How Antifreeze Affects New Automotive Cooling Standards?

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antifreeze Evolution and Automotive Cooling Goals

Antifreeze has played a crucial role in automotive cooling systems since the early days of the automobile industry. The evolution of antifreeze technology has been closely tied to the development of more efficient and environmentally friendly automotive cooling standards. Initially, methanol was used as an antifreeze agent, but its toxicity and corrosive properties led to the adoption of ethylene glycol in the 1920s.

As automotive technology advanced, the demands on cooling systems increased, necessitating improvements in antifreeze formulations. The introduction of aluminum engines in the 1970s required antifreeze with enhanced corrosion protection properties. This led to the development of Organic Acid Technology (OAT) coolants in the 1990s, which offered improved protection and longer service life.

The automotive industry's focus on sustainability and environmental protection has driven further innovations in antifreeze technology. Propylene glycol-based antifreeze, which is less toxic than ethylene glycol, has gained popularity in recent years. Additionally, the development of hybrid organic acid technology (HOAT) coolants has combined the benefits of traditional and OAT coolants, offering superior protection and compatibility with various engine materials.

Current automotive cooling goals are centered around improving engine efficiency, reducing emissions, and extending component lifespan. Modern antifreeze formulations are expected to contribute to these objectives by providing better heat transfer properties, minimizing corrosion, and reducing the frequency of coolant changes. The trend towards electric and hybrid vehicles has also introduced new challenges, as these powertrains have different cooling requirements compared to traditional internal combustion engines.

The automotive industry is now exploring advanced cooling technologies, such as split cooling systems and precision cooling, which require specialized antifreeze formulations. These systems aim to optimize engine temperature management, leading to improved fuel efficiency and reduced emissions. As a result, antifreeze manufacturers are developing products that can withstand higher operating temperatures and provide more efficient heat transfer.

Looking ahead, the automotive cooling goals are likely to focus on further reducing environmental impact, improving compatibility with new materials and technologies, and enhancing overall system efficiency. This may involve the development of bio-based antifreeze solutions, nanotechnology-enhanced coolants, and smart cooling systems that can adapt to varying driving conditions and vehicle loads.

As automotive technology advanced, the demands on cooling systems increased, necessitating improvements in antifreeze formulations. The introduction of aluminum engines in the 1970s required antifreeze with enhanced corrosion protection properties. This led to the development of Organic Acid Technology (OAT) coolants in the 1990s, which offered improved protection and longer service life.

The automotive industry's focus on sustainability and environmental protection has driven further innovations in antifreeze technology. Propylene glycol-based antifreeze, which is less toxic than ethylene glycol, has gained popularity in recent years. Additionally, the development of hybrid organic acid technology (HOAT) coolants has combined the benefits of traditional and OAT coolants, offering superior protection and compatibility with various engine materials.

Current automotive cooling goals are centered around improving engine efficiency, reducing emissions, and extending component lifespan. Modern antifreeze formulations are expected to contribute to these objectives by providing better heat transfer properties, minimizing corrosion, and reducing the frequency of coolant changes. The trend towards electric and hybrid vehicles has also introduced new challenges, as these powertrains have different cooling requirements compared to traditional internal combustion engines.

The automotive industry is now exploring advanced cooling technologies, such as split cooling systems and precision cooling, which require specialized antifreeze formulations. These systems aim to optimize engine temperature management, leading to improved fuel efficiency and reduced emissions. As a result, antifreeze manufacturers are developing products that can withstand higher operating temperatures and provide more efficient heat transfer.

Looking ahead, the automotive cooling goals are likely to focus on further reducing environmental impact, improving compatibility with new materials and technologies, and enhancing overall system efficiency. This may involve the development of bio-based antifreeze solutions, nanotechnology-enhanced coolants, and smart cooling systems that can adapt to varying driving conditions and vehicle loads.

Market Demand for Advanced Cooling Solutions

The automotive industry is experiencing a significant shift towards advanced cooling solutions, driven by the increasing complexity of modern vehicles and stringent environmental regulations. As vehicles become more sophisticated, with higher-performance engines, electric powertrains, and advanced electronics, the demand for efficient and reliable cooling systems has grown exponentially. This market trend is further amplified by the global push for reduced emissions and improved fuel efficiency, which requires more effective thermal management solutions.

The integration of antifreeze into these advanced cooling systems plays a crucial role in meeting new automotive cooling standards. Antifreeze, traditionally used to prevent freezing in cold climates, has evolved to become a vital component in maintaining optimal operating temperatures across a wide range of conditions. The market for advanced antifreeze formulations is expanding, with a focus on products that offer extended service life, improved heat transfer capabilities, and compatibility with new materials used in modern engines and cooling systems.

Automotive manufacturers are increasingly seeking cooling solutions that can handle the heat generated by high-performance engines and electric powertrains. This has led to a growing demand for antifreeze products that can maintain stability at higher temperatures and provide superior corrosion protection for aluminum and other lightweight materials commonly used in modern vehicle construction. Additionally, there is a rising interest in environmentally friendly antifreeze formulations that reduce the environmental impact of vehicle maintenance and disposal.

The market for advanced cooling solutions is also being driven by the rapid growth of electric and hybrid vehicles. These vehicles require sophisticated thermal management systems to regulate battery temperatures, optimize performance, and extend range. Antifreeze formulations designed specifically for electric vehicle applications are gaining traction, offering enhanced electrical conductivity protection and compatibility with unique cooling system designs.

Furthermore, the increasing adoption of autonomous driving technologies and advanced driver assistance systems (ADAS) is creating new thermal management challenges. These systems generate significant heat and require precise temperature control to function reliably. As a result, there is a growing demand for cooling solutions that can effectively manage heat dissipation in complex electronic systems while maintaining overall vehicle efficiency.

The aftermarket segment is also experiencing increased demand for advanced antifreeze products. As vehicle owners become more aware of the importance of proper cooling system maintenance, there is a trend towards premium, long-life antifreeze formulations that offer extended protection and reduced maintenance intervals. This shift is driving innovation in antifreeze technology and creating opportunities for manufacturers to differentiate their products in a competitive market.

The integration of antifreeze into these advanced cooling systems plays a crucial role in meeting new automotive cooling standards. Antifreeze, traditionally used to prevent freezing in cold climates, has evolved to become a vital component in maintaining optimal operating temperatures across a wide range of conditions. The market for advanced antifreeze formulations is expanding, with a focus on products that offer extended service life, improved heat transfer capabilities, and compatibility with new materials used in modern engines and cooling systems.

Automotive manufacturers are increasingly seeking cooling solutions that can handle the heat generated by high-performance engines and electric powertrains. This has led to a growing demand for antifreeze products that can maintain stability at higher temperatures and provide superior corrosion protection for aluminum and other lightweight materials commonly used in modern vehicle construction. Additionally, there is a rising interest in environmentally friendly antifreeze formulations that reduce the environmental impact of vehicle maintenance and disposal.

The market for advanced cooling solutions is also being driven by the rapid growth of electric and hybrid vehicles. These vehicles require sophisticated thermal management systems to regulate battery temperatures, optimize performance, and extend range. Antifreeze formulations designed specifically for electric vehicle applications are gaining traction, offering enhanced electrical conductivity protection and compatibility with unique cooling system designs.

Furthermore, the increasing adoption of autonomous driving technologies and advanced driver assistance systems (ADAS) is creating new thermal management challenges. These systems generate significant heat and require precise temperature control to function reliably. As a result, there is a growing demand for cooling solutions that can effectively manage heat dissipation in complex electronic systems while maintaining overall vehicle efficiency.

The aftermarket segment is also experiencing increased demand for advanced antifreeze products. As vehicle owners become more aware of the importance of proper cooling system maintenance, there is a trend towards premium, long-life antifreeze formulations that offer extended protection and reduced maintenance intervals. This shift is driving innovation in antifreeze technology and creating opportunities for manufacturers to differentiate their products in a competitive market.

Current Antifreeze Technology and Challenges

The current state of antifreeze technology in automotive cooling systems is characterized by a blend of traditional solutions and emerging innovations. Ethylene glycol-based antifreeze remains the most widely used coolant, valued for its excellent heat transfer properties and low freezing point. However, concerns about its toxicity have led to increased adoption of propylene glycol-based alternatives, which offer similar performance with reduced environmental and health risks.

One of the primary challenges facing antifreeze technology is the need for improved thermal management in modern vehicles. As engines become more compact and powerful, the demand for efficient heat dissipation grows. This has led to the development of advanced coolant formulations that incorporate nanoparticles to enhance thermal conductivity. These nanofluids show promise in improving overall cooling system efficiency, but their long-term stability and potential effects on engine components remain areas of ongoing research.

Another significant challenge is the compatibility of antifreeze with new materials used in automotive manufacturing. As manufacturers increasingly turn to lightweight materials like aluminum and composites to improve fuel efficiency, coolant formulations must be adapted to prevent corrosion and degradation of these materials. This has spurred research into new corrosion inhibitors and additives that can protect a wider range of materials while maintaining optimal cooling performance.

The push for more environmentally friendly solutions presents both a challenge and an opportunity for antifreeze technology. There is growing interest in biodegradable and renewable antifreeze options, such as those derived from plant-based glycols. While these alternatives show promise in reducing environmental impact, they often face hurdles in matching the performance and cost-effectiveness of traditional formulations.

Electrification of vehicles is also driving changes in antifreeze technology. Electric and hybrid vehicles require cooling systems that can manage both powertrain and battery temperatures effectively. This has led to the development of dual-circuit cooling systems and specialized coolants designed to meet the unique thermal management needs of electric drivetrains.

Lastly, the industry faces challenges in standardization and compatibility across different vehicle makes and models. As cooling system designs become more complex and varied, there is a growing need for universal coolant solutions that can perform effectively across a wide range of applications. This has prompted research into more versatile antifreeze formulations that can adapt to different cooling system requirements without compromising performance or longevity.

One of the primary challenges facing antifreeze technology is the need for improved thermal management in modern vehicles. As engines become more compact and powerful, the demand for efficient heat dissipation grows. This has led to the development of advanced coolant formulations that incorporate nanoparticles to enhance thermal conductivity. These nanofluids show promise in improving overall cooling system efficiency, but their long-term stability and potential effects on engine components remain areas of ongoing research.

Another significant challenge is the compatibility of antifreeze with new materials used in automotive manufacturing. As manufacturers increasingly turn to lightweight materials like aluminum and composites to improve fuel efficiency, coolant formulations must be adapted to prevent corrosion and degradation of these materials. This has spurred research into new corrosion inhibitors and additives that can protect a wider range of materials while maintaining optimal cooling performance.

The push for more environmentally friendly solutions presents both a challenge and an opportunity for antifreeze technology. There is growing interest in biodegradable and renewable antifreeze options, such as those derived from plant-based glycols. While these alternatives show promise in reducing environmental impact, they often face hurdles in matching the performance and cost-effectiveness of traditional formulations.

Electrification of vehicles is also driving changes in antifreeze technology. Electric and hybrid vehicles require cooling systems that can manage both powertrain and battery temperatures effectively. This has led to the development of dual-circuit cooling systems and specialized coolants designed to meet the unique thermal management needs of electric drivetrains.

Lastly, the industry faces challenges in standardization and compatibility across different vehicle makes and models. As cooling system designs become more complex and varied, there is a growing need for universal coolant solutions that can perform effectively across a wide range of applications. This has prompted research into more versatile antifreeze formulations that can adapt to different cooling system requirements without compromising performance or longevity.

Existing Antifreeze Formulations and Their Impact

01 Composition of antifreeze coolants

Antifreeze coolants are typically composed of a mixture of water and chemical additives. These additives often include glycols, corrosion inhibitors, and other compounds to enhance the coolant's performance and protect the cooling system. The specific composition may vary depending on the application and required standards.- Composition of antifreeze coolants: Antifreeze coolants are typically composed of a mixture of water and chemical additives. These additives often include glycols, corrosion inhibitors, and other compounds to enhance the cooling properties and protect the engine. The specific composition may vary depending on the application and environmental conditions.

- Temperature range and performance standards: Antifreeze cooling standards specify the temperature range in which the coolant must remain effective. This includes both low-temperature protection against freezing and high-temperature protection against boiling. Performance standards also cover factors such as heat transfer efficiency, corrosion protection, and long-term stability.

- Testing methods for antifreeze coolants: Standardized testing methods are used to evaluate the performance of antifreeze coolants. These tests may include freezing point depression, boiling point elevation, corrosion protection, and compatibility with various materials used in cooling systems. The results of these tests are used to ensure compliance with industry standards.

- Environmental and safety considerations: Antifreeze cooling standards also address environmental and safety concerns. This includes regulations on the disposal of used coolants, toxicity levels, and biodegradability. Some standards may require the use of more environmentally friendly alternatives to traditional ethylene glycol-based coolants.

- Application-specific standards: Different industries and applications may have specific antifreeze cooling standards. For example, automotive, aerospace, and industrial cooling systems may each have their own set of requirements. These standards take into account the unique operating conditions and performance needs of each application.

02 Testing and quality control standards

Antifreeze coolants must meet specific testing and quality control standards to ensure their effectiveness and safety. These standards may include tests for freezing point, boiling point, corrosion protection, and compatibility with various materials used in cooling systems. Standardized testing procedures are essential for maintaining consistent product quality across different manufacturers.Expand Specific Solutions03 Environmental and safety regulations

Antifreeze coolants are subject to environmental and safety regulations that govern their production, use, and disposal. These regulations may include restrictions on certain chemicals, requirements for biodegradability, and guidelines for proper handling and recycling. Manufacturers must adhere to these standards to ensure their products are environmentally friendly and safe for use.Expand Specific Solutions04 Performance requirements for specific applications

Different applications may have specific performance requirements for antifreeze coolants. For example, automotive coolants may have different standards compared to those used in industrial or marine applications. These standards may address factors such as heat transfer efficiency, long-term stability, and compatibility with specific engine materials.Expand Specific Solutions05 Innovations in antifreeze cooling technology

Ongoing research and development in antifreeze cooling technology lead to innovations that improve performance and meet evolving standards. These innovations may include new additives, improved formulations for extended service life, or advanced testing methods to ensure compliance with stricter regulations and performance requirements.Expand Specific Solutions

Key Players in Antifreeze and Cooling System Industry

The antifreeze technology market for automotive cooling systems is in a mature stage, with a global market size estimated to be in the billions of dollars. Major players like BASF, Prestone, and Shell dominate the industry, leveraging their extensive R&D capabilities and established distribution networks. The technology's maturity is evident in the widespread adoption of ethylene glycol-based solutions. However, innovation continues as companies like Honda and Hyundai explore more environmentally friendly and efficient coolant formulations. Emerging trends include the development of low-toxicity propylene glycol-based antifreeze and the integration of nanotechnology to enhance heat transfer properties. As automotive manufacturers increasingly focus on electric vehicles, new challenges and opportunities are arising in cooling system design, driving further innovation in antifreeze technology.

BASF Corp.

Technical Solution: BASF has developed advanced antifreeze formulations that meet new automotive cooling standards. Their Glysantin® G40® coolant technology uses organic acid technology (OAT) with silicate additives, providing extended protection against corrosion and cavitation. This formulation is compatible with modern engine materials, including aluminum and magnesium alloys [1]. BASF's antifreeze solutions also incorporate low-viscosity properties to improve heat transfer efficiency and reduce pump energy consumption, aligning with the automotive industry's focus on fuel efficiency and reduced emissions [2]. The company has invested in research to develop coolants that maintain stability at higher operating temperatures, addressing the needs of more compact, high-performance engines [3].

Strengths: Extensive R&D capabilities, global presence, and a wide range of tailored solutions for different OEMs. Weaknesses: Higher cost compared to conventional antifreeze formulations, which may impact adoption in price-sensitive markets.

Honda Motor Co., Ltd.

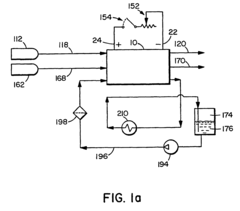

Technical Solution: Honda has implemented a two-circuit cooling system in their latest vehicle models to meet new automotive cooling standards. This innovative approach separates the engine block and cylinder head cooling circuits, allowing for more precise temperature control [4]. The system utilizes a low-viscosity, long-life coolant that improves heat dissipation and reduces the overall coolant volume needed. Honda's antifreeze solution incorporates organic acid technology (OAT) with specific inhibitors to protect aluminum components and prevent electrolytic corrosion in modern engines [5]. Additionally, Honda has developed smart thermal management systems that optimize coolant flow based on engine load and ambient conditions, further enhancing efficiency and reducing emissions [6].

Strengths: Integrated approach combining advanced cooling system design with tailored antifreeze formulations. Weaknesses: Proprietary technology may limit wider industry adoption and increase maintenance costs for consumers.

Innovations in Antifreeze Chemical Composition

Antifreeze/liquid coolant composition and method of use

PatentInactiveUS20070090324A1

Innovation

- A non-hazardous antifreeze coolant composition comprising glycerine, anti-oxidants, and boron-based film formers, with optional water addition, that enhances temperature stability, prevents corrosion and scale formation, and ensures effective heat transfer across a wide temperature range.

Antifreeze cooling subsystem

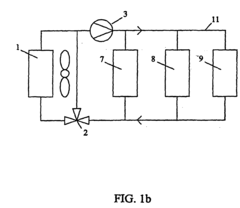

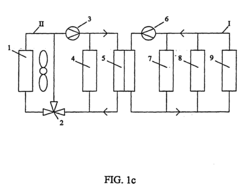

PatentInactiveEP1116296B1

Innovation

- Incorporating an ion exchange resin unit in the coolant circulation loop to maintain the purity of the glycol-based coolant, specifically using a strong base anion resin, to keep conductivity below 50 µS/cm and prevent glycol decomposition products from accumulating, thereby reducing corrosion and electrical shock risks.

Environmental Impact of Antifreeze Solutions

The environmental impact of antifreeze solutions is a critical consideration in the automotive industry's pursuit of new cooling standards. Traditional antifreeze formulations, primarily based on ethylene glycol or propylene glycol, have long been associated with potential ecological hazards. When improperly disposed of, these chemicals can contaminate soil and water sources, posing risks to wildlife and human health.

Recent studies have shown that ethylene glycol, the most common antifreeze component, can persist in the environment for extended periods. Its sweet taste attracts animals, leading to accidental ingestion and potential fatalities. Moreover, the breakdown of antifreeze in water bodies can deplete oxygen levels, adversely affecting aquatic ecosystems.

In response to these concerns, the automotive industry has been exploring more environmentally friendly alternatives. Bio-based antifreeze solutions, derived from renewable resources such as corn or soybean, have gained attention. These formulations offer comparable performance to traditional antifreeze while significantly reducing environmental toxicity and improving biodegradability.

Another approach focuses on enhancing the recyclability of antifreeze solutions. Advanced recycling technologies have been developed to purify used antifreeze, removing contaminants and restoring its protective properties. This circular economy approach not only reduces waste but also minimizes the need for new antifreeze production, thereby lowering the overall environmental footprint.

The industry is also investigating the potential of nanomaterials in antifreeze formulations. Nanoparticles can enhance the thermal conductivity and heat transfer properties of coolants, potentially allowing for reduced antifreeze concentrations while maintaining performance. This could lead to a decrease in the volume of potentially harmful substances released into the environment.

Regulatory bodies have responded to these environmental concerns by implementing stricter standards for antifreeze disposal and encouraging the use of more eco-friendly formulations. Some regions have introduced mandatory recycling programs for automotive fluids, including antifreeze, to prevent improper disposal and environmental contamination.

As automotive cooling systems evolve, there is a growing emphasis on developing closed-loop systems that minimize the risk of antifreeze leakage. These advanced systems not only improve vehicle performance but also reduce the likelihood of environmental exposure to harmful chemicals.

The shift towards electric vehicles (EVs) is also influencing antifreeze environmental considerations. EVs require different cooling solutions for their battery systems, prompting research into specialized coolants with lower environmental impact. These developments may lead to new standards that prioritize both performance and ecological sustainability in automotive cooling systems.

Recent studies have shown that ethylene glycol, the most common antifreeze component, can persist in the environment for extended periods. Its sweet taste attracts animals, leading to accidental ingestion and potential fatalities. Moreover, the breakdown of antifreeze in water bodies can deplete oxygen levels, adversely affecting aquatic ecosystems.

In response to these concerns, the automotive industry has been exploring more environmentally friendly alternatives. Bio-based antifreeze solutions, derived from renewable resources such as corn or soybean, have gained attention. These formulations offer comparable performance to traditional antifreeze while significantly reducing environmental toxicity and improving biodegradability.

Another approach focuses on enhancing the recyclability of antifreeze solutions. Advanced recycling technologies have been developed to purify used antifreeze, removing contaminants and restoring its protective properties. This circular economy approach not only reduces waste but also minimizes the need for new antifreeze production, thereby lowering the overall environmental footprint.

The industry is also investigating the potential of nanomaterials in antifreeze formulations. Nanoparticles can enhance the thermal conductivity and heat transfer properties of coolants, potentially allowing for reduced antifreeze concentrations while maintaining performance. This could lead to a decrease in the volume of potentially harmful substances released into the environment.

Regulatory bodies have responded to these environmental concerns by implementing stricter standards for antifreeze disposal and encouraging the use of more eco-friendly formulations. Some regions have introduced mandatory recycling programs for automotive fluids, including antifreeze, to prevent improper disposal and environmental contamination.

As automotive cooling systems evolve, there is a growing emphasis on developing closed-loop systems that minimize the risk of antifreeze leakage. These advanced systems not only improve vehicle performance but also reduce the likelihood of environmental exposure to harmful chemicals.

The shift towards electric vehicles (EVs) is also influencing antifreeze environmental considerations. EVs require different cooling solutions for their battery systems, prompting research into specialized coolants with lower environmental impact. These developments may lead to new standards that prioritize both performance and ecological sustainability in automotive cooling systems.

Regulatory Framework for Automotive Coolants

The regulatory framework for automotive coolants has evolved significantly in recent years, driven by the need for improved vehicle performance, environmental protection, and safety standards. Governments and industry bodies worldwide have established comprehensive guidelines and regulations to ensure the proper use and disposal of antifreeze and other coolants in automotive applications.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating automotive coolants. The EPA has set strict standards for the composition and disposal of antifreeze, particularly focusing on the reduction of toxic substances such as ethylene glycol. The agency's Significant New Alternatives Policy (SNAP) program evaluates and regulates substitutes for ozone-depleting substances, including those used in automotive cooling systems.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which affects the production and use of automotive coolants. This regulation requires manufacturers to register chemical substances and provide safety information, ensuring that potentially harmful substances in coolants are properly managed and controlled.

In addition to government regulations, industry standards such as those set by the American Society for Testing and Materials (ASTM) and the Society of Automotive Engineers (SAE) provide detailed specifications for automotive coolants. These standards cover aspects such as corrosion protection, freeze protection, and compatibility with various materials used in cooling systems.

The introduction of new coolant technologies, such as Organic Acid Technology (OAT) and Hybrid Organic Acid Technology (HOAT), has led to the development of specific regulations and standards. These new formulations offer improved performance and longevity but require careful management to ensure compatibility with existing systems and proper disposal practices.

Environmental concerns have also shaped the regulatory landscape for automotive coolants. Many jurisdictions now require the recycling of used antifreeze to reduce environmental impact and conserve resources. Regulations often mandate proper labeling, storage, and disposal procedures for coolants, with severe penalties for non-compliance.

As vehicle technologies advance, particularly with the rise of electric and hybrid vehicles, regulatory bodies are adapting their frameworks to address new cooling challenges. This includes regulations for battery thermal management systems and the use of alternative cooling fluids in these advanced propulsion systems.

The global nature of the automotive industry has led to efforts to harmonize coolant regulations across different regions. International organizations such as the United Nations Economic Commission for Europe (UNECE) work towards creating unified standards that can be adopted worldwide, simplifying compliance for manufacturers operating in multiple markets.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating automotive coolants. The EPA has set strict standards for the composition and disposal of antifreeze, particularly focusing on the reduction of toxic substances such as ethylene glycol. The agency's Significant New Alternatives Policy (SNAP) program evaluates and regulates substitutes for ozone-depleting substances, including those used in automotive cooling systems.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which affects the production and use of automotive coolants. This regulation requires manufacturers to register chemical substances and provide safety information, ensuring that potentially harmful substances in coolants are properly managed and controlled.

In addition to government regulations, industry standards such as those set by the American Society for Testing and Materials (ASTM) and the Society of Automotive Engineers (SAE) provide detailed specifications for automotive coolants. These standards cover aspects such as corrosion protection, freeze protection, and compatibility with various materials used in cooling systems.

The introduction of new coolant technologies, such as Organic Acid Technology (OAT) and Hybrid Organic Acid Technology (HOAT), has led to the development of specific regulations and standards. These new formulations offer improved performance and longevity but require careful management to ensure compatibility with existing systems and proper disposal practices.

Environmental concerns have also shaped the regulatory landscape for automotive coolants. Many jurisdictions now require the recycling of used antifreeze to reduce environmental impact and conserve resources. Regulations often mandate proper labeling, storage, and disposal procedures for coolants, with severe penalties for non-compliance.

As vehicle technologies advance, particularly with the rise of electric and hybrid vehicles, regulatory bodies are adapting their frameworks to address new cooling challenges. This includes regulations for battery thermal management systems and the use of alternative cooling fluids in these advanced propulsion systems.

The global nature of the automotive industry has led to efforts to harmonize coolant regulations across different regions. International organizations such as the United Nations Economic Commission for Europe (UNECE) work towards creating unified standards that can be adopted worldwide, simplifying compliance for manufacturers operating in multiple markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!