Potassium-Ion Battery Pack Design For Stationary Storage

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Potassium-Ion Battery Technology Evolution and Objectives

Potassium-ion battery technology has emerged as a promising alternative to lithium-ion batteries for stationary energy storage applications. The evolution of this technology can be traced back to the early 2010s when researchers began exploring potassium as an electrochemical energy storage medium due to the abundance and wide distribution of potassium resources compared to lithium. This exploration was driven by concerns about the long-term sustainability and cost of lithium-ion batteries, particularly for large-scale stationary storage applications.

The initial research phase focused primarily on fundamental electrochemistry and material science aspects, with significant breakthroughs occurring around 2015-2017 when viable cathode and anode materials were developed that could accommodate the larger potassium ions. These developments laid the groundwork for the first generation of potassium-ion cells with practical energy densities and cycle life.

By 2018-2020, the technology progressed from laboratory-scale demonstrations to small prototype cells, with energy densities approaching 100-120 Wh/kg. This period saw intensive research into electrolyte formulations and electrode architectures specifically designed to address the challenges posed by potassium's larger ionic radius and different electrochemical properties compared to lithium.

The current technological trajectory is focused on scaling up from cells to modules and full battery packs, with particular emphasis on thermal management systems and battery management systems (BMS) tailored to the unique characteristics of potassium-ion chemistry. Recent advancements have improved cycle stability, with some research cells demonstrating over 1,000 cycles at 80% capacity retention.

The primary objectives for potassium-ion battery pack design for stationary storage include achieving cost parity with or advantages over lithium-ion systems, with targets of below $100/kWh at the pack level. Additionally, researchers aim to develop systems with calendar life exceeding 15 years and cycle life of at least 5,000 cycles at 80% depth of discharge, which would make them competitive for grid-scale applications.

Another key objective is to design battery packs with enhanced safety profiles, leveraging potassium-ion's potentially lower thermal runaway risk compared to some lithium-ion chemistries. This includes developing passive and active safety systems specifically optimized for the thermal and electrical characteristics of potassium-ion cells.

The technology roadmap also prioritizes sustainability objectives, including designs that facilitate end-of-life recycling and recovery of materials, as well as manufacturing processes with reduced environmental footprints compared to existing battery technologies. These objectives align with the growing emphasis on circular economy principles in energy storage development.

The initial research phase focused primarily on fundamental electrochemistry and material science aspects, with significant breakthroughs occurring around 2015-2017 when viable cathode and anode materials were developed that could accommodate the larger potassium ions. These developments laid the groundwork for the first generation of potassium-ion cells with practical energy densities and cycle life.

By 2018-2020, the technology progressed from laboratory-scale demonstrations to small prototype cells, with energy densities approaching 100-120 Wh/kg. This period saw intensive research into electrolyte formulations and electrode architectures specifically designed to address the challenges posed by potassium's larger ionic radius and different electrochemical properties compared to lithium.

The current technological trajectory is focused on scaling up from cells to modules and full battery packs, with particular emphasis on thermal management systems and battery management systems (BMS) tailored to the unique characteristics of potassium-ion chemistry. Recent advancements have improved cycle stability, with some research cells demonstrating over 1,000 cycles at 80% capacity retention.

The primary objectives for potassium-ion battery pack design for stationary storage include achieving cost parity with or advantages over lithium-ion systems, with targets of below $100/kWh at the pack level. Additionally, researchers aim to develop systems with calendar life exceeding 15 years and cycle life of at least 5,000 cycles at 80% depth of discharge, which would make them competitive for grid-scale applications.

Another key objective is to design battery packs with enhanced safety profiles, leveraging potassium-ion's potentially lower thermal runaway risk compared to some lithium-ion chemistries. This includes developing passive and active safety systems specifically optimized for the thermal and electrical characteristics of potassium-ion cells.

The technology roadmap also prioritizes sustainability objectives, including designs that facilitate end-of-life recycling and recovery of materials, as well as manufacturing processes with reduced environmental footprints compared to existing battery technologies. These objectives align with the growing emphasis on circular economy principles in energy storage development.

Market Analysis for Stationary Energy Storage Solutions

The global stationary energy storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources and the need for grid stability. As of 2023, the market valuation stands at approximately $27 billion, with projections indicating a compound annual growth rate of 18-20% through 2030. This rapid expansion creates a fertile environment for innovative technologies like potassium-ion battery systems to establish market presence.

Lithium-ion batteries currently dominate the stationary storage sector, accounting for roughly 85% of new installations. However, supply chain vulnerabilities and raw material constraints are creating significant market gaps. Potassium, being the seventh most abundant element in the Earth's crust (2.1% versus lithium's 0.006%), presents a compelling alternative with substantially lower resource acquisition costs and reduced geopolitical supply risks.

Market segmentation reveals distinct opportunities for potassium-ion batteries. The utility-scale segment, valued at $12 billion, shows the highest growth potential with increasing demand for grid-level storage solutions exceeding 4-hour duration. Commercial and industrial applications represent a $9 billion segment where cost-effectiveness often outweighs energy density considerations, creating an ideal entry point for potassium-ion technology.

Regional analysis indicates Asia-Pacific leads deployment with 45% market share, followed by North America (28%) and Europe (20%). Notably, emerging markets in Africa and South America are showing accelerated adoption rates of 25-30% annually, often bypassing traditional infrastructure limitations through distributed storage solutions.

Customer demand patterns reveal increasing emphasis on total cost of ownership rather than upfront capital expenditure. With potassium-ion systems potentially offering 30-40% lower lifetime costs compared to lithium-ion alternatives, this shift in purchasing criteria creates favorable market conditions for adoption.

Regulatory landscapes are increasingly supportive of alternative battery chemistries. The European Battery Directive's recent amendments specifically acknowledge potassium-ion technology, while several Asian countries have introduced subsidy programs for non-lithium storage solutions. In the United States, the Inflation Reduction Act provides tax credits for domestic battery production regardless of chemistry, creating financial incentives for potassium-ion manufacturing.

Market barriers include technology maturity concerns, limited manufacturing scale, and conservative customer adoption patterns. However, these are counterbalanced by growing investor interest in alternative battery technologies, with venture capital funding for non-lithium chemistries reaching $1.8 billion in 2022, a 65% increase from the previous year.

Lithium-ion batteries currently dominate the stationary storage sector, accounting for roughly 85% of new installations. However, supply chain vulnerabilities and raw material constraints are creating significant market gaps. Potassium, being the seventh most abundant element in the Earth's crust (2.1% versus lithium's 0.006%), presents a compelling alternative with substantially lower resource acquisition costs and reduced geopolitical supply risks.

Market segmentation reveals distinct opportunities for potassium-ion batteries. The utility-scale segment, valued at $12 billion, shows the highest growth potential with increasing demand for grid-level storage solutions exceeding 4-hour duration. Commercial and industrial applications represent a $9 billion segment where cost-effectiveness often outweighs energy density considerations, creating an ideal entry point for potassium-ion technology.

Regional analysis indicates Asia-Pacific leads deployment with 45% market share, followed by North America (28%) and Europe (20%). Notably, emerging markets in Africa and South America are showing accelerated adoption rates of 25-30% annually, often bypassing traditional infrastructure limitations through distributed storage solutions.

Customer demand patterns reveal increasing emphasis on total cost of ownership rather than upfront capital expenditure. With potassium-ion systems potentially offering 30-40% lower lifetime costs compared to lithium-ion alternatives, this shift in purchasing criteria creates favorable market conditions for adoption.

Regulatory landscapes are increasingly supportive of alternative battery chemistries. The European Battery Directive's recent amendments specifically acknowledge potassium-ion technology, while several Asian countries have introduced subsidy programs for non-lithium storage solutions. In the United States, the Inflation Reduction Act provides tax credits for domestic battery production regardless of chemistry, creating financial incentives for potassium-ion manufacturing.

Market barriers include technology maturity concerns, limited manufacturing scale, and conservative customer adoption patterns. However, these are counterbalanced by growing investor interest in alternative battery technologies, with venture capital funding for non-lithium chemistries reaching $1.8 billion in 2022, a 65% increase from the previous year.

Current Status and Technical Barriers in K-Ion Battery Development

Potassium-ion battery (KIB) technology has emerged as a promising alternative to lithium-ion batteries for stationary energy storage applications. Currently, KIB development is at the early-to-middle stage of research, with significant progress made in laboratory settings but limited commercial deployment. Several research institutions and companies have demonstrated proof-of-concept KIB cells with energy densities ranging from 80-140 Wh/kg, which is competitive for stationary storage applications where energy density requirements are less stringent than for mobile applications.

The primary advantage driving KIB development is the abundance of potassium resources, which are approximately 1000 times more plentiful in the Earth's crust than lithium. This abundance translates to potentially lower raw material costs, with potassium salts costing approximately 20-30% less than their lithium counterparts. Additionally, potassium ions can be transported in aluminum current collectors rather than copper, further reducing material costs.

Despite these advantages, several significant technical barriers impede widespread KIB adoption. The larger ionic radius of potassium (1.38 Å) compared to lithium (0.76 Å) causes substantial volume changes during charge-discharge cycles, leading to structural degradation of electrode materials and reduced cycle life. Most laboratory KIB prototypes demonstrate cycle stability of only 500-1000 cycles, whereas commercial stationary storage applications typically require 3000-5000 cycles.

Electrolyte stability presents another major challenge. Conventional carbonate-based electrolytes used in lithium-ion batteries often decompose when used with potassium, creating unstable solid-electrolyte interphase (SEI) layers. This instability contributes to capacity fading and safety concerns. Research into novel electrolyte formulations, including ionic liquids and polymer-based systems, shows promise but remains in early stages.

The development of suitable cathode materials represents perhaps the most significant barrier. While graphite serves as an effective anode for KIBs, high-performance cathode materials with stable structures during potassium intercalation/deintercalation are limited. Prussian blue analogs have shown promise, but their low tap density and moisture sensitivity present manufacturing challenges.

From a systems engineering perspective, KIB pack design faces additional hurdles related to thermal management. Potassium-based systems typically generate more heat during operation than lithium-ion equivalents, necessitating more robust cooling systems. This increased thermal management requirement partially offsets the cost advantages of cheaper raw materials.

Safety concerns also persist, as potassium is more reactive with water than lithium, potentially creating more hazardous failure modes. This reactivity necessitates advanced battery management systems with sophisticated monitoring capabilities to prevent thermal runaway events.

The primary advantage driving KIB development is the abundance of potassium resources, which are approximately 1000 times more plentiful in the Earth's crust than lithium. This abundance translates to potentially lower raw material costs, with potassium salts costing approximately 20-30% less than their lithium counterparts. Additionally, potassium ions can be transported in aluminum current collectors rather than copper, further reducing material costs.

Despite these advantages, several significant technical barriers impede widespread KIB adoption. The larger ionic radius of potassium (1.38 Å) compared to lithium (0.76 Å) causes substantial volume changes during charge-discharge cycles, leading to structural degradation of electrode materials and reduced cycle life. Most laboratory KIB prototypes demonstrate cycle stability of only 500-1000 cycles, whereas commercial stationary storage applications typically require 3000-5000 cycles.

Electrolyte stability presents another major challenge. Conventional carbonate-based electrolytes used in lithium-ion batteries often decompose when used with potassium, creating unstable solid-electrolyte interphase (SEI) layers. This instability contributes to capacity fading and safety concerns. Research into novel electrolyte formulations, including ionic liquids and polymer-based systems, shows promise but remains in early stages.

The development of suitable cathode materials represents perhaps the most significant barrier. While graphite serves as an effective anode for KIBs, high-performance cathode materials with stable structures during potassium intercalation/deintercalation are limited. Prussian blue analogs have shown promise, but their low tap density and moisture sensitivity present manufacturing challenges.

From a systems engineering perspective, KIB pack design faces additional hurdles related to thermal management. Potassium-based systems typically generate more heat during operation than lithium-ion equivalents, necessitating more robust cooling systems. This increased thermal management requirement partially offsets the cost advantages of cheaper raw materials.

Safety concerns also persist, as potassium is more reactive with water than lithium, potentially creating more hazardous failure modes. This reactivity necessitates advanced battery management systems with sophisticated monitoring capabilities to prevent thermal runaway events.

Contemporary Pack Design Approaches for Stationary K-Ion Batteries

01 Battery pack design and structure

The design and structure of potassium-ion battery packs focus on optimizing space utilization, thermal management, and mechanical stability. These designs incorporate specific arrangements of cells, modules, and cooling systems to enhance performance and safety. Advanced structural elements protect against physical damage while allowing for efficient heat dissipation, which is crucial for maintaining optimal operating temperatures and extending battery life.- Battery pack design and structure: Potassium-ion battery packs require specific structural designs to accommodate the unique characteristics of potassium-ion cells. These designs include specialized housing configurations, thermal management systems, and mechanical support structures that ensure stability and safety during operation. The battery pack structure must account for the larger size of potassium ions compared to lithium ions, which affects cell expansion and contraction during cycling.

- Electrode materials for potassium-ion batteries: Advanced electrode materials are crucial for potassium-ion battery packs to achieve high energy density and cycling stability. These materials include specialized carbon-based anodes, potassium-containing cathode materials, and composite electrodes that facilitate efficient potassium ion intercalation and deintercalation. The development of these materials addresses challenges related to the larger ionic radius of potassium compared to lithium, which affects insertion kinetics and structural stability.

- Electrolyte formulations for potassium-ion battery packs: Specialized electrolyte formulations are developed for potassium-ion battery packs to enhance ionic conductivity, electrochemical stability, and safety. These formulations include potassium salts dissolved in organic solvents, ionic liquids, or polymer matrices, often with additives to form stable solid-electrolyte interfaces. The electrolyte composition is tailored to minimize side reactions with electrode materials and to withstand the operating conditions of the battery pack.

- Battery management systems for potassium-ion packs: Battery management systems (BMS) specifically designed for potassium-ion battery packs monitor and control various parameters to ensure optimal performance and safety. These systems include voltage monitoring, temperature control, state-of-charge estimation, and balancing circuits adapted to the unique characteristics of potassium-ion chemistry. The BMS algorithms account for the different voltage profiles and cycling behaviors of potassium-ion cells compared to conventional lithium-ion batteries.

- Integration and application of potassium-ion battery packs: Potassium-ion battery packs are being integrated into various applications as alternatives to lithium-ion batteries. These applications include grid energy storage, electric vehicles, and portable electronics. The integration involves adapting existing systems to accommodate the different voltage ranges, energy densities, and charging protocols of potassium-ion technology. The advantages of potassium-ion battery packs include potentially lower cost due to abundant potassium resources and reduced environmental impact compared to lithium-ion batteries.

02 Electrode materials for potassium-ion batteries

Innovative electrode materials are essential for potassium-ion battery packs, with research focusing on carbon-based anodes, transition metal compounds, and novel cathode materials. These materials are designed to accommodate the larger potassium ions while maintaining structural integrity during charge-discharge cycles. Developments include hierarchical porous structures, doped materials, and composite electrodes that enhance ion diffusion, capacity retention, and cycling stability.Expand Specific Solutions03 Battery management systems for potassium-ion packs

Specialized battery management systems (BMS) for potassium-ion battery packs monitor and control various parameters including voltage, current, temperature, and state of charge. These systems implement algorithms tailored to the unique characteristics of potassium-ion chemistry, enabling accurate state estimation and enhanced safety features. Advanced BMS designs incorporate predictive analytics for early fault detection and adaptive control strategies to optimize performance under varying operating conditions.Expand Specific Solutions04 Electrolyte formulations for potassium-ion batteries

Specialized electrolyte formulations for potassium-ion battery packs address challenges related to ion transport, interface stability, and safety. These formulations include optimized salt concentrations, solvent mixtures, and additives that enhance ionic conductivity while forming stable solid electrolyte interphases. Research focuses on developing electrolytes with wide electrochemical windows, low flammability, and compatibility with various electrode materials to improve overall battery performance and safety.Expand Specific Solutions05 Thermal management and safety features

Thermal management systems and safety features for potassium-ion battery packs are designed to prevent thermal runaway and ensure safe operation under various conditions. These systems incorporate cooling channels, phase change materials, and intelligent temperature control mechanisms. Safety features include pressure relief valves, current interrupt devices, and isolation mechanisms that activate during abnormal conditions. Advanced designs also implement fire-retardant materials and structural elements that contain potential failures within individual cells.Expand Specific Solutions

Leading Companies and Research Institutions in K-Ion Battery Field

The potassium-ion battery pack market for stationary storage is in an early growth phase, characterized by increasing R&D investment but limited commercial deployment. The market is projected to expand significantly as the technology matures, driven by lower costs compared to lithium-ion alternatives. Leading players include established battery manufacturers like LG Energy Solution, Samsung SDI, and Panasonic Holdings, who are leveraging their lithium-ion expertise to develop potassium-ion solutions. Research institutions such as the Chinese Academy of Sciences and University of Science & Technology Beijing are advancing fundamental technology, while specialized companies like Faradion are pioneering commercial applications. The competitive landscape features collaboration between academic institutions and industry partners, with Asian companies currently dominating patent activity and technology development.

LG Chem Ltd.

Technical Solution: LG Chem has developed advanced potassium-ion battery pack designs for stationary storage applications, leveraging their extensive experience in lithium-ion technology. Their K-ion battery system utilizes graphite and hard carbon composite anodes paired with layered oxide cathodes, achieving cell-level energy densities of approximately 120-140 Wh/kg. The pack architecture features a modular design with standardized 50kWh units that can be configured in parallel to meet various capacity requirements from residential to utility-scale applications. Each module incorporates sophisticated battery management systems that monitor individual cell voltages, temperatures, and state of health. LG Chem's thermal management solution uses liquid cooling channels integrated between cells to maintain uniform temperature distribution across the pack, critical for K-ion chemistry which shows optimal performance between 10-40°C. Their BMS algorithms are specifically calibrated for potassium-ion's unique voltage characteristics and degradation patterns, enabling accurate state-of-charge estimation and predictive maintenance capabilities. The packs include multiple safety features including cell-level fusing, gas venting mechanisms, and isolation systems to prevent thermal runaway propagation.

Strengths: Leverages established manufacturing infrastructure and expertise from lithium-ion production; competitive cost structure due to abundant potassium resources; good power performance suitable for grid stabilization applications. Weaknesses: Energy density limitations compared to their lithium-ion offerings; relatively early in commercialization cycle with limited field validation data; requires specialized BMS algorithms different from their established lithium-ion systems.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has engineered a comprehensive potassium-ion battery pack solution for stationary energy storage applications. Their system employs Prussian blue analogue cathodes paired with hard carbon anodes, delivering cell-level energy densities of approximately 130 Wh/kg. The pack design features a containerized approach with standardized 250kWh modules that can be scaled for multi-MWh installations. Each module contains Samsung's proprietary thermal management system utilizing phase-change materials to maintain optimal operating temperatures between 15-35°C without active cooling in most environments. The battery management system incorporates machine learning algorithms that continuously optimize charging protocols based on usage patterns and environmental conditions, extending cycle life beyond 3000 cycles at 80% depth of discharge. Samsung's pack design includes redundant safety systems with multiple layers of protection, including cell-level monitoring, automated fire suppression, and isolation mechanisms to prevent thermal event propagation. Their potassium-ion chemistry utilizes electrolyte additives that form stable solid-electrolyte interphase layers, reducing capacity fade and improving calendar life to over 10 years. The modular architecture allows for hot-swappable maintenance, with individual modules replaceable without taking the entire system offline.

Strengths: Excellent cycle life performance exceeding many competing technologies; advanced thermal management requiring minimal energy input; established global manufacturing and distribution network for rapid scaling. Weaknesses: Higher initial capital cost compared to some competing potassium-ion designs; system complexity requiring specialized maintenance personnel; performance degradation accelerates at temperature extremes below 0°C or above 45°C.

Critical Patents and Innovations in K-Ion Battery Pack Engineering

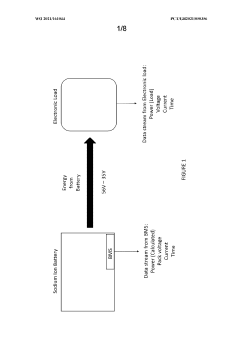

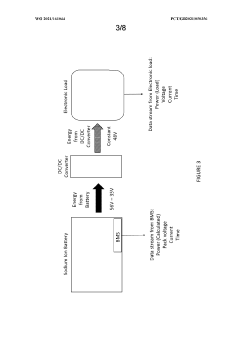

Sodium-ion battery pack

PatentWO2021161044A1

Innovation

- Incorporating voltage converters, specifically DC/DC converters, within the sodium-ion battery pack to align the output voltage with electronic components' requirements, allowing sodium-ion cells to operate within a wider voltage range and increasing the usable energy density and specific energy of the battery pack.

Safety and Thermal Management Strategies for K-Ion Battery Systems

Safety considerations for potassium-ion (K-ion) battery systems are paramount for their successful deployment in stationary storage applications. Unlike lithium-ion batteries, K-ion systems present unique thermal management challenges due to the higher reactivity of potassium with electrolytes and potential for more vigorous thermal runaway events. Current safety designs incorporate multi-layered protection strategies, beginning with cell-level innovations such as ceramic separators with high thermal stability and flame-retardant electrolyte additives specifically formulated for potassium chemistry.

At the module level, thermal management systems for K-ion batteries typically employ active cooling solutions with greater capacity than those used in lithium-ion equivalents. These systems often utilize liquid cooling channels positioned between cells to maintain optimal operating temperatures between 15-35°C, as K-ion batteries have demonstrated sensitivity to temperature extremes that can accelerate capacity fade and increase safety risks.

Battery management systems (BMS) for K-ion technology incorporate advanced algorithms specifically calibrated for potassium electrochemistry, with particular emphasis on early detection of thermal anomalies. These systems monitor individual cell temperatures with higher sampling rates than conventional BMS designs, allowing for faster intervention when temperature gradients exceed predetermined safety thresholds.

Physical protection measures include enhanced cell spacing within modules to prevent thermal propagation, with some designs incorporating phase-change materials between cells that absorb excess heat during temperature spikes. Intumescent materials that expand under heat exposure are increasingly being integrated into pack designs to provide passive fire protection and contain thermal events.

Venting mechanisms for K-ion systems require special consideration due to the different gas composition generated during thermal events compared to lithium-ion batteries. Current designs feature pressure-relief systems with filtration components to neutralize potassium-specific byproducts before venting to the atmosphere.

Testing protocols for K-ion battery safety certification are still evolving, with industry leaders advocating for modified standards that address the unique failure modes of potassium chemistry. These include specialized nail penetration tests, thermal abuse protocols, and overcharge scenarios designed to evaluate the effectiveness of safety measures under extreme conditions.

Recent advancements in computational modeling have enabled more accurate prediction of thermal behavior in K-ion systems, allowing designers to optimize cooling channel geometry and cell arrangement for maximum heat dissipation efficiency. These simulation tools account for the specific thermal conductivity properties of potassium-based electrode materials, which differ significantly from their lithium counterparts.

At the module level, thermal management systems for K-ion batteries typically employ active cooling solutions with greater capacity than those used in lithium-ion equivalents. These systems often utilize liquid cooling channels positioned between cells to maintain optimal operating temperatures between 15-35°C, as K-ion batteries have demonstrated sensitivity to temperature extremes that can accelerate capacity fade and increase safety risks.

Battery management systems (BMS) for K-ion technology incorporate advanced algorithms specifically calibrated for potassium electrochemistry, with particular emphasis on early detection of thermal anomalies. These systems monitor individual cell temperatures with higher sampling rates than conventional BMS designs, allowing for faster intervention when temperature gradients exceed predetermined safety thresholds.

Physical protection measures include enhanced cell spacing within modules to prevent thermal propagation, with some designs incorporating phase-change materials between cells that absorb excess heat during temperature spikes. Intumescent materials that expand under heat exposure are increasingly being integrated into pack designs to provide passive fire protection and contain thermal events.

Venting mechanisms for K-ion systems require special consideration due to the different gas composition generated during thermal events compared to lithium-ion batteries. Current designs feature pressure-relief systems with filtration components to neutralize potassium-specific byproducts before venting to the atmosphere.

Testing protocols for K-ion battery safety certification are still evolving, with industry leaders advocating for modified standards that address the unique failure modes of potassium chemistry. These include specialized nail penetration tests, thermal abuse protocols, and overcharge scenarios designed to evaluate the effectiveness of safety measures under extreme conditions.

Recent advancements in computational modeling have enabled more accurate prediction of thermal behavior in K-ion systems, allowing designers to optimize cooling channel geometry and cell arrangement for maximum heat dissipation efficiency. These simulation tools account for the specific thermal conductivity properties of potassium-based electrode materials, which differ significantly from their lithium counterparts.

Grid Integration and Scalability Considerations for K-Ion Storage

The integration of potassium-ion battery (KIB) systems into existing power grids presents both significant opportunities and technical challenges. Grid operators must consider the unique characteristics of KIB technology when planning for large-scale deployment in stationary storage applications. Unlike lithium-ion systems, KIB installations require specific voltage management protocols and power conversion systems optimized for their electrochemical properties, particularly their distinct charge-discharge profiles and voltage ranges.

Scalability of KIB storage systems depends heavily on modular design approaches that allow for incremental capacity expansion. Current engineering models suggest that KIB modules can be effectively arranged in parallel configurations to achieve multi-megawatt installations, with preliminary field tests demonstrating stable performance in grid-supporting roles. The inherent thermal stability of potassium-ion chemistry provides advantages for large-scale deployments, potentially reducing cooling infrastructure requirements compared to lithium-ion alternatives.

Grid integration protocols for KIB systems must address communication standards between battery management systems and grid control infrastructure. Industry consortia are currently developing specialized protocols that accommodate the unique state-of-charge estimation algorithms required for potassium-ion chemistry. These protocols aim to enable seamless integration with existing SCADA systems while providing the granular control necessary for grid services such as frequency regulation and peak shaving.

Regulatory frameworks present another critical consideration for KIB grid integration. Current grid codes in most jurisdictions were developed with conventional generation or lithium-ion storage in mind, creating potential compliance challenges for KIB systems. Forward-thinking utilities and regulatory bodies are beginning to develop technology-neutral performance requirements that would accommodate emerging storage technologies like KIB without requiring extensive regulatory revisions.

From an economic perspective, the scalability of KIB systems benefits from their use of abundant raw materials, potentially enabling more predictable cost structures for large-scale deployments compared to lithium-ion alternatives. However, the relative immaturity of KIB manufacturing processes currently limits economies of scale. Analysis suggests that grid-scale KIB installations will become increasingly cost-competitive as production volumes increase, with crossover points expected within 3-5 years in specific grid service applications.

The physical footprint and spatial requirements of KIB installations also merit consideration in grid integration planning. Current KIB designs offer energy density comparable to LFP lithium-ion batteries but require different spatial configurations to accommodate their thermal management systems and interconnection equipment. Grid planners must account for these differences when allocating substation space or repurposing existing infrastructure for KIB deployment.

Scalability of KIB storage systems depends heavily on modular design approaches that allow for incremental capacity expansion. Current engineering models suggest that KIB modules can be effectively arranged in parallel configurations to achieve multi-megawatt installations, with preliminary field tests demonstrating stable performance in grid-supporting roles. The inherent thermal stability of potassium-ion chemistry provides advantages for large-scale deployments, potentially reducing cooling infrastructure requirements compared to lithium-ion alternatives.

Grid integration protocols for KIB systems must address communication standards between battery management systems and grid control infrastructure. Industry consortia are currently developing specialized protocols that accommodate the unique state-of-charge estimation algorithms required for potassium-ion chemistry. These protocols aim to enable seamless integration with existing SCADA systems while providing the granular control necessary for grid services such as frequency regulation and peak shaving.

Regulatory frameworks present another critical consideration for KIB grid integration. Current grid codes in most jurisdictions were developed with conventional generation or lithium-ion storage in mind, creating potential compliance challenges for KIB systems. Forward-thinking utilities and regulatory bodies are beginning to develop technology-neutral performance requirements that would accommodate emerging storage technologies like KIB without requiring extensive regulatory revisions.

From an economic perspective, the scalability of KIB systems benefits from their use of abundant raw materials, potentially enabling more predictable cost structures for large-scale deployments compared to lithium-ion alternatives. However, the relative immaturity of KIB manufacturing processes currently limits economies of scale. Analysis suggests that grid-scale KIB installations will become increasingly cost-competitive as production volumes increase, with crossover points expected within 3-5 years in specific grid service applications.

The physical footprint and spatial requirements of KIB installations also merit consideration in grid integration planning. Current KIB designs offer energy density comparable to LFP lithium-ion batteries but require different spatial configurations to accommodate their thermal management systems and interconnection equipment. Grid planners must account for these differences when allocating substation space or repurposing existing infrastructure for KIB deployment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!