Safety And Thermal Management In Potassium-Ion Cells

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Potassium-Ion Battery Safety Evolution and Objectives

Potassium-ion battery (PIB) technology has emerged as a promising alternative to lithium-ion batteries (LIBs) over the past decade, primarily driven by the abundance and low cost of potassium resources. The evolution of PIB safety management can be traced back to early 2010s when researchers began exploring potassium as an alternative to lithium for energy storage applications. Initially, safety concerns were secondary to performance metrics, with early research focusing primarily on electrode materials and electrolyte compositions to achieve viable energy densities.

By mid-2010s, as PIB research intensified, thermal runaway incidents in prototype cells highlighted the unique safety challenges posed by potassium's higher reactivity compared to lithium. Potassium's lower melting point (63.5°C versus 180.5°C for lithium) and more vigorous reaction with water created distinct safety profiles requiring specialized management approaches. This period marked a shift toward dedicated safety research for PIBs rather than simply applying LIB safety protocols.

From 2018 onwards, systematic investigation of thermal behavior in potassium-ion cells became more prevalent, with researchers developing specific thermal management systems tailored to PIB characteristics. The larger ionic radius of K+ (1.38 Å) compared to Li+ (0.76 Å) necessitated different intercalation dynamics and heat dissipation strategies, driving innovation in cell design and cooling systems.

Current technical objectives in PIB safety management focus on several key areas. First, developing advanced electrolyte formulations with higher thermal stability and reduced flammability, particularly through flame-retardant additives compatible with potassium chemistry. Second, engineering more stable solid-electrolyte interphase (SEI) layers that can withstand the mechanical stresses caused by the larger K+ ions during cycling, thereby preventing internal short circuits.

Another critical objective is the creation of specialized battery management systems (BMS) calibrated specifically for PIB thermal characteristics, with algorithms designed to detect thermal anomalies unique to potassium chemistry. Researchers are also pursuing novel cell architectures that incorporate passive thermal regulation features, such as phase-change materials optimized for the temperature ranges relevant to PIB operation.

The long-term safety objective for PIB technology is to achieve thermal stability comparable to or exceeding that of commercial LIBs, while maintaining the cost advantages inherent to potassium-based systems. This includes developing standardized safety testing protocols specifically designed for PIBs, as current standards are predominantly tailored to lithium-ion chemistry and may not adequately address potassium-specific risks.

By mid-2010s, as PIB research intensified, thermal runaway incidents in prototype cells highlighted the unique safety challenges posed by potassium's higher reactivity compared to lithium. Potassium's lower melting point (63.5°C versus 180.5°C for lithium) and more vigorous reaction with water created distinct safety profiles requiring specialized management approaches. This period marked a shift toward dedicated safety research for PIBs rather than simply applying LIB safety protocols.

From 2018 onwards, systematic investigation of thermal behavior in potassium-ion cells became more prevalent, with researchers developing specific thermal management systems tailored to PIB characteristics. The larger ionic radius of K+ (1.38 Å) compared to Li+ (0.76 Å) necessitated different intercalation dynamics and heat dissipation strategies, driving innovation in cell design and cooling systems.

Current technical objectives in PIB safety management focus on several key areas. First, developing advanced electrolyte formulations with higher thermal stability and reduced flammability, particularly through flame-retardant additives compatible with potassium chemistry. Second, engineering more stable solid-electrolyte interphase (SEI) layers that can withstand the mechanical stresses caused by the larger K+ ions during cycling, thereby preventing internal short circuits.

Another critical objective is the creation of specialized battery management systems (BMS) calibrated specifically for PIB thermal characteristics, with algorithms designed to detect thermal anomalies unique to potassium chemistry. Researchers are also pursuing novel cell architectures that incorporate passive thermal regulation features, such as phase-change materials optimized for the temperature ranges relevant to PIB operation.

The long-term safety objective for PIB technology is to achieve thermal stability comparable to or exceeding that of commercial LIBs, while maintaining the cost advantages inherent to potassium-based systems. This includes developing standardized safety testing protocols specifically designed for PIBs, as current standards are predominantly tailored to lithium-ion chemistry and may not adequately address potassium-specific risks.

Market Analysis for Safe K-Ion Energy Storage Solutions

The global energy storage market is witnessing a significant shift towards safer and more sustainable battery technologies, with potassium-ion (K-ion) cells emerging as a promising alternative to conventional lithium-ion batteries. Current market projections indicate that the K-ion battery market could reach $2.5 billion by 2030, with a compound annual growth rate of approximately 25% from 2023 to 2030. This growth is primarily driven by increasing concerns over lithium supply chain vulnerabilities and the superior safety profile of K-ion technology.

The demand for K-ion energy storage solutions is particularly strong in grid-scale applications, where safety considerations outweigh energy density requirements. Utility companies are increasingly seeking alternatives to lithium-ion batteries due to well-documented thermal runaway incidents. Market research indicates that grid storage applications could account for nearly 45% of the total K-ion battery market by 2028, followed by electric vehicles (30%) and consumer electronics (15%).

Regional market analysis reveals that Asia-Pacific currently dominates K-ion battery research and development, with China, Japan, and South Korea collectively holding over 60% of related patents. However, North America and Europe are rapidly increasing investments in this technology, particularly focusing on safety enhancements and thermal management innovations.

Consumer surveys indicate growing awareness and concern regarding battery safety, with 78% of industrial energy storage customers ranking safety as their top priority when selecting battery technologies. This represents a significant market opportunity for K-ion cells, which demonstrate superior thermal stability compared to lithium-ion alternatives.

The economic value proposition of K-ion batteries is strengthened by potassium's abundance, costing approximately one-tenth the price of lithium. This translates to potential cost savings of 30-40% in raw material expenses, making K-ion solutions particularly attractive for price-sensitive market segments such as residential energy storage and developing economies.

Market barriers include the current lack of established manufacturing infrastructure specifically designed for K-ion cells and limited awareness among end-users. However, these challenges are being addressed through strategic partnerships between research institutions and industrial manufacturers, with several pilot production lines already operational in China and Germany.

Competitive analysis reveals that while established battery manufacturers are beginning to invest in K-ion technology, specialized startups focused exclusively on potassium-based energy storage solutions are gaining significant market traction, particularly those emphasizing enhanced thermal management systems and intrinsic safety features.

The demand for K-ion energy storage solutions is particularly strong in grid-scale applications, where safety considerations outweigh energy density requirements. Utility companies are increasingly seeking alternatives to lithium-ion batteries due to well-documented thermal runaway incidents. Market research indicates that grid storage applications could account for nearly 45% of the total K-ion battery market by 2028, followed by electric vehicles (30%) and consumer electronics (15%).

Regional market analysis reveals that Asia-Pacific currently dominates K-ion battery research and development, with China, Japan, and South Korea collectively holding over 60% of related patents. However, North America and Europe are rapidly increasing investments in this technology, particularly focusing on safety enhancements and thermal management innovations.

Consumer surveys indicate growing awareness and concern regarding battery safety, with 78% of industrial energy storage customers ranking safety as their top priority when selecting battery technologies. This represents a significant market opportunity for K-ion cells, which demonstrate superior thermal stability compared to lithium-ion alternatives.

The economic value proposition of K-ion batteries is strengthened by potassium's abundance, costing approximately one-tenth the price of lithium. This translates to potential cost savings of 30-40% in raw material expenses, making K-ion solutions particularly attractive for price-sensitive market segments such as residential energy storage and developing economies.

Market barriers include the current lack of established manufacturing infrastructure specifically designed for K-ion cells and limited awareness among end-users. However, these challenges are being addressed through strategic partnerships between research institutions and industrial manufacturers, with several pilot production lines already operational in China and Germany.

Competitive analysis reveals that while established battery manufacturers are beginning to invest in K-ion technology, specialized startups focused exclusively on potassium-based energy storage solutions are gaining significant market traction, particularly those emphasizing enhanced thermal management systems and intrinsic safety features.

Thermal Management Challenges in K-Ion Cell Technology

Potassium-ion (K-ion) battery technology faces significant thermal management challenges that must be addressed before widespread commercial adoption. The primary concern stems from potassium's higher reactivity compared to lithium and sodium, creating elevated safety risks during thermal events. When K-ion cells experience temperature increases, the reaction kinetics accelerate exponentially, potentially triggering thermal runaway at lower threshold temperatures than in lithium-ion systems.

The large ionic radius of potassium (1.38Å versus 0.76Å for lithium) creates substantial mechanical stress during intercalation/deintercalation cycles, generating more heat through increased internal resistance. This characteristic necessitates more robust thermal management solutions than those currently employed in commercial lithium-ion batteries. Additionally, the higher atomic weight of potassium contributes to greater thermal mass within the cell, affecting both heat generation dynamics and dissipation requirements.

Current electrolyte formulations for K-ion cells present another thermal management hurdle. Most research focuses on organic carbonate-based electrolytes similar to those used in lithium-ion batteries, but these demonstrate lower thermal stability when paired with potassium. Decomposition of these electrolytes begins at approximately 70-80°C (compared to 130-150°C in optimized lithium-ion systems), creating a narrower operational temperature window and requiring more precise thermal control systems.

The SEI (Solid Electrolyte Interphase) formation in K-ion cells exhibits different thermal characteristics than in lithium-ion counterparts. The SEI layer tends to be less stable at elevated temperatures, breaking down and reforming more readily, which generates additional heat and consumes active materials. This cyclical process can accelerate capacity fade while simultaneously increasing thermal management demands.

Electrode materials in K-ion cells, particularly Prussian Blue Analogues and organic compounds being explored as cathodes, demonstrate varying thermal conductivity properties that complicate uniform heat distribution within cells. These materials often exhibit anisotropic thermal conductivity, creating potential hotspots that conventional thermal management approaches struggle to address effectively.

Scale-up challenges further complicate thermal management in K-ion technology. As cell sizes increase from laboratory coin cells to practical pouch or cylindrical formats, heat dissipation pathways become more complex. The center-to-edge temperature gradients can be more pronounced in K-ion cells due to their unique electrochemical properties, requiring novel cooling strategies that balance effectiveness with manufacturing practicality and cost considerations.

The large ionic radius of potassium (1.38Å versus 0.76Å for lithium) creates substantial mechanical stress during intercalation/deintercalation cycles, generating more heat through increased internal resistance. This characteristic necessitates more robust thermal management solutions than those currently employed in commercial lithium-ion batteries. Additionally, the higher atomic weight of potassium contributes to greater thermal mass within the cell, affecting both heat generation dynamics and dissipation requirements.

Current electrolyte formulations for K-ion cells present another thermal management hurdle. Most research focuses on organic carbonate-based electrolytes similar to those used in lithium-ion batteries, but these demonstrate lower thermal stability when paired with potassium. Decomposition of these electrolytes begins at approximately 70-80°C (compared to 130-150°C in optimized lithium-ion systems), creating a narrower operational temperature window and requiring more precise thermal control systems.

The SEI (Solid Electrolyte Interphase) formation in K-ion cells exhibits different thermal characteristics than in lithium-ion counterparts. The SEI layer tends to be less stable at elevated temperatures, breaking down and reforming more readily, which generates additional heat and consumes active materials. This cyclical process can accelerate capacity fade while simultaneously increasing thermal management demands.

Electrode materials in K-ion cells, particularly Prussian Blue Analogues and organic compounds being explored as cathodes, demonstrate varying thermal conductivity properties that complicate uniform heat distribution within cells. These materials often exhibit anisotropic thermal conductivity, creating potential hotspots that conventional thermal management approaches struggle to address effectively.

Scale-up challenges further complicate thermal management in K-ion technology. As cell sizes increase from laboratory coin cells to practical pouch or cylindrical formats, heat dissipation pathways become more complex. The center-to-edge temperature gradients can be more pronounced in K-ion cells due to their unique electrochemical properties, requiring novel cooling strategies that balance effectiveness with manufacturing practicality and cost considerations.

Current Thermal Management Systems for K-Ion Cells

01 Thermal management systems for potassium-ion batteries

Effective thermal management systems are crucial for maintaining the safety and performance of potassium-ion cells. These systems help regulate temperature during operation, preventing thermal runaway and extending battery life. Advanced cooling mechanisms, including liquid cooling circuits, heat sinks, and thermal interface materials, can efficiently dissipate heat generated during charging and discharging cycles. Proper thermal management also helps maintain uniform temperature distribution across battery packs, which is essential for consistent performance and safety.- Thermal management systems for potassium-ion batteries: Advanced thermal management systems are crucial for maintaining safe operating temperatures in potassium-ion cells. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring devices that prevent thermal runaway. Effective thermal management extends battery life, improves performance, and enhances safety by regulating temperature distribution across cell components during charging and discharging cycles.

- Electrolyte formulations for improved safety: Specialized electrolyte formulations can significantly enhance the safety profile of potassium-ion cells. These formulations include flame-retardant additives, stabilizing compounds, and ionic liquids that reduce flammability and volatility. Advanced electrolytes also help prevent dendrite formation and minimize side reactions that could lead to thermal events, thereby improving the overall safety and stability of potassium-ion battery systems.

- Structural safety features and cell design: Innovative structural designs and safety features are implemented in potassium-ion cells to prevent catastrophic failures. These include pressure relief mechanisms, separator designs that prevent internal short circuits, and robust cell casings that contain potential failures. Advanced cell architectures also incorporate features that limit thermal propagation between cells in a battery pack, enhancing overall system safety.

- Battery management systems for safety monitoring: Sophisticated battery management systems (BMS) are essential for monitoring and controlling potassium-ion cells to ensure safe operation. These systems continuously track parameters such as voltage, current, and temperature across individual cells and the entire battery pack. The BMS can detect abnormal conditions, implement protective measures, and balance cells to prevent overcharging or deep discharging, significantly reducing safety risks.

- Novel electrode materials for enhanced thermal stability: Research into advanced electrode materials focuses on improving the thermal stability of potassium-ion cells. These materials include modified cathodes and anodes with higher thermal decomposition thresholds, reduced exothermic reactions, and improved structural integrity at elevated temperatures. Such materials minimize the risk of thermal runaway and enhance the overall safety profile of potassium-ion batteries while maintaining or improving energy density and cycle life.

02 Safety mechanisms and protective structures

Various safety mechanisms and protective structures can be incorporated into potassium-ion cells to enhance their safety profile. These include pressure relief valves, thermal fuses, and current interrupt devices that activate during abnormal conditions. Protective coatings and separator technologies can prevent internal short circuits, while battery management systems continuously monitor cell parameters to detect potential safety issues. Structural reinforcements and encapsulation techniques also help contain failures and prevent cascading thermal events in battery packs.Expand Specific Solutions03 Electrolyte formulations for improved safety

Advanced electrolyte formulations play a significant role in enhancing the safety of potassium-ion cells. Non-flammable or flame-retardant electrolytes reduce fire hazards, while additives can suppress gas generation during cycling. Solid-state and gel electrolytes offer improved thermal stability compared to conventional liquid electrolytes. Optimized electrolyte compositions can also form stable solid-electrolyte interphase layers that prevent unwanted side reactions and enhance the overall safety and thermal stability of potassium-ion batteries.Expand Specific Solutions04 Battery management systems for thermal control

Sophisticated battery management systems (BMS) are essential for monitoring and controlling the thermal behavior of potassium-ion cells. These systems employ temperature sensors, predictive algorithms, and real-time monitoring to detect thermal anomalies before they become critical. Advanced BMS can implement adaptive charging protocols that adjust based on temperature conditions, preventing overheating during fast charging. They also enable thermal balancing across cell arrays and can initiate protective measures such as load reduction or emergency shutdown when unsafe conditions are detected.Expand Specific Solutions05 Novel electrode materials for thermal stability

Research into novel electrode materials has yielded significant improvements in the thermal stability of potassium-ion cells. Advanced cathode and anode materials with higher thermal decomposition temperatures reduce the risk of thermal runaway. Nanostructured electrodes can better accommodate volume changes during cycling, reducing mechanical stress that could lead to safety issues. Composite electrodes incorporating thermally conductive materials help dissipate heat more efficiently. These material innovations contribute to safer potassium-ion batteries with improved performance under various thermal conditions.Expand Specific Solutions

Leading Companies in K-Ion Battery Safety Research

Potassium-ion cell safety and thermal management is emerging as a critical focus in the early commercialization stage of this technology. The market remains relatively small but shows promising growth potential as an alternative to lithium-ion batteries. Technical maturity varies significantly among key players, with research institutions like Chinese Academy of Sciences and Guangdong University of Technology leading fundamental research, while established companies including Robert Bosch, Samsung SDI, and CATL are advancing practical applications. Automotive manufacturers (Mercedes-Benz, BMW, Volkswagen) are exploring potassium-ion technology to diversify battery options, while specialized firms like Electrovaya and Latent Heat Solutions contribute targeted thermal management innovations. The technology's development trajectory suggests increasing commercial viability as safety challenges are addressed.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has engineered a sophisticated safety and thermal management system for potassium-ion cells that leverages their extensive automotive expertise. Their approach centers on a dual-circuit cooling architecture that separates high-demand and baseline thermal management functions. The primary circuit employs a proprietary coolant formulation with enhanced thermal conductivity that circulates through microchannels directly bonded to cell surfaces, achieving temperature uniformity within ±2°C across the entire battery pack. Bosch's secondary circuit provides additional cooling capacity during extreme operating conditions or rapid charging scenarios. The system incorporates predictive thermal modeling using real-time sensor data processed through Bosch's automotive-grade ECUs, enabling preemptive cooling adjustments based on anticipated load profiles. For safety management, Bosch has developed specialized pressure relief valves calibrated specifically for potassium-ion chemistry that can safely vent gases while preventing air ingress. Their comprehensive approach includes redundant temperature monitoring with optical fiber sensors that maintain functionality even during electrical system failures. Bosch's thermal management solution integrates with vehicle HVAC systems to optimize overall energy efficiency, recovering waste heat during cold conditions while leveraging vehicle cooling capacity during high-demand scenarios.

Strengths: Exceptional temperature uniformity across large battery packs; robust automotive-grade reliability and redundancy; intelligent integration with vehicle systems; comprehensive safety features with multiple redundancies. Weaknesses: Relatively complex and expensive implementation requiring sophisticated manufacturing; higher weight penalty compared to simpler systems; requires integration with vehicle-level thermal management which limits standalone applications.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has pioneered a comprehensive safety and thermal management system for potassium-ion cells that addresses the unique challenges of this emerging battery chemistry. Their approach integrates a multi-layered safety architecture with specialized cooling technology. At the cell level, Samsung employs a proprietary ceramic-coated separator that maintains structural integrity at temperatures exceeding 200°C, significantly higher than conventional separators. The company has developed a novel electrolyte formulation with flame-retardant additives specifically optimized for potassium-ion chemistry, reducing fire hazards during thermal events. For thermal management, Samsung utilizes a direct liquid cooling system with microchannels that achieves 30% more efficient heat dissipation compared to traditional cooling methods. Their battery management system incorporates AI-driven predictive thermal modeling that continuously monitors cell conditions and can preemptively adjust charging parameters to prevent thermal runaway scenarios. Samsung's design also features pressure-sensitive current interrupt devices that physically disconnect cells when internal pressure exceeds safety thresholds, effectively containing thermal events to individual cells rather than allowing propagation through the pack.

Strengths: Exceptional thermal stability through advanced materials engineering; superior heat dissipation efficiency; intelligent predictive thermal management; comprehensive multi-layer safety approach. Weaknesses: Higher production costs due to specialized materials and complex cooling infrastructure; increased weight compared to simpler thermal management systems; requires sophisticated manufacturing processes that may limit production scaling.

Critical Patents in K-Ion Battery Thermal Runaway Prevention

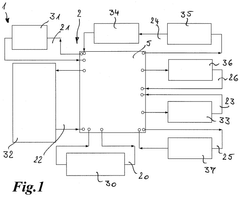

Active thermal management and thermal runaway prevention for high energy density lithium ion battery packs

PatentWO2014186044A1

Innovation

- An active thermal management system where at least one battery cell is partially submerged in a liquid within a battery case, with a pump circulating the liquid through a cooling unit, and a processor controlling the cooling based on temperature thresholds to maintain optimal temperatures and prevent thermal runaway, utilizing a phase change material or other suitable coolant.

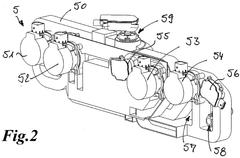

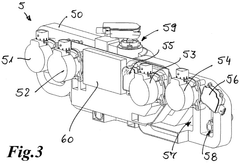

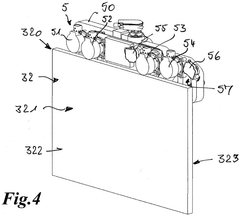

Thermal management system comprising at least one thermal management module, thermal management module, prefabricated unit and battery-electric vehicle comprising a thermal management system comprising a thermal management module

PatentWO2025073388A1

Innovation

- A thermal management system featuring a standardized thermal management module with a flat, plate-like structural component that integrates components for temperature medium conveyance and mass flow control, allowing for direct connection to the main heat exchanger and reducing the complexity and cost of the system.

Regulatory Framework for K-Ion Battery Safety Standards

The regulatory landscape for potassium-ion battery safety is currently in a developmental phase, with significant gaps compared to the well-established frameworks for lithium-ion technologies. As K-ion batteries emerge as promising energy storage alternatives, regulatory bodies worldwide are beginning to recognize the need for specific safety standards that address their unique characteristics and potential hazards.

Currently, most K-ion battery manufacturers must comply with general battery safety regulations such as IEC 62133 (safety requirements for portable sealed secondary cells) and UN 38.3 (transportation testing requirements). However, these standards were primarily designed with lithium-ion chemistry in mind and may not adequately address the specific thermal runaway mechanisms and safety concerns unique to potassium-ion systems.

The European Union, through its Battery Directive (2006/66/EC) and the newer proposed Battery Regulation, is taking steps to incorporate emerging battery technologies including potassium-ion cells. These regulations focus on environmental impact, recycling requirements, and basic safety parameters, though specific thermal management provisions for K-ion technology remain limited.

In the United States, the Consumer Product Safety Commission (CPSC) and Department of Transportation (DOT) oversee battery safety, but have yet to develop K-ion specific guidelines. Similarly, China's GB standards, which heavily influence global battery manufacturing, are only beginning to consider separate classifications for potassium-ion technology.

Industry consortiums and research institutions are actively working to establish testing protocols that specifically address K-ion battery safety concerns. These include thermal stability tests under various conditions, overcharge/overdischarge safety evaluations, and specific thermal management system requirements that account for K-ion's different thermal behavior compared to lithium-ion cells.

A significant regulatory challenge lies in the diversity of K-ion battery designs and electrolyte formulations currently under development. This technological diversity makes standardization difficult, as safety parameters may vary significantly between different K-ion implementations. Regulatory frameworks will need to be flexible enough to accommodate this variation while still ensuring minimum safety standards.

Looking forward, the development of comprehensive K-ion battery safety standards will likely follow a similar trajectory to lithium-ion regulations, beginning with transportation safety requirements and gradually expanding to cover manufacturing, usage, and end-of-life considerations. The establishment of these standards will be crucial for market acceptance and commercialization of K-ion technology in grid storage, electric vehicles, and consumer electronics applications.

Currently, most K-ion battery manufacturers must comply with general battery safety regulations such as IEC 62133 (safety requirements for portable sealed secondary cells) and UN 38.3 (transportation testing requirements). However, these standards were primarily designed with lithium-ion chemistry in mind and may not adequately address the specific thermal runaway mechanisms and safety concerns unique to potassium-ion systems.

The European Union, through its Battery Directive (2006/66/EC) and the newer proposed Battery Regulation, is taking steps to incorporate emerging battery technologies including potassium-ion cells. These regulations focus on environmental impact, recycling requirements, and basic safety parameters, though specific thermal management provisions for K-ion technology remain limited.

In the United States, the Consumer Product Safety Commission (CPSC) and Department of Transportation (DOT) oversee battery safety, but have yet to develop K-ion specific guidelines. Similarly, China's GB standards, which heavily influence global battery manufacturing, are only beginning to consider separate classifications for potassium-ion technology.

Industry consortiums and research institutions are actively working to establish testing protocols that specifically address K-ion battery safety concerns. These include thermal stability tests under various conditions, overcharge/overdischarge safety evaluations, and specific thermal management system requirements that account for K-ion's different thermal behavior compared to lithium-ion cells.

A significant regulatory challenge lies in the diversity of K-ion battery designs and electrolyte formulations currently under development. This technological diversity makes standardization difficult, as safety parameters may vary significantly between different K-ion implementations. Regulatory frameworks will need to be flexible enough to accommodate this variation while still ensuring minimum safety standards.

Looking forward, the development of comprehensive K-ion battery safety standards will likely follow a similar trajectory to lithium-ion regulations, beginning with transportation safety requirements and gradually expanding to cover manufacturing, usage, and end-of-life considerations. The establishment of these standards will be crucial for market acceptance and commercialization of K-ion technology in grid storage, electric vehicles, and consumer electronics applications.

Environmental Impact of K-Ion Battery Thermal Management Solutions

The environmental implications of potassium-ion battery thermal management systems represent a critical consideration in the broader adoption of this emerging technology. Unlike lithium-ion batteries, potassium-ion cells utilize more abundant raw materials, potentially reducing the environmental footprint associated with resource extraction. However, the thermal management solutions employed for these batteries introduce their own environmental considerations that must be carefully evaluated.

Cooling systems for K-ion batteries, whether air-based, liquid-based, or phase-change material systems, consume energy during operation, contributing to the overall carbon footprint of the battery system. Liquid cooling systems, while more efficient, often utilize glycol-based coolants that pose environmental risks if leaked or improperly disposed of. The manufacturing processes for specialized thermal management components also generate additional environmental impacts through energy consumption and material processing.

The end-of-life management of thermal management systems presents another environmental challenge. Many cooling systems contain materials that require specific recycling processes, and the integration of cooling components with battery cells can complicate disassembly and material recovery. Research indicates that advanced thermal management solutions can extend K-ion battery lifespan by 30-40%, potentially offsetting initial environmental costs through reduced replacement frequency.

From a lifecycle perspective, the environmental trade-offs between different thermal management approaches must be considered. Passive cooling systems generally have lower operational environmental impacts but may result in reduced battery efficiency and lifespan. Active cooling systems improve battery performance and longevity but increase energy consumption during operation. Recent studies suggest that hybrid approaches combining passive and active elements may offer the optimal balance between environmental impact and performance.

Emerging bio-based coolants and recyclable phase-change materials show promise for reducing the environmental footprint of K-ion battery thermal management. These materials can potentially replace conventional petroleum-derived coolants while offering comparable thermal performance. Additionally, the development of thermal management systems designed for disassembly and material recovery could significantly improve end-of-life environmental outcomes.

Regulatory frameworks increasingly recognize the importance of considering thermal management systems in environmental assessments of battery technologies. The EU Battery Directive revisions and similar initiatives worldwide are beginning to incorporate requirements for the environmental performance of battery cooling systems, driving innovation toward more sustainable thermal management solutions for potassium-ion and other next-generation battery technologies.

Cooling systems for K-ion batteries, whether air-based, liquid-based, or phase-change material systems, consume energy during operation, contributing to the overall carbon footprint of the battery system. Liquid cooling systems, while more efficient, often utilize glycol-based coolants that pose environmental risks if leaked or improperly disposed of. The manufacturing processes for specialized thermal management components also generate additional environmental impacts through energy consumption and material processing.

The end-of-life management of thermal management systems presents another environmental challenge. Many cooling systems contain materials that require specific recycling processes, and the integration of cooling components with battery cells can complicate disassembly and material recovery. Research indicates that advanced thermal management solutions can extend K-ion battery lifespan by 30-40%, potentially offsetting initial environmental costs through reduced replacement frequency.

From a lifecycle perspective, the environmental trade-offs between different thermal management approaches must be considered. Passive cooling systems generally have lower operational environmental impacts but may result in reduced battery efficiency and lifespan. Active cooling systems improve battery performance and longevity but increase energy consumption during operation. Recent studies suggest that hybrid approaches combining passive and active elements may offer the optimal balance between environmental impact and performance.

Emerging bio-based coolants and recyclable phase-change materials show promise for reducing the environmental footprint of K-ion battery thermal management. These materials can potentially replace conventional petroleum-derived coolants while offering comparable thermal performance. Additionally, the development of thermal management systems designed for disassembly and material recovery could significantly improve end-of-life environmental outcomes.

Regulatory frameworks increasingly recognize the importance of considering thermal management systems in environmental assessments of battery technologies. The EU Battery Directive revisions and similar initiatives worldwide are beginning to incorporate requirements for the environmental performance of battery cooling systems, driving innovation toward more sustainable thermal management solutions for potassium-ion and other next-generation battery technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!