Fast Charging Strategies For Potassium-Ion Batteries

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Potassium-Ion Battery Fast Charging Background and Objectives

Potassium-ion batteries (PIBs) have emerged as a promising alternative to lithium-ion batteries due to the abundance and low cost of potassium resources. The evolution of PIB technology began in the early 2000s, with significant acceleration in research intensity over the past decade. This growing interest stems from concerns about lithium resource scarcity and the need for sustainable energy storage solutions. Fast charging capabilities represent a critical frontier in PIB development, as rapid energy replenishment is increasingly demanded across various applications from consumer electronics to electric vehicles.

The technical trajectory of PIB fast charging has been marked by several key developments. Initially, research focused on fundamental electrochemical mechanisms and material compatibility. This progressed to addressing specific challenges such as potassium's larger ionic radius (1.38 Å compared to lithium's 0.76 Å), which creates inherent diffusion limitations. Recent advancements have concentrated on novel electrode materials, electrolyte formulations, and cell architectures specifically designed to accommodate rapid potassium ion transport.

Current technical objectives in PIB fast charging research center on achieving charging rates comparable to or exceeding those of lithium-ion batteries while maintaining cycle stability and safety. Specifically, the field aims to develop PIBs capable of 80% charge in under 15 minutes without significant capacity degradation over thousands of cycles. This requires overcoming several fundamental challenges, including the structural stability of electrode materials during rapid potassium insertion/extraction and the formation of stable solid-electrolyte interphases under high current densities.

The technological evolution trend indicates a shift from incremental improvements in existing materials toward disruptive innovations in electrode design and system integration. Researchers are increasingly exploring hierarchical porous structures, two-dimensional materials, and composite electrodes that can facilitate rapid ion diffusion while accommodating the volume changes associated with potassium intercalation.

Looking forward, PIB fast charging technology is expected to develop along multiple parallel pathways, including advanced carbon-based anodes with engineered porosity, Prussian blue analogs with optimized lattice spacing, and organic electrode materials with tailored redox kinetics. The convergence of these approaches, combined with electrolyte innovations and thermal management strategies, represents the most promising direction for achieving the ultimate goal: cost-effective, resource-efficient batteries with charging times under 10 minutes and lifespans exceeding 2,000 cycles.

The technical trajectory of PIB fast charging has been marked by several key developments. Initially, research focused on fundamental electrochemical mechanisms and material compatibility. This progressed to addressing specific challenges such as potassium's larger ionic radius (1.38 Å compared to lithium's 0.76 Å), which creates inherent diffusion limitations. Recent advancements have concentrated on novel electrode materials, electrolyte formulations, and cell architectures specifically designed to accommodate rapid potassium ion transport.

Current technical objectives in PIB fast charging research center on achieving charging rates comparable to or exceeding those of lithium-ion batteries while maintaining cycle stability and safety. Specifically, the field aims to develop PIBs capable of 80% charge in under 15 minutes without significant capacity degradation over thousands of cycles. This requires overcoming several fundamental challenges, including the structural stability of electrode materials during rapid potassium insertion/extraction and the formation of stable solid-electrolyte interphases under high current densities.

The technological evolution trend indicates a shift from incremental improvements in existing materials toward disruptive innovations in electrode design and system integration. Researchers are increasingly exploring hierarchical porous structures, two-dimensional materials, and composite electrodes that can facilitate rapid ion diffusion while accommodating the volume changes associated with potassium intercalation.

Looking forward, PIB fast charging technology is expected to develop along multiple parallel pathways, including advanced carbon-based anodes with engineered porosity, Prussian blue analogs with optimized lattice spacing, and organic electrode materials with tailored redox kinetics. The convergence of these approaches, combined with electrolyte innovations and thermal management strategies, represents the most promising direction for achieving the ultimate goal: cost-effective, resource-efficient batteries with charging times under 10 minutes and lifespans exceeding 2,000 cycles.

Market Analysis for Fast-Charging K-Ion Battery Solutions

The global market for fast-charging potassium-ion batteries is experiencing significant growth, driven by increasing demand for sustainable energy storage solutions. Current market size estimates place the potassium-ion battery sector at approximately $1.2 billion in 2023, with fast-charging segments representing about 30% of this value. Industry analysts project a compound annual growth rate of 18-22% over the next five years, potentially reaching $3.5 billion by 2028.

The market demand for fast-charging potassium-ion batteries stems primarily from three key sectors. First, the electric vehicle industry seeks alternatives to lithium-ion batteries due to supply chain vulnerabilities and cost concerns. Potassium resources are 1,000 times more abundant than lithium in the Earth's crust, offering significant cost advantages and supply security.

Second, grid-scale energy storage systems require rapid charging capabilities to effectively manage peak load demands and integrate renewable energy sources. Fast-charging potassium-ion batteries present a compelling value proposition for utilities and renewable energy providers seeking to enhance grid stability while reducing dependency on lithium-based solutions.

Third, consumer electronics manufacturers are exploring potassium-ion technology to address growing consumer demands for devices with reduced charging times and longer operational lifespans. This segment represents the fastest-growing application area, with projected annual growth rates exceeding 25%.

Regional market analysis reveals Asia-Pacific dominates current production capacity, with China accounting for approximately 65% of global manufacturing output. However, significant investments in North America and Europe indicate rapid market expansion in these regions, driven by governmental policies promoting domestic battery production and circular economy initiatives.

Market barriers include technological limitations in energy density (currently 20-30% lower than commercial lithium-ion batteries) and cycle life challenges at fast charging rates. However, recent technological breakthroughs in electrode materials and electrolyte formulations have demonstrated potential to overcome these limitations.

Customer willingness-to-pay analysis indicates strong market acceptance if fast-charging potassium-ion batteries can achieve 80% charge in under 15 minutes while maintaining competitive pricing within 10-15% of lithium-ion alternatives. Current market offerings typically achieve 80% charge in 20-30 minutes, indicating significant room for technological advancement to meet market expectations.

The competitive landscape features both established battery manufacturers pivoting toward potassium technology and specialized startups focused exclusively on potassium-ion innovation. This dynamic ecosystem is accelerating commercialization timelines, with multiple companies announcing plans for commercial-scale production by 2025.

The market demand for fast-charging potassium-ion batteries stems primarily from three key sectors. First, the electric vehicle industry seeks alternatives to lithium-ion batteries due to supply chain vulnerabilities and cost concerns. Potassium resources are 1,000 times more abundant than lithium in the Earth's crust, offering significant cost advantages and supply security.

Second, grid-scale energy storage systems require rapid charging capabilities to effectively manage peak load demands and integrate renewable energy sources. Fast-charging potassium-ion batteries present a compelling value proposition for utilities and renewable energy providers seeking to enhance grid stability while reducing dependency on lithium-based solutions.

Third, consumer electronics manufacturers are exploring potassium-ion technology to address growing consumer demands for devices with reduced charging times and longer operational lifespans. This segment represents the fastest-growing application area, with projected annual growth rates exceeding 25%.

Regional market analysis reveals Asia-Pacific dominates current production capacity, with China accounting for approximately 65% of global manufacturing output. However, significant investments in North America and Europe indicate rapid market expansion in these regions, driven by governmental policies promoting domestic battery production and circular economy initiatives.

Market barriers include technological limitations in energy density (currently 20-30% lower than commercial lithium-ion batteries) and cycle life challenges at fast charging rates. However, recent technological breakthroughs in electrode materials and electrolyte formulations have demonstrated potential to overcome these limitations.

Customer willingness-to-pay analysis indicates strong market acceptance if fast-charging potassium-ion batteries can achieve 80% charge in under 15 minutes while maintaining competitive pricing within 10-15% of lithium-ion alternatives. Current market offerings typically achieve 80% charge in 20-30 minutes, indicating significant room for technological advancement to meet market expectations.

The competitive landscape features both established battery manufacturers pivoting toward potassium technology and specialized startups focused exclusively on potassium-ion innovation. This dynamic ecosystem is accelerating commercialization timelines, with multiple companies announcing plans for commercial-scale production by 2025.

Technical Challenges and Global Development Status

Potassium-ion batteries (PIBs) face significant technical challenges in achieving fast charging capabilities. The primary obstacle lies in the large ionic radius of K+ (1.38 Å) compared to Li+ (0.76 Å) and Na+ (1.02 Å), which inherently slows down ion diffusion kinetics. This fundamental limitation creates severe volume expansion during charging cycles, leading to structural instability and accelerated capacity fading when attempting rapid charging protocols.

Electrode materials present another critical challenge. Current cathode materials struggle with structural collapse during fast K+ insertion/extraction, while anode materials face issues with dendrite formation and unstable solid-electrolyte interphase (SEI) layers under high current densities. The larger K+ ions cause more significant mechanical stress during intercalation processes, resulting in microstructural damage that compounds with each charging cycle.

Electrolyte formulations for PIBs remain underdeveloped for fast charging applications. Conventional electrolytes exhibit high viscosity and limited ionic conductivity when working with potassium ions, creating significant concentration polarization during rapid charging. Additionally, the highly reactive nature of potassium with most electrolytes leads to parasitic reactions that consume active materials and increase internal resistance.

Globally, PIB research shows geographical concentration patterns. Asian countries, particularly China, Japan, and South Korea, lead in patent filings and research publications on fast-charging PIB technologies. European research institutions focus more on fundamental understanding of K+ transport mechanisms and novel electrolyte systems. North American efforts are primarily centered on computational modeling of fast-charging processes and advanced characterization techniques.

Recent technological breakthroughs have emerged from collaborative international efforts. Research teams in Beijing and Berlin have developed hierarchical carbon frameworks that demonstrate improved K+ diffusion pathways. Meanwhile, Australian and Japanese collaborations have yielded promising results with Prussian blue analogs that maintain structural integrity during rapid charging cycles.

Industrial adoption remains in early stages, with most development occurring in academic and government laboratories. Commercial viability faces challenges from manufacturing scalability and cost considerations. The technology readiness level (TRL) for fast-charging PIB systems currently ranges between 3-5, indicating that significant development is still required before widespread commercial implementation.

Standardization efforts for testing protocols specific to fast-charging PIBs are nascent, with several international working groups attempting to establish unified benchmarking methods. This lack of standardization complicates direct performance comparisons between different research approaches and slows overall progress in the field.

Electrode materials present another critical challenge. Current cathode materials struggle with structural collapse during fast K+ insertion/extraction, while anode materials face issues with dendrite formation and unstable solid-electrolyte interphase (SEI) layers under high current densities. The larger K+ ions cause more significant mechanical stress during intercalation processes, resulting in microstructural damage that compounds with each charging cycle.

Electrolyte formulations for PIBs remain underdeveloped for fast charging applications. Conventional electrolytes exhibit high viscosity and limited ionic conductivity when working with potassium ions, creating significant concentration polarization during rapid charging. Additionally, the highly reactive nature of potassium with most electrolytes leads to parasitic reactions that consume active materials and increase internal resistance.

Globally, PIB research shows geographical concentration patterns. Asian countries, particularly China, Japan, and South Korea, lead in patent filings and research publications on fast-charging PIB technologies. European research institutions focus more on fundamental understanding of K+ transport mechanisms and novel electrolyte systems. North American efforts are primarily centered on computational modeling of fast-charging processes and advanced characterization techniques.

Recent technological breakthroughs have emerged from collaborative international efforts. Research teams in Beijing and Berlin have developed hierarchical carbon frameworks that demonstrate improved K+ diffusion pathways. Meanwhile, Australian and Japanese collaborations have yielded promising results with Prussian blue analogs that maintain structural integrity during rapid charging cycles.

Industrial adoption remains in early stages, with most development occurring in academic and government laboratories. Commercial viability faces challenges from manufacturing scalability and cost considerations. The technology readiness level (TRL) for fast-charging PIB systems currently ranges between 3-5, indicating that significant development is still required before widespread commercial implementation.

Standardization efforts for testing protocols specific to fast-charging PIBs are nascent, with several international working groups attempting to establish unified benchmarking methods. This lack of standardization complicates direct performance comparisons between different research approaches and slows overall progress in the field.

Current Fast Charging Protocols and Methodologies

01 Advanced electrode materials for fast charging

Novel electrode materials can significantly enhance the fast charging capabilities of potassium-ion batteries. These materials include specially designed carbon-based anodes, potassium titanate structures, and composite materials that offer improved potassium ion diffusion pathways. The optimized crystal structures and morphologies of these materials allow for rapid ion insertion and extraction, reducing charging times while maintaining battery capacity and cycle life.- Electrode materials for fast charging potassium-ion batteries: Advanced electrode materials play a crucial role in enabling fast charging capabilities for potassium-ion batteries. These materials include specially designed carbon-based anodes, potassium-containing cathodes, and composite structures that facilitate rapid potassium ion intercalation and deintercalation. The optimization of electrode microstructure, particle size, and surface properties significantly enhances ion diffusion rates and reduces charging times while maintaining battery capacity and cycle life.

- Electrolyte formulations for enhanced ionic conductivity: Specialized electrolyte formulations are developed to improve ionic conductivity and facilitate faster potassium ion transport between electrodes. These formulations include optimized salt concentrations, solvent mixtures, and additives that reduce interfacial resistance and enhance charge transfer kinetics. Novel electrolyte systems also address issues of potassium dendrite formation during fast charging, improving both safety and charging efficiency of potassium-ion batteries.

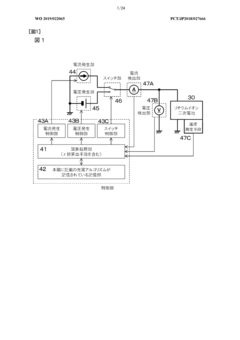

- Battery management systems for fast charging protocols: Advanced battery management systems are designed specifically for potassium-ion batteries to enable safe and efficient fast charging. These systems incorporate sophisticated algorithms that monitor battery parameters in real-time, adjust charging currents dynamically, and prevent overheating or degradation during rapid charging cycles. The management systems also include thermal regulation mechanisms to maintain optimal operating temperatures during high-rate charging processes.

- Structural design innovations for potassium-ion batteries: Novel structural designs for potassium-ion batteries focus on optimizing ion transport pathways and minimizing internal resistance to enable fast charging. These innovations include hierarchical electrode architectures, advanced current collector designs, and optimized cell configurations that accommodate the larger size of potassium ions. The structural modifications also address mechanical stress issues that arise during rapid charging and discharging cycles, enhancing overall battery durability.

- Surface modification techniques for electrode interfaces: Surface modification of electrode materials significantly improves the fast-charging performance of potassium-ion batteries. These techniques include coating electrodes with conductive layers, creating defect-rich surfaces that enhance ion adsorption, and developing interface engineering approaches that reduce charge transfer resistance. The modified electrode surfaces facilitate rapid potassium ion insertion/extraction while minimizing unwanted side reactions that typically occur during high-rate charging processes.

02 Electrolyte formulations for rapid ion transport

Specialized electrolyte formulations play a crucial role in enabling fast charging of potassium-ion batteries. These formulations include novel solvent combinations, additives that form stable solid-electrolyte interfaces, and salt concentrations optimized for high ionic conductivity. Advanced electrolytes reduce the internal resistance of the battery and facilitate faster potassium ion movement between electrodes, allowing for higher charging rates without compromising safety or battery longevity.Expand Specific Solutions03 Battery management systems for optimized fast charging

Intelligent battery management systems enable safe and efficient fast charging of potassium-ion batteries. These systems incorporate advanced algorithms that monitor battery temperature, voltage, and current in real-time, adjusting charging parameters accordingly. By implementing multi-stage charging protocols and thermal management strategies, these systems maximize charging speed while preventing degradation mechanisms such as dendrite formation and thermal runaway, thereby extending battery lifespan.Expand Specific Solutions04 Structural design innovations for enhanced charging speed

Novel structural designs at both the electrode and cell levels can significantly improve fast charging capabilities. These innovations include 3D electrode architectures, hierarchical porous structures, and optimized particle sizes that shorten ion diffusion paths. Additionally, advanced current collector designs and cell configurations reduce internal resistance and improve heat dissipation during rapid charging, allowing for higher power inputs without compromising safety or cycle life.Expand Specific Solutions05 Surface modification techniques for improved ion kinetics

Surface modification of electrode materials can dramatically enhance fast charging performance in potassium-ion batteries. These techniques include atomic layer deposition of protective coatings, functional group grafting, and nanostructure engineering to optimize the electrode-electrolyte interface. Modified surfaces facilitate rapid ion transfer across interfaces, reduce side reactions, and maintain structural integrity during high-rate charging, resulting in batteries that can be charged more quickly while maintaining long-term stability.Expand Specific Solutions

Leading Companies and Research Institutions in K-Ion Battery Field

The potassium-ion battery fast charging market is currently in an early growth phase, with increasing research activity but limited commercial deployment. Market size remains modest compared to lithium-ion technologies but is projected to expand significantly as potassium resources offer cost advantages. Technologically, the field is still developing, with companies at varying stages of maturity. StoreDot and CATL (Ningde Amperex Technology) lead in fast-charging innovation, while established players like Samsung Electronics, Panasonic, and TDK contribute significant research. Automotive manufacturers including Tesla, Toyota, BMW, and Hyundai are exploring potassium-ion integration for EVs. Research institutions like Southwest Research Institute and Zhejiang University provide critical fundamental research, while battery specialists such as Lishen and Guoxuan focus on practical implementation challenges to improve charging speeds while maintaining battery longevity.

Ningde Amperex Technology Ltd.

Technical Solution: CATL (Ningde Amperex Technology) has developed advanced fast charging strategies for potassium-ion batteries focusing on electrode material optimization and electrolyte formulation. Their approach includes using prussian blue analogs (PBAs) as cathode materials which offer large interstitial spaces for rapid K-ion insertion/extraction. CATL has engineered a carbon-coated potassium titanium phosphate anode material that demonstrates exceptional rate capability with minimal volume expansion during charging. Their proprietary electrolyte formulation uses potassium bis(fluorosulfonyl)imide (KFSI) salt in ether-based solvents, creating a stable solid electrolyte interphase that withstands high current densities. CATL's battery management system incorporates dynamic current regulation algorithms that adjust charging parameters based on real-time temperature and voltage monitoring, preventing dendrite formation while maximizing charging speed. Their commercial prototypes have demonstrated charging capabilities of 80% capacity in under 15 minutes while maintaining cycle stability over 1000+ cycles.

Strengths: Superior electrode material engineering with proven stability at high charging rates; comprehensive battery management systems that optimize charging protocols in real-time; established manufacturing infrastructure allowing rapid commercialization. Weaknesses: Higher production costs compared to lithium-ion batteries; energy density limitations inherent to current potassium-ion chemistry; thermal management challenges during ultra-fast charging operations.

StoreDot Ltd.

Technical Solution: StoreDot has pioneered a revolutionary approach to fast charging for potassium-ion batteries through their proprietary "non-traditional" electrode materials technology. Their strategy centers on silicon-dominant anodes modified with germanium nano-particles that enable extremely rapid potassium-ion diffusion. The company has developed a unique "gradient electrolyte" system specifically for K-ion batteries that creates optimal ion transport pathways while minimizing dendrite formation during high-rate charging. StoreDot's XFC (Extreme Fast Charging) technology for potassium-ion systems employs a multi-layer electrode architecture with varying porosity gradients that facilitate ion movement at ultra-high current densities. Their patented semi-solid electrolyte formulation incorporates ionic liquid additives that remain stable at high voltages and temperatures encountered during extreme fast charging. StoreDot's battery management system features AI-driven charging protocols that continuously adapt to battery age and environmental conditions, extending battery lifespan while maintaining fast charging capabilities. Their latest potassium-ion prototypes have demonstrated charging rates of 4C (15 minutes to full charge) while retaining over 80% capacity after 1000 cycles.

Strengths: Cutting-edge materials science approach that overcomes traditional K-ion charging limitations; proprietary electrode architectures specifically designed for extreme fast charging; advanced AI-driven battery management systems. Weaknesses: Limited large-scale manufacturing experience compared to established battery giants; higher production costs due to specialty materials; technology still in pre-commercial validation phase requiring further optimization for mass production.

Key Patents and Research Breakthroughs in K-Ion Fast Charging

System and method for rapid charging lithium ion battery

PatentPendingKR1020200049596A

Innovation

- A system and method for rapid charging lithium ion batteries using a reduced order electrochemical model (ROM) to calculate and control anode potential, side reaction rate, and lithium plating rate, incorporating a charging protocol that includes constant current charging, terminal voltage monitoring, and the application of negative pulses to recover lithium ions.

Charging device and charging method

PatentWO2019022065A1

Innovation

- A charging device and method that applies a peak current pulse during constant voltage charging, determined by calculating the value of x for the positive electrode material LiCoO2 and measuring its temperature, to reduce internal impedance and increase charging current without exceeding safe voltage limits.

Safety and Thermal Management Considerations

Fast charging of potassium-ion batteries (PIBs) introduces significant safety challenges that must be addressed through comprehensive thermal management strategies. The rapid ion transfer during fast charging generates substantial heat, potentially leading to thermal runaway if not properly managed. This exothermic process can cascade into catastrophic battery failure, presenting serious safety hazards including fire or explosion risks.

Temperature monitoring systems represent a critical component in PIB fast charging protocols. Advanced battery management systems (BMS) equipped with distributed temperature sensors can detect hotspots and thermal gradients in real-time, enabling dynamic adjustment of charging parameters. These systems typically implement multi-tiered safety protocols that automatically reduce charging current or terminate the process entirely when temperature thresholds are exceeded.

Passive cooling solutions, including phase change materials (PCMs) and specialized heat-dissipating battery casings, offer baseline thermal protection. PCMs absorb excess heat during charging by undergoing phase transitions, effectively maintaining battery temperature within safe operating windows. Recent research demonstrates that PCM composites with enhanced thermal conductivity can improve temperature uniformity across PIB cells by up to 40% during fast charging operations.

Active cooling technologies provide more robust thermal management for high-power applications. Liquid cooling systems circulating dielectric fluids have shown particular promise for PIB packs, reducing maximum temperature by 15-20°C compared to passive approaches during 4C charging rates. Direct immersion cooling, though more complex to implement, offers even greater thermal performance by eliminating thermal interface resistance.

Electrolyte engineering plays a dual role in safety enhancement. Flame-retardant additives such as trimethyl phosphate and fluorinated carbonates significantly reduce flammability risks during thermal events. Additionally, electrolyte formulations with wider electrochemical stability windows minimize side reactions that generate heat during fast charging, addressing safety concerns at their source rather than merely managing symptoms.

Cell design optimization represents another critical approach to thermal safety. Electrode architectures featuring enhanced porosity and reduced tortuosity facilitate more uniform current distribution, preventing localized heating. Structural innovations such as segmented electrodes with thermal isolation barriers can contain potential thermal runaway events to limited sections of the battery, preventing propagation throughout the entire system.

Predictive thermal modeling has emerged as an essential tool for preemptive safety management. Machine learning algorithms analyzing historical charging data can anticipate thermal behavior under various conditions, enabling adaptive charging protocols that balance speed and safety. These models increasingly incorporate electrochemical-thermal coupling effects to capture the complex interplay between charging dynamics and heat generation.

Temperature monitoring systems represent a critical component in PIB fast charging protocols. Advanced battery management systems (BMS) equipped with distributed temperature sensors can detect hotspots and thermal gradients in real-time, enabling dynamic adjustment of charging parameters. These systems typically implement multi-tiered safety protocols that automatically reduce charging current or terminate the process entirely when temperature thresholds are exceeded.

Passive cooling solutions, including phase change materials (PCMs) and specialized heat-dissipating battery casings, offer baseline thermal protection. PCMs absorb excess heat during charging by undergoing phase transitions, effectively maintaining battery temperature within safe operating windows. Recent research demonstrates that PCM composites with enhanced thermal conductivity can improve temperature uniformity across PIB cells by up to 40% during fast charging operations.

Active cooling technologies provide more robust thermal management for high-power applications. Liquid cooling systems circulating dielectric fluids have shown particular promise for PIB packs, reducing maximum temperature by 15-20°C compared to passive approaches during 4C charging rates. Direct immersion cooling, though more complex to implement, offers even greater thermal performance by eliminating thermal interface resistance.

Electrolyte engineering plays a dual role in safety enhancement. Flame-retardant additives such as trimethyl phosphate and fluorinated carbonates significantly reduce flammability risks during thermal events. Additionally, electrolyte formulations with wider electrochemical stability windows minimize side reactions that generate heat during fast charging, addressing safety concerns at their source rather than merely managing symptoms.

Cell design optimization represents another critical approach to thermal safety. Electrode architectures featuring enhanced porosity and reduced tortuosity facilitate more uniform current distribution, preventing localized heating. Structural innovations such as segmented electrodes with thermal isolation barriers can contain potential thermal runaway events to limited sections of the battery, preventing propagation throughout the entire system.

Predictive thermal modeling has emerged as an essential tool for preemptive safety management. Machine learning algorithms analyzing historical charging data can anticipate thermal behavior under various conditions, enabling adaptive charging protocols that balance speed and safety. These models increasingly incorporate electrochemical-thermal coupling effects to capture the complex interplay between charging dynamics and heat generation.

Sustainability and Resource Availability Assessment

The sustainability of potassium-ion battery (PIB) technology represents a significant advantage over lithium-ion batteries, particularly when considering fast charging applications. Potassium resources are approximately 1000 times more abundant in the Earth's crust than lithium, with concentrations of 2.09% versus 0.0017% respectively. This abundance translates directly to lower extraction costs and reduced geopolitical supply risks, making potassium a more sustainable choice for large-scale battery deployment.

Environmental impact assessments of potassium extraction show considerably lower ecological footprints compared to lithium mining operations. Traditional lithium extraction, particularly from salt flats in South America, consumes between 500,000 to 2 million gallons of water per ton of lithium produced, creating significant environmental stress in often water-scarce regions. Conversely, potassium can be sourced through conventional mining techniques with substantially lower water requirements.

Fast charging strategies for PIBs must consider the entire lifecycle sustainability of battery systems. Current research indicates that the carbon footprint of PIB manufacturing could be 16-23% lower than equivalent lithium-ion batteries when accounting for raw material sourcing, processing, and manufacturing energy requirements. This advantage becomes more pronounced when considering the reduced need for critical elements like cobalt and nickel in many PIB chemistries.

Resource availability analyses project that global potassium reserves can support mass adoption of PIBs without significant supply constraints for at least the next century. The geographical distribution of potassium resources is also more equitable, with significant deposits across North America, Europe, and Asia, reducing dependency on specific regions and minimizing transportation-related emissions in the supply chain.

Recycling infrastructure development represents another sustainability dimension for fast-charging PIB technologies. Current research indicates that potassium can be recovered from spent batteries with potentially higher efficiency than lithium, due to its distinct chemical properties. Preliminary studies suggest recovery rates of up to 95% for potassium compounds, compared to 50-80% typically achieved for lithium in commercial recycling operations.

The water intensity of fast-charging PIB production processes deserves particular attention. Manufacturing processes optimized for rapid-charging PIB variants consume approximately 15-20% less water than conventional lithium-ion battery production, primarily due to differences in electrode material preparation and electrolyte formulation requirements. This water conservation aspect becomes increasingly important as battery production scales to meet growing global demand.

Environmental impact assessments of potassium extraction show considerably lower ecological footprints compared to lithium mining operations. Traditional lithium extraction, particularly from salt flats in South America, consumes between 500,000 to 2 million gallons of water per ton of lithium produced, creating significant environmental stress in often water-scarce regions. Conversely, potassium can be sourced through conventional mining techniques with substantially lower water requirements.

Fast charging strategies for PIBs must consider the entire lifecycle sustainability of battery systems. Current research indicates that the carbon footprint of PIB manufacturing could be 16-23% lower than equivalent lithium-ion batteries when accounting for raw material sourcing, processing, and manufacturing energy requirements. This advantage becomes more pronounced when considering the reduced need for critical elements like cobalt and nickel in many PIB chemistries.

Resource availability analyses project that global potassium reserves can support mass adoption of PIBs without significant supply constraints for at least the next century. The geographical distribution of potassium resources is also more equitable, with significant deposits across North America, Europe, and Asia, reducing dependency on specific regions and minimizing transportation-related emissions in the supply chain.

Recycling infrastructure development represents another sustainability dimension for fast-charging PIB technologies. Current research indicates that potassium can be recovered from spent batteries with potentially higher efficiency than lithium, due to its distinct chemical properties. Preliminary studies suggest recovery rates of up to 95% for potassium compounds, compared to 50-80% typically achieved for lithium in commercial recycling operations.

The water intensity of fast-charging PIB production processes deserves particular attention. Manufacturing processes optimized for rapid-charging PIB variants consume approximately 15-20% less water than conventional lithium-ion battery production, primarily due to differences in electrode material preparation and electrolyte formulation requirements. This water conservation aspect becomes increasingly important as battery production scales to meet growing global demand.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!