QNED in High-Durability Display Applications

JUN 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QNED Technology Evolution

QNED (Quantum Nano Emitting Diode) technology has undergone significant evolution since its inception, marking key milestones in the development of high-durability display applications. The journey of QNED began with the fundamental research into quantum dot technology, which laid the groundwork for this innovative display solution.

In its early stages, QNED faced challenges in achieving stable quantum dot emission and integrating these nanoparticles into practical display structures. Researchers focused on enhancing the quantum yield and stability of quantum dots, particularly in blue light emission, which is crucial for creating a full-color display.

A major breakthrough came with the development of cadmium-free quantum dots, addressing environmental concerns and regulatory requirements. This advancement opened doors for wider adoption of QNED technology in consumer electronics and professional display markets.

The next phase of QNED evolution saw improvements in manufacturing processes, enabling the production of larger display panels with consistent quality. Engineers developed novel methods for precisely depositing quantum dots onto substrates, ensuring uniform light emission across the entire display surface.

Advancements in color conversion layers and light management films further enhanced the efficiency and color gamut of QNED displays. These improvements resulted in displays with superior color accuracy and brightness compared to traditional LCD and OLED technologies.

Recent years have witnessed a focus on improving the longevity and durability of QNED displays. Researchers have developed protective encapsulation techniques to shield quantum dots from environmental factors, significantly extending the lifespan of QNED panels. This has made QNED an increasingly attractive option for high-durability applications such as outdoor signage, automotive displays, and industrial monitors.

The integration of QNED with Mini-LED backlight technology has been a game-changer, allowing for precise local dimming and enhanced contrast ratios. This hybrid approach combines the color performance of quantum dots with the high brightness and HDR capabilities of Mini-LED, resulting in displays that excel in both image quality and durability.

Current research is centered on further improving the energy efficiency of QNED displays, with a focus on reducing power consumption without compromising on brightness or color performance. Additionally, efforts are being made to simplify the manufacturing process, potentially lowering production costs and making QNED technology more accessible for a wider range of applications.

As QNED technology continues to mature, we can expect to see its implementation in an increasingly diverse array of display products, from consumer electronics to specialized industrial and commercial applications requiring high durability and exceptional visual performance.

In its early stages, QNED faced challenges in achieving stable quantum dot emission and integrating these nanoparticles into practical display structures. Researchers focused on enhancing the quantum yield and stability of quantum dots, particularly in blue light emission, which is crucial for creating a full-color display.

A major breakthrough came with the development of cadmium-free quantum dots, addressing environmental concerns and regulatory requirements. This advancement opened doors for wider adoption of QNED technology in consumer electronics and professional display markets.

The next phase of QNED evolution saw improvements in manufacturing processes, enabling the production of larger display panels with consistent quality. Engineers developed novel methods for precisely depositing quantum dots onto substrates, ensuring uniform light emission across the entire display surface.

Advancements in color conversion layers and light management films further enhanced the efficiency and color gamut of QNED displays. These improvements resulted in displays with superior color accuracy and brightness compared to traditional LCD and OLED technologies.

Recent years have witnessed a focus on improving the longevity and durability of QNED displays. Researchers have developed protective encapsulation techniques to shield quantum dots from environmental factors, significantly extending the lifespan of QNED panels. This has made QNED an increasingly attractive option for high-durability applications such as outdoor signage, automotive displays, and industrial monitors.

The integration of QNED with Mini-LED backlight technology has been a game-changer, allowing for precise local dimming and enhanced contrast ratios. This hybrid approach combines the color performance of quantum dots with the high brightness and HDR capabilities of Mini-LED, resulting in displays that excel in both image quality and durability.

Current research is centered on further improving the energy efficiency of QNED displays, with a focus on reducing power consumption without compromising on brightness or color performance. Additionally, efforts are being made to simplify the manufacturing process, potentially lowering production costs and making QNED technology more accessible for a wider range of applications.

As QNED technology continues to mature, we can expect to see its implementation in an increasingly diverse array of display products, from consumer electronics to specialized industrial and commercial applications requiring high durability and exceptional visual performance.

Market Demand Analysis

The market demand for high-durability display applications utilizing QNED (Quantum Nano Emitting Diode) technology is experiencing significant growth across various sectors. This emerging display technology combines the advantages of quantum dots and mini-LEDs, offering superior brightness, contrast, and color accuracy while maintaining long-term durability.

In the automotive industry, there is a rising demand for QNED displays in dashboard systems and infotainment units. The automotive market values QNED's ability to maintain high visibility in bright sunlight and its resistance to temperature fluctuations, making it ideal for in-vehicle applications. The increasing trend towards electric and autonomous vehicles is further driving the need for advanced, durable display solutions.

The outdoor advertising sector is another key market for QNED technology. Digital billboards and signage in high-traffic areas require displays that can withstand harsh environmental conditions while delivering vibrant, eye-catching visuals. QNED's durability and superior image quality make it an attractive option for advertisers looking to maximize impact and minimize maintenance costs.

In the industrial and manufacturing sectors, QNED displays are gaining traction for use in control panels and monitoring systems. The technology's resistance to dust, vibration, and extreme temperatures aligns well with the demanding environments found in factories and industrial facilities. The long lifespan of QNED displays also reduces the frequency of replacements, leading to lower total cost of ownership for businesses.

The healthcare industry is showing increased interest in QNED technology for medical imaging and diagnostic equipment. The high color accuracy and contrast ratio of QNED displays can enhance the clarity of medical images, potentially improving diagnostic accuracy. Additionally, the durability of these displays ensures consistent performance in critical healthcare settings.

Public transportation systems are another potential growth area for QNED displays. Information boards at train stations, airports, and bus terminals require displays that can operate continuously while maintaining clarity in various lighting conditions. QNED's durability and high brightness make it well-suited for these applications.

The retail sector is exploring QNED technology for in-store digital signage and interactive kiosks. The vibrant colors and high contrast of QNED displays can create engaging shopping experiences, while their durability ensures longevity in high-traffic retail environments.

As smart cities continue to develop, there is a growing demand for durable, high-quality displays for public information systems and interactive city services. QNED technology's combination of visual performance and resilience positions it as a strong contender in this emerging market.

While the market potential for QNED in high-durability applications is substantial, it's important to note that the technology is still relatively new. As manufacturing processes mature and economies of scale are achieved, the cost of QNED displays is expected to decrease, potentially accelerating market adoption across these various sectors.

In the automotive industry, there is a rising demand for QNED displays in dashboard systems and infotainment units. The automotive market values QNED's ability to maintain high visibility in bright sunlight and its resistance to temperature fluctuations, making it ideal for in-vehicle applications. The increasing trend towards electric and autonomous vehicles is further driving the need for advanced, durable display solutions.

The outdoor advertising sector is another key market for QNED technology. Digital billboards and signage in high-traffic areas require displays that can withstand harsh environmental conditions while delivering vibrant, eye-catching visuals. QNED's durability and superior image quality make it an attractive option for advertisers looking to maximize impact and minimize maintenance costs.

In the industrial and manufacturing sectors, QNED displays are gaining traction for use in control panels and monitoring systems. The technology's resistance to dust, vibration, and extreme temperatures aligns well with the demanding environments found in factories and industrial facilities. The long lifespan of QNED displays also reduces the frequency of replacements, leading to lower total cost of ownership for businesses.

The healthcare industry is showing increased interest in QNED technology for medical imaging and diagnostic equipment. The high color accuracy and contrast ratio of QNED displays can enhance the clarity of medical images, potentially improving diagnostic accuracy. Additionally, the durability of these displays ensures consistent performance in critical healthcare settings.

Public transportation systems are another potential growth area for QNED displays. Information boards at train stations, airports, and bus terminals require displays that can operate continuously while maintaining clarity in various lighting conditions. QNED's durability and high brightness make it well-suited for these applications.

The retail sector is exploring QNED technology for in-store digital signage and interactive kiosks. The vibrant colors and high contrast of QNED displays can create engaging shopping experiences, while their durability ensures longevity in high-traffic retail environments.

As smart cities continue to develop, there is a growing demand for durable, high-quality displays for public information systems and interactive city services. QNED technology's combination of visual performance and resilience positions it as a strong contender in this emerging market.

While the market potential for QNED in high-durability applications is substantial, it's important to note that the technology is still relatively new. As manufacturing processes mature and economies of scale are achieved, the cost of QNED displays is expected to decrease, potentially accelerating market adoption across these various sectors.

QNED Challenges

QNED (Quantum Nano Emitting Diode) technology faces several significant challenges in its application to high-durability displays. One of the primary obstacles is the stability of quantum dots over extended periods. While quantum dots offer superior color performance, their tendency to degrade when exposed to heat, light, and oxygen poses a major hurdle for long-term durability. This degradation can lead to color shift and reduced brightness over time, compromising the display's performance and longevity.

Another critical challenge lies in the manufacturing process of QNED displays. The precise placement and alignment of nanoparticles in the display structure require highly sophisticated and controlled manufacturing techniques. Any inconsistencies in this process can result in non-uniform light emission, affecting the overall display quality. Moreover, scaling up these intricate manufacturing processes for mass production while maintaining consistent quality remains a significant technical challenge.

The integration of quantum dots with existing display technologies also presents difficulties. Ensuring compatibility between quantum dot materials and other components of the display, such as the backlight system and color filters, is crucial for optimal performance. This integration must be achieved without compromising the unique properties of quantum dots that make them advantageous for display applications.

Heat management is another substantial challenge in QNED technology. The high current densities required for bright displays can generate significant heat, which can accelerate the degradation of quantum dots and other display components. Developing effective heat dissipation mechanisms without increasing the overall thickness or weight of the display is a complex engineering problem.

Furthermore, the environmental impact and potential toxicity of some quantum dot materials raise concerns. Many high-performance quantum dots contain heavy metals like cadmium, which are subject to regulatory restrictions in various regions. Developing alternative, environmentally friendly quantum dot materials that maintain the same level of performance is an ongoing challenge for researchers and manufacturers.

Cost-effectiveness remains a significant hurdle in the widespread adoption of QNED technology. The materials and manufacturing processes associated with QNED displays are currently more expensive than those of conventional display technologies. Reducing these costs while maintaining or improving performance is crucial for QNED to compete in the broader display market.

Lastly, achieving consistent and reliable performance across different operating conditions is challenging. QNED displays must maintain their color accuracy, brightness, and overall quality under varying ambient light conditions, temperatures, and usage patterns. This requires robust design and engineering solutions to ensure the technology's viability in diverse real-world applications.

Another critical challenge lies in the manufacturing process of QNED displays. The precise placement and alignment of nanoparticles in the display structure require highly sophisticated and controlled manufacturing techniques. Any inconsistencies in this process can result in non-uniform light emission, affecting the overall display quality. Moreover, scaling up these intricate manufacturing processes for mass production while maintaining consistent quality remains a significant technical challenge.

The integration of quantum dots with existing display technologies also presents difficulties. Ensuring compatibility between quantum dot materials and other components of the display, such as the backlight system and color filters, is crucial for optimal performance. This integration must be achieved without compromising the unique properties of quantum dots that make them advantageous for display applications.

Heat management is another substantial challenge in QNED technology. The high current densities required for bright displays can generate significant heat, which can accelerate the degradation of quantum dots and other display components. Developing effective heat dissipation mechanisms without increasing the overall thickness or weight of the display is a complex engineering problem.

Furthermore, the environmental impact and potential toxicity of some quantum dot materials raise concerns. Many high-performance quantum dots contain heavy metals like cadmium, which are subject to regulatory restrictions in various regions. Developing alternative, environmentally friendly quantum dot materials that maintain the same level of performance is an ongoing challenge for researchers and manufacturers.

Cost-effectiveness remains a significant hurdle in the widespread adoption of QNED technology. The materials and manufacturing processes associated with QNED displays are currently more expensive than those of conventional display technologies. Reducing these costs while maintaining or improving performance is crucial for QNED to compete in the broader display market.

Lastly, achieving consistent and reliable performance across different operating conditions is challenging. QNED displays must maintain their color accuracy, brightness, and overall quality under varying ambient light conditions, temperatures, and usage patterns. This requires robust design and engineering solutions to ensure the technology's viability in diverse real-world applications.

Current QNED Solutions

01 Protective layers for QNED durability

Implementing protective layers or encapsulation techniques can significantly enhance the durability of Quantum Nano Emitting Diodes. These layers shield the sensitive quantum structures from environmental factors such as moisture and oxygen, which can degrade performance over time. Advanced materials and deposition methods are used to create these protective barriers, improving the overall lifespan and stability of QNED devices.- Protective layers for QNED durability: Implementing protective layers in QNED structures can significantly enhance their durability. These layers, often composed of materials resistant to environmental factors, shield the sensitive quantum nano-emitting components from degradation. Such protective measures can include encapsulation techniques or the application of barrier films, which help to prevent moisture ingress and oxidation, thereby extending the operational lifespan of the device.

- Optimized quantum dot composition: Improving the durability of QNEDs involves optimizing the composition of quantum dots. This can include developing more stable core-shell structures, adjusting the size and shape of quantum dots, or incorporating new materials that enhance resistance to photo-oxidation and thermal degradation. These advancements in quantum dot composition contribute to increased stability and longevity of QNED devices under various operating conditions.

- Advanced manufacturing techniques: Employing advanced manufacturing techniques can significantly improve QNED durability. These may include precision deposition methods, controlled atmosphere processing, or novel patterning techniques that minimize defects and enhance structural integrity. Such manufacturing innovations can lead to more robust QNED structures with improved resistance to mechanical stress and environmental factors.

- Thermal management strategies: Effective thermal management is crucial for enhancing QNED durability. This involves designing heat dissipation mechanisms, implementing thermal interface materials, or developing novel device architectures that minimize heat accumulation. Proper thermal management helps prevent degradation of quantum dots and other components due to excessive heat, thereby extending the overall lifespan of QNED devices.

- Electrical stress mitigation: Mitigating electrical stress is essential for improving QNED durability. This can be achieved through the development of advanced driving schemes, implementation of current-limiting circuits, or the use of materials with enhanced electrical stability. These approaches help to reduce the impact of electrical stress on quantum dots and other device components, leading to improved long-term performance and reliability of QNED devices.

02 Optimized quantum dot composition

Developing quantum dots with optimized chemical compositions and structures can lead to improved durability in QNEDs. This involves engineering the core-shell structure of quantum dots, selecting appropriate materials, and fine-tuning the synthesis process to create more stable and resilient nanoparticles. These enhancements can result in quantum dots that are less susceptible to degradation from heat, light, and electrical stress.Expand Specific Solutions03 Thermal management strategies

Implementing effective thermal management strategies is crucial for maintaining QNED durability. This includes designing heat dissipation structures, using thermally conductive materials, and optimizing device architecture to minimize heat buildup. Proper thermal management helps prevent degradation of quantum dots and other components, thereby extending the operational lifetime of QNED devices.Expand Specific Solutions04 Advanced manufacturing techniques

Utilizing advanced manufacturing techniques can enhance the durability of QNEDs. This includes precision deposition methods, improved alignment processes, and novel patterning techniques that ensure better structural integrity and uniformity of the quantum dot layers. These manufacturing advancements lead to more robust devices with improved resistance to mechanical stress and environmental factors.Expand Specific Solutions05 Electrical stress mitigation

Developing strategies to mitigate electrical stress on QNEDs is essential for long-term durability. This involves optimizing driving circuits, implementing current-limiting mechanisms, and designing more efficient charge transport layers. By reducing electrical stress on the quantum dots and surrounding materials, these approaches help prevent premature degradation and extend the operational lifespan of QNED devices.Expand Specific Solutions

Key QNED Players

The research on QNED in high-durability display applications is in its early stages, with the market still developing. The technology's potential for long-lasting, high-performance displays has attracted significant interest, but market size remains limited. Companies like BOE Technology Group, Samsung Electronics, and LG Display are at the forefront, leveraging their expertise in display technologies. Sharp Corp. and Kateeva, Inc. are also making strides in QNED development. The technology's maturity is progressing, with universities like Zhejiang University and Southeast University contributing to fundamental research. While QNED shows promise, it's still evolving, with key players focusing on overcoming technical challenges to enhance durability and performance for widespread commercial adoption.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a QNED (Quantum Nano Emitting Diode) technology that combines quantum dot and mini-LED technologies. Their approach involves using a blue mini-LED backlight with red and green quantum dots to achieve high color gamut and brightness. BOE's QNED displays feature a high contrast ratio, wide color gamut, and improved energy efficiency. The company has implemented advanced quantum dot materials and precise light control algorithms to enhance the display's durability and longevity, making it suitable for high-durability applications such as outdoor signage, automotive displays, and industrial monitors.

Strengths: High brightness and contrast ratio, wide color gamut, improved energy efficiency. Weaknesses: Potential for color shift over time, higher production costs compared to traditional LCD technologies.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has been researching QNED technology as part of its next-generation display solutions. Their approach focuses on developing self-emissive quantum nano-emitting diodes, which combine the advantages of quantum dot and micro-LED technologies. Samsung's QNED displays aim to achieve ultra-high resolution, perfect black levels, and wide color gamut. The company has been working on improving the stability and lifespan of QNED materials to ensure high durability in various applications. Samsung's research includes developing specialized quantum dot materials and advanced manufacturing processes to enhance the overall performance and longevity of QNED displays.

Strengths: Potential for ultra-high resolution and perfect black levels, expertise in quantum dot technology. Weaknesses: Technology still in research phase, potential high production costs.

QNED Core Innovations

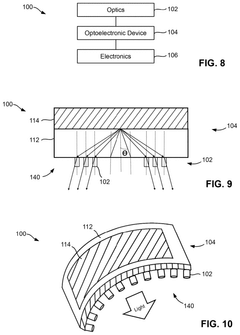

Integrated optoelectronic devices for lighting and display applications

PatentPendingUS20240341118A1

Innovation

- Incorporation of metasurfaces with two-dimensional arrays of nanostructures into the light-emitting devices to reduce photon reflection, control light direction, and manipulate emission profiles, combined with machine-learning methods for optimizing light patterns and using flexible substrates like hybrid silver nanowires and carbon nanotubes for improved conductivity and stability.

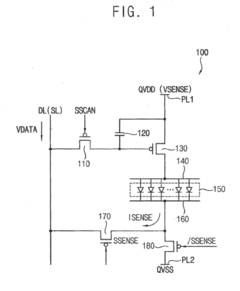

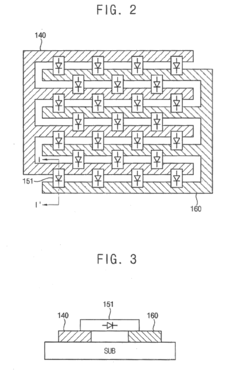

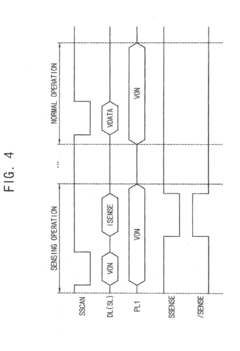

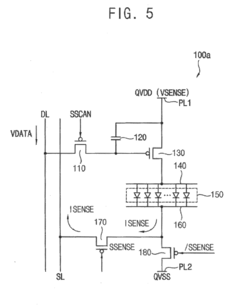

Quantum-nano light emitting diode pixel and quantum-nano light emitting diode display device

PatentActiveUS20190081261A1

Innovation

- A Q-NED pixel and display device design that includes a switching transistor, storage capacitor, driving transistor, and sensing transistors to sense and compensate for ohmic contact resistance deviations, utilizing inorganic materials like gallium nitride for the Q-NEDs, with anode and cathode electrodes having a comb shape to enhance light emission efficiency and maintain luminance over time.

QNED Manufacturing

The manufacturing process of QNED (Quantum Nano Emitting Diode) displays involves several complex steps that combine traditional LCD manufacturing techniques with advanced quantum dot and nanorod technologies. The process begins with the production of the LCD backplane, which serves as the foundation for the display. This backplane is typically manufactured using thin-film transistor (TFT) technology, similar to conventional LCD panels.

The next critical step is the preparation of the quantum dot and nanorod materials. These nanomaterials are synthesized through precise chemical processes, ensuring uniform size and composition. The quantum dots are responsible for producing blue light, while the nanorods emit red and green light. The synthesis of these materials requires strict control over temperature, pressure, and chemical composition to achieve the desired optical properties.

Once the nanomaterials are prepared, they are integrated into the display structure. This integration process involves depositing the quantum dots and nanorods onto a substrate, typically using advanced printing or coating techniques. The deposition must be highly uniform to ensure consistent color reproduction across the entire display area. A key challenge in this step is preventing agglomeration of the nanoparticles, which can lead to reduced efficiency and color accuracy.

Following the deposition of nanomaterials, the QNED panel undergoes a series of layering processes. These layers include color filters, polarizers, and protective films, each serving a specific function in the display's operation. The assembly of these layers requires precise alignment and bonding techniques to maintain the integrity of the nanoparticle layer and ensure optimal light transmission.

The final stages of QNED manufacturing involve the integration of the display panel with electronic components, such as drivers and control circuits. This integration process is similar to that of traditional LCD manufacturing but may require specialized handling to protect the sensitive nanoparticle layer. Quality control measures are implemented throughout the manufacturing process, with particular attention paid to color accuracy, brightness uniformity, and durability of the nanoparticle layer.

One of the key challenges in QNED manufacturing is scaling the production process while maintaining consistent quality. As the technology is relatively new, manufacturers are continually refining their processes to improve yield rates and reduce production costs. Additionally, ensuring the long-term stability of the quantum dot and nanorod materials under various operating conditions remains a focus area for ongoing research and development in QNED manufacturing.

The next critical step is the preparation of the quantum dot and nanorod materials. These nanomaterials are synthesized through precise chemical processes, ensuring uniform size and composition. The quantum dots are responsible for producing blue light, while the nanorods emit red and green light. The synthesis of these materials requires strict control over temperature, pressure, and chemical composition to achieve the desired optical properties.

Once the nanomaterials are prepared, they are integrated into the display structure. This integration process involves depositing the quantum dots and nanorods onto a substrate, typically using advanced printing or coating techniques. The deposition must be highly uniform to ensure consistent color reproduction across the entire display area. A key challenge in this step is preventing agglomeration of the nanoparticles, which can lead to reduced efficiency and color accuracy.

Following the deposition of nanomaterials, the QNED panel undergoes a series of layering processes. These layers include color filters, polarizers, and protective films, each serving a specific function in the display's operation. The assembly of these layers requires precise alignment and bonding techniques to maintain the integrity of the nanoparticle layer and ensure optimal light transmission.

The final stages of QNED manufacturing involve the integration of the display panel with electronic components, such as drivers and control circuits. This integration process is similar to that of traditional LCD manufacturing but may require specialized handling to protect the sensitive nanoparticle layer. Quality control measures are implemented throughout the manufacturing process, with particular attention paid to color accuracy, brightness uniformity, and durability of the nanoparticle layer.

One of the key challenges in QNED manufacturing is scaling the production process while maintaining consistent quality. As the technology is relatively new, manufacturers are continually refining their processes to improve yield rates and reduce production costs. Additionally, ensuring the long-term stability of the quantum dot and nanorod materials under various operating conditions remains a focus area for ongoing research and development in QNED manufacturing.

QNED Sustainability

QNED (Quantum Nano Emitting Diode) technology has shown promising potential in high-durability display applications, but its long-term sustainability remains a critical concern. The sustainability of QNED displays encompasses various aspects, including environmental impact, resource efficiency, and longevity of the technology.

One of the primary sustainability advantages of QNED displays is their potential for improved energy efficiency compared to traditional LED and OLED technologies. The quantum dot-based emitters in QNED displays can produce more vibrant colors with less power consumption, potentially reducing the overall energy footprint of display devices. This energy efficiency not only contributes to lower operational costs but also aligns with global efforts to reduce carbon emissions in consumer electronics.

The manufacturing process of QNED displays presents both challenges and opportunities for sustainability. While the production of quantum dots and nanoparticles used in QNED technology may require specialized materials and processes, ongoing research aims to develop more environmentally friendly synthesis methods. Efforts are being made to reduce the use of toxic materials and improve the recyclability of QNED components, which could significantly enhance the technology's overall sustainability profile.

Durability is a key factor in the sustainability of QNED displays. The inherent stability of inorganic quantum dots used in QNED technology suggests potential for longer-lasting displays compared to organic-based alternatives. This increased lifespan could lead to reduced electronic waste and less frequent need for device replacement, contributing to a more sustainable consumer electronics ecosystem.

However, the long-term environmental impact of QNED technology remains an area of ongoing research. As the technology is relatively new, comprehensive life cycle assessments are still being conducted to fully understand its environmental footprint from production to disposal. Researchers are particularly focused on developing efficient recycling methods for QNED displays to recover valuable materials and minimize waste.

The sustainability of QNED technology also extends to its potential for integration with other emerging technologies. For instance, the compatibility of QNED displays with flexible and transparent substrates opens up possibilities for innovative product designs that could promote more sustainable consumer behaviors and extended product lifecycles.

In conclusion, while QNED technology shows promise in terms of energy efficiency and durability, ongoing research and development efforts are crucial to fully realize its sustainability potential. As the technology matures, it will be essential to continue addressing environmental concerns and optimizing the entire lifecycle of QNED displays to ensure their long-term viability in the sustainable electronics landscape.

One of the primary sustainability advantages of QNED displays is their potential for improved energy efficiency compared to traditional LED and OLED technologies. The quantum dot-based emitters in QNED displays can produce more vibrant colors with less power consumption, potentially reducing the overall energy footprint of display devices. This energy efficiency not only contributes to lower operational costs but also aligns with global efforts to reduce carbon emissions in consumer electronics.

The manufacturing process of QNED displays presents both challenges and opportunities for sustainability. While the production of quantum dots and nanoparticles used in QNED technology may require specialized materials and processes, ongoing research aims to develop more environmentally friendly synthesis methods. Efforts are being made to reduce the use of toxic materials and improve the recyclability of QNED components, which could significantly enhance the technology's overall sustainability profile.

Durability is a key factor in the sustainability of QNED displays. The inherent stability of inorganic quantum dots used in QNED technology suggests potential for longer-lasting displays compared to organic-based alternatives. This increased lifespan could lead to reduced electronic waste and less frequent need for device replacement, contributing to a more sustainable consumer electronics ecosystem.

However, the long-term environmental impact of QNED technology remains an area of ongoing research. As the technology is relatively new, comprehensive life cycle assessments are still being conducted to fully understand its environmental footprint from production to disposal. Researchers are particularly focused on developing efficient recycling methods for QNED displays to recover valuable materials and minimize waste.

The sustainability of QNED technology also extends to its potential for integration with other emerging technologies. For instance, the compatibility of QNED displays with flexible and transparent substrates opens up possibilities for innovative product designs that could promote more sustainable consumer behaviors and extended product lifecycles.

In conclusion, while QNED technology shows promise in terms of energy efficiency and durability, ongoing research and development efforts are crucial to fully realize its sustainability potential. As the technology matures, it will be essential to continue addressing environmental concerns and optimizing the entire lifecycle of QNED displays to ensure their long-term viability in the sustainable electronics landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!