How to Leverage QNED for Flexible Display Developments?

JUN 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QNED Flexible Display Evolution and Objectives

Quantum Nano-Emitting Diode (QNED) technology represents a significant leap forward in the evolution of flexible display technologies. This innovative approach combines the advantages of quantum dot technology with the structural benefits of nano-emitting diodes, offering a promising pathway for the development of next-generation flexible displays.

The evolution of QNED technology for flexible displays can be traced back to the early 2010s when researchers began exploring the potential of quantum dots in display applications. The initial focus was on enhancing color gamut and brightness in traditional rigid displays. However, as the demand for flexible and foldable devices grew, the research shifted towards integrating quantum dots into flexible substrates.

A key milestone in this evolution was the development of quantum dot light-emitting diodes (QLEDs) in the mid-2010s. These devices demonstrated the potential for high color purity and energy efficiency but faced challenges in terms of stability and manufacturing scalability. The introduction of nano-emitting diodes as a potential solution to these challenges marked the birth of QNED technology.

The primary objective of QNED technology in flexible display development is to create ultra-thin, highly flexible displays with superior color performance and energy efficiency. This aligns with the broader industry goals of producing lightweight, durable, and visually stunning flexible devices for various applications, including smartphones, wearables, and automotive displays.

Another critical objective is to overcome the limitations of current flexible display technologies, such as OLED. QNED aims to provide better color accuracy, higher brightness, and improved longevity, addressing some of the key drawbacks of OLED in flexible applications. Additionally, QNED technology seeks to simplify the manufacturing process, potentially reducing production costs and increasing yield rates for flexible displays.

Looking forward, the evolution of QNED for flexible displays is expected to focus on several key areas. These include improving the flexibility and durability of QNED panels, enhancing the quantum yield of nano-emitters, and developing more efficient electron transport layers. Researchers are also working on optimizing the integration of QNED technology with flexible substrates and protective layers to ensure long-term reliability under repeated bending and folding.

The ultimate goal is to leverage QNED technology to create flexible displays that can seamlessly conform to various shapes and forms while maintaining exceptional visual quality and performance. This could potentially revolutionize product design across multiple industries, enabling new form factors and user experiences that were previously impossible with rigid display technologies.

The evolution of QNED technology for flexible displays can be traced back to the early 2010s when researchers began exploring the potential of quantum dots in display applications. The initial focus was on enhancing color gamut and brightness in traditional rigid displays. However, as the demand for flexible and foldable devices grew, the research shifted towards integrating quantum dots into flexible substrates.

A key milestone in this evolution was the development of quantum dot light-emitting diodes (QLEDs) in the mid-2010s. These devices demonstrated the potential for high color purity and energy efficiency but faced challenges in terms of stability and manufacturing scalability. The introduction of nano-emitting diodes as a potential solution to these challenges marked the birth of QNED technology.

The primary objective of QNED technology in flexible display development is to create ultra-thin, highly flexible displays with superior color performance and energy efficiency. This aligns with the broader industry goals of producing lightweight, durable, and visually stunning flexible devices for various applications, including smartphones, wearables, and automotive displays.

Another critical objective is to overcome the limitations of current flexible display technologies, such as OLED. QNED aims to provide better color accuracy, higher brightness, and improved longevity, addressing some of the key drawbacks of OLED in flexible applications. Additionally, QNED technology seeks to simplify the manufacturing process, potentially reducing production costs and increasing yield rates for flexible displays.

Looking forward, the evolution of QNED for flexible displays is expected to focus on several key areas. These include improving the flexibility and durability of QNED panels, enhancing the quantum yield of nano-emitters, and developing more efficient electron transport layers. Researchers are also working on optimizing the integration of QNED technology with flexible substrates and protective layers to ensure long-term reliability under repeated bending and folding.

The ultimate goal is to leverage QNED technology to create flexible displays that can seamlessly conform to various shapes and forms while maintaining exceptional visual quality and performance. This could potentially revolutionize product design across multiple industries, enabling new form factors and user experiences that were previously impossible with rigid display technologies.

Market Demand for Flexible Display Technologies

The flexible display market has been experiencing significant growth in recent years, driven by the increasing demand for innovative and portable electronic devices. As consumers seek more versatile and durable products, flexible displays have become a key focus for manufacturers across various industries, including smartphones, wearables, automotive, and smart home devices.

The global flexible display market is projected to expand rapidly, with a compound annual growth rate (CAGR) exceeding 30% over the next five years. This growth is primarily fueled by the rising adoption of OLED technology, which offers superior flexibility and image quality compared to traditional LCD displays. The smartphone segment currently dominates the flexible display market, accounting for a substantial portion of the overall demand.

Consumer preferences are shifting towards devices with larger screens and improved durability, making flexible displays an attractive option for manufacturers. The ability to create foldable and rollable devices has opened up new possibilities for product design and functionality, leading to increased consumer interest and market potential.

In the wearable technology sector, flexible displays are becoming increasingly important for smartwatches, fitness trackers, and other body-worn devices. The demand for curved and conformable displays that can adapt to the contours of the human body is driving innovation in this space.

The automotive industry is another significant market for flexible display technologies. As vehicles become more connected and autonomous, there is a growing need for advanced infotainment systems and digital dashboards that can seamlessly integrate into curved surfaces and unconventional form factors.

Emerging applications in smart home devices, such as curved televisions and flexible digital signage, are also contributing to the expanding market for flexible displays. These applications leverage the unique properties of flexible displays to create immersive viewing experiences and adaptable information displays.

However, the market demand for flexible display technologies is not without challenges. High production costs and technical limitations in areas such as durability and longevity continue to be obstacles for widespread adoption. Additionally, the need for specialized manufacturing processes and equipment presents barriers to entry for some manufacturers.

Despite these challenges, the potential benefits of flexible displays, including enhanced user experiences, improved portability, and novel design possibilities, continue to drive market demand. As technology advances and production costs decrease, the flexible display market is expected to see further growth and diversification across various industries and applications.

The global flexible display market is projected to expand rapidly, with a compound annual growth rate (CAGR) exceeding 30% over the next five years. This growth is primarily fueled by the rising adoption of OLED technology, which offers superior flexibility and image quality compared to traditional LCD displays. The smartphone segment currently dominates the flexible display market, accounting for a substantial portion of the overall demand.

Consumer preferences are shifting towards devices with larger screens and improved durability, making flexible displays an attractive option for manufacturers. The ability to create foldable and rollable devices has opened up new possibilities for product design and functionality, leading to increased consumer interest and market potential.

In the wearable technology sector, flexible displays are becoming increasingly important for smartwatches, fitness trackers, and other body-worn devices. The demand for curved and conformable displays that can adapt to the contours of the human body is driving innovation in this space.

The automotive industry is another significant market for flexible display technologies. As vehicles become more connected and autonomous, there is a growing need for advanced infotainment systems and digital dashboards that can seamlessly integrate into curved surfaces and unconventional form factors.

Emerging applications in smart home devices, such as curved televisions and flexible digital signage, are also contributing to the expanding market for flexible displays. These applications leverage the unique properties of flexible displays to create immersive viewing experiences and adaptable information displays.

However, the market demand for flexible display technologies is not without challenges. High production costs and technical limitations in areas such as durability and longevity continue to be obstacles for widespread adoption. Additionally, the need for specialized manufacturing processes and equipment presents barriers to entry for some manufacturers.

Despite these challenges, the potential benefits of flexible displays, including enhanced user experiences, improved portability, and novel design possibilities, continue to drive market demand. As technology advances and production costs decrease, the flexible display market is expected to see further growth and diversification across various industries and applications.

QNED Flexible Display: Current State and Challenges

QNED (Quantum Nano Emitting Diode) technology represents a significant advancement in display technology, offering potential solutions for flexible display development. However, the current state of QNED flexible displays faces several challenges that need to be addressed for successful implementation.

The primary challenge lies in the fabrication process of QNED displays on flexible substrates. Traditional manufacturing techniques used for rigid displays are not directly applicable to flexible substrates, requiring the development of new production methods. These methods must ensure uniform deposition of quantum dots and maintain their optical properties while accommodating the stress and strain associated with flexible materials.

Another significant hurdle is the durability and longevity of QNED flexible displays. Repeated bending and folding can lead to degradation of the quantum dot layer, potentially affecting color accuracy and overall display performance. Researchers are working on developing protective encapsulation techniques to shield the quantum dots from environmental factors and mechanical stress.

Power efficiency remains a concern for QNED flexible displays. While QNEDs offer improved energy efficiency compared to traditional LED displays, further optimization is needed to reduce power consumption, especially for battery-powered devices. This challenge is particularly crucial for wearable and portable applications where energy constraints are more stringent.

The integration of QNED technology with flexible electronics poses another challenge. Developing flexible circuits and components that can seamlessly work with QNED displays while maintaining performance and reliability under various bending conditions is an ongoing area of research.

Color accuracy and consistency across the entire display area, especially when bent or folded, present additional technical hurdles. Ensuring uniform light emission and maintaining color gamut under different viewing angles and display configurations is crucial for the widespread adoption of QNED flexible displays.

Scalability and cost-effectiveness of QNED flexible display production are also significant challenges. Current manufacturing processes for quantum dots and flexible substrates are complex and expensive, limiting mass production capabilities. Developing more efficient and cost-effective production methods is essential for the commercial viability of QNED flexible displays.

Lastly, the environmental impact and recyclability of QNED flexible displays need to be addressed. As sustainability becomes increasingly important in technology development, finding eco-friendly materials and production processes for quantum dots and flexible substrates is a critical challenge facing the industry.

The primary challenge lies in the fabrication process of QNED displays on flexible substrates. Traditional manufacturing techniques used for rigid displays are not directly applicable to flexible substrates, requiring the development of new production methods. These methods must ensure uniform deposition of quantum dots and maintain their optical properties while accommodating the stress and strain associated with flexible materials.

Another significant hurdle is the durability and longevity of QNED flexible displays. Repeated bending and folding can lead to degradation of the quantum dot layer, potentially affecting color accuracy and overall display performance. Researchers are working on developing protective encapsulation techniques to shield the quantum dots from environmental factors and mechanical stress.

Power efficiency remains a concern for QNED flexible displays. While QNEDs offer improved energy efficiency compared to traditional LED displays, further optimization is needed to reduce power consumption, especially for battery-powered devices. This challenge is particularly crucial for wearable and portable applications where energy constraints are more stringent.

The integration of QNED technology with flexible electronics poses another challenge. Developing flexible circuits and components that can seamlessly work with QNED displays while maintaining performance and reliability under various bending conditions is an ongoing area of research.

Color accuracy and consistency across the entire display area, especially when bent or folded, present additional technical hurdles. Ensuring uniform light emission and maintaining color gamut under different viewing angles and display configurations is crucial for the widespread adoption of QNED flexible displays.

Scalability and cost-effectiveness of QNED flexible display production are also significant challenges. Current manufacturing processes for quantum dots and flexible substrates are complex and expensive, limiting mass production capabilities. Developing more efficient and cost-effective production methods is essential for the commercial viability of QNED flexible displays.

Lastly, the environmental impact and recyclability of QNED flexible displays need to be addressed. As sustainability becomes increasingly important in technology development, finding eco-friendly materials and production processes for quantum dots and flexible substrates is a critical challenge facing the industry.

Current QNED Flexible Display Solutions

01 Flexible QNED structures

Quantum Nano Emitting Diodes (QNEDs) can be designed with flexible structures to enhance their adaptability and application in various devices. This involves using flexible substrates, incorporating bendable materials, and developing novel fabrication techniques that allow the QNEDs to maintain their performance while being flexible.- Flexible QNED structures: Quantum Nano Emitting Diodes (QNEDs) can be designed with flexible structures to enhance their adaptability and application in various devices. This involves using flexible substrates, incorporating bendable materials, and developing novel fabrication techniques that allow the QNEDs to maintain their performance while being flexible.

- Quantum dot integration for flexibility: Integration of quantum dots into QNED structures can improve both the emission properties and flexibility of the devices. This approach involves carefully selecting and incorporating quantum dot materials that maintain their optical properties under mechanical stress, allowing for the creation of bendable and stretchable QNED displays.

- Flexible electrode materials for QNEDs: Developing flexible electrode materials is crucial for creating bendable QNED devices. This includes the use of transparent conductive materials that can withstand bending and stretching without compromising electrical conductivity or optical transparency, enabling the fabrication of flexible QNED displays and lighting solutions.

- Encapsulation techniques for flexible QNEDs: Advanced encapsulation techniques are essential for protecting flexible QNED devices from environmental factors while maintaining their bendability. This involves developing thin, flexible barrier layers that effectively seal the device components while allowing for mechanical deformation without compromising the device's performance or lifespan.

- Fabrication methods for flexible QNED arrays: Innovative fabrication methods are being developed to create large-area, flexible QNED arrays. These techniques focus on maintaining uniform performance across the array while ensuring flexibility, including roll-to-roll processing, transfer printing, and solution-based deposition methods that are compatible with flexible substrates.

02 Quantum dot integration for flexibility

The integration of quantum dots into QNED structures can contribute to their flexibility. Quantum dots, being nanoscale semiconductors, can be dispersed in flexible matrices or incorporated into pliable layers, allowing for the creation of bendable and stretchable QNED devices without compromising their light-emitting properties.Expand Specific Solutions03 Flexible electrode materials

The use of flexible electrode materials is crucial for achieving QNED flexibility. This involves developing and implementing conductive materials that can withstand bending and stretching while maintaining electrical connectivity. Potential materials include conductive polymers, metal nanowires, or graphene-based electrodes.Expand Specific Solutions04 Encapsulation techniques for flexible QNEDs

Advanced encapsulation techniques are essential for protecting flexible QNED devices from environmental factors while maintaining their bendability. This may involve the use of flexible barrier materials, multi-layer encapsulation structures, or novel sealing methods that can accommodate the movement and deformation of the flexible device.Expand Specific Solutions05 Fabrication processes for flexible QNEDs

Developing specialized fabrication processes is key to producing flexible QNEDs. This includes adapting existing manufacturing techniques or creating new ones that can handle flexible substrates and materials. Low-temperature processes, roll-to-roll fabrication, and solution-based methods may be employed to achieve the desired flexibility in QNED devices.Expand Specific Solutions

Key Players in QNED Flexible Display Industry

The QNED (Quantum Nano Emitting Diode) technology for flexible displays is in its early development stage, with the market showing significant growth potential. The industry is transitioning from research to commercialization, with major players like Samsung Electronics, LG Display, and BOE Technology Group leading the charge. These companies are investing heavily in R&D to overcome technical challenges and improve manufacturing processes. The technology's maturity is still evolving, with companies like TCL China Star Optoelectronics and Tianma Microelectronics also making strides. As QNED promises superior image quality and energy efficiency, competition is intensifying among display manufacturers to bring this technology to market, potentially revolutionizing the flexible display industry.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has been actively researching QNED (Quantum Nano Emitting Diode) technology for flexible displays. Their approach involves integrating quantum dot nanoparticles with micro-LED technology to create ultra-thin, flexible, and energy-efficient displays. BOE's QNED solution uses a unique quantum dot color conversion layer that enhances color gamut and brightness while maintaining flexibility. The company has also developed advanced manufacturing processes to ensure uniform quantum dot distribution and precise alignment with micro-LEDs, crucial for maintaining display quality in flexible applications.

Strengths: Superior color performance, high energy efficiency, and potential for ultra-thin flexible displays. Weaknesses: Complex manufacturing process and higher production costs compared to traditional display technologies.

LG Display Co., Ltd.

Technical Solution: LG Display has been pioneering QNED technology for flexible displays, focusing on combining quantum dots with their proprietary NanoCell technology. Their approach involves using a quantum dot color conversion layer on top of mini-LED backlighting, which is then integrated into a flexible substrate. LG's QNED flexible display solution aims to achieve superior color accuracy, high contrast ratios, and improved energy efficiency while maintaining flexibility. The company has also developed specialized manufacturing techniques to ensure the quantum dot layer remains stable and effective when the display is bent or flexed.

Strengths: Excellent color reproduction, high contrast ratios, and potential for large-scale flexible displays. Weaknesses: Challenges in maintaining consistent performance across the entire flexible surface and potential issues with long-term durability.

Core QNED Innovations for Flexible Displays

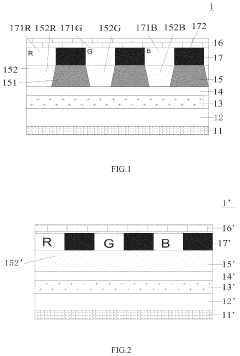

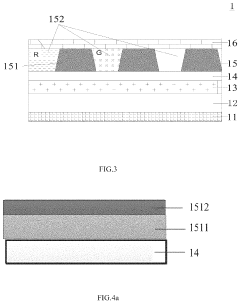

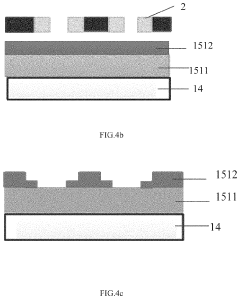

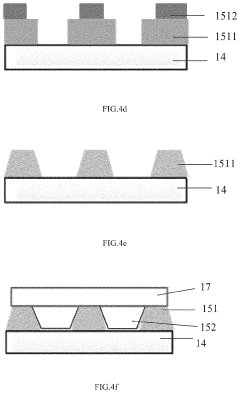

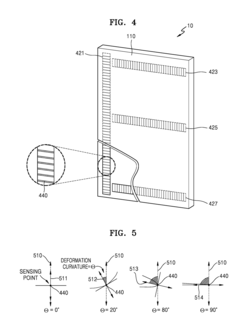

Flexible display panel, flexible display device and method of forming flexible display panel

PatentActiveUS20220158109A1

Innovation

- A flexible display panel design featuring a quantum dot photoconversion layer with isolation portions that surround quantum dot luminescent materials, reducing interference from adjacent pixels and scattering, and a color film layer with a black matrix and filter films to concentrate and filter light effectively, thereby minimizing color shift and enhancing display quality.

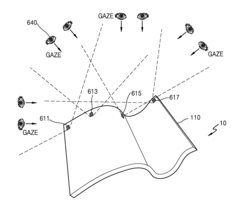

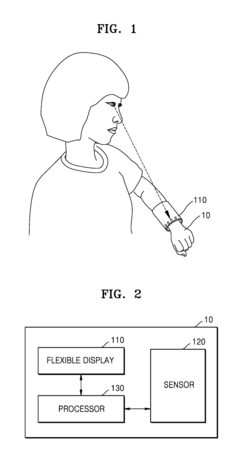

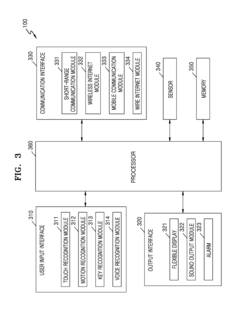

Flexible display device and displaying method of flexible display device

PatentActiveUS20180137801A1

Innovation

- A flexible display device equipped with sensors to obtain user gaze information and curvature data, using a processor to determine and adjust the activated region for content display, correcting image distortion, and dynamically changing the display based on user interaction and distance.

Supply Chain Analysis for QNED Flexible Displays

The supply chain for QNED (Quantum Nano Emitting Diode) flexible displays is a complex network involving multiple key components and processes. At the core of this supply chain are the quantum dot materials, which are typically produced by specialized chemical companies. These materials are crucial for the color performance and efficiency of QNED displays.

Semiconductor manufacturers play a vital role in producing the micro-LED chips that form the basis of QNED technology. These chips are then integrated with quantum dots in a process that requires precision engineering and advanced manufacturing capabilities. This integration step is often performed by display panel manufacturers or specialized QNED module producers.

The flexible substrate is another critical component in the QNED flexible display supply chain. Suppliers of flexible materials, such as polyimide films or ultra-thin glass, are essential partners in enabling the flexibility of these displays. These substrates must meet stringent requirements for durability, transparency, and thermal stability.

Electronic component suppliers provide the necessary drivers, controllers, and other circuitry required to operate QNED displays. These components must be designed to work with the unique characteristics of QNED technology and be compatible with flexible form factors.

Assembly and integration of all these components into a final flexible QNED display product is typically carried out by major display manufacturers or OEMs. These companies often have established relationships with suppliers across the entire supply chain and may also engage in vertical integration to secure key technologies and components.

Testing and quality control equipment manufacturers are also crucial to the supply chain, providing the tools necessary to ensure the performance and reliability of QNED flexible displays throughout the production process.

The global nature of the QNED flexible display supply chain presents both opportunities and challenges. While it allows for specialization and cost optimization, it also introduces potential vulnerabilities to disruptions in global trade and logistics. Companies involved in QNED flexible display development must carefully manage their supply chains to ensure resilience and maintain competitive advantages in this emerging technology sector.

Semiconductor manufacturers play a vital role in producing the micro-LED chips that form the basis of QNED technology. These chips are then integrated with quantum dots in a process that requires precision engineering and advanced manufacturing capabilities. This integration step is often performed by display panel manufacturers or specialized QNED module producers.

The flexible substrate is another critical component in the QNED flexible display supply chain. Suppliers of flexible materials, such as polyimide films or ultra-thin glass, are essential partners in enabling the flexibility of these displays. These substrates must meet stringent requirements for durability, transparency, and thermal stability.

Electronic component suppliers provide the necessary drivers, controllers, and other circuitry required to operate QNED displays. These components must be designed to work with the unique characteristics of QNED technology and be compatible with flexible form factors.

Assembly and integration of all these components into a final flexible QNED display product is typically carried out by major display manufacturers or OEMs. These companies often have established relationships with suppliers across the entire supply chain and may also engage in vertical integration to secure key technologies and components.

Testing and quality control equipment manufacturers are also crucial to the supply chain, providing the tools necessary to ensure the performance and reliability of QNED flexible displays throughout the production process.

The global nature of the QNED flexible display supply chain presents both opportunities and challenges. While it allows for specialization and cost optimization, it also introduces potential vulnerabilities to disruptions in global trade and logistics. Companies involved in QNED flexible display development must carefully manage their supply chains to ensure resilience and maintain competitive advantages in this emerging technology sector.

Environmental Impact of QNED Flexible Displays

The environmental impact of QNED (Quantum Nano Emitting Diode) flexible displays is a crucial consideration in the development and adoption of this emerging technology. As QNED displays gain traction in the market, it is essential to assess their ecological footprint throughout their lifecycle, from production to disposal.

In the manufacturing phase, QNED displays require the use of rare earth elements and other specialized materials. The extraction and processing of these resources can have significant environmental implications, including habitat disruption, energy consumption, and potential pollution. However, compared to traditional LCD and OLED technologies, QNED displays may offer advantages in terms of resource efficiency and reduced waste generation during production.

The operational phase of QNED flexible displays presents potential environmental benefits. These displays are expected to consume less energy than their counterparts, particularly in bright ambient conditions. This improved energy efficiency could lead to reduced power consumption and, consequently, lower greenhouse gas emissions associated with electricity generation.

The flexibility and durability of QNED displays may contribute to extended product lifespans, potentially reducing electronic waste generation. However, the complex nature of these displays could pose challenges for recycling and proper disposal at the end of their life cycle. The integration of various materials and components may require specialized recycling processes to recover valuable resources and minimize environmental impact.

As QNED technology advances, there is an opportunity to incorporate eco-design principles from the outset. This could include the use of more sustainable materials, designing for easy disassembly and recycling, and optimizing production processes to minimize resource consumption and emissions.

The potential for QNED flexible displays to enable new form factors and applications in various industries could have indirect environmental impacts. For instance, their use in automotive displays could contribute to lighter, more fuel-efficient vehicles. In the consumer electronics sector, the versatility of QNED displays might lead to the consolidation of multiple devices into single, multifunctional units, potentially reducing overall electronic waste.

However, the widespread adoption of QNED technology could also lead to increased consumption of electronic devices, driven by novel applications and form factors. This potential rebound effect must be carefully considered and managed to ensure that the environmental benefits of the technology are not offset by increased production and disposal of electronic products.

In conclusion, while QNED flexible displays show promise for reduced energy consumption and potentially longer product lifespans, their overall environmental impact will depend on factors such as manufacturing processes, material choices, and end-of-life management. As the technology matures, ongoing research and development efforts should focus on minimizing negative environmental impacts throughout the entire lifecycle of QNED displays.

In the manufacturing phase, QNED displays require the use of rare earth elements and other specialized materials. The extraction and processing of these resources can have significant environmental implications, including habitat disruption, energy consumption, and potential pollution. However, compared to traditional LCD and OLED technologies, QNED displays may offer advantages in terms of resource efficiency and reduced waste generation during production.

The operational phase of QNED flexible displays presents potential environmental benefits. These displays are expected to consume less energy than their counterparts, particularly in bright ambient conditions. This improved energy efficiency could lead to reduced power consumption and, consequently, lower greenhouse gas emissions associated with electricity generation.

The flexibility and durability of QNED displays may contribute to extended product lifespans, potentially reducing electronic waste generation. However, the complex nature of these displays could pose challenges for recycling and proper disposal at the end of their life cycle. The integration of various materials and components may require specialized recycling processes to recover valuable resources and minimize environmental impact.

As QNED technology advances, there is an opportunity to incorporate eco-design principles from the outset. This could include the use of more sustainable materials, designing for easy disassembly and recycling, and optimizing production processes to minimize resource consumption and emissions.

The potential for QNED flexible displays to enable new form factors and applications in various industries could have indirect environmental impacts. For instance, their use in automotive displays could contribute to lighter, more fuel-efficient vehicles. In the consumer electronics sector, the versatility of QNED displays might lead to the consolidation of multiple devices into single, multifunctional units, potentially reducing overall electronic waste.

However, the widespread adoption of QNED technology could also lead to increased consumption of electronic devices, driven by novel applications and form factors. This potential rebound effect must be carefully considered and managed to ensure that the environmental benefits of the technology are not offset by increased production and disposal of electronic products.

In conclusion, while QNED flexible displays show promise for reduced energy consumption and potentially longer product lifespans, their overall environmental impact will depend on factors such as manufacturing processes, material choices, and end-of-life management. As the technology matures, ongoing research and development efforts should focus on minimizing negative environmental impacts throughout the entire lifecycle of QNED displays.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!