Hybrid Potassium Dual-Ion Battery Concepts For High Power

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Potassium Dual-Ion Battery Evolution and Objectives

Potassium dual-ion batteries (KDIBs) have emerged as a promising alternative to lithium-ion batteries due to the abundance and low cost of potassium resources. The evolution of KDIBs can be traced back to the early 2010s when researchers began exploring potassium-based energy storage systems as a response to concerns about lithium resource limitations and increasing demand for energy storage solutions.

The initial development phase of KDIBs focused primarily on understanding the fundamental electrochemical mechanisms and identifying suitable electrode materials. Early prototypes faced significant challenges including poor cycling stability, limited power density, and safety concerns related to potassium's high reactivity. These limitations restricted their practical applications despite the theoretical advantages.

A significant breakthrough occurred around 2015-2016 when researchers successfully demonstrated improved cycling performance through novel electrode materials and electrolyte formulations. This period marked the transition from purely academic research to more application-oriented development, with increasing attention from both academic institutions and industry players.

The concept of hybrid potassium dual-ion batteries represents a further evolution in this technology trajectory. By combining different ion storage mechanisms and electrode materials, hybrid designs aim to leverage the advantages of multiple systems while mitigating their individual limitations. This approach has shown particular promise for high-power applications where traditional battery technologies often fall short.

Current research objectives in the field of hybrid KDIBs for high-power applications focus on several key areas. First, developing electrode materials with optimized structures for rapid ion insertion/extraction to enable high charge/discharge rates without significant capacity degradation. Second, engineering electrolyte systems that maintain stability under high current densities while ensuring efficient ion transport. Third, designing battery architectures that effectively manage heat generation during high-power operation.

Long-term objectives include achieving power densities comparable to or exceeding those of supercapacitors while maintaining the higher energy density characteristic of batteries. Researchers also aim to extend cycle life beyond 10,000 cycles at high power rates, a critical requirement for applications such as grid frequency regulation and electric vehicle fast charging infrastructure.

The technology roadmap for hybrid KDIBs envisions gradual improvement in performance metrics, with commercial viability for specialized high-power applications expected within the next 3-5 years, followed by broader market penetration as manufacturing processes mature and economies of scale reduce costs.

The initial development phase of KDIBs focused primarily on understanding the fundamental electrochemical mechanisms and identifying suitable electrode materials. Early prototypes faced significant challenges including poor cycling stability, limited power density, and safety concerns related to potassium's high reactivity. These limitations restricted their practical applications despite the theoretical advantages.

A significant breakthrough occurred around 2015-2016 when researchers successfully demonstrated improved cycling performance through novel electrode materials and electrolyte formulations. This period marked the transition from purely academic research to more application-oriented development, with increasing attention from both academic institutions and industry players.

The concept of hybrid potassium dual-ion batteries represents a further evolution in this technology trajectory. By combining different ion storage mechanisms and electrode materials, hybrid designs aim to leverage the advantages of multiple systems while mitigating their individual limitations. This approach has shown particular promise for high-power applications where traditional battery technologies often fall short.

Current research objectives in the field of hybrid KDIBs for high-power applications focus on several key areas. First, developing electrode materials with optimized structures for rapid ion insertion/extraction to enable high charge/discharge rates without significant capacity degradation. Second, engineering electrolyte systems that maintain stability under high current densities while ensuring efficient ion transport. Third, designing battery architectures that effectively manage heat generation during high-power operation.

Long-term objectives include achieving power densities comparable to or exceeding those of supercapacitors while maintaining the higher energy density characteristic of batteries. Researchers also aim to extend cycle life beyond 10,000 cycles at high power rates, a critical requirement for applications such as grid frequency regulation and electric vehicle fast charging infrastructure.

The technology roadmap for hybrid KDIBs envisions gradual improvement in performance metrics, with commercial viability for specialized high-power applications expected within the next 3-5 years, followed by broader market penetration as manufacturing processes mature and economies of scale reduce costs.

Market Analysis for High-Power Energy Storage Solutions

The global market for high-power energy storage solutions is experiencing unprecedented growth, driven by the increasing demand for renewable energy integration, electric vehicles, and grid stabilization technologies. The compound annual growth rate (CAGR) for this sector is projected to exceed 20% through 2030, with the total addressable market expected to reach $400 billion by 2028.

Hybrid Potassium Dual-Ion Battery (KPIB) technology represents an emerging segment within this expanding market. Unlike traditional lithium-ion batteries, KPIBs offer significant advantages in power density, cost-effectiveness, and resource availability, positioning them as a compelling alternative for high-power applications.

The industrial sector currently dominates the demand for high-power energy storage, accounting for approximately 45% of the market share. This is followed by transportation (30%), grid infrastructure (15%), and consumer electronics (10%). Within these segments, applications requiring rapid charge-discharge cycles and high power output are particularly well-suited for KPIB technology adoption.

Regional analysis reveals Asia-Pacific as the dominant market for high-power energy storage solutions, commanding 40% of global market share. This is attributed to robust manufacturing capabilities, government incentives, and accelerated adoption of renewable energy technologies. North America and Europe follow with 30% and 25% market shares respectively, with both regions demonstrating strong growth trajectories driven by decarbonization initiatives.

Market penetration for potassium-based battery technologies remains relatively low at 5%, presenting substantial growth opportunities. The primary market barriers include technological maturity, manufacturing scalability, and competition from established lithium-ion technologies. However, supply chain advantages and raw material accessibility position KPIBs favorably for future market expansion.

Customer segmentation analysis indicates that early adopters of KPIB technology will likely emerge from industries with acute price sensitivity and high-power requirements, such as grid-scale energy storage, industrial equipment, and commercial electric vehicles. These segments value the lower cost per kilowatt and abundant raw materials that potassium-based systems offer.

Competitive landscape assessment identifies several key players investing in potassium battery research, including established battery manufacturers and emerging startups. Strategic partnerships between technology developers and end-users are accelerating commercialization efforts, with several pilot projects demonstrating promising results in real-world applications.

Market forecasts suggest that hybrid potassium dual-ion batteries could capture up to 15% of the high-power energy storage market by 2030, representing a significant shift in the industry landscape. This growth trajectory is contingent upon continued technological advancement, manufacturing optimization, and favorable regulatory frameworks supporting alternative battery chemistries.

Hybrid Potassium Dual-Ion Battery (KPIB) technology represents an emerging segment within this expanding market. Unlike traditional lithium-ion batteries, KPIBs offer significant advantages in power density, cost-effectiveness, and resource availability, positioning them as a compelling alternative for high-power applications.

The industrial sector currently dominates the demand for high-power energy storage, accounting for approximately 45% of the market share. This is followed by transportation (30%), grid infrastructure (15%), and consumer electronics (10%). Within these segments, applications requiring rapid charge-discharge cycles and high power output are particularly well-suited for KPIB technology adoption.

Regional analysis reveals Asia-Pacific as the dominant market for high-power energy storage solutions, commanding 40% of global market share. This is attributed to robust manufacturing capabilities, government incentives, and accelerated adoption of renewable energy technologies. North America and Europe follow with 30% and 25% market shares respectively, with both regions demonstrating strong growth trajectories driven by decarbonization initiatives.

Market penetration for potassium-based battery technologies remains relatively low at 5%, presenting substantial growth opportunities. The primary market barriers include technological maturity, manufacturing scalability, and competition from established lithium-ion technologies. However, supply chain advantages and raw material accessibility position KPIBs favorably for future market expansion.

Customer segmentation analysis indicates that early adopters of KPIB technology will likely emerge from industries with acute price sensitivity and high-power requirements, such as grid-scale energy storage, industrial equipment, and commercial electric vehicles. These segments value the lower cost per kilowatt and abundant raw materials that potassium-based systems offer.

Competitive landscape assessment identifies several key players investing in potassium battery research, including established battery manufacturers and emerging startups. Strategic partnerships between technology developers and end-users are accelerating commercialization efforts, with several pilot projects demonstrating promising results in real-world applications.

Market forecasts suggest that hybrid potassium dual-ion batteries could capture up to 15% of the high-power energy storage market by 2030, representing a significant shift in the industry landscape. This growth trajectory is contingent upon continued technological advancement, manufacturing optimization, and favorable regulatory frameworks supporting alternative battery chemistries.

Current Challenges in Hybrid Potassium Battery Technology

Despite the promising potential of hybrid potassium dual-ion batteries (KDIBs) for high-power applications, several significant technical challenges currently impede their widespread adoption and commercialization. The most pressing issue remains the limited cycle life, with most current systems demonstrating rapid capacity fading after 500-1000 cycles, falling short of the 2000+ cycles required for commercial viability in high-power applications.

Electrode material instability presents another major hurdle. Potassium ions, with their larger ionic radius (1.38 Å) compared to lithium (0.76 Å), cause substantial volume changes during intercalation/deintercalation processes. This volumetric stress leads to structural degradation of electrode materials, particularly in carbon-based anodes where expansion can exceed 60%, resulting in particle pulverization and electrical contact loss.

Electrolyte decomposition and the formation of unstable solid-electrolyte interphase (SEI) layers further complicate KDIB development. The high reactivity of potassium with conventional carbonate-based electrolytes creates parasitic reactions that consume active materials and increase internal resistance. Current electrolyte formulations struggle to form stable passivation layers that can withstand the mechanical stresses during cycling.

The dual-ion mechanism itself introduces unique challenges, particularly in managing the concentration fluctuations of electrolyte ions during charge-discharge processes. As both cations and anions participate in the electrochemical reactions, significant electrolyte depletion can occur, leading to increased cell resistance and reduced power capability at high cycling rates.

Temperature sensitivity represents another significant barrier, with most hybrid potassium systems showing dramatic performance deterioration outside the 15-35°C range. This narrow operating window severely limits their applicability in automotive and grid storage applications where temperature extremes are common.

Safety concerns also persist due to potassium's high reactivity with moisture and oxygen. Current cell designs lack robust protection mechanisms against thermal runaway events, which are more energetic than in lithium-based systems due to potassium's greater chemical reactivity.

From a manufacturing perspective, the lack of standardized production protocols and quality control metrics specific to potassium-based systems hinders scalability. The higher sensitivity of potassium materials to ambient conditions necessitates more stringent manufacturing environments than those established for lithium-ion batteries.

Cost considerations present additional challenges, as current hybrid potassium battery prototypes require specialized materials and processing techniques that offset the inherent cost advantage of abundant potassium resources. The balance between performance enhancement and cost-effectiveness remains difficult to achieve in existing designs.

Electrode material instability presents another major hurdle. Potassium ions, with their larger ionic radius (1.38 Å) compared to lithium (0.76 Å), cause substantial volume changes during intercalation/deintercalation processes. This volumetric stress leads to structural degradation of electrode materials, particularly in carbon-based anodes where expansion can exceed 60%, resulting in particle pulverization and electrical contact loss.

Electrolyte decomposition and the formation of unstable solid-electrolyte interphase (SEI) layers further complicate KDIB development. The high reactivity of potassium with conventional carbonate-based electrolytes creates parasitic reactions that consume active materials and increase internal resistance. Current electrolyte formulations struggle to form stable passivation layers that can withstand the mechanical stresses during cycling.

The dual-ion mechanism itself introduces unique challenges, particularly in managing the concentration fluctuations of electrolyte ions during charge-discharge processes. As both cations and anions participate in the electrochemical reactions, significant electrolyte depletion can occur, leading to increased cell resistance and reduced power capability at high cycling rates.

Temperature sensitivity represents another significant barrier, with most hybrid potassium systems showing dramatic performance deterioration outside the 15-35°C range. This narrow operating window severely limits their applicability in automotive and grid storage applications where temperature extremes are common.

Safety concerns also persist due to potassium's high reactivity with moisture and oxygen. Current cell designs lack robust protection mechanisms against thermal runaway events, which are more energetic than in lithium-based systems due to potassium's greater chemical reactivity.

From a manufacturing perspective, the lack of standardized production protocols and quality control metrics specific to potassium-based systems hinders scalability. The higher sensitivity of potassium materials to ambient conditions necessitates more stringent manufacturing environments than those established for lithium-ion batteries.

Cost considerations present additional challenges, as current hybrid potassium battery prototypes require specialized materials and processing techniques that offset the inherent cost advantage of abundant potassium resources. The balance between performance enhancement and cost-effectiveness remains difficult to achieve in existing designs.

State-of-the-Art Hybrid KDIB Design Approaches

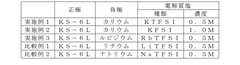

01 Electrode materials for potassium dual-ion batteries

Various electrode materials can be used in potassium dual-ion batteries to enhance power performance. These include carbon-based materials like graphite and hard carbon, as well as metal oxides and organic compounds. The selection of appropriate electrode materials is crucial for achieving high power density and cycling stability in hybrid potassium dual-ion batteries. These materials facilitate efficient potassium ion intercalation and deintercalation processes.- Electrode materials for potassium dual-ion batteries: Various electrode materials can be used in potassium dual-ion batteries to enhance power performance. These include carbon-based materials (graphite, hard carbon), transition metal compounds, and organic materials. The selection and optimization of these electrode materials significantly impact the battery's capacity, cycling stability, and power output. Advanced electrode designs with optimized structures can facilitate faster ion transport and electron transfer, resulting in higher power density.

- Electrolyte formulations for high-power performance: Specialized electrolyte formulations play a crucial role in potassium dual-ion batteries for high-power applications. These formulations typically include potassium salts dissolved in organic solvents, with additives to enhance stability and conductivity. The concentration and composition of the electrolyte directly affect ion mobility, interfacial resistance, and overall battery performance. Optimized electrolyte systems can significantly improve rate capability and power output while maintaining good cycling stability.

- Hybrid battery system architectures: Hybrid potassium dual-ion battery systems combine different battery technologies or materials to leverage their respective advantages. These hybrid architectures may integrate potassium-ion storage with other mechanisms such as capacitive storage or alternative ion systems. The synergistic effect of these combinations can lead to enhanced power density, energy density, and cycling performance. Design considerations include optimizing the ratio of different components and ensuring compatibility between the hybrid elements.

- Advanced manufacturing techniques for high-power batteries: Manufacturing processes significantly impact the performance of hybrid potassium dual-ion batteries. Advanced techniques such as controlled particle synthesis, precise electrode fabrication, and innovative cell assembly methods can enhance power capabilities. These processes focus on optimizing interfaces, reducing resistance, and ensuring uniform distribution of active materials. Precision manufacturing enables better control over microstructure and morphology, which directly influences ion diffusion pathways and electron transport, ultimately leading to higher power output.

- Battery management and power optimization systems: Sophisticated battery management systems are essential for maximizing the power performance of hybrid potassium dual-ion batteries. These systems monitor and control parameters such as temperature, voltage, and current to optimize operation and prevent degradation. Advanced algorithms can dynamically adjust charging and discharging protocols based on power demands and battery state. Thermal management solutions help maintain optimal operating temperatures during high-power applications, while electronic control systems ensure balanced utilization of the battery's capacity.

02 Electrolyte compositions for enhanced performance

Specialized electrolyte formulations play a critical role in hybrid potassium dual-ion batteries. These may include potassium salts dissolved in organic solvents, ionic liquids, or polymer-based electrolytes. The electrolyte composition affects ion transport, interfacial stability, and overall battery performance. Additives can be incorporated to improve the electrolyte-electrode interface, reduce side reactions, and enhance the power capability of the battery system.Expand Specific Solutions03 Battery structure and cell design optimization

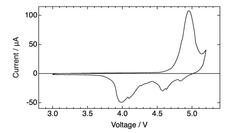

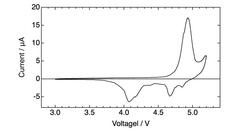

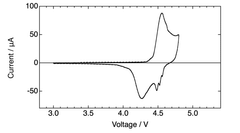

The structural design of hybrid potassium dual-ion batteries significantly impacts their power performance. This includes considerations such as electrode thickness, separator properties, current collector materials, and cell assembly techniques. Optimized cell designs can reduce internal resistance, improve ion diffusion pathways, and enhance heat dissipation, all contributing to higher power capabilities. Advanced manufacturing techniques ensure uniform electrode coating and optimal electrolyte distribution.Expand Specific Solutions04 Dual-ion intercalation mechanisms

Hybrid potassium dual-ion batteries operate on the principle of simultaneous intercalation of both potassium cations and anions into different electrodes. This dual-ion mechanism allows for higher energy density and power output compared to conventional battery systems. Understanding and optimizing the intercalation kinetics of both ion types is essential for achieving high power performance. The dual-ion approach also helps mitigate issues related to volume expansion during cycling.Expand Specific Solutions05 Hybrid battery system integration

Hybrid potassium dual-ion batteries can be integrated with other energy storage technologies to create hybrid systems with enhanced power capabilities. These hybrid configurations may combine the high energy density of potassium-based chemistry with the high power characteristics of supercapacitors or other battery chemistries. System-level design considerations include thermal management, battery management systems, and power electronics for optimal performance across various operating conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions in KDIB Field

The hybrid potassium dual-ion battery (KDIB) market is currently in an early growth phase, characterized by intensive R&D activities across academic institutions and industrial players. Market size remains relatively modest but shows promising expansion potential due to increasing demand for high-power energy storage solutions. From a technological maturity perspective, KDIBs are transitioning from laboratory research to early commercialization stages. Leading research institutions like Shenzhen Institutes of Advanced Technology and Central South University are advancing fundamental science, while established corporations including Samsung SDI, NEC, and Toshiba are developing proprietary technologies. Industrial players such as Kawasaki Heavy Industries and Robert Bosch are exploring applications in transportation and industrial sectors. The competitive landscape features collaboration between academic institutions and commercial entities, with Asian companies (particularly Japanese and Chinese) demonstrating significant patent activity and technological advancement in this emerging field.

The Shenzhen Institutes of Advanced Technology

Technical Solution: The Shenzhen Institutes of Advanced Technology (SIAT) has developed cutting-edge hybrid potassium dual-ion battery technology through their Energy Research Institute. Their approach utilizes a novel electrode architecture combining expanded graphite cathodes with potassium-rich Prussian blue analogue anodes. SIAT's research has focused on electrolyte engineering, developing concentrated electrolyte formulations based on potassium bis(fluorosulfonyl)imide (KFSI) in ether-based solvents that significantly suppress potassium dendrite formation and enhance anion intercalation kinetics. Their prototype cells demonstrate power densities exceeding 2000 W/kg while maintaining energy densities of approximately 90-110 Wh/kg. SIAT has pioneered advanced characterization techniques including in-situ transmission electron microscopy to visualize ion transport mechanisms at the nanoscale, leading to fundamental understanding of intercalation processes in dual-ion systems. Their research has also explored the use of biomass-derived carbon materials as sustainable electrode components, demonstrating comparable performance to synthetic carbons while reducing environmental impact. SIAT's technology shows particular promise for grid-scale energy storage applications requiring high power capability and long cycle life.

Strengths: Exceptional power density surpassing many commercial alternatives; utilization of abundant and low-cost materials; demonstrated cycle life exceeding 2000 cycles with minimal capacity degradation. Weaknesses: Lower energy density compared to commercial lithium-ion technologies; challenges with scaling laboratory prototypes to commercial cell formats; current reliance on specialized manufacturing techniques that may limit mass production feasibility.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed advanced hybrid potassium dual-ion battery (KPIB) technology that combines potassium-ion and dual-ion mechanisms to achieve high power density. Their approach utilizes graphite cathodes and potassium metal anodes with optimized electrolyte formulations containing potassium salts (typically KPF6) in organic solvents. The company has engineered specialized electrolyte additives that form stable solid electrolyte interphase (SEI) layers, significantly reducing dendrite formation on the potassium metal anode. Samsung's KPIB cells demonstrate power densities exceeding 1000 W/kg while maintaining energy densities around 130-150 Wh/kg, positioning them between supercapacitors and traditional lithium-ion batteries in performance characteristics. Their proprietary electrode manufacturing process incorporates nano-structured carbon materials that enhance ion intercalation kinetics and improve rate capability.

Strengths: Superior power density compared to conventional lithium-ion batteries; cost advantage due to abundant potassium resources; excellent cycling stability (>1000 cycles with minimal capacity fade). Weaknesses: Lower energy density than commercial lithium-ion batteries; challenges with potassium metal anode stability at high cycling rates; temperature sensitivity requiring advanced thermal management systems.

Critical Patents and Breakthroughs in Electrode Materials

Dual-ion battery

PatentWO2022004623A1

Innovation

- A dual ion battery design featuring a positive electrode with a carbonaceous material and a negative electrode containing potassium or rubidium metal, facilitating an anion insertion/extraction reaction and metal precipitation/dissolution reaction, respectively, to enable high-voltage charging and discharging.

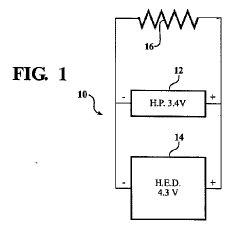

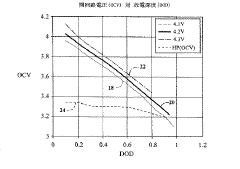

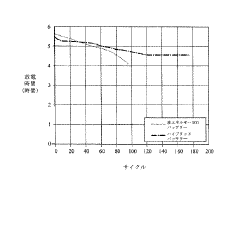

hybrid battery system

PatentActiveJP2015508552A

Innovation

- A hybrid rechargeable battery system comprising high power cells and high energy density cells with different voltages, charge/discharge characteristics, and chemistries, designed with impedance matching, allowing for self-regulation without the need for additional charge controllers.

Material Sustainability and Resource Availability Assessment

The sustainability of materials used in hybrid potassium dual-ion batteries (KDIBs) represents a critical factor in their long-term viability as high-power energy storage solutions. Potassium resources demonstrate significant advantages over lithium, with global potassium reserves estimated at approximately 250 billion tons—over 1,000 times more abundant than lithium reserves. This abundance translates directly to lower material costs, with potassium salts typically priced at one-third the cost of their lithium counterparts.

The extraction processes for potassium compounds generally require less water and energy compared to lithium extraction, particularly when compared to the water-intensive brine evaporation methods used for lithium in South America. Potassium is primarily sourced from potash mining operations, which are geographically distributed across Canada, Russia, Belarus, and China, reducing supply chain vulnerabilities associated with geopolitical concentration.

Carbon materials, essential components in dual-ion battery cathodes, present another sustainability advantage. These materials can be derived from renewable biomass sources or recycled carbon waste, offering pathways to reduce the environmental footprint of battery production. Recent research demonstrates promising results using sustainable carbon precursors such as lignin, cellulose, and agricultural waste to create high-performance carbon cathodes.

The recyclability profile of KDIBs shows potential advantages over conventional lithium-ion technologies. The simpler chemistry of potassium-based electrolytes facilitates more straightforward recycling processes. Additionally, the carbon-based electrodes can be more readily recovered and repurposed compared to transition metal-based cathodes in traditional batteries.

Life cycle assessments indicate that hybrid potassium dual-ion batteries could reduce greenhouse gas emissions by 30-45% compared to conventional lithium-ion batteries when accounting for material extraction, processing, and end-of-life considerations. This advantage stems primarily from the reduced energy requirements for potassium extraction and processing.

Critical material dependencies remain a consideration, particularly regarding electrolyte additives and specialized separator materials. While potassium itself poses no supply risk, certain fluorinated compounds used in electrolyte formulations face potential sustainability challenges due to their environmental persistence and limited recycling options.

Future research directions should focus on developing fluorine-free electrolyte systems and exploring earth-abundant alternatives to graphite for anode materials to further enhance the sustainability profile of hybrid potassium dual-ion battery technologies.

The extraction processes for potassium compounds generally require less water and energy compared to lithium extraction, particularly when compared to the water-intensive brine evaporation methods used for lithium in South America. Potassium is primarily sourced from potash mining operations, which are geographically distributed across Canada, Russia, Belarus, and China, reducing supply chain vulnerabilities associated with geopolitical concentration.

Carbon materials, essential components in dual-ion battery cathodes, present another sustainability advantage. These materials can be derived from renewable biomass sources or recycled carbon waste, offering pathways to reduce the environmental footprint of battery production. Recent research demonstrates promising results using sustainable carbon precursors such as lignin, cellulose, and agricultural waste to create high-performance carbon cathodes.

The recyclability profile of KDIBs shows potential advantages over conventional lithium-ion technologies. The simpler chemistry of potassium-based electrolytes facilitates more straightforward recycling processes. Additionally, the carbon-based electrodes can be more readily recovered and repurposed compared to transition metal-based cathodes in traditional batteries.

Life cycle assessments indicate that hybrid potassium dual-ion batteries could reduce greenhouse gas emissions by 30-45% compared to conventional lithium-ion batteries when accounting for material extraction, processing, and end-of-life considerations. This advantage stems primarily from the reduced energy requirements for potassium extraction and processing.

Critical material dependencies remain a consideration, particularly regarding electrolyte additives and specialized separator materials. While potassium itself poses no supply risk, certain fluorinated compounds used in electrolyte formulations face potential sustainability challenges due to their environmental persistence and limited recycling options.

Future research directions should focus on developing fluorine-free electrolyte systems and exploring earth-abundant alternatives to graphite for anode materials to further enhance the sustainability profile of hybrid potassium dual-ion battery technologies.

Safety Standards and Thermal Management Considerations

The safety standards for Hybrid Potassium Dual-Ion Batteries (KDIBs) are still evolving as this technology advances toward commercial applications. Current safety protocols primarily adapt existing lithium-ion battery standards, with modifications to address potassium's unique chemical properties. Key safety standards include IEC 62660 for performance and abuse testing, UL 1642 for cell-level safety requirements, and UN 38.3 for transportation regulations. These standards must be revised to account for potassium's higher reactivity with water compared to lithium, requiring more stringent moisture control protocols during manufacturing and operation.

Thermal management represents a critical challenge for high-power KDIBs due to their elevated operating temperatures and potential for thermal runaway. The dual-ion mechanism, involving both cation and anion intercalation, generates significant heat during rapid charging and discharging cycles. Effective thermal management systems must maintain cell temperatures between 15-35°C to optimize performance while preventing degradation mechanisms that accelerate at higher temperatures.

Advanced cooling strategies being developed specifically for hybrid KDIBs include phase-change materials (PCMs) that absorb excess heat during operation, liquid cooling systems with potassium-compatible coolants, and composite heat spreaders that efficiently distribute thermal energy across battery packs. These systems must be designed to handle the unique thermal signature of dual-ion intercalation processes, which differ significantly from conventional lithium-ion batteries.

Safety testing protocols for KDIBs emphasize nail penetration tests, thermal abuse evaluations, and overcharge/overdischarge scenarios. Recent research indicates that graphite-based cathodes in KDIBs demonstrate improved thermal stability compared to transition metal oxide cathodes in conventional lithium-ion systems, potentially offering inherent safety advantages when properly managed.

Fire suppression systems for KDIB installations require potassium-specific formulations, as traditional lithium-ion fire suppressants may be ineffective or potentially reactive. Class D fire extinguishing agents compatible with alkali metals are recommended for facility safety planning. Battery management systems (BMS) for KDIBs must incorporate specialized algorithms to detect thermal anomalies earlier in their development cycle, as the thermal runaway progression in potassium systems can differ from lithium-ion batteries.

Emerging research suggests that hybrid electrolyte formulations may offer improved safety profiles by reducing flammability while maintaining ionic conductivity. These developments, coupled with advanced thermal management strategies, will be essential for the safe deployment of high-power KDIB systems in applications where thermal loads are significant, such as grid storage and electric vehicle fast-charging infrastructure.

Thermal management represents a critical challenge for high-power KDIBs due to their elevated operating temperatures and potential for thermal runaway. The dual-ion mechanism, involving both cation and anion intercalation, generates significant heat during rapid charging and discharging cycles. Effective thermal management systems must maintain cell temperatures between 15-35°C to optimize performance while preventing degradation mechanisms that accelerate at higher temperatures.

Advanced cooling strategies being developed specifically for hybrid KDIBs include phase-change materials (PCMs) that absorb excess heat during operation, liquid cooling systems with potassium-compatible coolants, and composite heat spreaders that efficiently distribute thermal energy across battery packs. These systems must be designed to handle the unique thermal signature of dual-ion intercalation processes, which differ significantly from conventional lithium-ion batteries.

Safety testing protocols for KDIBs emphasize nail penetration tests, thermal abuse evaluations, and overcharge/overdischarge scenarios. Recent research indicates that graphite-based cathodes in KDIBs demonstrate improved thermal stability compared to transition metal oxide cathodes in conventional lithium-ion systems, potentially offering inherent safety advantages when properly managed.

Fire suppression systems for KDIB installations require potassium-specific formulations, as traditional lithium-ion fire suppressants may be ineffective or potentially reactive. Class D fire extinguishing agents compatible with alkali metals are recommended for facility safety planning. Battery management systems (BMS) for KDIBs must incorporate specialized algorithms to detect thermal anomalies earlier in their development cycle, as the thermal runaway progression in potassium systems can differ from lithium-ion batteries.

Emerging research suggests that hybrid electrolyte formulations may offer improved safety profiles by reducing flammability while maintaining ionic conductivity. These developments, coupled with advanced thermal management strategies, will be essential for the safe deployment of high-power KDIB systems in applications where thermal loads are significant, such as grid storage and electric vehicle fast-charging infrastructure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!