How to Attain Display Visual Excellence with QNED?

JUN 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QNED Display Evolution

QNED (Quantum Nano Emitting Diode) display technology represents a significant evolution in the pursuit of visual excellence. This innovative display solution combines the strengths of quantum dot technology with mini-LED backlighting, offering a promising path towards enhanced picture quality and energy efficiency.

The journey of QNED displays began with the development of quantum dot technology in the early 2000s. Quantum dots, nanoscale semiconductor particles, were initially used to enhance color reproduction in LCD displays. As research progressed, scientists discovered ways to integrate quantum dots more effectively into display panels, leading to the concept of QNED.

In the mid-2010s, mini-LED backlighting emerged as a breakthrough in display technology, offering improved local dimming capabilities and higher contrast ratios compared to traditional LED backlighting. The marriage of quantum dots and mini-LED backlighting gave birth to QNED displays, marking a significant milestone in display evolution.

QNED technology addresses several limitations of existing display technologies. Unlike OLED displays, QNED panels are less susceptible to burn-in issues and can achieve higher peak brightness levels. Compared to traditional LCD displays, QNED offers superior color accuracy, wider color gamut, and enhanced contrast ratios.

The evolution of QNED displays has been driven by continuous improvements in quantum dot synthesis, mini-LED manufacturing processes, and panel design. Recent advancements include the development of cadmium-free quantum dots, addressing environmental concerns, and the integration of AI-powered local dimming algorithms to optimize picture quality.

As QNED technology matures, it is poised to revolutionize various display applications. In the consumer electronics sector, QNED displays are finding their way into high-end televisions and monitors, offering cinematic viewing experiences. The professional market is also embracing QNED technology for color-critical applications in fields such as graphic design, video editing, and medical imaging.

Looking ahead, the QNED display evolution is expected to focus on further enhancing energy efficiency, expanding color gamut coverage, and improving manufacturing processes to reduce costs. Researchers are exploring novel quantum dot materials and structures to push the boundaries of color reproduction and brightness. Additionally, efforts are underway to develop flexible QNED displays, opening up new possibilities for curved and foldable devices.

The journey of QNED displays began with the development of quantum dot technology in the early 2000s. Quantum dots, nanoscale semiconductor particles, were initially used to enhance color reproduction in LCD displays. As research progressed, scientists discovered ways to integrate quantum dots more effectively into display panels, leading to the concept of QNED.

In the mid-2010s, mini-LED backlighting emerged as a breakthrough in display technology, offering improved local dimming capabilities and higher contrast ratios compared to traditional LED backlighting. The marriage of quantum dots and mini-LED backlighting gave birth to QNED displays, marking a significant milestone in display evolution.

QNED technology addresses several limitations of existing display technologies. Unlike OLED displays, QNED panels are less susceptible to burn-in issues and can achieve higher peak brightness levels. Compared to traditional LCD displays, QNED offers superior color accuracy, wider color gamut, and enhanced contrast ratios.

The evolution of QNED displays has been driven by continuous improvements in quantum dot synthesis, mini-LED manufacturing processes, and panel design. Recent advancements include the development of cadmium-free quantum dots, addressing environmental concerns, and the integration of AI-powered local dimming algorithms to optimize picture quality.

As QNED technology matures, it is poised to revolutionize various display applications. In the consumer electronics sector, QNED displays are finding their way into high-end televisions and monitors, offering cinematic viewing experiences. The professional market is also embracing QNED technology for color-critical applications in fields such as graphic design, video editing, and medical imaging.

Looking ahead, the QNED display evolution is expected to focus on further enhancing energy efficiency, expanding color gamut coverage, and improving manufacturing processes to reduce costs. Researchers are exploring novel quantum dot materials and structures to push the boundaries of color reproduction and brightness. Additionally, efforts are underway to develop flexible QNED displays, opening up new possibilities for curved and foldable devices.

Market Demand Analysis

The market demand for QNED (Quantum Nano Emitting Diode) display technology is rapidly growing as consumers and industries seek superior visual experiences. QNED combines the benefits of quantum dot and mini-LED technologies, offering enhanced color accuracy, brightness, and contrast ratios compared to traditional LCD and OLED displays.

In the consumer electronics sector, there is a strong demand for high-end televisions and monitors that can deliver exceptional picture quality. QNED displays are well-positioned to meet this demand, as they offer deeper blacks, brighter whites, and a wider color gamut than conventional displays. This makes them particularly appealing to enthusiasts, gamers, and content creators who require precise color reproduction and high dynamic range.

The professional market also shows significant interest in QNED technology. Industries such as graphic design, video production, and medical imaging require displays with exceptional color accuracy and consistency. QNED's ability to provide a wider color gamut and improved color volume makes it an attractive option for these sectors, potentially driving adoption in high-end professional monitors and specialized display equipment.

In the automotive industry, there is a growing trend towards larger, more advanced in-vehicle displays. QNED technology's high brightness and contrast capabilities make it well-suited for automotive applications, where displays need to be easily readable in various lighting conditions, including direct sunlight. This presents a substantial market opportunity as vehicle manufacturers continue to integrate more sophisticated infotainment systems and digital dashboards.

The digital signage and advertising sectors are also potential growth areas for QNED displays. The technology's ability to produce vibrant, eye-catching visuals with high brightness levels makes it ideal for large-format displays in retail environments, outdoor advertising, and public spaces. As businesses seek to create more immersive and engaging customer experiences, the demand for high-quality display solutions like QNED is expected to increase.

Looking at market trends, the global display market is projected to grow significantly in the coming years, driven by factors such as increasing adoption of 4K and 8K resolution displays, rising demand for OLED technology, and the growing popularity of smart devices. QNED technology is well-positioned to capitalize on these trends, offering a compelling alternative to existing display technologies and potentially capturing a significant share of the premium display market.

However, the adoption of QNED technology may face challenges such as higher production costs compared to traditional LCD displays and competition from established OLED technology. Overcoming these hurdles will be crucial for QNED to gain widespread market acceptance and achieve its full potential in various industry segments.

In the consumer electronics sector, there is a strong demand for high-end televisions and monitors that can deliver exceptional picture quality. QNED displays are well-positioned to meet this demand, as they offer deeper blacks, brighter whites, and a wider color gamut than conventional displays. This makes them particularly appealing to enthusiasts, gamers, and content creators who require precise color reproduction and high dynamic range.

The professional market also shows significant interest in QNED technology. Industries such as graphic design, video production, and medical imaging require displays with exceptional color accuracy and consistency. QNED's ability to provide a wider color gamut and improved color volume makes it an attractive option for these sectors, potentially driving adoption in high-end professional monitors and specialized display equipment.

In the automotive industry, there is a growing trend towards larger, more advanced in-vehicle displays. QNED technology's high brightness and contrast capabilities make it well-suited for automotive applications, where displays need to be easily readable in various lighting conditions, including direct sunlight. This presents a substantial market opportunity as vehicle manufacturers continue to integrate more sophisticated infotainment systems and digital dashboards.

The digital signage and advertising sectors are also potential growth areas for QNED displays. The technology's ability to produce vibrant, eye-catching visuals with high brightness levels makes it ideal for large-format displays in retail environments, outdoor advertising, and public spaces. As businesses seek to create more immersive and engaging customer experiences, the demand for high-quality display solutions like QNED is expected to increase.

Looking at market trends, the global display market is projected to grow significantly in the coming years, driven by factors such as increasing adoption of 4K and 8K resolution displays, rising demand for OLED technology, and the growing popularity of smart devices. QNED technology is well-positioned to capitalize on these trends, offering a compelling alternative to existing display technologies and potentially capturing a significant share of the premium display market.

However, the adoption of QNED technology may face challenges such as higher production costs compared to traditional LCD displays and competition from established OLED technology. Overcoming these hurdles will be crucial for QNED to gain widespread market acceptance and achieve its full potential in various industry segments.

QNED Tech Challenges

QNED (Quantum Nano Emitting Diode) technology faces several significant challenges in its pursuit of display visual excellence. One of the primary hurdles is the precise control of quantum dot synthesis and deposition. The uniformity and consistency of quantum dot size and distribution directly impact color accuracy and brightness. Achieving nanometer-level precision in manufacturing processes remains a complex task, requiring advanced equipment and stringent quality control measures.

Another major challenge lies in the development of efficient and stable blue QNED emitters. While red and green quantum dots have shown promising performance, blue emitters often suffer from lower efficiency and shorter lifespans. This imbalance can lead to color shift over time and reduced overall display longevity. Researchers are exploring various material compositions and structures to enhance blue QNED stability and efficiency, but significant improvements are still needed to match the performance of other colors.

The integration of QNED technology with existing display architectures presents another set of challenges. Incorporating quantum dots into LED backlight systems or as direct emissive layers requires careful optimization of optical and electrical properties. Issues such as light outcoupling efficiency, thermal management, and electrical current distribution must be addressed to maximize the potential of QNED displays.

Scalability and cost-effectiveness pose additional hurdles for QNED technology. While quantum dots offer superior color performance, the materials and manufacturing processes involved are currently more expensive than traditional display technologies. Developing economically viable production methods for large-scale QNED displays is crucial for widespread adoption in consumer electronics.

Environmental and regulatory concerns also present challenges for QNED technology. Some quantum dot materials contain heavy metals or other potentially harmful substances. Meeting stringent environmental regulations and ensuring the long-term sustainability of QNED production are essential considerations for the industry.

Lastly, achieving consistent performance across different viewing angles remains a challenge for QNED displays. Quantum dot emission characteristics can vary depending on the viewing angle, potentially leading to color shifts or reduced brightness at off-center viewing positions. Developing optical designs and materials that maintain visual excellence across a wide range of viewing angles is crucial for the success of QNED technology in various applications, from mobile devices to large-format displays.

Another major challenge lies in the development of efficient and stable blue QNED emitters. While red and green quantum dots have shown promising performance, blue emitters often suffer from lower efficiency and shorter lifespans. This imbalance can lead to color shift over time and reduced overall display longevity. Researchers are exploring various material compositions and structures to enhance blue QNED stability and efficiency, but significant improvements are still needed to match the performance of other colors.

The integration of QNED technology with existing display architectures presents another set of challenges. Incorporating quantum dots into LED backlight systems or as direct emissive layers requires careful optimization of optical and electrical properties. Issues such as light outcoupling efficiency, thermal management, and electrical current distribution must be addressed to maximize the potential of QNED displays.

Scalability and cost-effectiveness pose additional hurdles for QNED technology. While quantum dots offer superior color performance, the materials and manufacturing processes involved are currently more expensive than traditional display technologies. Developing economically viable production methods for large-scale QNED displays is crucial for widespread adoption in consumer electronics.

Environmental and regulatory concerns also present challenges for QNED technology. Some quantum dot materials contain heavy metals or other potentially harmful substances. Meeting stringent environmental regulations and ensuring the long-term sustainability of QNED production are essential considerations for the industry.

Lastly, achieving consistent performance across different viewing angles remains a challenge for QNED displays. Quantum dot emission characteristics can vary depending on the viewing angle, potentially leading to color shifts or reduced brightness at off-center viewing positions. Developing optical designs and materials that maintain visual excellence across a wide range of viewing angles is crucial for the success of QNED technology in various applications, from mobile devices to large-format displays.

Current QNED Solutions

01 Quantum dot-based light emitting diodes

QNED technology utilizes quantum dots to create light-emitting diodes. These quantum dots are nanoscale semiconductor particles that emit light when excited. The use of quantum dots allows for improved color accuracy, brightness, and energy efficiency in display technologies.- Quantum dot-based light emitting diodes: QNED technology utilizes quantum dots as the light-emitting material in diodes. These nanoscale semiconductor particles offer superior color purity and efficiency compared to traditional LED technologies. The quantum confinement effect in these nanostructures allows for precise control over the emission wavelength, resulting in excellent color reproduction and visual quality.

- Nanostructure fabrication techniques: Advanced fabrication methods are crucial for creating high-quality QNED devices. These techniques include epitaxial growth, lithography, and self-assembly processes to produce uniform and precisely controlled nanostructures. The development of these methods enables the production of QNEDs with consistent performance and high yield, contributing to their visual excellence.

- Display integration and optimization: Integrating QNED technology into display systems requires careful optimization of various components. This includes developing suitable driving circuits, pixel architectures, and color filters to fully exploit the advantages of QNEDs. The integration process focuses on maximizing brightness, contrast, and color gamut while maintaining energy efficiency and long-term stability.

- Enhanced optical properties: QNED technology offers significant improvements in optical properties compared to conventional display technologies. This includes wider color gamut, higher brightness, and better contrast ratios. The unique properties of quantum dots allow for more efficient light emission and better color selectivity, resulting in visually stunning and more lifelike images.

- Material composition and structure optimization: Ongoing research focuses on optimizing the material composition and structure of QNEDs to further enhance their performance. This includes exploring new quantum dot materials, developing novel core-shell structures, and investigating the effects of doping and surface treatments. These advancements aim to improve efficiency, stability, and color purity of QNED displays.

02 Nanostructure design for enhanced performance

The design and fabrication of nanostructures play a crucial role in QNED visual excellence. Researchers focus on optimizing the size, shape, and composition of quantum dots and other nanostructures to enhance light emission, color purity, and overall display performance.Expand Specific Solutions03 Integration of QNED technology in display devices

QNED technology is being integrated into various display devices, including televisions, monitors, and mobile devices. This integration involves developing manufacturing processes and display architectures that can effectively incorporate quantum nano-emitting diodes to achieve superior visual quality.Expand Specific Solutions04 Color enhancement and control techniques

QNED technology enables advanced color enhancement and control techniques. This includes methods for achieving wider color gamuts, improved color accuracy, and better control over color temperature and brightness. These techniques contribute to the overall visual excellence of QNED displays.Expand Specific Solutions05 Energy efficiency and power management

QNED technology offers improvements in energy efficiency and power management for display devices. Researchers are developing methods to optimize power consumption while maintaining high visual quality, including techniques for selective pixel activation and advanced backlight control.Expand Specific Solutions

Key QNED Players

The QNED (Quantum Nano Emitting Diode) display technology market is in its early growth stage, with significant potential for expansion. The global market size for advanced display technologies is projected to reach billions of dollars in the coming years. QNED's competitive landscape is characterized by a mix of established display manufacturers and innovative startups. Companies like Samsung Display, BOE Technology Group, and TCL China Star Optoelectronics are investing heavily in QNED research and development. The technology's maturity is progressing rapidly, with firms like Jade Bird Display and Hefei Visionox Technology making notable advancements. However, QNED still faces competition from other emerging display technologies, and its widespread commercial adoption is yet to be fully realized.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has been developing its own version of QNED technology, focusing on combining nanoLED light sources with quantum dot color conversion. Their approach involves creating extremely small LED chips, typically less than 100 nanometers in size, and arranging them in a precise array to form the display's backlight. These nanoLEDs are then paired with a quantum dot layer for color conversion. BOE's QNED technology aims to achieve high brightness, wide color gamut, and excellent contrast ratios. They are also exploring advanced manufacturing techniques, such as nanoprinting and self-assembled monolayers, to improve the efficiency and consistency of nanoLED placement.

Strengths: Potential for very high pixel density and resolution due to the small size of nanoLEDs. Excellent color performance and brightness capabilities. Weaknesses: Challenges in mass production and yield rates due to the complexity of nanoLED manufacturing. Potential for high costs in the initial stages of production.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has developed QNED (Quantum Nano Emitting Diode) technology, which combines quantum dot and nano-LED technologies. Their approach involves using ultra-small LEDs as the light source, with sizes ranging from 10 to 20 nanometers. These nano-LEDs are precisely controlled to emit blue light, which is then converted to red and green using quantum dots. This results in a display with exceptional color accuracy, brightness, and contrast ratios. Samsung's QNED displays also incorporate advanced local dimming techniques to enhance black levels and overall picture quality.

Strengths: Superior color accuracy and wide color gamut due to quantum dot technology. Excellent brightness and contrast ratios. Potential for lower power consumption compared to traditional LED-LCD. Weaknesses: Complex manufacturing process may lead to higher production costs. Potential yield issues due to the precision required in nano-LED placement.

QNED Core Innovations

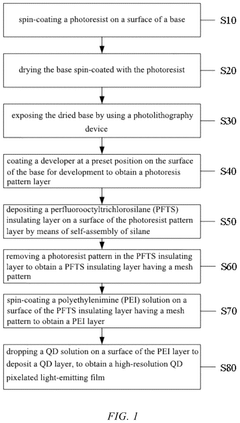

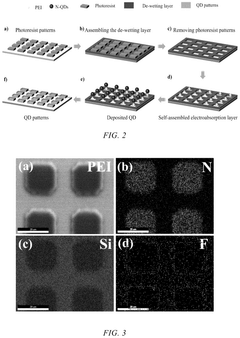

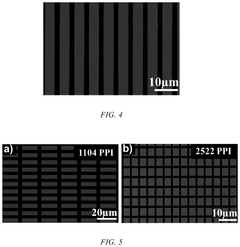

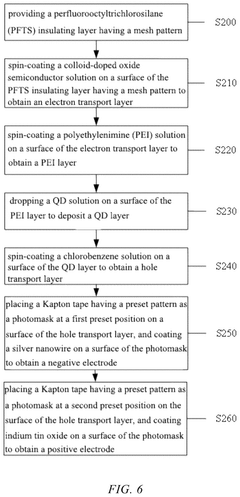

Method for preparing high-resolution quantum dot (QD) pixelated light-emitting film

PatentActiveUS12120941B1

Innovation

- A method involving spin-coating a photoresist, exposing, and developing to create a pattern, followed by depositing a perfluorooctyltrichlorosilane (PFTS) insulating layer, then a polyethylenimine (PEI) layer, and finally a QD layer, using self-assembly and electrostatic interactions to avoid direct photolithography on the QD layer, thereby preventing damage and improving film quality.

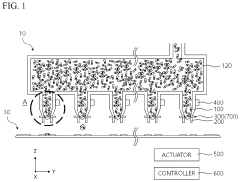

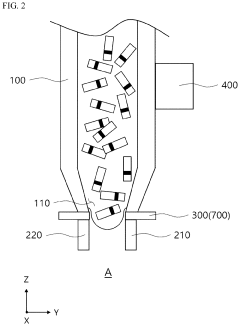

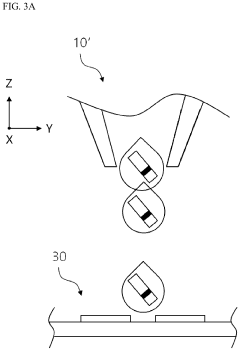

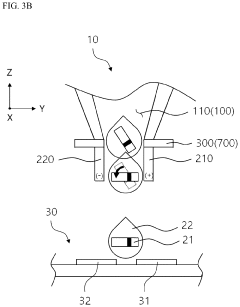

Inkjet head and method of ejecting ink using the same

PatentActiveUS11845276B2

Innovation

- An inkjet head with nozzles and pairs of electrodes that apply an electrode voltage to the light-emitting elements, including a first and second piezoelectric element, and a controller to independently control the electrode voltage, allowing for precise arrangement of light-emitting elements on a substrate with separate electrodes before and during the jetting process.

QNED Manufacturing

QNED (Quantum Nano Emitting Diode) manufacturing represents a critical aspect of achieving display visual excellence. This advanced manufacturing process combines quantum dot technology with mini-LED backlighting to produce displays with superior color accuracy, contrast, and brightness.

The QNED manufacturing process begins with the production of quantum dots, typically composed of semiconductor nanocrystals. These quantum dots are carefully engineered to emit specific wavelengths of light when excited, allowing for precise color control. The size and composition of the quantum dots are crucial factors in determining the color output, requiring stringent quality control measures throughout the manufacturing process.

Next, the quantum dots are integrated into a film layer, which is then incorporated into the display panel. This integration process demands high precision to ensure uniform distribution of quantum dots across the entire display surface. Any inconsistencies in this step can lead to color variations and reduced display quality.

The mini-LED backlighting system is another key component in QNED manufacturing. These miniaturized LEDs are produced using advanced semiconductor fabrication techniques, allowing for a high density of light sources behind the display panel. The manufacturing process must ensure consistent performance across thousands of individual mini-LEDs, as variations can impact overall display uniformity.

Assembly of the QNED display involves carefully layering the quantum dot film, LCD panel, and mini-LED backlight system. This process requires precise alignment and bonding techniques to maintain the integrity of each layer and optimize light transmission through the display stack.

Quality control is paramount throughout the QNED manufacturing process. Advanced testing equipment and procedures are employed to verify color accuracy, brightness uniformity, and contrast performance. This includes spectral analysis of individual quantum dots, as well as comprehensive testing of the assembled display units.

The manufacturing environment for QNED displays must be tightly controlled to prevent contamination and ensure consistency. Clean room facilities with stringent temperature, humidity, and particulate control are essential for maintaining the high standards required for quantum dot and mini-LED production.

Continuous improvement in manufacturing techniques is crucial for advancing QNED technology. This includes refining quantum dot synthesis methods, enhancing mini-LED fabrication processes, and developing more efficient assembly techniques. These ongoing efforts aim to improve display performance while reducing production costs, making QNED technology more accessible for a wider range of applications.

The QNED manufacturing process begins with the production of quantum dots, typically composed of semiconductor nanocrystals. These quantum dots are carefully engineered to emit specific wavelengths of light when excited, allowing for precise color control. The size and composition of the quantum dots are crucial factors in determining the color output, requiring stringent quality control measures throughout the manufacturing process.

Next, the quantum dots are integrated into a film layer, which is then incorporated into the display panel. This integration process demands high precision to ensure uniform distribution of quantum dots across the entire display surface. Any inconsistencies in this step can lead to color variations and reduced display quality.

The mini-LED backlighting system is another key component in QNED manufacturing. These miniaturized LEDs are produced using advanced semiconductor fabrication techniques, allowing for a high density of light sources behind the display panel. The manufacturing process must ensure consistent performance across thousands of individual mini-LEDs, as variations can impact overall display uniformity.

Assembly of the QNED display involves carefully layering the quantum dot film, LCD panel, and mini-LED backlight system. This process requires precise alignment and bonding techniques to maintain the integrity of each layer and optimize light transmission through the display stack.

Quality control is paramount throughout the QNED manufacturing process. Advanced testing equipment and procedures are employed to verify color accuracy, brightness uniformity, and contrast performance. This includes spectral analysis of individual quantum dots, as well as comprehensive testing of the assembled display units.

The manufacturing environment for QNED displays must be tightly controlled to prevent contamination and ensure consistency. Clean room facilities with stringent temperature, humidity, and particulate control are essential for maintaining the high standards required for quantum dot and mini-LED production.

Continuous improvement in manufacturing techniques is crucial for advancing QNED technology. This includes refining quantum dot synthesis methods, enhancing mini-LED fabrication processes, and developing more efficient assembly techniques. These ongoing efforts aim to improve display performance while reducing production costs, making QNED technology more accessible for a wider range of applications.

QNED vs Competitors

QNED (Quantum Nano Emitting Diode) technology represents a significant advancement in display technology, offering several advantages over its competitors in the pursuit of visual excellence. When compared to traditional LCD, OLED, and even QLED displays, QNED stands out in several key areas.

Firstly, QNED technology combines the best aspects of both QLED and OLED. It utilizes quantum dots for enhanced color reproduction and brightness, similar to QLED, while also incorporating self-emissive properties akin to OLED. This hybrid approach results in superior contrast ratios, deeper blacks, and more vibrant colors than conventional LCD or QLED displays.

In terms of brightness, QNED outperforms OLED technology. While OLED displays are known for their excellent contrast and deep blacks, they often struggle with peak brightness, especially in well-lit environments. QNED, on the other hand, can achieve higher brightness levels without compromising on black levels, making it more suitable for a wider range of viewing conditions.

Longevity is another area where QNED holds an advantage. OLED displays are susceptible to burn-in over time, particularly when static images are displayed for extended periods. QNED technology is more resistant to this issue, potentially offering a longer lifespan and more consistent performance over time.

Energy efficiency is a crucial factor in modern display technology. QNED displays are generally more energy-efficient than their LCD counterparts, as they do not require a constant backlight. This efficiency is comparable to OLED but without the potential drawbacks of organic materials degradation.

In terms of response time and motion handling, QNED technology offers significant improvements over LCD. The self-emissive nature of QNED pixels allows for faster pixel response times, resulting in reduced motion blur and smoother overall motion performance. This makes QNED displays particularly well-suited for fast-paced content such as sports or action movies.

While QNED technology shows great promise, it's important to note that it is still relatively new compared to more established technologies like LCD and OLED. As such, the manufacturing processes and economies of scale are still evolving, which currently impacts the cost of QNED displays. However, as the technology matures and production scales up, it is expected that QNED will become more cost-competitive with other high-end display technologies.

In conclusion, QNED technology offers a compelling combination of high contrast, excellent color reproduction, superior brightness, and improved longevity compared to its competitors. These attributes position QNED as a strong contender in the pursuit of display visual excellence, particularly for applications that demand top-tier performance across a wide range of viewing conditions.

Firstly, QNED technology combines the best aspects of both QLED and OLED. It utilizes quantum dots for enhanced color reproduction and brightness, similar to QLED, while also incorporating self-emissive properties akin to OLED. This hybrid approach results in superior contrast ratios, deeper blacks, and more vibrant colors than conventional LCD or QLED displays.

In terms of brightness, QNED outperforms OLED technology. While OLED displays are known for their excellent contrast and deep blacks, they often struggle with peak brightness, especially in well-lit environments. QNED, on the other hand, can achieve higher brightness levels without compromising on black levels, making it more suitable for a wider range of viewing conditions.

Longevity is another area where QNED holds an advantage. OLED displays are susceptible to burn-in over time, particularly when static images are displayed for extended periods. QNED technology is more resistant to this issue, potentially offering a longer lifespan and more consistent performance over time.

Energy efficiency is a crucial factor in modern display technology. QNED displays are generally more energy-efficient than their LCD counterparts, as they do not require a constant backlight. This efficiency is comparable to OLED but without the potential drawbacks of organic materials degradation.

In terms of response time and motion handling, QNED technology offers significant improvements over LCD. The self-emissive nature of QNED pixels allows for faster pixel response times, resulting in reduced motion blur and smoother overall motion performance. This makes QNED displays particularly well-suited for fast-paced content such as sports or action movies.

While QNED technology shows great promise, it's important to note that it is still relatively new compared to more established technologies like LCD and OLED. As such, the manufacturing processes and economies of scale are still evolving, which currently impacts the cost of QNED displays. However, as the technology matures and production scales up, it is expected that QNED will become more cost-competitive with other high-end display technologies.

In conclusion, QNED technology offers a compelling combination of high contrast, excellent color reproduction, superior brightness, and improved longevity compared to its competitors. These attributes position QNED as a strong contender in the pursuit of display visual excellence, particularly for applications that demand top-tier performance across a wide range of viewing conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!