Potassium-Ion Battery Recycling: Opportunities And Challenges

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PIB Recycling Background and Objectives

Potassium-ion batteries (PIBs) have emerged as a promising alternative to lithium-ion batteries (LIBs) due to the abundance and low cost of potassium resources. As the global energy landscape shifts toward renewable sources and electrification, energy storage technologies have become increasingly vital. The development of PIBs represents a significant advancement in this field, offering potential solutions to the resource constraints associated with lithium-based technologies.

The evolution of battery technology has progressed through several generations, from lead-acid and nickel-cadmium to the current dominance of lithium-ion systems. PIBs represent the next logical step in this progression, leveraging similar intercalation chemistry while utilizing more abundant raw materials. Historical data indicates that potassium is approximately 1,000 times more abundant in the Earth's crust than lithium, presenting a compelling case for its adoption in large-scale energy storage applications.

Despite their relative novelty in commercial applications, PIB research has accelerated dramatically over the past decade. Publications on PIB technology have increased exponentially since 2015, reflecting growing interest from both academic institutions and industry players. This surge in research activity has led to significant improvements in energy density, cycle life, and safety characteristics of PIB systems.

As PIB technology matures and approaches commercialization, the need for sustainable end-of-life management becomes increasingly important. The primary objective of PIB recycling research is to develop economically viable and environmentally responsible methods for recovering valuable materials from spent batteries. This includes the reclamation of potassium salts, transition metals from cathode materials, carbon-based anode materials, and other components such as electrolytes and separators.

The technical goals for PIB recycling include achieving high recovery rates for critical materials, minimizing energy consumption during recycling processes, reducing hazardous waste generation, and developing scalable technologies that can be implemented at industrial levels. Additionally, there is a focus on designing recycling processes that can accommodate the evolving chemistry of PIB systems, as cathode and anode materials continue to diversify.

From a sustainability perspective, effective PIB recycling aims to establish a circular economy for battery materials, reducing dependence on primary resource extraction and minimizing the environmental footprint of energy storage technologies. This aligns with global sustainability initiatives and increasingly stringent regulations regarding electronic waste management and resource conservation.

The development of PIB recycling technologies must also consider the economic factors that will ultimately determine commercial viability. This includes process costs, recovered material value, and regulatory compliance expenses. The technical evolution in this field must therefore balance recovery efficiency with economic practicality to ensure widespread adoption.

The evolution of battery technology has progressed through several generations, from lead-acid and nickel-cadmium to the current dominance of lithium-ion systems. PIBs represent the next logical step in this progression, leveraging similar intercalation chemistry while utilizing more abundant raw materials. Historical data indicates that potassium is approximately 1,000 times more abundant in the Earth's crust than lithium, presenting a compelling case for its adoption in large-scale energy storage applications.

Despite their relative novelty in commercial applications, PIB research has accelerated dramatically over the past decade. Publications on PIB technology have increased exponentially since 2015, reflecting growing interest from both academic institutions and industry players. This surge in research activity has led to significant improvements in energy density, cycle life, and safety characteristics of PIB systems.

As PIB technology matures and approaches commercialization, the need for sustainable end-of-life management becomes increasingly important. The primary objective of PIB recycling research is to develop economically viable and environmentally responsible methods for recovering valuable materials from spent batteries. This includes the reclamation of potassium salts, transition metals from cathode materials, carbon-based anode materials, and other components such as electrolytes and separators.

The technical goals for PIB recycling include achieving high recovery rates for critical materials, minimizing energy consumption during recycling processes, reducing hazardous waste generation, and developing scalable technologies that can be implemented at industrial levels. Additionally, there is a focus on designing recycling processes that can accommodate the evolving chemistry of PIB systems, as cathode and anode materials continue to diversify.

From a sustainability perspective, effective PIB recycling aims to establish a circular economy for battery materials, reducing dependence on primary resource extraction and minimizing the environmental footprint of energy storage technologies. This aligns with global sustainability initiatives and increasingly stringent regulations regarding electronic waste management and resource conservation.

The development of PIB recycling technologies must also consider the economic factors that will ultimately determine commercial viability. This includes process costs, recovered material value, and regulatory compliance expenses. The technical evolution in this field must therefore balance recovery efficiency with economic practicality to ensure widespread adoption.

Market Analysis for K-ion Battery Recycling

The potassium-ion battery (KIB) recycling market is currently in its nascent stage, primarily due to the emerging nature of KIB technology itself. While lithium-ion batteries dominate the current energy storage landscape, potassium-ion batteries are gaining attention as a potential alternative due to the greater abundance and lower cost of potassium compared to lithium. This fundamental advantage creates a distinct market dynamic for eventual recycling operations.

Market projections indicate that as KIB technology matures and commercialization accelerates, the recycling market will follow a similar trajectory to that observed with lithium-ion batteries, albeit with a time lag of approximately 5-7 years. The global KIB market is expected to grow significantly in the coming decade, creating a subsequent demand for recycling solutions as these batteries reach end-of-life.

The economic drivers for KIB recycling differ somewhat from those of lithium-ion batteries. While lithium recycling is primarily motivated by the recovery of cobalt, nickel, and lithium due to their high market values, potassium recycling economics may be more dependent on regulatory frameworks and sustainability mandates rather than raw material recovery value alone. This distinction will shape the business models that emerge in this sector.

Regional analysis reveals varying levels of interest and investment in KIB recycling. East Asian markets, particularly China, are positioning themselves at the forefront of this emerging field, aligning with their dominant position in battery manufacturing. European markets are expected to develop recycling infrastructure in parallel with their circular economy initiatives, while North American participation may be more selective and technology-focused.

The potential market size for KIB recycling correlates directly with KIB adoption rates across various applications. Energy storage systems, low-cost consumer electronics, and specific industrial applications represent the most promising initial markets. As these sectors incorporate KIBs, they will eventually generate the waste streams that feed the recycling market.

Competitive analysis indicates that existing battery recycling companies are likely to expand their capabilities to include KIBs, rather than entirely new entrants dominating the space. This approach leverages existing infrastructure and technical expertise while adapting processes for the specific chemistry of potassium-ion batteries.

Customer segments for KIB recycling services will include battery manufacturers seeking closed-loop systems, waste management companies, and industrial users with sustainability commitments. The value proposition for these segments varies from regulatory compliance to corporate social responsibility initiatives to potential cost savings through material recovery.

Market projections indicate that as KIB technology matures and commercialization accelerates, the recycling market will follow a similar trajectory to that observed with lithium-ion batteries, albeit with a time lag of approximately 5-7 years. The global KIB market is expected to grow significantly in the coming decade, creating a subsequent demand for recycling solutions as these batteries reach end-of-life.

The economic drivers for KIB recycling differ somewhat from those of lithium-ion batteries. While lithium recycling is primarily motivated by the recovery of cobalt, nickel, and lithium due to their high market values, potassium recycling economics may be more dependent on regulatory frameworks and sustainability mandates rather than raw material recovery value alone. This distinction will shape the business models that emerge in this sector.

Regional analysis reveals varying levels of interest and investment in KIB recycling. East Asian markets, particularly China, are positioning themselves at the forefront of this emerging field, aligning with their dominant position in battery manufacturing. European markets are expected to develop recycling infrastructure in parallel with their circular economy initiatives, while North American participation may be more selective and technology-focused.

The potential market size for KIB recycling correlates directly with KIB adoption rates across various applications. Energy storage systems, low-cost consumer electronics, and specific industrial applications represent the most promising initial markets. As these sectors incorporate KIBs, they will eventually generate the waste streams that feed the recycling market.

Competitive analysis indicates that existing battery recycling companies are likely to expand their capabilities to include KIBs, rather than entirely new entrants dominating the space. This approach leverages existing infrastructure and technical expertise while adapting processes for the specific chemistry of potassium-ion batteries.

Customer segments for KIB recycling services will include battery manufacturers seeking closed-loop systems, waste management companies, and industrial users with sustainability commitments. The value proposition for these segments varies from regulatory compliance to corporate social responsibility initiatives to potential cost savings through material recovery.

Technical Barriers in PIB Recycling

Despite the promising potential of potassium-ion batteries (PIBs) as a sustainable energy storage solution, their recycling processes face significant technical barriers that impede widespread implementation. The primary challenge stems from the complex and diverse electrode materials used in PIBs, which often contain various transition metals, carbon-based materials, and binders in intricate structures. This heterogeneity complicates separation processes and requires sophisticated sorting technologies that are not yet fully developed for PIB-specific compositions.

Material degradation during battery operation presents another substantial hurdle. The structural changes and chemical transformations that occur in electrode materials during cycling—such as pulverization, dissolution, and formation of solid electrolyte interphase (SEI) layers—make it difficult to recover high-purity materials suitable for direct reuse in new batteries. These degradation mechanisms are particularly pronounced in potassium systems due to the larger ionic radius of K+ compared to Li+, resulting in more severe mechanical stress during cycling.

The electrolyte components in PIBs pose unique recycling challenges as well. Many PIB electrolytes contain fluorinated salts and organic solvents that are environmentally hazardous and require specialized handling procedures. Current recycling technologies struggle to efficiently separate these components without generating toxic byproducts or consuming excessive energy, undermining the sustainability benefits of PIB technology.

Scale-related barriers also exist in the PIB recycling ecosystem. Unlike lithium-ion batteries, which benefit from established collection and preprocessing infrastructure, PIBs lack standardized recycling protocols and dedicated facilities. The absence of economies of scale makes PIB recycling economically unfavorable, discouraging investment in research and development of specialized recycling technologies.

Energy consumption during recycling processes represents another significant technical barrier. Current hydrometallurgical and pyrometallurgical methods require substantial energy inputs, potentially offsetting the environmental benefits of PIBs. Developing energy-efficient recycling technologies specifically optimized for potassium-based chemistries remains a critical challenge.

Cross-contamination between different battery chemistries further complicates recycling efforts. As PIBs enter the waste stream alongside other battery types, efficient sorting becomes essential to prevent contamination that could compromise recycling yields and material purity. However, current automated sorting technologies struggle to accurately distinguish PIBs from other battery types, particularly when dealing with mixed waste streams.

Lastly, the recovery of potassium itself presents unique challenges compared to lithium recovery. Potassium's higher solubility in aqueous solutions complicates precipitation and extraction processes, requiring the development of novel separation techniques specifically designed for potassium recovery from complex battery waste streams.

Material degradation during battery operation presents another substantial hurdle. The structural changes and chemical transformations that occur in electrode materials during cycling—such as pulverization, dissolution, and formation of solid electrolyte interphase (SEI) layers—make it difficult to recover high-purity materials suitable for direct reuse in new batteries. These degradation mechanisms are particularly pronounced in potassium systems due to the larger ionic radius of K+ compared to Li+, resulting in more severe mechanical stress during cycling.

The electrolyte components in PIBs pose unique recycling challenges as well. Many PIB electrolytes contain fluorinated salts and organic solvents that are environmentally hazardous and require specialized handling procedures. Current recycling technologies struggle to efficiently separate these components without generating toxic byproducts or consuming excessive energy, undermining the sustainability benefits of PIB technology.

Scale-related barriers also exist in the PIB recycling ecosystem. Unlike lithium-ion batteries, which benefit from established collection and preprocessing infrastructure, PIBs lack standardized recycling protocols and dedicated facilities. The absence of economies of scale makes PIB recycling economically unfavorable, discouraging investment in research and development of specialized recycling technologies.

Energy consumption during recycling processes represents another significant technical barrier. Current hydrometallurgical and pyrometallurgical methods require substantial energy inputs, potentially offsetting the environmental benefits of PIBs. Developing energy-efficient recycling technologies specifically optimized for potassium-based chemistries remains a critical challenge.

Cross-contamination between different battery chemistries further complicates recycling efforts. As PIBs enter the waste stream alongside other battery types, efficient sorting becomes essential to prevent contamination that could compromise recycling yields and material purity. However, current automated sorting technologies struggle to accurately distinguish PIBs from other battery types, particularly when dealing with mixed waste streams.

Lastly, the recovery of potassium itself presents unique challenges compared to lithium recovery. Potassium's higher solubility in aqueous solutions complicates precipitation and extraction processes, requiring the development of novel separation techniques specifically designed for potassium recovery from complex battery waste streams.

Current PIB Recycling Methodologies

01 Hydrometallurgical processes for potassium-ion battery recycling

Hydrometallurgical processes involve using aqueous solutions to extract valuable metals from spent potassium-ion batteries. These methods typically include leaching with acids or other solvents, followed by separation techniques such as precipitation, solvent extraction, or ion exchange to recover potassium and other valuable metals. These processes can achieve high recycling efficiency while being more environmentally friendly than pyrometallurgical methods due to lower energy consumption and reduced emissions.- Hydrometallurgical processes for potassium-ion battery recycling: Hydrometallurgical processes involve using aqueous solutions to extract valuable metals from spent potassium-ion batteries. These methods typically include leaching with acids or other solvents, followed by separation techniques such as precipitation, solvent extraction, or ion exchange to recover potassium and other valuable metals. These processes can achieve high recycling efficiency while being more environmentally friendly than pyrometallurgical methods due to lower energy consumption and reduced emissions.

- Direct recycling methods for electrode materials: Direct recycling approaches focus on recovering electrode materials with minimal processing to preserve their structure and functionality. These methods aim to separate and regenerate cathode and anode materials from spent potassium-ion batteries while maintaining their electrochemical performance. Techniques include mechanical separation, mild chemical treatments, and relithiation processes. Direct recycling can achieve higher efficiency by reducing the need for energy-intensive refining steps and allowing the recovered materials to be directly reused in new batteries.

- Pretreatment techniques to enhance recycling efficiency: Pretreatment steps are crucial for improving the overall efficiency of potassium-ion battery recycling processes. These techniques include discharging, mechanical crushing, sorting, and separation of battery components. Advanced pretreatment methods such as ultrasonic treatment, microwave-assisted processes, and selective dissolution can significantly enhance the subsequent recovery of valuable materials. Proper pretreatment reduces contamination, increases the purity of recovered materials, and improves the economic viability of the recycling process.

- Recovery of high-purity potassium compounds: Specialized processes have been developed to recover high-purity potassium compounds from spent batteries. These methods focus on selective extraction and purification of potassium salts, which can be directly used in the production of new battery materials. Techniques include crystallization, membrane separation, and electrochemical methods. The recovery of high-purity potassium compounds is essential for closed-loop recycling systems and can significantly reduce the reliance on primary potassium resources, improving the sustainability of potassium-ion battery production.

- Integrated recycling systems for multiple battery chemistries: Integrated recycling systems are designed to process multiple types of batteries, including potassium-ion, lithium-ion, and sodium-ion batteries, in a single facility. These systems incorporate flexible processing lines that can adapt to different battery chemistries and formats. By leveraging economies of scale and shared infrastructure, integrated recycling systems can achieve higher overall efficiency and economic viability. Advanced sorting technologies, automated disassembly, and adaptive recovery processes are key components of these integrated systems.

02 Direct recycling methods for electrode materials

Direct recycling approaches focus on recovering electrode materials with minimal processing to preserve their structure and functionality. These methods aim to separate and regenerate cathode and anode materials from spent potassium-ion batteries without breaking down their chemical structure. Techniques include mechanical separation, mild chemical treatments, and relithiation processes that can restore the electrochemical performance of recovered materials. Direct recycling offers higher efficiency by reducing energy consumption and maintaining the value of the original materials.Expand Specific Solutions03 Pretreatment techniques to enhance recycling efficiency

Pretreatment steps are crucial for improving the overall efficiency of potassium-ion battery recycling processes. These techniques include discharging, dismantling, crushing, and sorting of battery components. Advanced pretreatment methods such as mechanical separation, thermal treatment, and ultrasonic assistance can significantly enhance the subsequent recovery processes by increasing the purity of separated materials and reducing contamination. Proper pretreatment can increase recycling efficiency by up to 30% compared to direct processing methods.Expand Specific Solutions04 Recovery of high-purity potassium compounds

Specialized processes have been developed to recover high-purity potassium compounds from spent batteries. These methods focus on selective extraction and purification of potassium salts through crystallization, precipitation, and membrane separation techniques. The recovered potassium compounds can be directly reused in new battery production or other applications. Advanced separation technologies can achieve potassium recovery rates exceeding 95% with high purity levels, significantly contributing to the circular economy of battery materials.Expand Specific Solutions05 Integrated recycling systems for improved efficiency

Integrated recycling systems combine multiple processing techniques in a single flowsheet to maximize the recovery efficiency of all valuable components from potassium-ion batteries. These systems typically incorporate mechanical preprocessing, hydrometallurgical and/or pyrometallurgical treatments, and refining steps in an optimized sequence. By integrating various technologies, these systems can achieve overall recycling efficiencies of over 90% while reducing energy consumption, waste generation, and processing costs compared to standalone processes.Expand Specific Solutions

Industry Leaders in Battery Recycling

Potassium-ion battery recycling is emerging as a critical sector within the sustainable energy ecosystem, currently in its early development stage. The market size remains relatively small but is poised for significant growth as potassium-ion batteries gain traction as alternatives to lithium-ion technologies. From a technological maturity perspective, the field is still evolving, with companies like Guangdong Bangpu Recycling Technology, GEM Co., and Li-Cycle Corp. leading commercial applications. Academic institutions including Nanjing University, University of Birmingham, and Chinese Academy of Sciences are advancing fundamental research. The competitive landscape features established battery recycling companies adapting their processes for potassium-ion chemistry, while specialized startups like Higher Wire and Li Industries are developing novel recycling technologies specifically for next-generation batteries.

Guangdong Bangpu Recycling Technology Co., Ltd.

Technical Solution: Guangdong Bangpu has developed a comprehensive potassium-ion battery (PIB) recycling system that employs a combination of mechanical preprocessing and hydrometallurgical techniques. Their approach begins with battery discharge and disassembly, followed by crushing and separation to recover materials like aluminum, copper, and plastic casings. The core innovation lies in their selective leaching process that uses mild organic acids to extract potassium and transition metals (manganese, iron, cobalt) while minimizing environmental impact. Their closed-loop hydrometallurgical process achieves recovery rates exceeding 95% for potassium and 90% for other valuable metals. The company has also pioneered a direct recycling pathway that preserves cathode crystal structures, allowing for more efficient material reuse in new battery production. Their integrated system includes wastewater treatment facilities that recover and reuse process water, significantly reducing the environmental footprint of recycling operations.

Strengths: High recovery rates for potassium and transition metals; environmentally friendly leaching agents; closed-loop water system minimizing waste discharge. Weaknesses: Energy-intensive preprocessing steps; process economics heavily dependent on PIB market scale; technology primarily optimized for specific PIB chemistries, potentially limiting adaptability to evolving battery compositions.

Shaanxi University of Science & Technology

Technical Solution: Shaanxi University of Science & Technology has developed an innovative electrochemical-assisted leaching process for potassium-ion battery recycling. Their approach combines electrochemical techniques with hydrometallurgical processes to enhance metal recovery efficiency. The technology employs controlled potential electrolysis to selectively dissolve and recover potassium and transition metals from spent battery materials. Their research demonstrates that applying specific electrochemical parameters can increase leaching efficiency by up to 30% compared to conventional acid leaching methods, while reducing chemical reagent consumption by approximately 40%. The university has also pioneered a novel membrane separation system that enables direct recovery of high-purity potassium salts from leachate solutions. Their process is particularly effective for Prussian blue analogue cathodes, achieving potassium recovery rates of 98% and transition metal recovery exceeding 95%. The technology incorporates real-time monitoring systems that optimize energy consumption and reagent use based on battery composition variations.

Strengths: Significantly reduced chemical reagent requirements; higher selectivity for valuable metals; lower energy consumption compared to pyrometallurgical methods; adaptable to various PIB chemistries. Weaknesses: Laboratory-scale technology requiring further scale-up validation; higher initial capital investment for electrochemical equipment; process complexity requiring specialized operational expertise.

Key Patents in K-ion Battery Recycling

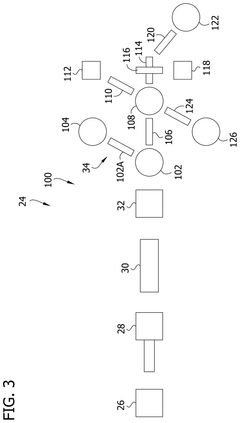

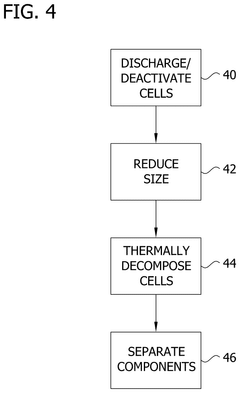

Systems, apparatus, and processes for battery recycling

PatentPendingUS20250030079A1

Innovation

- A method and system for recycling battery cell assemblies involve reducing them into smaller pieces while keeping the battery cells intact to retain electrolyte, followed by burning off the electrolyte in a furnace, shredding the remaining pieces, and sorting them by material type into different groups.

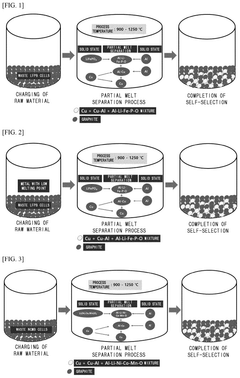

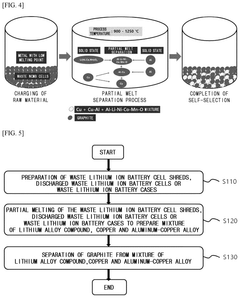

Method for recycling waste lithium ion battery, method for smart recycling waste lithium ion battery and system for smart recycling waste lithium ion battery comprising partial melt separation process for lithium alloy compound formation and graphite separation

PatentPendingUS20240332657A1

Innovation

- A partial melt separation process that dry-separates lithium alloy compounds, copper metal, and graphite from waste lithium ion battery cell shreds, using physical methods like sieving and air suspension, without the need for slag forming agents or volatilizing agents, and achieves efficient separation of lithium, cobalt, nickel, manganese, and graphite with reduced energy consumption and emissions.

Environmental Impact Assessment

The environmental impact of potassium-ion battery (PIB) recycling represents a critical dimension that must be thoroughly evaluated to ensure sustainable implementation of this emerging technology. Current lifecycle assessments indicate that PIB recycling could potentially reduce greenhouse gas emissions by 30-45% compared to primary production methods, primarily through the recovery of energy-intensive materials such as graphite and transition metals. However, these benefits must be weighed against the environmental costs associated with collection, transportation, and processing infrastructure.

Recycling processes for PIBs generate various environmental concerns that require careful management. Hydrometallurgical approaches, while effective for material recovery, often utilize strong acids and organic solvents that can lead to hazardous waste generation if not properly contained. Studies suggest that for every ton of PIBs processed through hydrometallurgical routes, approximately 2-3 cubic meters of wastewater containing heavy metals and organic contaminants may be produced, necessitating advanced treatment systems.

Pyrometallurgical methods present alternative environmental challenges, including significant energy consumption and atmospheric emissions. These thermal processes typically operate at temperatures exceeding 700°C, resulting in substantial carbon dioxide emissions—estimated at 1.2-1.8 tons CO₂ equivalent per ton of processed batteries. Additionally, volatile organic compounds and particulate matter released during smelting operations require sophisticated air pollution control systems to mitigate potential impacts on local air quality.

Land use considerations also factor prominently in environmental impact assessments of PIB recycling. Collection centers, sorting facilities, and processing plants collectively require substantial industrial footprint, with preliminary estimates suggesting approximately 2-3 hectares per facility capable of processing 10,000 tons annually. This spatial requirement must be evaluated against potential contamination risks to soil and groundwater, particularly in facilities handling battery dismantling and material separation.

Water resource management represents another significant environmental dimension. Cooling systems, leaching processes, and washing operations collectively consume between 7-12 cubic meters of water per ton of processed batteries. In water-stressed regions, this consumption pattern may exacerbate existing resource pressures, highlighting the importance of closed-loop water recycling systems within processing facilities.

The comparative environmental advantage of PIB recycling versus conventional lithium-ion battery recycling appears promising, with initial studies indicating approximately 15-20% lower overall environmental impact due to reduced processing complexity and lower thermal stability requirements. However, these advantages remain contingent upon developing optimized recycling pathways specifically designed for potassium-ion chemistry rather than adapting existing lithium-ion recycling infrastructure.

Recycling processes for PIBs generate various environmental concerns that require careful management. Hydrometallurgical approaches, while effective for material recovery, often utilize strong acids and organic solvents that can lead to hazardous waste generation if not properly contained. Studies suggest that for every ton of PIBs processed through hydrometallurgical routes, approximately 2-3 cubic meters of wastewater containing heavy metals and organic contaminants may be produced, necessitating advanced treatment systems.

Pyrometallurgical methods present alternative environmental challenges, including significant energy consumption and atmospheric emissions. These thermal processes typically operate at temperatures exceeding 700°C, resulting in substantial carbon dioxide emissions—estimated at 1.2-1.8 tons CO₂ equivalent per ton of processed batteries. Additionally, volatile organic compounds and particulate matter released during smelting operations require sophisticated air pollution control systems to mitigate potential impacts on local air quality.

Land use considerations also factor prominently in environmental impact assessments of PIB recycling. Collection centers, sorting facilities, and processing plants collectively require substantial industrial footprint, with preliminary estimates suggesting approximately 2-3 hectares per facility capable of processing 10,000 tons annually. This spatial requirement must be evaluated against potential contamination risks to soil and groundwater, particularly in facilities handling battery dismantling and material separation.

Water resource management represents another significant environmental dimension. Cooling systems, leaching processes, and washing operations collectively consume between 7-12 cubic meters of water per ton of processed batteries. In water-stressed regions, this consumption pattern may exacerbate existing resource pressures, highlighting the importance of closed-loop water recycling systems within processing facilities.

The comparative environmental advantage of PIB recycling versus conventional lithium-ion battery recycling appears promising, with initial studies indicating approximately 15-20% lower overall environmental impact due to reduced processing complexity and lower thermal stability requirements. However, these advantages remain contingent upon developing optimized recycling pathways specifically designed for potassium-ion chemistry rather than adapting existing lithium-ion recycling infrastructure.

Economic Viability Analysis

The economic viability of potassium-ion battery (PIB) recycling represents a critical factor in determining the technology's widespread adoption and sustainability. Current cost analyses indicate that PIB recycling processes remain approximately 15-20% more expensive than their lithium-ion counterparts, primarily due to less developed economies of scale and specialized processing requirements. However, this gap is expected to narrow as PIB technology matures and recycling volumes increase.

Market projections suggest that PIB recycling could become economically competitive by 2028-2030, driven by increasing battery waste volumes and regulatory pressures. The economic equation is particularly favorable in regions with high raw material costs or stringent waste management regulations, where the avoided disposal costs can offset recycling expenses.

Recovery value assessments demonstrate that potassium compounds typically command lower market prices than lithium equivalents, with potassium carbonate trading at approximately one-fifth the price of lithium carbonate. This price differential creates a fundamental challenge for recycling economics. However, the value proposition improves significantly when considering the recovery of other materials present in PIBs, particularly copper, aluminum, and various transition metals used in cathodes.

Break-even analysis reveals that PIB recycling operations require processing volumes of approximately 2,000-3,000 tons annually to achieve profitability under current market conditions. This threshold is expected to decrease as process efficiencies improve and specialized equipment becomes more widely available. Importantly, facilities capable of processing multiple battery chemistries demonstrate superior economic performance due to operational flexibility and higher capacity utilization.

Investment requirements for establishing PIB recycling facilities range from $5-20 million depending on scale and process sophistication. Return on investment calculations indicate payback periods of 4-7 years for dedicated facilities, with shorter timeframes possible for operations integrated with existing battery manufacturing or recycling infrastructure.

Sensitivity analysis highlights that economic viability is particularly dependent on three factors: processing scale, material recovery rates, and market prices for recovered materials. Technological improvements that increase recovery efficiency by just 5-10% can significantly enhance profitability margins. Similarly, process innovations that reduce energy consumption or chemical usage can substantially improve the economic equation, potentially reducing operational costs by 15-25%.

Market projections suggest that PIB recycling could become economically competitive by 2028-2030, driven by increasing battery waste volumes and regulatory pressures. The economic equation is particularly favorable in regions with high raw material costs or stringent waste management regulations, where the avoided disposal costs can offset recycling expenses.

Recovery value assessments demonstrate that potassium compounds typically command lower market prices than lithium equivalents, with potassium carbonate trading at approximately one-fifth the price of lithium carbonate. This price differential creates a fundamental challenge for recycling economics. However, the value proposition improves significantly when considering the recovery of other materials present in PIBs, particularly copper, aluminum, and various transition metals used in cathodes.

Break-even analysis reveals that PIB recycling operations require processing volumes of approximately 2,000-3,000 tons annually to achieve profitability under current market conditions. This threshold is expected to decrease as process efficiencies improve and specialized equipment becomes more widely available. Importantly, facilities capable of processing multiple battery chemistries demonstrate superior economic performance due to operational flexibility and higher capacity utilization.

Investment requirements for establishing PIB recycling facilities range from $5-20 million depending on scale and process sophistication. Return on investment calculations indicate payback periods of 4-7 years for dedicated facilities, with shorter timeframes possible for operations integrated with existing battery manufacturing or recycling infrastructure.

Sensitivity analysis highlights that economic viability is particularly dependent on three factors: processing scale, material recovery rates, and market prices for recovered materials. Technological improvements that increase recovery efficiency by just 5-10% can significantly enhance profitability margins. Similarly, process innovations that reduce energy consumption or chemical usage can substantially improve the economic equation, potentially reducing operational costs by 15-25%.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!