Functional Integration of Borosilicate Glass in Smart Windows

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Borosilicate Glass in Smart Windows: Background and Objectives

Smart windows have emerged as a revolutionary technology in the field of energy-efficient building design. At the forefront of this innovation is the integration of borosilicate glass, a material known for its exceptional thermal and chemical properties. The evolution of smart window technology can be traced back to the early 1990s, with significant advancements occurring in the past two decades.

Borosilicate glass, first developed in the late 19th century, has traditionally been used in laboratory glassware and cookware due to its low thermal expansion coefficient and high resistance to thermal shock. Its application in smart windows represents a convergence of material science and energy management technologies, aiming to address the growing demand for sustainable building solutions.

The primary objective of integrating borosilicate glass in smart windows is to enhance energy efficiency in buildings while maintaining optimal indoor comfort. This technology seeks to dynamically control the transmission of light and heat through windows, adapting to changing environmental conditions and user preferences. By doing so, it aims to reduce the energy consumption associated with heating, cooling, and lighting systems in both residential and commercial structures.

Another key goal is to improve the durability and longevity of smart window systems. Borosilicate glass offers superior resistance to scratching, chemical corrosion, and thermal stress compared to conventional glass, potentially extending the lifespan of smart windows and reducing maintenance costs. This aligns with the broader trend towards sustainable construction practices and life-cycle cost reduction in building management.

The integration of borosilicate glass also aims to expand the functional capabilities of smart windows. Beyond basic light and heat control, researchers are exploring ways to incorporate additional features such as self-cleaning properties, enhanced sound insulation, and even energy generation through photovoltaic integration. These multifunctional smart windows could potentially transform windows from passive building elements into active contributors to energy management and environmental control systems.

From a market perspective, the development of borosilicate glass-based smart windows is driven by increasingly stringent energy efficiency regulations in many countries, as well as growing consumer awareness of environmental issues. The technology is expected to play a crucial role in achieving net-zero energy buildings, a concept gaining traction in urban planning and sustainable architecture.

As we delve deeper into this technology, it becomes clear that the integration of borosilicate glass in smart windows represents a significant step forward in building technology. It promises to address multiple challenges simultaneously: energy efficiency, occupant comfort, and sustainable construction. The ongoing research and development in this field are set to redefine our expectations of what windows can do, transforming them from simple openings to sophisticated, multifunctional components of smart building systems.

Borosilicate glass, first developed in the late 19th century, has traditionally been used in laboratory glassware and cookware due to its low thermal expansion coefficient and high resistance to thermal shock. Its application in smart windows represents a convergence of material science and energy management technologies, aiming to address the growing demand for sustainable building solutions.

The primary objective of integrating borosilicate glass in smart windows is to enhance energy efficiency in buildings while maintaining optimal indoor comfort. This technology seeks to dynamically control the transmission of light and heat through windows, adapting to changing environmental conditions and user preferences. By doing so, it aims to reduce the energy consumption associated with heating, cooling, and lighting systems in both residential and commercial structures.

Another key goal is to improve the durability and longevity of smart window systems. Borosilicate glass offers superior resistance to scratching, chemical corrosion, and thermal stress compared to conventional glass, potentially extending the lifespan of smart windows and reducing maintenance costs. This aligns with the broader trend towards sustainable construction practices and life-cycle cost reduction in building management.

The integration of borosilicate glass also aims to expand the functional capabilities of smart windows. Beyond basic light and heat control, researchers are exploring ways to incorporate additional features such as self-cleaning properties, enhanced sound insulation, and even energy generation through photovoltaic integration. These multifunctional smart windows could potentially transform windows from passive building elements into active contributors to energy management and environmental control systems.

From a market perspective, the development of borosilicate glass-based smart windows is driven by increasingly stringent energy efficiency regulations in many countries, as well as growing consumer awareness of environmental issues. The technology is expected to play a crucial role in achieving net-zero energy buildings, a concept gaining traction in urban planning and sustainable architecture.

As we delve deeper into this technology, it becomes clear that the integration of borosilicate glass in smart windows represents a significant step forward in building technology. It promises to address multiple challenges simultaneously: energy efficiency, occupant comfort, and sustainable construction. The ongoing research and development in this field are set to redefine our expectations of what windows can do, transforming them from simple openings to sophisticated, multifunctional components of smart building systems.

Market Analysis for Smart Window Technologies

The smart window technology market has been experiencing significant growth in recent years, driven by increasing demand for energy-efficient building solutions and advancements in materials science. The global smart window market size was valued at approximately $4.5 billion in 2020 and is projected to reach $8.9 billion by 2026, growing at a CAGR of 12.1% during the forecast period.

The integration of borosilicate glass in smart windows represents a promising development in this market. Borosilicate glass offers several advantages over traditional glass materials, including higher durability, improved thermal resistance, and enhanced optical properties. These characteristics make it particularly suitable for smart window applications, where performance and longevity are crucial factors.

The market for smart windows with borosilicate glass is primarily driven by the construction and automotive industries. In the construction sector, there is a growing emphasis on green building practices and energy conservation. Smart windows with borosilicate glass can significantly reduce heating and cooling costs by dynamically controlling light transmission and heat gain. This aligns well with stringent building energy codes and sustainability certifications, such as LEED.

In the automotive industry, the demand for advanced glazing solutions is increasing, with a focus on improving passenger comfort and vehicle energy efficiency. Borosilicate glass-based smart windows can offer better temperature regulation and glare reduction, enhancing the overall driving experience. The automotive smart glass market is expected to grow at a CAGR of 15.2% from 2021 to 2028, presenting a substantial opportunity for borosilicate glass integration.

Geographically, North America and Europe are currently the largest markets for smart window technologies, including those incorporating borosilicate glass. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid urbanization, increasing disposable income, and growing awareness of energy-efficient technologies.

Key market players in the smart window industry are actively exploring the potential of borosilicate glass integration. Companies such as Saint-Gobain, AGC Inc., and Corning Incorporated are investing in research and development to enhance the performance and cost-effectiveness of borosilicate glass-based smart window solutions. This trend is likely to accelerate market adoption and drive further innovation in the field.

Despite the promising outlook, challenges remain in the widespread adoption of borosilicate glass in smart windows. These include higher initial costs compared to traditional glass solutions and the need for specialized manufacturing processes. However, as production scales up and technology matures, these barriers are expected to diminish, further expanding market opportunities.

The integration of borosilicate glass in smart windows represents a promising development in this market. Borosilicate glass offers several advantages over traditional glass materials, including higher durability, improved thermal resistance, and enhanced optical properties. These characteristics make it particularly suitable for smart window applications, where performance and longevity are crucial factors.

The market for smart windows with borosilicate glass is primarily driven by the construction and automotive industries. In the construction sector, there is a growing emphasis on green building practices and energy conservation. Smart windows with borosilicate glass can significantly reduce heating and cooling costs by dynamically controlling light transmission and heat gain. This aligns well with stringent building energy codes and sustainability certifications, such as LEED.

In the automotive industry, the demand for advanced glazing solutions is increasing, with a focus on improving passenger comfort and vehicle energy efficiency. Borosilicate glass-based smart windows can offer better temperature regulation and glare reduction, enhancing the overall driving experience. The automotive smart glass market is expected to grow at a CAGR of 15.2% from 2021 to 2028, presenting a substantial opportunity for borosilicate glass integration.

Geographically, North America and Europe are currently the largest markets for smart window technologies, including those incorporating borosilicate glass. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid urbanization, increasing disposable income, and growing awareness of energy-efficient technologies.

Key market players in the smart window industry are actively exploring the potential of borosilicate glass integration. Companies such as Saint-Gobain, AGC Inc., and Corning Incorporated are investing in research and development to enhance the performance and cost-effectiveness of borosilicate glass-based smart window solutions. This trend is likely to accelerate market adoption and drive further innovation in the field.

Despite the promising outlook, challenges remain in the widespread adoption of borosilicate glass in smart windows. These include higher initial costs compared to traditional glass solutions and the need for specialized manufacturing processes. However, as production scales up and technology matures, these barriers are expected to diminish, further expanding market opportunities.

Current Challenges in Borosilicate Glass Integration

The integration of borosilicate glass in smart windows faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary obstacles is the difficulty in achieving uniform and consistent electrical conductivity across the glass surface. This is crucial for the even distribution of electric fields necessary for controlling the optical properties of smart windows. The inherent insulating nature of borosilicate glass makes it challenging to create conductive pathways without compromising its transparency or structural integrity.

Another major challenge lies in the thermal expansion mismatch between borosilicate glass and the functional layers required for smart window operation. This mismatch can lead to stress buildup during temperature fluctuations, potentially causing delamination or cracking of the functional layers. The problem is exacerbated by the need for multiple thin-film layers in smart window designs, each with its own thermal expansion coefficient.

The durability and longevity of smart windows incorporating borosilicate glass also present significant hurdles. The repeated cycling of electrochromic or other active materials can lead to degradation over time, affecting the overall performance and lifespan of the smart window system. Additionally, the interface between the glass and the functional layers is susceptible to environmental factors such as moisture and UV radiation, which can compromise the adhesion and functionality of the smart window components.

Manufacturing scalability remains a critical challenge in the integration of borosilicate glass in smart windows. The precise deposition of functional layers on large-area borosilicate glass substrates while maintaining uniformity and performance is technically demanding and cost-intensive. This is particularly problematic when considering the need for mass production to make smart windows economically viable for widespread adoption.

Energy efficiency and power management also pose significant challenges. While smart windows aim to reduce energy consumption in buildings, the power required to operate these systems, especially in large-scale applications, can be substantial. Developing low-power solutions that can effectively control the optical properties of borosilicate glass-based smart windows without compromising performance is an ongoing challenge.

Lastly, the integration of smart window functionality with existing building management systems and IoT infrastructure presents both technical and standardization challenges. Ensuring seamless communication and control between smart windows and other building systems requires overcoming compatibility issues and developing robust, interoperable protocols.

Another major challenge lies in the thermal expansion mismatch between borosilicate glass and the functional layers required for smart window operation. This mismatch can lead to stress buildup during temperature fluctuations, potentially causing delamination or cracking of the functional layers. The problem is exacerbated by the need for multiple thin-film layers in smart window designs, each with its own thermal expansion coefficient.

The durability and longevity of smart windows incorporating borosilicate glass also present significant hurdles. The repeated cycling of electrochromic or other active materials can lead to degradation over time, affecting the overall performance and lifespan of the smart window system. Additionally, the interface between the glass and the functional layers is susceptible to environmental factors such as moisture and UV radiation, which can compromise the adhesion and functionality of the smart window components.

Manufacturing scalability remains a critical challenge in the integration of borosilicate glass in smart windows. The precise deposition of functional layers on large-area borosilicate glass substrates while maintaining uniformity and performance is technically demanding and cost-intensive. This is particularly problematic when considering the need for mass production to make smart windows economically viable for widespread adoption.

Energy efficiency and power management also pose significant challenges. While smart windows aim to reduce energy consumption in buildings, the power required to operate these systems, especially in large-scale applications, can be substantial. Developing low-power solutions that can effectively control the optical properties of borosilicate glass-based smart windows without compromising performance is an ongoing challenge.

Lastly, the integration of smart window functionality with existing building management systems and IoT infrastructure presents both technical and standardization challenges. Ensuring seamless communication and control between smart windows and other building systems requires overcoming compatibility issues and developing robust, interoperable protocols.

Existing Borosilicate Glass Integration Methods

01 Thermal resistance and low thermal expansion

Borosilicate glass is known for its excellent thermal resistance and low coefficient of thermal expansion. This property makes it ideal for applications involving rapid temperature changes or extreme temperature conditions. It can withstand thermal shock without cracking or breaking, making it suitable for laboratory glassware, cookware, and industrial applications.- High thermal resistance: Borosilicate glass exhibits exceptional thermal resistance, making it suitable for applications involving extreme temperature changes. This property allows it to withstand thermal shock without cracking or shattering, making it ideal for laboratory glassware, cookware, and industrial equipment.

- Chemical durability: Borosilicate glass possesses high chemical resistance, making it inert to most chemicals and corrosive substances. This characteristic makes it valuable in laboratory settings, pharmaceutical packaging, and chemical processing equipment where material compatibility is crucial.

- Optical properties: Borosilicate glass offers excellent optical clarity and low refractive index, making it suitable for various optical applications. It is commonly used in telescope mirrors, camera lenses, and other precision optical instruments where high-quality light transmission is required.

- Electrical insulation: Borosilicate glass exhibits good electrical insulation properties, making it suitable for use in electrical and electronic components. It is often used in the manufacturing of insulators, capacitors, and other electrical devices where high dielectric strength is necessary.

- Low thermal expansion: Borosilicate glass has a low coefficient of thermal expansion, which contributes to its resistance to thermal shock and dimensional stability. This property makes it ideal for precision instruments, sealing applications, and situations where maintaining exact dimensions under varying temperatures is critical.

02 Chemical durability

Borosilicate glass exhibits high chemical resistance, making it inert to many corrosive substances and chemicals. This characteristic is valuable in laboratory equipment, pharmaceutical packaging, and chemical processing industries. It maintains its integrity and does not contaminate the contents it holds, ensuring the purity of chemicals and reagents.Expand Specific Solutions03 Optical properties

Borosilicate glass possesses excellent optical properties, including high transparency and low refractive index. These characteristics make it suitable for various optical applications such as lenses, mirrors, and optical fibers. It is also used in astronomical telescopes and other precision optical instruments due to its ability to maintain shape and clarity under different environmental conditions.Expand Specific Solutions04 Electrical insulation

Borosilicate glass is an excellent electrical insulator, making it useful in various electrical and electronic applications. It is used in the production of insulators, capacitors, and other electrical components. Its low dielectric constant and high resistivity contribute to its effectiveness as an insulating material in high-voltage and high-frequency applications.Expand Specific Solutions05 Versatility in manufacturing and shaping

Borosilicate glass can be easily shaped, molded, and worked into various forms using different manufacturing techniques. This versatility allows for the production of complex shapes and structures, making it suitable for a wide range of applications. It can be blown, pressed, drawn into fibers, or machined to create custom components for specific industrial, scientific, or consumer product needs.Expand Specific Solutions

Key Players in Smart Glass and Window Industry

The functional integration of borosilicate glass in smart windows is an emerging technology in the advanced materials sector. The market is in its early growth stage, with increasing demand driven by energy efficiency and smart building trends. While the global smart glass market is projected to reach $8.35 billion by 2023, the specific borosilicate segment is still developing. Major players like SCHOTT AG, AGC Inc., and Corning Inc. are leveraging their expertise in specialty glass to advance this technology. These companies are investing in R&D to improve the performance and cost-effectiveness of borosilicate-based smart windows, aiming to enhance durability, optical clarity, and energy-saving capabilities. The technology's maturity is progressing, with ongoing efforts to optimize manufacturing processes and scale production for wider commercial adoption.

SCHOTT AG

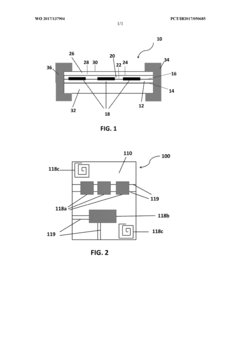

Technical Solution: SCHOTT AG has developed advanced borosilicate glass solutions for smart windows, leveraging their expertise in specialty glass manufacturing. Their technology integrates electrochromic properties into borosilicate glass, allowing for dynamic control of light transmission and heat management[1]. The company's smart window solution utilizes a thin film of electrochromic material sandwiched between two layers of borosilicate glass, which changes opacity when an electric current is applied[2]. This enables users to adjust the transparency of windows in response to changing environmental conditions or personal preferences, enhancing energy efficiency and comfort in buildings[3].

Strengths: High durability and thermal resistance of borosilicate glass, precise control over light transmission. Weaknesses: Higher production costs compared to conventional glass, complexity in large-scale manufacturing.

AGC, Inc. (Japan)

Technical Solution: AGC has pioneered the integration of borosilicate glass in smart windows through their proprietary WONDERLITE technology. This innovation combines the thermal and chemical resistance of borosilicate glass with advanced electrochromic coatings[4]. The smart window system uses a multi-layer structure, with borosilicate glass as the substrate, coated with transparent conductive oxides and an active electrochromic layer[5]. When a low voltage is applied, the electrochromic layer changes its optical properties, allowing for dynamic control of solar heat gain and visible light transmission. AGC's solution also incorporates IoT connectivity, enabling integration with building management systems for optimized energy performance[6].

Strengths: Excellent optical quality, high durability, and seamless integration with smart building systems. Weaknesses: Higher initial costs, potential for technological obsolescence in rapidly evolving smart building market.

Innovative Approaches in Borosilicate Smart Windows

Smart glass-polymer assembly, method of manufacture, and smart window

PatentWO2017137904A1

Innovation

- A smart glass-polymer assembly is manufactured using a roll-to-roll process, comprising an optically clear polymer film with smart functionalities and a glass layer encapsulated by an adhesive, which enhances structural strength and moisture/gas barrier properties, allowing for cost-effective and lightweight integration of advanced features.

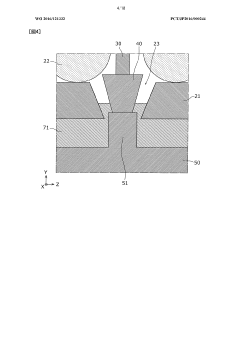

Insulated glazing and optical device

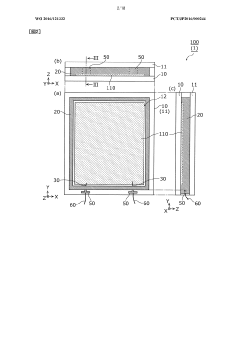

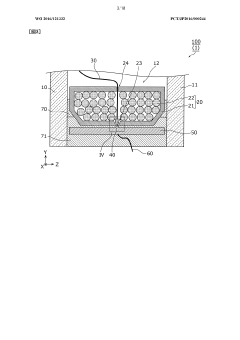

PatentWO2016121332A1

Innovation

- A double-glazed glass configuration with a metal layer interposed between glass plates, electrically connected to electrode wiring through a spacer, which includes a desiccant and a metal plate to cover the wiring, reducing moisture infiltration.

Energy Efficiency Impact of Smart Windows

The integration of smart windows with borosilicate glass has significant implications for energy efficiency in buildings. Smart windows, equipped with electrochromic or thermochromic properties, can dynamically adjust their tint in response to external conditions, effectively regulating solar heat gain and daylight transmission. This adaptability directly impacts the energy consumption associated with heating, cooling, and lighting systems within a building.

Borosilicate glass, known for its low thermal expansion coefficient and high chemical resistance, enhances the performance and durability of smart windows. Its incorporation allows for improved thermal insulation properties, reducing heat transfer between the interior and exterior environments. This characteristic is particularly beneficial in extreme climates, where maintaining a stable indoor temperature is crucial for energy conservation.

The energy efficiency impact of smart windows with borosilicate glass is multifaceted. During summer months, these windows can transition to a darker tint, reflecting a higher percentage of solar radiation and reducing the cooling load on HVAC systems. Conversely, in winter, they can maximize solar heat gain by maintaining a clearer state, thereby decreasing the demand for artificial heating. This dynamic control of solar heat gain can lead to substantial energy savings, with some studies reporting reductions in HVAC energy consumption by up to 20-30% in commercial buildings.

Lighting energy consumption is another area where smart windows demonstrate significant efficiency gains. By optimizing daylight transmission, these windows reduce the need for artificial lighting during daytime hours. Advanced daylight harvesting systems, when coupled with smart windows, can automatically adjust interior lighting levels in response to available natural light, further enhancing energy savings.

The long-term durability of borosilicate glass in smart window applications contributes to sustained energy efficiency over the building's lifecycle. Its resistance to thermal stress and chemical degradation ensures that the window's performance remains consistent over time, maintaining its energy-saving capabilities without frequent replacements or maintenance.

Moreover, the integration of smart windows with building management systems allows for optimized energy use across entire structures. By coordinating window tinting with HVAC and lighting controls, buildings can achieve a more holistic approach to energy management, potentially leading to even greater efficiency gains and reduced overall energy consumption.

In conclusion, the functional integration of borosilicate glass in smart windows presents a compelling solution for improving building energy efficiency. Its impact extends beyond mere temperature regulation, encompassing lighting optimization and long-term performance stability, making it a valuable technology in the pursuit of sustainable and energy-efficient architecture.

Borosilicate glass, known for its low thermal expansion coefficient and high chemical resistance, enhances the performance and durability of smart windows. Its incorporation allows for improved thermal insulation properties, reducing heat transfer between the interior and exterior environments. This characteristic is particularly beneficial in extreme climates, where maintaining a stable indoor temperature is crucial for energy conservation.

The energy efficiency impact of smart windows with borosilicate glass is multifaceted. During summer months, these windows can transition to a darker tint, reflecting a higher percentage of solar radiation and reducing the cooling load on HVAC systems. Conversely, in winter, they can maximize solar heat gain by maintaining a clearer state, thereby decreasing the demand for artificial heating. This dynamic control of solar heat gain can lead to substantial energy savings, with some studies reporting reductions in HVAC energy consumption by up to 20-30% in commercial buildings.

Lighting energy consumption is another area where smart windows demonstrate significant efficiency gains. By optimizing daylight transmission, these windows reduce the need for artificial lighting during daytime hours. Advanced daylight harvesting systems, when coupled with smart windows, can automatically adjust interior lighting levels in response to available natural light, further enhancing energy savings.

The long-term durability of borosilicate glass in smart window applications contributes to sustained energy efficiency over the building's lifecycle. Its resistance to thermal stress and chemical degradation ensures that the window's performance remains consistent over time, maintaining its energy-saving capabilities without frequent replacements or maintenance.

Moreover, the integration of smart windows with building management systems allows for optimized energy use across entire structures. By coordinating window tinting with HVAC and lighting controls, buildings can achieve a more holistic approach to energy management, potentially leading to even greater efficiency gains and reduced overall energy consumption.

In conclusion, the functional integration of borosilicate glass in smart windows presents a compelling solution for improving building energy efficiency. Its impact extends beyond mere temperature regulation, encompassing lighting optimization and long-term performance stability, making it a valuable technology in the pursuit of sustainable and energy-efficient architecture.

Durability and Longevity of Borosilicate Smart Windows

The durability and longevity of borosilicate smart windows are critical factors in their widespread adoption and long-term performance. Borosilicate glass, known for its exceptional thermal and chemical resistance, offers significant advantages in smart window applications. These properties contribute to the overall resilience of the smart window system, ensuring sustained functionality over extended periods.

One of the primary benefits of using borosilicate glass in smart windows is its superior resistance to thermal shock. This characteristic allows the windows to withstand rapid temperature changes without cracking or shattering, a crucial feature for buildings exposed to varying environmental conditions. The low coefficient of thermal expansion of borosilicate glass also minimizes stress on the window structure during temperature fluctuations, further enhancing its durability.

Chemical stability is another key factor contributing to the longevity of borosilicate smart windows. The glass's resistance to corrosion and chemical attack helps maintain its optical clarity and structural integrity over time, even when exposed to harsh environmental conditions or cleaning agents. This resistance is particularly important for smart windows that incorporate electrochromic or other active layers, as it helps prevent degradation of these functional components.

The mechanical strength of borosilicate glass also plays a significant role in the durability of smart windows. Its higher tensile strength compared to conventional soda-lime glass allows for thinner, lighter window constructions without compromising on structural integrity. This characteristic not only enhances the overall durability but also contributes to improved energy efficiency and reduced material costs.

Long-term stability of the smart window's functional layers is crucial for maintaining its performance over time. Borosilicate glass provides an excellent substrate for these layers due to its smooth surface and chemical inertness. This compatibility helps ensure strong adhesion and reduces the risk of delamination or degradation of the active components, thereby extending the operational lifespan of the smart window system.

The inherent UV resistance of borosilicate glass further contributes to the longevity of smart windows. By effectively blocking harmful ultraviolet radiation, it helps protect the internal functional layers and any organic components from photodegradation. This protection is essential for maintaining the optical and switching properties of the smart window over extended periods of exposure to sunlight.

In conclusion, the integration of borosilicate glass in smart windows significantly enhances their durability and longevity. Its unique combination of thermal, chemical, and mechanical properties provides a robust foundation for advanced window technologies, ensuring sustained performance and reliability in various environmental conditions. As smart window technologies continue to evolve, the role of borosilicate glass in extending their operational lifespan and maintaining long-term functionality remains crucial for their successful implementation in modern architecture and energy-efficient building designs.

One of the primary benefits of using borosilicate glass in smart windows is its superior resistance to thermal shock. This characteristic allows the windows to withstand rapid temperature changes without cracking or shattering, a crucial feature for buildings exposed to varying environmental conditions. The low coefficient of thermal expansion of borosilicate glass also minimizes stress on the window structure during temperature fluctuations, further enhancing its durability.

Chemical stability is another key factor contributing to the longevity of borosilicate smart windows. The glass's resistance to corrosion and chemical attack helps maintain its optical clarity and structural integrity over time, even when exposed to harsh environmental conditions or cleaning agents. This resistance is particularly important for smart windows that incorporate electrochromic or other active layers, as it helps prevent degradation of these functional components.

The mechanical strength of borosilicate glass also plays a significant role in the durability of smart windows. Its higher tensile strength compared to conventional soda-lime glass allows for thinner, lighter window constructions without compromising on structural integrity. This characteristic not only enhances the overall durability but also contributes to improved energy efficiency and reduced material costs.

Long-term stability of the smart window's functional layers is crucial for maintaining its performance over time. Borosilicate glass provides an excellent substrate for these layers due to its smooth surface and chemical inertness. This compatibility helps ensure strong adhesion and reduces the risk of delamination or degradation of the active components, thereby extending the operational lifespan of the smart window system.

The inherent UV resistance of borosilicate glass further contributes to the longevity of smart windows. By effectively blocking harmful ultraviolet radiation, it helps protect the internal functional layers and any organic components from photodegradation. This protection is essential for maintaining the optical and switching properties of the smart window over extended periods of exposure to sunlight.

In conclusion, the integration of borosilicate glass in smart windows significantly enhances their durability and longevity. Its unique combination of thermal, chemical, and mechanical properties provides a robust foundation for advanced window technologies, ensuring sustained performance and reliability in various environmental conditions. As smart window technologies continue to evolve, the role of borosilicate glass in extending their operational lifespan and maintaining long-term functionality remains crucial for their successful implementation in modern architecture and energy-efficient building designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!