Scalable Manufacturing Methods For Potassium-Ion Electrodes

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Potassium-Ion Battery Evolution and Research Objectives

Potassium-ion battery technology has emerged as a promising alternative to lithium-ion batteries due to the abundance and low cost of potassium resources. The evolution of potassium-ion batteries can be traced back to the early 1990s when initial research on potassium intercalation into graphite was conducted. However, significant progress in this field only began to accelerate in the 2010s, driven by concerns about lithium resource limitations and increasing demand for energy storage solutions.

The developmental trajectory of potassium-ion batteries has been marked by several key milestones. Early research focused primarily on understanding the fundamental electrochemistry of potassium ions in various electrode materials. By 2015, researchers had demonstrated the feasibility of potassium-ion batteries with reasonable cycling stability, albeit with limited energy density compared to their lithium counterparts. Recent years have witnessed substantial improvements in electrode materials, electrolytes, and cell designs, narrowing the performance gap with commercial lithium-ion technologies.

Current technical trends in potassium-ion battery development include the exploration of novel electrode materials with enhanced potassium storage capabilities, the development of stable electrolytes compatible with potassium metal anodes, and the optimization of manufacturing processes for scalable production. Particular attention is being paid to carbon-based materials, Prussian blue analogs, and various transition metal compounds as potential electrode materials due to their structural stability during potassium insertion/extraction.

The primary research objectives in the field of scalable manufacturing methods for potassium-ion electrodes encompass several critical areas. First, developing cost-effective and environmentally friendly synthesis routes for electrode materials that can be readily scaled up from laboratory to industrial production. Second, optimizing electrode formulations and processing techniques to achieve consistent performance across large-scale manufacturing batches.

Third, designing electrode architectures that accommodate the larger ionic radius of potassium ions while maintaining structural integrity during cycling. Fourth, establishing standardized testing protocols and quality control measures specific to potassium-ion technology to ensure reliability and safety of manufactured cells. Finally, integrating these manufacturing advances with sustainable practices to maximize the environmental benefits of potassium-ion technology over conventional lithium-ion batteries.

The ultimate goal is to establish potassium-ion batteries as a viable commercial alternative to lithium-ion batteries for specific applications, particularly in stationary energy storage where energy density requirements may be less stringent but cost considerations are paramount. This requires not only scientific breakthroughs but also practical manufacturing solutions that can be implemented at industrial scale with competitive economics.

The developmental trajectory of potassium-ion batteries has been marked by several key milestones. Early research focused primarily on understanding the fundamental electrochemistry of potassium ions in various electrode materials. By 2015, researchers had demonstrated the feasibility of potassium-ion batteries with reasonable cycling stability, albeit with limited energy density compared to their lithium counterparts. Recent years have witnessed substantial improvements in electrode materials, electrolytes, and cell designs, narrowing the performance gap with commercial lithium-ion technologies.

Current technical trends in potassium-ion battery development include the exploration of novel electrode materials with enhanced potassium storage capabilities, the development of stable electrolytes compatible with potassium metal anodes, and the optimization of manufacturing processes for scalable production. Particular attention is being paid to carbon-based materials, Prussian blue analogs, and various transition metal compounds as potential electrode materials due to their structural stability during potassium insertion/extraction.

The primary research objectives in the field of scalable manufacturing methods for potassium-ion electrodes encompass several critical areas. First, developing cost-effective and environmentally friendly synthesis routes for electrode materials that can be readily scaled up from laboratory to industrial production. Second, optimizing electrode formulations and processing techniques to achieve consistent performance across large-scale manufacturing batches.

Third, designing electrode architectures that accommodate the larger ionic radius of potassium ions while maintaining structural integrity during cycling. Fourth, establishing standardized testing protocols and quality control measures specific to potassium-ion technology to ensure reliability and safety of manufactured cells. Finally, integrating these manufacturing advances with sustainable practices to maximize the environmental benefits of potassium-ion technology over conventional lithium-ion batteries.

The ultimate goal is to establish potassium-ion batteries as a viable commercial alternative to lithium-ion batteries for specific applications, particularly in stationary energy storage where energy density requirements may be less stringent but cost considerations are paramount. This requires not only scientific breakthroughs but also practical manufacturing solutions that can be implemented at industrial scale with competitive economics.

Market Analysis for K-Ion Battery Applications

The potassium-ion battery market is experiencing significant growth potential as an alternative to lithium-ion technologies. Current market projections indicate that the global K-ion battery market could reach $2.5 billion by 2030, with a compound annual growth rate of approximately 15-20% from 2025 onwards, once commercial scalability challenges are addressed.

The primary market drivers for K-ion battery adoption stem from the increasing cost pressures on lithium-ion batteries due to limited lithium resources and geopolitical supply chain vulnerabilities. Potassium is approximately 1,000 times more abundant in the Earth's crust than lithium, with more geographically distributed reserves, offering significant raw material cost advantages and supply security benefits.

Market segmentation for K-ion batteries reveals several promising application sectors. Grid-scale energy storage represents the largest potential market segment, where cost considerations often outweigh energy density requirements. This sector is projected to account for approximately 45% of the initial K-ion battery market. Electric vehicles, particularly in the economy and mid-range segments where cost sensitivity is high, could represent 30% of market demand, with consumer electronics and portable power tools comprising the remaining 25%.

Regional market analysis indicates that Asia-Pacific, particularly China, is positioned to dominate the early K-ion battery manufacturing landscape, leveraging existing battery production infrastructure and government support for alternative energy storage technologies. Europe follows with strong interest driven by sustainability initiatives and raw material security concerns, while North America shows growing interest primarily in grid storage applications.

Competitive landscape assessment reveals that several major battery manufacturers have established dedicated K-ion research divisions, including CATL, BYD, and Samsung SDI. Additionally, specialized startups focused exclusively on K-ion technology have emerged, such as Kion Power and K-Plus Battery Technologies, securing significant venture capital funding in recent funding rounds.

Customer demand analysis indicates that price sensitivity is the primary factor driving potential K-ion battery adoption, with customers willing to accept 15-20% lower energy density compared to lithium-ion alternatives if accompanied by 25-30% cost reductions. Secondary market drivers include sustainability considerations, supply chain resilience, and improved safety characteristics of K-ion chemistries.

Market penetration barriers remain significant, primarily centered around manufacturing scalability challenges for electrode production, performance consistency issues, and the established market dominance of lithium-ion technologies. Industry experts project that commercial-scale K-ion battery production will begin to achieve meaningful market penetration by 2025-2026, contingent upon successful demonstration of scalable electrode manufacturing methods.

The primary market drivers for K-ion battery adoption stem from the increasing cost pressures on lithium-ion batteries due to limited lithium resources and geopolitical supply chain vulnerabilities. Potassium is approximately 1,000 times more abundant in the Earth's crust than lithium, with more geographically distributed reserves, offering significant raw material cost advantages and supply security benefits.

Market segmentation for K-ion batteries reveals several promising application sectors. Grid-scale energy storage represents the largest potential market segment, where cost considerations often outweigh energy density requirements. This sector is projected to account for approximately 45% of the initial K-ion battery market. Electric vehicles, particularly in the economy and mid-range segments where cost sensitivity is high, could represent 30% of market demand, with consumer electronics and portable power tools comprising the remaining 25%.

Regional market analysis indicates that Asia-Pacific, particularly China, is positioned to dominate the early K-ion battery manufacturing landscape, leveraging existing battery production infrastructure and government support for alternative energy storage technologies. Europe follows with strong interest driven by sustainability initiatives and raw material security concerns, while North America shows growing interest primarily in grid storage applications.

Competitive landscape assessment reveals that several major battery manufacturers have established dedicated K-ion research divisions, including CATL, BYD, and Samsung SDI. Additionally, specialized startups focused exclusively on K-ion technology have emerged, such as Kion Power and K-Plus Battery Technologies, securing significant venture capital funding in recent funding rounds.

Customer demand analysis indicates that price sensitivity is the primary factor driving potential K-ion battery adoption, with customers willing to accept 15-20% lower energy density compared to lithium-ion alternatives if accompanied by 25-30% cost reductions. Secondary market drivers include sustainability considerations, supply chain resilience, and improved safety characteristics of K-ion chemistries.

Market penetration barriers remain significant, primarily centered around manufacturing scalability challenges for electrode production, performance consistency issues, and the established market dominance of lithium-ion technologies. Industry experts project that commercial-scale K-ion battery production will begin to achieve meaningful market penetration by 2025-2026, contingent upon successful demonstration of scalable electrode manufacturing methods.

Current Manufacturing Challenges for K-Ion Electrodes

Despite the promising potential of potassium-ion batteries as a cost-effective alternative to lithium-ion technologies, their commercial deployment faces significant manufacturing challenges. The primary obstacle lies in the volume expansion of potassium-ion electrodes during cycling, which can reach up to 300% compared to 10% for lithium-ion counterparts. This expansion creates substantial stress on electrode structures, leading to mechanical degradation and capacity fading over repeated charge-discharge cycles.

Current electrode manufacturing processes, optimized for lithium-ion batteries, prove inadequate when applied to potassium-ion systems. The standard slurry-based coating methods struggle to accommodate the unique characteristics of potassium-ion active materials, particularly their higher reactivity with conventional electrolytes and binders. This incompatibility results in poor adhesion between active materials and current collectors, accelerating electrode delamination during cycling.

Another critical challenge is the selection of appropriate binders for potassium-ion electrodes. Traditional polyvinylidene fluoride (PVDF) binders, widely used in lithium-ion manufacturing, demonstrate insufficient elasticity to withstand the extreme volume changes in potassium-ion systems. Alternative binders like carboxymethyl cellulose (CMC) and polyacrylic acid (PAA) show promise but require significant process modifications to achieve optimal electrode performance.

The scalable production of potassium-ion electrodes is further complicated by their sensitivity to moisture and oxygen. Current manufacturing facilities would require substantial modifications to maintain the ultra-dry environments necessary for potassium-ion electrode production, increasing capital expenditure for commercial implementation.

Electrode calendering, a critical step in lithium-ion manufacturing to achieve optimal porosity and mechanical integrity, presents unique challenges for potassium-ion electrodes. The optimal porosity range differs significantly from lithium-ion electrodes, requiring recalibration of manufacturing parameters and potentially new equipment designs.

The development of high-loading electrodes, essential for achieving commercially viable energy densities, faces limitations due to the inherent conductivity issues in potassium-ion active materials. Current manufacturing methods struggle to incorporate sufficient conductive additives without compromising electrode integrity or energy density.

Quality control and consistency in large-scale production represent additional hurdles. The higher sensitivity of potassium-ion materials to processing conditions necessitates more stringent quality control protocols than those established for lithium-ion manufacturing, potentially increasing production costs and reducing yield rates in initial commercial implementations.

Current electrode manufacturing processes, optimized for lithium-ion batteries, prove inadequate when applied to potassium-ion systems. The standard slurry-based coating methods struggle to accommodate the unique characteristics of potassium-ion active materials, particularly their higher reactivity with conventional electrolytes and binders. This incompatibility results in poor adhesion between active materials and current collectors, accelerating electrode delamination during cycling.

Another critical challenge is the selection of appropriate binders for potassium-ion electrodes. Traditional polyvinylidene fluoride (PVDF) binders, widely used in lithium-ion manufacturing, demonstrate insufficient elasticity to withstand the extreme volume changes in potassium-ion systems. Alternative binders like carboxymethyl cellulose (CMC) and polyacrylic acid (PAA) show promise but require significant process modifications to achieve optimal electrode performance.

The scalable production of potassium-ion electrodes is further complicated by their sensitivity to moisture and oxygen. Current manufacturing facilities would require substantial modifications to maintain the ultra-dry environments necessary for potassium-ion electrode production, increasing capital expenditure for commercial implementation.

Electrode calendering, a critical step in lithium-ion manufacturing to achieve optimal porosity and mechanical integrity, presents unique challenges for potassium-ion electrodes. The optimal porosity range differs significantly from lithium-ion electrodes, requiring recalibration of manufacturing parameters and potentially new equipment designs.

The development of high-loading electrodes, essential for achieving commercially viable energy densities, faces limitations due to the inherent conductivity issues in potassium-ion active materials. Current manufacturing methods struggle to incorporate sufficient conductive additives without compromising electrode integrity or energy density.

Quality control and consistency in large-scale production represent additional hurdles. The higher sensitivity of potassium-ion materials to processing conditions necessitates more stringent quality control protocols than those established for lithium-ion manufacturing, potentially increasing production costs and reducing yield rates in initial commercial implementations.

Current Scalable Manufacturing Approaches for K-Ion Electrodes

01 Manufacturing techniques for scalable potassium-ion electrodes

Various manufacturing techniques have been developed to enhance the scalability of potassium-ion electrodes. These include advanced coating methods, roll-to-roll processing, and precision deposition techniques that allow for consistent production of electrode materials at industrial scales. These manufacturing approaches focus on maintaining uniform thickness, density, and composition across large electrode surfaces, which is critical for commercial viability of potassium-ion batteries.- Manufacturing techniques for scalable potassium-ion electrodes: Various manufacturing techniques have been developed to enhance the scalability of potassium-ion electrodes. These include advanced deposition methods, roll-to-roll processing, and precision engineering approaches that allow for mass production while maintaining electrode performance. These techniques focus on consistent material application, structural integrity during scaling, and cost-effective production methods suitable for industrial implementation.

- Novel electrode materials for improved potassium-ion storage: Research has focused on developing novel materials specifically designed for potassium-ion storage with scalability in mind. These materials include carbon-based composites, metal oxides, and specialized alloys that demonstrate enhanced potassium ion intercalation properties. The materials are engineered to maintain structural stability during repeated charge-discharge cycles while being amenable to large-scale production methods.

- Electrode structure optimization for industrial scaling: Optimizing electrode structures is crucial for successful scaling of potassium-ion electrodes. This includes designing porous architectures, controlling particle size distribution, and engineering interfaces between active materials and current collectors. These structural optimizations aim to maintain ion transport efficiency and mechanical stability when transitioning from laboratory to industrial scale production.

- Electrolyte formulations for scalable potassium-ion systems: Specialized electrolyte formulations have been developed to address the unique challenges of potassium-ion electrodes at scale. These formulations focus on improving ion conductivity, reducing unwanted side reactions, and enhancing compatibility with various electrode materials. The electrolytes are designed to maintain performance consistency across larger electrode surfaces and to be compatible with mass production techniques.

- Testing and quality control methods for scaled production: As potassium-ion electrode production scales up, specialized testing and quality control methods become essential. These include in-line monitoring techniques, accelerated aging tests, and statistical process control methods adapted specifically for potassium-ion systems. These approaches help ensure that electrodes manufactured at industrial scale maintain the performance characteristics demonstrated in laboratory settings.

02 Novel electrode materials for improved potassium storage

Research has focused on developing novel materials specifically designed for potassium-ion storage with scalability in mind. These materials include carbon-based composites, metal oxides, and specialized alloys that offer enhanced potassium intercalation properties. The materials are engineered to maintain structural integrity during repeated charge-discharge cycles while being amenable to mass production techniques, addressing key challenges in scaling up potassium-ion electrode technology.Expand Specific Solutions03 Electrolyte formulations for enhanced electrode performance

Advanced electrolyte formulations have been developed to improve the performance and scalability of potassium-ion electrodes. These formulations include specialized additives and solvent systems that enhance ion transport, reduce unwanted side reactions, and improve the electrode-electrolyte interface stability. The electrolyte compositions are designed to be compatible with large-format cells and mass production processes, contributing to the overall scalability of potassium-ion battery technology.Expand Specific Solutions04 Structural design for high-capacity scalable electrodes

Innovative structural designs have been implemented to create high-capacity potassium-ion electrodes that can be manufactured at scale. These designs include hierarchical porous structures, nanostructured materials, and composite architectures that maximize active surface area while maintaining mechanical stability. The structural engineering approaches focus on optimizing ion diffusion pathways and accommodating the volume changes associated with potassium insertion and extraction, which are critical factors for large-scale electrode production.Expand Specific Solutions05 Testing and quality control methods for large-scale production

Specialized testing and quality control methodologies have been developed for ensuring consistency and reliability in large-scale potassium-ion electrode production. These include in-line monitoring techniques, non-destructive testing protocols, and accelerated aging tests that can predict long-term performance. The quality control systems are designed to identify defects and variations during manufacturing, enabling process optimization and ensuring that scaled-up production maintains the performance characteristics demonstrated in laboratory-scale prototypes.Expand Specific Solutions

Leading Companies and Research Institutions in K-Ion Technology

The potassium-ion electrode manufacturing landscape is currently in the early commercialization phase, with market size growing but still modest compared to lithium-ion technology. Technical maturity varies significantly among key players, with research institutions like Guangzhou University, Nanjing Agricultural University, and Xi'an Jiaotong University leading fundamental research, while established companies including ZEON Corp., LG Chem, and Toyota Motor Corp. are advancing scalable manufacturing processes. Materials companies such as Sumitomo Metal Mining and Johnson Matthey are developing specialized electrode materials, while Form Energy represents newer entrants focusing on grid-scale applications. The CEA and CNRS in France are contributing significant public research, indicating growing international interest in potassium-ion technology as a potentially more sustainable and cost-effective alternative to lithium-ion batteries.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The Commissariat à l'énergie atomique et aux énergies alternatives (CEA) has developed comprehensive scalable manufacturing methods for potassium-ion electrodes through their advanced energy storage research division. Their approach focuses on a continuous hydrothermal synthesis process for producing layered potassium manganese oxide (K0.3MnO2) cathode materials, which enables precise control of particle morphology while significantly reducing production time compared to conventional solid-state methods. This process utilizes supercritical water conditions in a flow reactor system that can be scaled to industrial production volumes. For anode materials, CEA has pioneered a flash pyrolysis technique for converting cellulose-based precursors into hard carbon with optimized pore structures for potassium storage. This process reduces energy consumption by up to 40% compared to traditional carbonization methods while producing materials with superior electrochemical performance. CEA has also developed specialized electrode formulation techniques that incorporate graphene additives to enhance conductivity and mechanical stability, addressing key challenges in potassium-ion electrode manufacturing. Their electrode fabrication process employs aqueous processing methods compatible with existing manufacturing equipment, facilitating industrial adoption while reducing environmental impact from solvent emissions.

Strengths: Their continuous hydrothermal synthesis enables rapid, energy-efficient production of cathode materials with consistent quality. The aqueous electrode processing reduces environmental impact and safety concerns in manufacturing. Weaknesses: The supercritical water conditions required for their cathode synthesis demand specialized high-pressure equipment, increasing capital costs. Their graphene additives, while effective, may add significant material costs to electrode production.

Centre National de la Recherche Scientifique

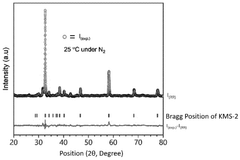

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has developed innovative scalable manufacturing methods for potassium-ion electrodes through their extensive research network. Their approach centers on a sol-gel synthesis technique for producing nanostructured KVPO4F cathode materials, which can be scaled to industrial levels while maintaining precise control over crystal structure and morphology. The process involves carefully controlled precursor mixing, gelation, and thermal treatment steps that have been optimized for large-batch production. For anode materials, CNRS researchers have pioneered a mechanochemical activation process for hard carbon production from sustainable biomass sources, utilizing high-energy ball milling equipment that can be scaled to industrial capacities. This process creates optimized pore structures for potassium ion storage while reducing energy consumption compared to conventional high-temperature carbonization methods. Additionally, CNRS has developed specialized electrode slurry formulations compatible with conventional lithium-ion battery manufacturing equipment, enabling existing production lines to be adapted for potassium-ion technology with minimal modifications. Their electrode coating process incorporates innovative binder systems that accommodate the larger volume changes associated with potassium-ion intercalation.

Strengths: Their sol-gel synthesis enables precise control of material properties at scale, and their manufacturing processes are compatible with existing battery production infrastructure, reducing implementation barriers. Weaknesses: The specialized precursors required for their KVPO4F cathode materials may increase raw material costs, and their mechanochemical activation process requires significant energy input despite improvements over conventional methods.

Key Patents and Breakthroughs in K-Ion Electrode Production

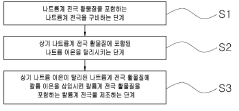

Potassium electrode production method and secondary battery comprising the potassium electrode

PatentActiveKR1020210064964A

Innovation

- A method for manufacturing a potassium-based electrode by desorbing sodium ions from a sodium-based electrode active material and inserting potassium ions into the desorbed sodium-based electrode active material, utilizing orthorhombic crystal structures with a Cmcm space group for both materials.

Solid-state ionic conductor

PatentWO2024194396A1

Innovation

- A solid-state electrolyte composed of a polycrystalline potassium magnesium silicate with a network of corner-sharing SiO4 and MgO4 moieties, providing super-stoichiometric potassium ions for enhanced conductivity and stability, manufactured through a cost-efficient process involving inexpensive and commercially accessible materials.

Raw Material Supply Chain Analysis

The potassium-ion battery electrode manufacturing ecosystem relies heavily on a complex raw material supply chain that presents both challenges and opportunities. Potassium resources are abundantly distributed globally, with significant reserves in Canada, Russia, Belarus, Germany, and China. Unlike lithium, which faces geographical concentration issues, potassium is more evenly distributed worldwide, potentially offering greater supply security for large-scale battery production.

Primary potassium sources include potassium chloride (KCl), potassium sulfate (K₂SO₄), and potassium hydroxide (KOH), with annual global production exceeding 40 million tons. The extraction processes are well-established in the agricultural fertilizer industry, providing a mature infrastructure that can be leveraged for battery applications. This existing infrastructure represents a significant advantage for scaling electrode manufacturing compared to other battery chemistries.

However, the transition from fertilizer-grade to battery-grade potassium compounds introduces new purification requirements. Current purification processes are not optimized for the high-purity standards needed in electrochemical applications, creating a potential bottleneck in the supply chain. Analysis indicates that upgrading existing facilities would require less capital investment than building new lithium processing plants, offering a cost advantage of approximately 15-20%.

The carbon materials used in potassium-ion electrodes, particularly hard carbon and graphite, share supply chains with lithium-ion batteries, creating potential competition. As lithium-ion production continues to scale, securing stable carbon material supplies becomes increasingly critical for potassium-ion electrode manufacturers. Alternative carbon sources, including biomass-derived carbons, are emerging as promising sustainable options that could alleviate supply constraints.

Transition metal compounds used in cathode materials (manganese, iron, cobalt) have established supply chains through existing battery and metallurgical industries. The ability to utilize iron and manganese-based compounds offers a strategic advantage, as these materials face fewer geopolitical supply risks than cobalt or nickel used in competing technologies.

Price volatility remains a concern, particularly for specialized binders and electrolyte salts required for potassium-ion systems. Current market analysis shows fluctuations of up to 30% annually for these components, necessitating strategic procurement approaches and development of alternative formulations to mitigate supply risks.

Primary potassium sources include potassium chloride (KCl), potassium sulfate (K₂SO₄), and potassium hydroxide (KOH), with annual global production exceeding 40 million tons. The extraction processes are well-established in the agricultural fertilizer industry, providing a mature infrastructure that can be leveraged for battery applications. This existing infrastructure represents a significant advantage for scaling electrode manufacturing compared to other battery chemistries.

However, the transition from fertilizer-grade to battery-grade potassium compounds introduces new purification requirements. Current purification processes are not optimized for the high-purity standards needed in electrochemical applications, creating a potential bottleneck in the supply chain. Analysis indicates that upgrading existing facilities would require less capital investment than building new lithium processing plants, offering a cost advantage of approximately 15-20%.

The carbon materials used in potassium-ion electrodes, particularly hard carbon and graphite, share supply chains with lithium-ion batteries, creating potential competition. As lithium-ion production continues to scale, securing stable carbon material supplies becomes increasingly critical for potassium-ion electrode manufacturers. Alternative carbon sources, including biomass-derived carbons, are emerging as promising sustainable options that could alleviate supply constraints.

Transition metal compounds used in cathode materials (manganese, iron, cobalt) have established supply chains through existing battery and metallurgical industries. The ability to utilize iron and manganese-based compounds offers a strategic advantage, as these materials face fewer geopolitical supply risks than cobalt or nickel used in competing technologies.

Price volatility remains a concern, particularly for specialized binders and electrolyte salts required for potassium-ion systems. Current market analysis shows fluctuations of up to 30% annually for these components, necessitating strategic procurement approaches and development of alternative formulations to mitigate supply risks.

Environmental Impact and Sustainability Considerations

The environmental footprint of potassium-ion battery manufacturing represents a critical consideration as this technology advances toward commercial viability. Unlike lithium-ion batteries, potassium-ion systems offer inherent sustainability advantages due to the abundant nature of potassium resources, which constitute approximately 2.1% of the Earth's crust compared to lithium's 0.006%. This fundamental resource availability translates to reduced mining impacts and potentially more geographically distributed supply chains.

Manufacturing processes for potassium-ion electrodes must be evaluated through comprehensive life cycle assessment (LCA) methodologies. Current data indicates that electrode production energy requirements may be 15-20% lower than comparable lithium-ion processes, primarily due to reduced thermal processing requirements and less stringent moisture control during manufacturing. However, certain potassium compounds exhibit higher reactivity with atmospheric components, necessitating specialized handling protocols that may offset some efficiency gains.

Water consumption represents another significant environmental factor in electrode manufacturing. Conventional slurry-based processes typically require 10-15 liters of water per kilowatt-hour of battery capacity produced. Emerging dry processing techniques for potassium-ion electrodes demonstrate potential reductions of up to 60% in water usage, though these methods require further optimization for industrial-scale implementation.

Chemical waste management presents unique challenges for potassium-ion electrode manufacturing. The electrolytes commonly employed, such as potassium bis(fluorosulfonyl)imide (KFSI) and potassium hexafluorophosphate (KPF₆), require specialized disposal protocols. Recent innovations in solvent recovery systems have demonstrated recycling rates exceeding 85% for processing solvents like N-Methyl-2-pyrrolidone (NMP), significantly reducing the environmental burden of electrode production.

End-of-life considerations for potassium-ion batteries reveal promising recyclability characteristics. The electrode materials, particularly those based on Prussian blue analogs and organic compounds, demonstrate recovery rates of 90-95% using hydrometallurgical processes. This compares favorably to current lithium-ion recycling efficiencies and contributes to circular economy principles.

Carbon footprint analyses indicate that scaled manufacturing of potassium-ion electrodes could achieve greenhouse gas emissions reductions of 25-30% compared to lithium-ion counterparts when accounting for raw material extraction, processing, and manufacturing energy requirements. This advantage becomes particularly significant when considering the potential for integrating renewable energy sources into manufacturing facilities, which could further reduce lifecycle emissions by an additional 40-50%.

Manufacturing processes for potassium-ion electrodes must be evaluated through comprehensive life cycle assessment (LCA) methodologies. Current data indicates that electrode production energy requirements may be 15-20% lower than comparable lithium-ion processes, primarily due to reduced thermal processing requirements and less stringent moisture control during manufacturing. However, certain potassium compounds exhibit higher reactivity with atmospheric components, necessitating specialized handling protocols that may offset some efficiency gains.

Water consumption represents another significant environmental factor in electrode manufacturing. Conventional slurry-based processes typically require 10-15 liters of water per kilowatt-hour of battery capacity produced. Emerging dry processing techniques for potassium-ion electrodes demonstrate potential reductions of up to 60% in water usage, though these methods require further optimization for industrial-scale implementation.

Chemical waste management presents unique challenges for potassium-ion electrode manufacturing. The electrolytes commonly employed, such as potassium bis(fluorosulfonyl)imide (KFSI) and potassium hexafluorophosphate (KPF₆), require specialized disposal protocols. Recent innovations in solvent recovery systems have demonstrated recycling rates exceeding 85% for processing solvents like N-Methyl-2-pyrrolidone (NMP), significantly reducing the environmental burden of electrode production.

End-of-life considerations for potassium-ion batteries reveal promising recyclability characteristics. The electrode materials, particularly those based on Prussian blue analogs and organic compounds, demonstrate recovery rates of 90-95% using hydrometallurgical processes. This compares favorably to current lithium-ion recycling efficiencies and contributes to circular economy principles.

Carbon footprint analyses indicate that scaled manufacturing of potassium-ion electrodes could achieve greenhouse gas emissions reductions of 25-30% compared to lithium-ion counterparts when accounting for raw material extraction, processing, and manufacturing energy requirements. This advantage becomes particularly significant when considering the potential for integrating renewable energy sources into manufacturing facilities, which could further reduce lifecycle emissions by an additional 40-50%.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!