advancements in this field. The competitive landscape is characterized by a mix of established display manufacturers and emerging tech companies, with collaborations between industry and academic institutions like The Hong Kong University of Science & Technology driving innovation in QNED technology for glare reduction.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a QNED (Quantum Nano Emitting Diode) display technology that combines quantum dot and mini-LED technologies to reduce glare. Their approach involves using a quantum dot color conversion layer on top of mini-LED backlights. This allows for precise control of local dimming zones, enhancing contrast and reducing glare. BOE's QNED panels utilize advanced light management films and anti-reflective coatings to further minimize unwanted reflections and glare. The company has also implemented AI-driven algorithms to dynamically adjust backlight intensity based on ambient light conditions, optimizing visibility and reducing eye strain in various environments.

Strengths: High contrast ratio, wide color gamut, and effective glare reduction. Weaknesses: Higher production costs compared to traditional LCD panels and potential for color shift at extreme viewing angles.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has developed a QNED display technology that addresses glare reduction through a multi-faceted approach. Their QNED panels incorporate quantum dot color conversion layers combined with mini-LED backlighting for precise light control. To combat glare, TCL CSOT has implemented a proprietary anti-reflective (AR) coating that utilizes nano-scale structures to disrupt light reflection patterns. This coating is applied using an advanced deposition process that ensures uniformity across large panel sizes. Additionally, TCL CSOT has developed a dynamic backlight control system that adjusts local dimming zones in real-time based on content and ambient light conditions. This system works in conjunction with their "Intelligent Eye Protection" feature, which modulates blue light output and overall brightness to reduce eye strain and perceived glare. TCL CSOT has also incorporated advanced light guide plates with optimized micro-lens arrays to improve light distribution and minimize hot spots that can contribute to glare.

Strengths: Effective glare reduction in various lighting conditions, enhanced eye comfort features, and compatibility with large-format displays. Weaknesses: Potential for increased production costs due to complex AR coating process and sophisticated backlight control systems.

Core QNED Patents and Technical Literature

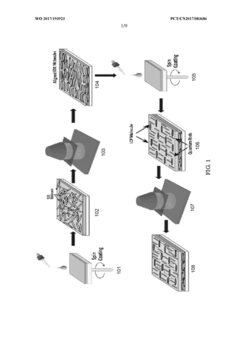

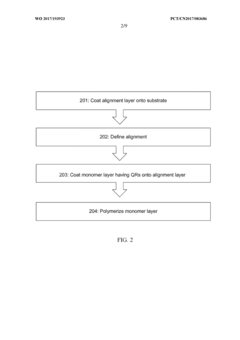

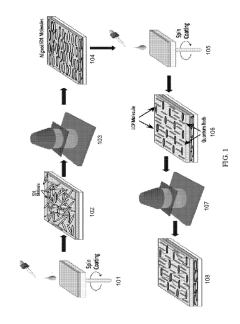

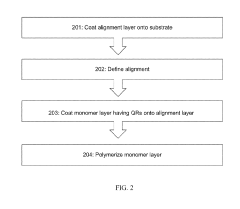

Photoaligned quantum rod enhancement films

PatentWO2017193923A1

Innovation

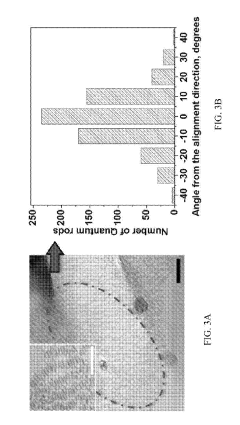

- Utilizes a photoaligned quantum rod enhancement film (QREF) with aligned quantum rods to improve LCD image quality and efficiency.

- Employs a photoalignment layer to control the orientation of quantum rods, enabling more flexible and scalable manufacturing.

- Combines the benefits of quantum rod polarized light emission with LCD technology to reduce light losses from polarizers.

Photoaligned quantum rod enhancement films

PatentActiveUS20190129252A1

Innovation

- A photoaligned quantum rod enhancement film (QREF) is developed, comprising a substrate with a photoalignment layer and a polymer layer containing quantum rods that emit polarized light, allowing for flexible alignment and increased polarization efficiency.

QNED Manufacturing Process Analysis

The manufacturing process of QNED (Quantum Nano Emitting Diode) displays involves several intricate steps that combine quantum dot technology with mini-LED backlighting. The process begins with the production of quantum dots, typically using colloidal synthesis methods. These quantum dots are then precisely deposited onto a substrate, forming a uniform layer that will serve as the color conversion element in the display.

Concurrently, the mini-LED backlight units are manufactured. This involves the production of tiny LED chips, often less than 200 micrometers in size, which are then arranged in a dense array on a separate substrate. The mini-LEDs are typically produced using advanced epitaxial growth techniques and require precise control over the semiconductor materials and doping processes.

The integration of the quantum dot layer with the mini-LED backlight is a critical step in the QNED manufacturing process. This is achieved through a carefully controlled bonding process that ensures optimal alignment and minimal light loss between the two components. The bonding process often involves the use of specialized optical adhesives that maintain transparency while providing structural integrity.

Following the integration of the quantum dot layer and mini-LED backlight, the display panel undergoes a series of quality control checks. These include tests for color accuracy, brightness uniformity, and overall display performance. Any defects or inconsistencies detected at this stage may require rework or, in some cases, rejection of the panel.

The final stages of QNED manufacturing involve the assembly of the display module, including the addition of driving circuits, power management systems, and protective layers. The entire assembly is then encased in a frame or housing suitable for the intended application, whether it be a television, monitor, or other display device.

Throughout the manufacturing process, strict environmental controls are maintained to prevent contamination and ensure the stability of the quantum dot materials. This often includes the use of cleanroom facilities and specialized handling equipment to minimize exposure to moisture, oxygen, and other potential contaminants that could degrade the performance of the quantum dots or mini-LEDs.

The complexity of QNED manufacturing necessitates a high degree of automation and precision engineering. Advanced robotics and machine vision systems are employed to ensure accurate placement of components and consistent quality across large production volumes. Continuous process optimization and yield improvement efforts are crucial for making QNED technology commercially viable and competitive with other display technologies.

Concurrently, the mini-LED backlight units are manufactured. This involves the production of tiny LED chips, often less than 200 micrometers in size, which are then arranged in a dense array on a separate substrate. The mini-LEDs are typically produced using advanced epitaxial growth techniques and require precise control over the semiconductor materials and doping processes.

The integration of the quantum dot layer with the mini-LED backlight is a critical step in the QNED manufacturing process. This is achieved through a carefully controlled bonding process that ensures optimal alignment and minimal light loss between the two components. The bonding process often involves the use of specialized optical adhesives that maintain transparency while providing structural integrity.

Following the integration of the quantum dot layer and mini-LED backlight, the display panel undergoes a series of quality control checks. These include tests for color accuracy, brightness uniformity, and overall display performance. Any defects or inconsistencies detected at this stage may require rework or, in some cases, rejection of the panel.

The final stages of QNED manufacturing involve the assembly of the display module, including the addition of driving circuits, power management systems, and protective layers. The entire assembly is then encased in a frame or housing suitable for the intended application, whether it be a television, monitor, or other display device.

Throughout the manufacturing process, strict environmental controls are maintained to prevent contamination and ensure the stability of the quantum dot materials. This often includes the use of cleanroom facilities and specialized handling equipment to minimize exposure to moisture, oxygen, and other potential contaminants that could degrade the performance of the quantum dots or mini-LEDs.

The complexity of QNED manufacturing necessitates a high degree of automation and precision engineering. Advanced robotics and machine vision systems are employed to ensure accurate placement of components and consistent quality across large production volumes. Continuous process optimization and yield improvement efforts are crucial for making QNED technology commercially viable and competitive with other display technologies.

Environmental Impact of QNED Technology

The implementation of Quantum Nano Emitting Diode (QNED) technology for reducing display glare brings significant environmental considerations to the forefront. QNED displays, while offering superior visual performance, also present potential environmental benefits and challenges that warrant careful examination.

One of the primary environmental advantages of QNED technology lies in its energy efficiency. QNED displays consume less power compared to traditional LCD and OLED technologies, potentially leading to reduced energy consumption on a global scale. This efficiency stems from the quantum dot nanoparticles' ability to produce precise colors with minimal energy input. As displays account for a substantial portion of electronic device power consumption, the widespread adoption of QNED could contribute to lower overall energy demand and, consequently, reduced carbon emissions from power generation.

The manufacturing process of QNED displays also presents environmental implications. The production of quantum dots involves the use of rare earth elements and heavy metals, which raises concerns about resource depletion and potential environmental contamination. However, the minute quantities required for QNED displays may mitigate these concerns to some extent. Additionally, the improved durability and longevity of QNED displays could lead to a reduction in electronic waste, as consumers may need to replace their devices less frequently.

Water usage in the production of QNED displays is another environmental factor to consider. The manufacturing process may require significant amounts of ultra-pure water, potentially straining local water resources in production areas. However, advancements in water recycling and purification technologies in the electronics industry could help address this issue.

The end-of-life management of QNED displays poses both challenges and opportunities. The presence of nanoparticles and specialized materials may complicate recycling processes, requiring the development of new recycling technologies and infrastructure. On the other hand, the valuable materials used in QNED displays could incentivize more efficient recycling practices, potentially leading to improved resource recovery rates across the electronics industry.

Lastly, the reduction of display glare through QNED technology may have indirect environmental benefits. By enhancing visibility in various lighting conditions, QNED displays could reduce the need for artificial lighting in certain environments, further contributing to energy savings. Moreover, the improved visual comfort may lead to increased productivity and reduced eye strain, potentially resulting in lower healthcare-related environmental impacts.

In conclusion, while QNED technology offers promising environmental benefits, particularly in terms of energy efficiency and potential waste reduction, it also presents challenges that require careful management and further technological innovation to fully realize its positive environmental potential.

One of the primary environmental advantages of QNED technology lies in its energy efficiency. QNED displays consume less power compared to traditional LCD and OLED technologies, potentially leading to reduced energy consumption on a global scale. This efficiency stems from the quantum dot nanoparticles' ability to produce precise colors with minimal energy input. As displays account for a substantial portion of electronic device power consumption, the widespread adoption of QNED could contribute to lower overall energy demand and, consequently, reduced carbon emissions from power generation.

The manufacturing process of QNED displays also presents environmental implications. The production of quantum dots involves the use of rare earth elements and heavy metals, which raises concerns about resource depletion and potential environmental contamination. However, the minute quantities required for QNED displays may mitigate these concerns to some extent. Additionally, the improved durability and longevity of QNED displays could lead to a reduction in electronic waste, as consumers may need to replace their devices less frequently.

Water usage in the production of QNED displays is another environmental factor to consider. The manufacturing process may require significant amounts of ultra-pure water, potentially straining local water resources in production areas. However, advancements in water recycling and purification technologies in the electronics industry could help address this issue.

The end-of-life management of QNED displays poses both challenges and opportunities. The presence of nanoparticles and specialized materials may complicate recycling processes, requiring the development of new recycling technologies and infrastructure. On the other hand, the valuable materials used in QNED displays could incentivize more efficient recycling practices, potentially leading to improved resource recovery rates across the electronics industry.

Lastly, the reduction of display glare through QNED technology may have indirect environmental benefits. By enhancing visibility in various lighting conditions, QNED displays could reduce the need for artificial lighting in certain environments, further contributing to energy savings. Moreover, the improved visual comfort may lead to increased productivity and reduced eye strain, potentially resulting in lower healthcare-related environmental impacts.

In conclusion, while QNED technology offers promising environmental benefits, particularly in terms of energy efficiency and potential waste reduction, it also presents challenges that require careful management and further technological innovation to fully realize its positive environmental potential.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!