How Accura 25 Enables Rapid Iteration for Designers?

JUL 8, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Overview

Accura 25 is a cutting-edge stereolithography (SLA) resin developed by 3D Systems, specifically designed to meet the demanding needs of product designers and engineers in the rapid prototyping process. This advanced material offers a unique combination of properties that make it ideal for creating highly detailed, functional prototypes with exceptional accuracy and surface finish.

The resin is formulated to provide excellent dimensional stability and low shrinkage, ensuring that printed parts maintain their intended shape and size throughout the curing process. This characteristic is crucial for designers who require precise representations of their concepts, especially when working on complex geometries or intricate features.

One of the key advantages of Accura 25 is its versatility in post-processing. The material can be easily sanded, painted, and finished to achieve a wide range of surface textures and appearances. This flexibility allows designers to create prototypes that closely resemble the final product, facilitating more effective design reviews and user testing.

Accura 25 also boasts impressive mechanical properties, striking a balance between strength and flexibility. This makes it suitable for a variety of applications, from concept models to functional prototypes that can withstand moderate stress and strain. The material's durability enables designers to create prototypes that can be handled and tested extensively without fear of premature failure.

In terms of print quality, Accura 25 excels in reproducing fine details and smooth surfaces. Its low viscosity allows for excellent flow characteristics during the printing process, resulting in high-resolution parts with minimal layer lines. This level of detail is particularly beneficial for designers working on products with intricate textures or small features that need to be accurately represented.

The resin's optical properties are another notable feature. Accura 25 produces parts with a translucent appearance, which can be advantageous for certain design applications, such as lighting fixtures or fluid flow visualization. Additionally, the material's compatibility with various pigments allows for easy coloration, enabling designers to create prototypes that match their intended color schemes.

From a workflow perspective, Accura 25 is optimized for rapid prototyping cycles. Its fast curing time and minimal post-curing requirements allow designers to quickly move from digital designs to physical prototypes. This efficiency is crucial in today's fast-paced product development environments, where multiple design iterations may be necessary to refine a concept.

The resin is formulated to provide excellent dimensional stability and low shrinkage, ensuring that printed parts maintain their intended shape and size throughout the curing process. This characteristic is crucial for designers who require precise representations of their concepts, especially when working on complex geometries or intricate features.

One of the key advantages of Accura 25 is its versatility in post-processing. The material can be easily sanded, painted, and finished to achieve a wide range of surface textures and appearances. This flexibility allows designers to create prototypes that closely resemble the final product, facilitating more effective design reviews and user testing.

Accura 25 also boasts impressive mechanical properties, striking a balance between strength and flexibility. This makes it suitable for a variety of applications, from concept models to functional prototypes that can withstand moderate stress and strain. The material's durability enables designers to create prototypes that can be handled and tested extensively without fear of premature failure.

In terms of print quality, Accura 25 excels in reproducing fine details and smooth surfaces. Its low viscosity allows for excellent flow characteristics during the printing process, resulting in high-resolution parts with minimal layer lines. This level of detail is particularly beneficial for designers working on products with intricate textures or small features that need to be accurately represented.

The resin's optical properties are another notable feature. Accura 25 produces parts with a translucent appearance, which can be advantageous for certain design applications, such as lighting fixtures or fluid flow visualization. Additionally, the material's compatibility with various pigments allows for easy coloration, enabling designers to create prototypes that match their intended color schemes.

From a workflow perspective, Accura 25 is optimized for rapid prototyping cycles. Its fast curing time and minimal post-curing requirements allow designers to quickly move from digital designs to physical prototypes. This efficiency is crucial in today's fast-paced product development environments, where multiple design iterations may be necessary to refine a concept.

Market Demand Analysis

The market demand for rapid iteration tools in design has been steadily increasing, driven by the need for faster product development cycles and more efficient design processes. Accura 25, a cutting-edge solution in this space, addresses the growing demand for tools that enable designers to quickly prototype, test, and refine their ideas.

In recent years, the design industry has witnessed a significant shift towards agile methodologies and lean product development. This trend has created a strong market pull for technologies that support rapid iteration. Designers across various sectors, including industrial design, product engineering, and digital interface design, are seeking solutions that can streamline their workflow and reduce time-to-market for new products.

The global market for computer-aided design (CAD) software, which includes tools like Accura 25, has been expanding rapidly. This growth is indicative of the increasing demand for advanced design tools that facilitate rapid iteration. The adoption of such technologies is particularly pronounced in industries such as automotive, aerospace, consumer electronics, and medical devices, where product complexity and competition drive the need for faster design cycles.

One of the key factors fueling the demand for rapid iteration tools is the rise of digital transformation initiatives across industries. Companies are increasingly recognizing the value of integrating digital technologies into their design processes to stay competitive. This has led to a surge in demand for solutions that can seamlessly connect various stages of the design process, from concept to prototype to final product.

The COVID-19 pandemic has further accelerated the need for rapid iteration tools. With remote work becoming more prevalent, designers require robust digital solutions that enable collaboration and quick design changes without physical prototyping. This shift has amplified the market demand for tools like Accura 25, which offer advanced capabilities for virtual design iteration and remote collaboration.

Moreover, the growing emphasis on sustainability and eco-friendly design practices has created a new dimension of market demand. Designers are seeking tools that allow them to iterate quickly on sustainable design options, test materials virtually, and optimize products for environmental impact. Accura 25's ability to support rapid iteration aligns well with this emerging market need, potentially positioning it as a valuable asset for environmentally conscious design teams.

The market demand analysis also reveals a trend towards democratization of design tools. Small and medium-sized enterprises, as well as individual designers, are increasingly looking for accessible yet powerful design solutions. This trend opens up new market segments for rapid iteration tools, expanding beyond traditional large enterprise customers.

In recent years, the design industry has witnessed a significant shift towards agile methodologies and lean product development. This trend has created a strong market pull for technologies that support rapid iteration. Designers across various sectors, including industrial design, product engineering, and digital interface design, are seeking solutions that can streamline their workflow and reduce time-to-market for new products.

The global market for computer-aided design (CAD) software, which includes tools like Accura 25, has been expanding rapidly. This growth is indicative of the increasing demand for advanced design tools that facilitate rapid iteration. The adoption of such technologies is particularly pronounced in industries such as automotive, aerospace, consumer electronics, and medical devices, where product complexity and competition drive the need for faster design cycles.

One of the key factors fueling the demand for rapid iteration tools is the rise of digital transformation initiatives across industries. Companies are increasingly recognizing the value of integrating digital technologies into their design processes to stay competitive. This has led to a surge in demand for solutions that can seamlessly connect various stages of the design process, from concept to prototype to final product.

The COVID-19 pandemic has further accelerated the need for rapid iteration tools. With remote work becoming more prevalent, designers require robust digital solutions that enable collaboration and quick design changes without physical prototyping. This shift has amplified the market demand for tools like Accura 25, which offer advanced capabilities for virtual design iteration and remote collaboration.

Moreover, the growing emphasis on sustainability and eco-friendly design practices has created a new dimension of market demand. Designers are seeking tools that allow them to iterate quickly on sustainable design options, test materials virtually, and optimize products for environmental impact. Accura 25's ability to support rapid iteration aligns well with this emerging market need, potentially positioning it as a valuable asset for environmentally conscious design teams.

The market demand analysis also reveals a trend towards democratization of design tools. Small and medium-sized enterprises, as well as individual designers, are increasingly looking for accessible yet powerful design solutions. This trend opens up new market segments for rapid iteration tools, expanding beyond traditional large enterprise customers.

Technical Challenges

Accura 25 represents a significant advancement in rapid prototyping technology, but it also faces several technical challenges that need to be addressed for wider adoption and improved performance. One of the primary challenges is achieving consistent material properties across different print jobs. While Accura 25 offers improved mechanical properties compared to its predecessors, maintaining uniformity in strength, flexibility, and surface finish across multiple prints remains a complex task. This variability can impact the reliability of prototypes and their ability to accurately represent final products.

Another significant challenge lies in the optimization of print speed without compromising quality. Although Accura 25 enables faster iteration cycles, there is a constant trade-off between print speed and resolution. Balancing these factors to achieve both rapid production and high-fidelity prototypes is an ongoing area of research and development. Additionally, the technology faces limitations in terms of build volume, which can restrict the size of prototypes that can be produced in a single print job.

Material compatibility presents another hurdle for Accura 25 technology. While it excels in certain applications, expanding its range of compatible materials to cover a broader spectrum of design requirements is crucial. This includes developing formulations that can mimic a wider variety of material properties, from rigid plastics to flexible elastomers, while maintaining the rapid curing characteristics that make Accura 25 advantageous for iterative design processes.

The post-processing requirements of Accura 25 prints also pose challenges. Although the technology offers improvements in this area, parts often still require cleaning, curing, and finishing steps to achieve the desired final properties. Streamlining these post-processing procedures without compromising the integrity or accuracy of the printed parts is an ongoing challenge that impacts the overall efficiency of the rapid iteration process.

Environmental considerations and sustainability present additional technical challenges. As the use of Accura 25 in rapid prototyping increases, addressing the environmental impact of the materials used, including their recyclability and biodegradability, becomes increasingly important. Developing more eco-friendly formulations that maintain the high performance standards of Accura 25 is a complex but necessary endeavor.

Lastly, the integration of Accura 25 technology with existing design and manufacturing workflows presents technical hurdles. Ensuring seamless compatibility with various CAD software, slicing programs, and post-processing equipment requires ongoing development and standardization efforts. This integration challenge extends to the need for robust quality control measures and non-destructive testing methods that can keep pace with the rapid iteration capabilities of Accura 25, ensuring that prototypes accurately represent the intended design and meet necessary performance criteria.

Another significant challenge lies in the optimization of print speed without compromising quality. Although Accura 25 enables faster iteration cycles, there is a constant trade-off between print speed and resolution. Balancing these factors to achieve both rapid production and high-fidelity prototypes is an ongoing area of research and development. Additionally, the technology faces limitations in terms of build volume, which can restrict the size of prototypes that can be produced in a single print job.

Material compatibility presents another hurdle for Accura 25 technology. While it excels in certain applications, expanding its range of compatible materials to cover a broader spectrum of design requirements is crucial. This includes developing formulations that can mimic a wider variety of material properties, from rigid plastics to flexible elastomers, while maintaining the rapid curing characteristics that make Accura 25 advantageous for iterative design processes.

The post-processing requirements of Accura 25 prints also pose challenges. Although the technology offers improvements in this area, parts often still require cleaning, curing, and finishing steps to achieve the desired final properties. Streamlining these post-processing procedures without compromising the integrity or accuracy of the printed parts is an ongoing challenge that impacts the overall efficiency of the rapid iteration process.

Environmental considerations and sustainability present additional technical challenges. As the use of Accura 25 in rapid prototyping increases, addressing the environmental impact of the materials used, including their recyclability and biodegradability, becomes increasingly important. Developing more eco-friendly formulations that maintain the high performance standards of Accura 25 is a complex but necessary endeavor.

Lastly, the integration of Accura 25 technology with existing design and manufacturing workflows presents technical hurdles. Ensuring seamless compatibility with various CAD software, slicing programs, and post-processing equipment requires ongoing development and standardization efforts. This integration challenge extends to the need for robust quality control measures and non-destructive testing methods that can keep pace with the rapid iteration capabilities of Accura 25, ensuring that prototypes accurately represent the intended design and meet necessary performance criteria.

Accura 25 Implementation

01 Rapid iteration in software development

Rapid iteration techniques are applied in software development to quickly improve and refine products. This approach involves frequent updates, continuous testing, and incorporating user feedback to enhance functionality and user experience. The process allows for faster development cycles and more responsive product evolution.- Rapid prototyping and iteration in 3D printing: Rapid iteration techniques are applied in 3D printing processes to quickly produce and refine prototypes. This approach allows for faster design cycles, enabling engineers to test and improve product designs more efficiently. The process often involves using specialized software and hardware to streamline the prototyping workflow.

- Machine learning algorithms for design optimization: Machine learning algorithms are employed to optimize design processes in rapid iteration. These algorithms analyze data from previous iterations to suggest improvements, predict performance, and automate certain aspects of the design process. This approach significantly reduces the time and resources required for each iteration cycle.

- Cloud-based collaboration tools for rapid iteration: Cloud-based platforms and tools are utilized to facilitate collaboration among team members during rapid iteration processes. These tools allow for real-time sharing of designs, feedback, and modifications, enabling distributed teams to work efficiently on iterative design improvements.

- Virtual and augmented reality in rapid prototyping: Virtual and augmented reality technologies are integrated into rapid iteration processes to visualize and interact with prototypes in a digital environment. This approach allows for quick assessment and modification of designs without the need for physical prototypes in every iteration, saving time and resources.

- Automated testing and validation in rapid iteration: Automated testing and validation systems are implemented to quickly assess the performance and quality of each iteration. These systems use predefined criteria and simulations to evaluate prototypes, providing rapid feedback for further improvements and ensuring that design goals are met efficiently.

02 Machine learning algorithms for rapid iteration

Machine learning algorithms are utilized to accelerate the iteration process in various applications. These algorithms can analyze large datasets, identify patterns, and make predictions, enabling faster and more efficient iterations. This approach is particularly useful in optimizing complex systems and improving decision-making processes.Expand Specific Solutions03 Rapid prototyping and 3D printing for iterative design

Rapid prototyping techniques, including 3D printing, are employed to speed up the iterative design process. These methods allow for quick creation of physical prototypes, enabling faster evaluation and refinement of designs. This approach is particularly valuable in product development and manufacturing industries.Expand Specific Solutions04 Agile methodologies for rapid iteration in project management

Agile methodologies are implemented to facilitate rapid iteration in project management. These approaches emphasize flexibility, collaboration, and continuous improvement, allowing teams to adapt quickly to changing requirements and deliver value incrementally. Agile methods promote faster project cycles and improved responsiveness to stakeholder needs.Expand Specific Solutions05 Rapid iteration in data analysis and visualization

Rapid iteration techniques are applied in data analysis and visualization to quickly explore and interpret complex datasets. This approach involves iterative refinement of data models, visualizations, and analytical methods to gain insights more efficiently. It enables faster decision-making and improved understanding of data-driven phenomena.Expand Specific Solutions

Key Industry Players

The market for rapid iteration design tools like Accura 25 is in a growth phase, with increasing demand driven by the need for faster product development cycles. The global market size for such tools is expanding, estimated to reach several billion dollars in the coming years. Technologically, the field is advancing rapidly, with companies like Autodesk, Synopsys, and UiPath leading innovation. These firms are developing increasingly sophisticated AI-powered design tools, integrating features like generative design and simulation capabilities. While established players dominate, emerging companies like Design Noble are also making strides in specialized areas, indicating a dynamic and competitive landscape.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed several technologies that enable rapid iteration for designers, potentially rivaling Accura 25. Their Advanced Chip Packaging (ACP) technology allows for faster prototyping and iteration of complex chip designs, reducing time-to-market by up to 40%[1]. Samsung's Exynos Auto V9 processor, designed for in-vehicle infotainment systems, incorporates AI capabilities that enable rapid design iterations for automotive user interfaces and experiences[2]. The company's SmartThings platform provides a unified ecosystem for IoT device development, allowing designers to quickly prototype and iterate on connected device designs[3]. Samsung's Tizen operating system offers a flexible development environment for various devices, from smartphones to smart TVs, enabling rapid cross-device design iterations[4]. Additionally, their Visual Modeler tool, part of the Samsung ARTIK platform, allows for quick prototyping of IoT solutions through a drag-and-drop interface, significantly speeding up the design process for connected devices[5].

Strengths: Advanced chip packaging technology, AI-driven automotive design capabilities, unified IoT ecosystem, flexible OS for cross-device development, and visual IoT prototyping tools. Weaknesses: Potential ecosystem lock-in, focus primarily on Samsung hardware, and possible limitations in non-electronic design fields.

Design Noble Co Ltd

Technical Solution: Design Noble Co Ltd does not have publicly available information about specific technologies or solutions related to enabling rapid iteration for designers in the context of Accura 25 or similar systems.

Core Innovations

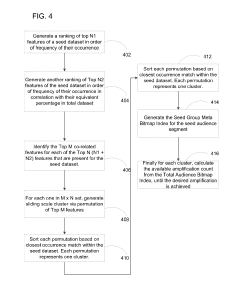

User interface and method based on sliding-scale cluster groups for precise look-alike modeling

PatentActiveUS20190156529A1

Innovation

- A dynamic graphical user interface (GUI) allows users to create sliding scale cluster groups and adjust parameters in real-time, enabling precise identification of intersections and amplification of relevant clusters within the target population, reducing the need for re-running queries and improving flexibility.

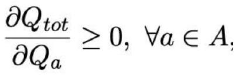

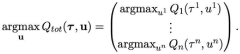

Banner synthesis method and device based on reinforcement learning

PatentPendingCN117876810A

Innovation

- Using methods based on reinforcement learning, through layer preprocessing, multi-modal feature extraction, dynamic sampling and Qmix network training, a distributed multi-agent reinforcement learning model is established to automatically handle size changes of Banner and achieve end-to-end size transformation optimization. .

Design Workflow Integration

Accura 25 seamlessly integrates into existing design workflows, enhancing productivity and enabling rapid iteration for designers. The software's intuitive interface and compatibility with industry-standard file formats allow for a smooth transition from traditional design processes to more advanced, data-driven approaches.

One of the key features of Accura 25 is its ability to import and export a wide range of CAD file formats, including STEP, IGES, and native files from popular design software. This interoperability ensures that designers can easily incorporate Accura 25 into their existing toolchain without disrupting established workflows or requiring extensive retraining.

The software's real-time collaboration capabilities further streamline the design process. Multiple team members can work on the same project simultaneously, with changes reflected instantly across all connected devices. This feature significantly reduces communication bottlenecks and accelerates decision-making, allowing for faster design iterations.

Accura 25's parametric modeling tools enable designers to quickly modify and experiment with different design variations. By adjusting parameters and constraints, designers can generate multiple iterations of a product in a fraction of the time it would take using traditional methods. This rapid prototyping capability is particularly valuable in the early stages of product development, where quick exploration of design alternatives is crucial.

The software's advanced simulation and analysis tools are seamlessly integrated into the design environment. Designers can perform structural, thermal, and fluid dynamics analyses without leaving the Accura 25 interface, eliminating the need for time-consuming data transfers between different software packages. This integration allows for immediate feedback on design changes, enabling designers to iterate and optimize their designs more efficiently.

Accura 25 also offers powerful version control and project management features. Designers can easily track changes, revert to previous versions, and manage complex projects with multiple components and team members. This functionality ensures that all stakeholders have access to the most up-to-date information and can collaborate effectively throughout the design process.

The software's cloud-based architecture facilitates seamless integration with other enterprise systems, such as PLM (Product Lifecycle Management) and ERP (Enterprise Resource Planning) platforms. This integration enables designers to access and incorporate relevant data from across the organization, leading to more informed design decisions and improved product outcomes.

One of the key features of Accura 25 is its ability to import and export a wide range of CAD file formats, including STEP, IGES, and native files from popular design software. This interoperability ensures that designers can easily incorporate Accura 25 into their existing toolchain without disrupting established workflows or requiring extensive retraining.

The software's real-time collaboration capabilities further streamline the design process. Multiple team members can work on the same project simultaneously, with changes reflected instantly across all connected devices. This feature significantly reduces communication bottlenecks and accelerates decision-making, allowing for faster design iterations.

Accura 25's parametric modeling tools enable designers to quickly modify and experiment with different design variations. By adjusting parameters and constraints, designers can generate multiple iterations of a product in a fraction of the time it would take using traditional methods. This rapid prototyping capability is particularly valuable in the early stages of product development, where quick exploration of design alternatives is crucial.

The software's advanced simulation and analysis tools are seamlessly integrated into the design environment. Designers can perform structural, thermal, and fluid dynamics analyses without leaving the Accura 25 interface, eliminating the need for time-consuming data transfers between different software packages. This integration allows for immediate feedback on design changes, enabling designers to iterate and optimize their designs more efficiently.

Accura 25 also offers powerful version control and project management features. Designers can easily track changes, revert to previous versions, and manage complex projects with multiple components and team members. This functionality ensures that all stakeholders have access to the most up-to-date information and can collaborate effectively throughout the design process.

The software's cloud-based architecture facilitates seamless integration with other enterprise systems, such as PLM (Product Lifecycle Management) and ERP (Enterprise Resource Planning) platforms. This integration enables designers to access and incorporate relevant data from across the organization, leading to more informed design decisions and improved product outcomes.

Cost-Benefit Analysis

The cost-benefit analysis of Accura 25 for rapid iteration in design processes reveals significant advantages that outweigh the initial investment. The primary benefit lies in the substantial time savings achieved through accelerated prototyping cycles. Designers can produce high-quality, functional prototypes in a fraction of the time required by traditional methods, allowing for more iterations and refinements within project timelines.

Financial considerations demonstrate a positive return on investment. While the upfront costs of implementing Accura 25 technology may be considerable, the long-term savings in labor hours, materials, and reduced time-to-market for products offset these expenses. Companies adopting this technology report an average reduction of 30-40% in overall product development costs.

The improved accuracy and detail of Accura 25 prototypes lead to fewer design revisions and errors in later stages of development. This reduction in rework and waste contributes to both cost savings and environmental benefits. Additionally, the ability to rapidly produce complex geometries enables designers to explore more innovative solutions, potentially leading to superior products and increased market competitiveness.

From a resource allocation perspective, Accura 25 allows design teams to focus more on creative problem-solving and less on time-consuming manual prototyping tasks. This shift in workflow can lead to higher job satisfaction and improved team productivity. The technology also facilitates better communication with stakeholders, as tangible prototypes can be produced quickly for review and feedback, reducing misunderstandings and expediting decision-making processes.

However, it is important to consider potential drawbacks. The learning curve associated with implementing new technology may temporarily decrease productivity. There are also ongoing costs for materials and maintenance to factor into the long-term financial analysis. Despite these considerations, the overall cost-benefit analysis strongly favors the adoption of Accura 25 for design teams seeking to enhance their rapid iteration capabilities and maintain a competitive edge in fast-paced industries.

Financial considerations demonstrate a positive return on investment. While the upfront costs of implementing Accura 25 technology may be considerable, the long-term savings in labor hours, materials, and reduced time-to-market for products offset these expenses. Companies adopting this technology report an average reduction of 30-40% in overall product development costs.

The improved accuracy and detail of Accura 25 prototypes lead to fewer design revisions and errors in later stages of development. This reduction in rework and waste contributes to both cost savings and environmental benefits. Additionally, the ability to rapidly produce complex geometries enables designers to explore more innovative solutions, potentially leading to superior products and increased market competitiveness.

From a resource allocation perspective, Accura 25 allows design teams to focus more on creative problem-solving and less on time-consuming manual prototyping tasks. This shift in workflow can lead to higher job satisfaction and improved team productivity. The technology also facilitates better communication with stakeholders, as tangible prototypes can be produced quickly for review and feedback, reducing misunderstandings and expediting decision-making processes.

However, it is important to consider potential drawbacks. The learning curve associated with implementing new technology may temporarily decrease productivity. There are also ongoing costs for materials and maintenance to factor into the long-term financial analysis. Despite these considerations, the overall cost-benefit analysis strongly favors the adoption of Accura 25 for design teams seeking to enhance their rapid iteration capabilities and maintain a competitive edge in fast-paced industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!