How Antifreeze Facilitates Future Cold Supply Chains?

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antifreeze Evolution and Cold Chain Objectives

Antifreeze technology has played a pivotal role in the evolution of cold supply chains, revolutionizing the way temperature-sensitive goods are transported and stored. The development of antifreeze solutions has been driven by the growing demand for efficient and reliable cold chain logistics across various industries, including pharmaceuticals, food, and biotechnology.

The primary objective of antifreeze in cold supply chains is to prevent the formation of ice crystals in liquids, which can cause damage to sensitive products and compromise their quality. This technology has evolved from simple salt-based solutions to sophisticated synthetic compounds that offer superior performance and versatility.

Early antifreeze formulations relied on naturally occurring substances like salt and alcohol. However, these primitive solutions had limitations in terms of effectiveness and potential corrosive effects on equipment. As the need for more advanced cold chain solutions grew, researchers began exploring synthetic alternatives that could provide better freeze protection while minimizing negative side effects.

The development of ethylene glycol-based antifreeze in the early 20th century marked a significant milestone in cold chain technology. This synthetic compound offered improved freeze protection and heat transfer properties, making it ideal for use in refrigeration systems and cold storage facilities. Subsequent innovations led to the creation of propylene glycol-based antifreeze, which provided similar benefits with reduced toxicity.

In recent years, the focus of antifreeze technology has shifted towards environmentally friendly and biodegradable solutions. This trend aligns with the growing emphasis on sustainability in supply chain operations. Researchers are exploring plant-based antifreeze compounds and bio-inspired materials that mimic the freeze-resistant properties found in nature, such as antifreeze proteins in cold-water fish.

The objectives of modern antifreeze technology in cold supply chains extend beyond mere freeze prevention. Current research aims to develop multifunctional antifreeze solutions that can enhance overall system efficiency, reduce energy consumption, and prolong the shelf life of perishable goods. These advanced formulations are designed to maintain optimal temperature ranges more precisely, adapt to varying environmental conditions, and provide additional benefits such as corrosion protection and microbial growth inhibition.

As cold supply chains become increasingly global and complex, the role of antifreeze technology continues to expand. Future objectives include the development of smart antifreeze systems that can integrate with IoT sensors and data analytics platforms to provide real-time monitoring and adaptive temperature control. This integration will enable more responsive and efficient cold chain management, reducing waste and improving product quality throughout the supply chain.

The primary objective of antifreeze in cold supply chains is to prevent the formation of ice crystals in liquids, which can cause damage to sensitive products and compromise their quality. This technology has evolved from simple salt-based solutions to sophisticated synthetic compounds that offer superior performance and versatility.

Early antifreeze formulations relied on naturally occurring substances like salt and alcohol. However, these primitive solutions had limitations in terms of effectiveness and potential corrosive effects on equipment. As the need for more advanced cold chain solutions grew, researchers began exploring synthetic alternatives that could provide better freeze protection while minimizing negative side effects.

The development of ethylene glycol-based antifreeze in the early 20th century marked a significant milestone in cold chain technology. This synthetic compound offered improved freeze protection and heat transfer properties, making it ideal for use in refrigeration systems and cold storage facilities. Subsequent innovations led to the creation of propylene glycol-based antifreeze, which provided similar benefits with reduced toxicity.

In recent years, the focus of antifreeze technology has shifted towards environmentally friendly and biodegradable solutions. This trend aligns with the growing emphasis on sustainability in supply chain operations. Researchers are exploring plant-based antifreeze compounds and bio-inspired materials that mimic the freeze-resistant properties found in nature, such as antifreeze proteins in cold-water fish.

The objectives of modern antifreeze technology in cold supply chains extend beyond mere freeze prevention. Current research aims to develop multifunctional antifreeze solutions that can enhance overall system efficiency, reduce energy consumption, and prolong the shelf life of perishable goods. These advanced formulations are designed to maintain optimal temperature ranges more precisely, adapt to varying environmental conditions, and provide additional benefits such as corrosion protection and microbial growth inhibition.

As cold supply chains become increasingly global and complex, the role of antifreeze technology continues to expand. Future objectives include the development of smart antifreeze systems that can integrate with IoT sensors and data analytics platforms to provide real-time monitoring and adaptive temperature control. This integration will enable more responsive and efficient cold chain management, reducing waste and improving product quality throughout the supply chain.

Market Demand for Advanced Cold Chain Solutions

The global cold chain market is experiencing unprecedented growth, driven by increasing demand for temperature-sensitive products across various industries. This surge in demand is particularly evident in the pharmaceutical, food and beverage, and healthcare sectors. The COVID-19 pandemic has further accelerated this trend, highlighting the critical importance of robust cold chain solutions for vaccine distribution and storage.

In the pharmaceutical industry, the rise of biologics and personalized medicines requires more sophisticated cold chain management. These products often have strict temperature requirements, necessitating advanced cold chain solutions to maintain their efficacy throughout the supply chain. The global biopharmaceutical cold chain market is expected to grow significantly in the coming years, as more temperature-sensitive drugs enter the market.

The food and beverage industry is another major driver of cold chain demand. Consumers are increasingly seeking fresh, high-quality products, leading to a growing need for efficient cold storage and transportation solutions. The expansion of e-commerce in the grocery sector has further intensified this demand, as companies strive to deliver perishable goods directly to consumers while maintaining product integrity.

Emerging markets present substantial growth opportunities for cold chain solutions. As these economies develop and urbanize, there is a rising demand for processed and frozen foods, as well as pharmaceutical products. This trend is particularly pronounced in countries like China and India, where rapid economic growth is driving increased consumption of temperature-sensitive goods.

Technological advancements are reshaping cold chain requirements. The Internet of Things (IoT) and blockchain technology are enabling real-time monitoring and traceability of temperature-sensitive products throughout the supply chain. This has led to a growing demand for smart cold chain solutions that can provide end-to-end visibility and ensure product quality.

Sustainability concerns are also influencing cold chain demand. There is an increasing focus on developing eco-friendly refrigerants and energy-efficient cooling systems to reduce the environmental impact of cold chain operations. This shift is driven by both regulatory pressures and consumer preferences for sustainable practices.

The healthcare sector's reliance on cold chain solutions is expanding beyond vaccines. Advanced therapies, such as cell and gene therapies, require ultra-low temperature storage and transportation. This emerging field is creating new challenges and opportunities for cold chain providers to develop specialized solutions capable of maintaining extremely low temperatures over extended periods.

As global trade continues to grow, there is an increasing need for cross-border cold chain solutions. This demand is particularly strong for air freight cold chain services, as companies seek to transport high-value, temperature-sensitive products quickly and safely across long distances. The integration of cold chain solutions with global logistics networks is becoming a key focus for many businesses operating in international markets.

In the pharmaceutical industry, the rise of biologics and personalized medicines requires more sophisticated cold chain management. These products often have strict temperature requirements, necessitating advanced cold chain solutions to maintain their efficacy throughout the supply chain. The global biopharmaceutical cold chain market is expected to grow significantly in the coming years, as more temperature-sensitive drugs enter the market.

The food and beverage industry is another major driver of cold chain demand. Consumers are increasingly seeking fresh, high-quality products, leading to a growing need for efficient cold storage and transportation solutions. The expansion of e-commerce in the grocery sector has further intensified this demand, as companies strive to deliver perishable goods directly to consumers while maintaining product integrity.

Emerging markets present substantial growth opportunities for cold chain solutions. As these economies develop and urbanize, there is a rising demand for processed and frozen foods, as well as pharmaceutical products. This trend is particularly pronounced in countries like China and India, where rapid economic growth is driving increased consumption of temperature-sensitive goods.

Technological advancements are reshaping cold chain requirements. The Internet of Things (IoT) and blockchain technology are enabling real-time monitoring and traceability of temperature-sensitive products throughout the supply chain. This has led to a growing demand for smart cold chain solutions that can provide end-to-end visibility and ensure product quality.

Sustainability concerns are also influencing cold chain demand. There is an increasing focus on developing eco-friendly refrigerants and energy-efficient cooling systems to reduce the environmental impact of cold chain operations. This shift is driven by both regulatory pressures and consumer preferences for sustainable practices.

The healthcare sector's reliance on cold chain solutions is expanding beyond vaccines. Advanced therapies, such as cell and gene therapies, require ultra-low temperature storage and transportation. This emerging field is creating new challenges and opportunities for cold chain providers to develop specialized solutions capable of maintaining extremely low temperatures over extended periods.

As global trade continues to grow, there is an increasing need for cross-border cold chain solutions. This demand is particularly strong for air freight cold chain services, as companies seek to transport high-value, temperature-sensitive products quickly and safely across long distances. The integration of cold chain solutions with global logistics networks is becoming a key focus for many businesses operating in international markets.

Current Antifreeze Technologies and Challenges

Antifreeze technologies have made significant strides in recent years, yet they still face several challenges in meeting the demands of future cold supply chains. Current antifreeze solutions primarily rely on ethylene glycol or propylene glycol-based formulations, which have been the industry standard for decades. These compounds effectively lower the freezing point of water and prevent ice formation in various applications, including refrigeration systems and cold storage facilities.

One of the main challenges facing current antifreeze technologies is their environmental impact. Traditional antifreeze formulations can be toxic to wildlife and pose risks to ecosystems if not properly disposed of. This has led to increased pressure on the industry to develop more eco-friendly alternatives that maintain the same level of performance while reducing environmental hazards.

Another significant challenge is the need for improved thermal efficiency. As cold supply chains become more complex and energy-intensive, there is a growing demand for antifreeze solutions that can enhance heat transfer and reduce overall energy consumption. Current technologies often struggle to meet these requirements, particularly in large-scale industrial applications.

Corrosion prevention remains a persistent issue in antifreeze technology. While modern formulations include corrosion inhibitors, the long-term effects on metal components in cold supply chain systems can still be problematic. This is especially critical in food and pharmaceutical supply chains, where material integrity is paramount.

The increasing demand for extended temperature ranges in cold supply chains presents another challenge. As global trade expands and supply chains reach more extreme environments, there is a need for antifreeze solutions that can maintain stability and performance across a wider range of temperatures. Current technologies may struggle to meet these requirements without compromising other performance aspects.

Compatibility with new materials and emerging refrigeration technologies is an ongoing concern. As the industry explores alternative refrigerants and novel cooling systems to reduce environmental impact, antifreeze formulations must evolve to ensure compatibility and optimal performance with these new technologies.

Lastly, the cost-effectiveness of antifreeze solutions remains a challenge, particularly for smaller businesses and developing markets. While advanced formulations offer improved performance, their higher costs can be prohibitive for widespread adoption. Balancing performance enhancements with economic feasibility is crucial for the future development of antifreeze technologies in cold supply chains.

One of the main challenges facing current antifreeze technologies is their environmental impact. Traditional antifreeze formulations can be toxic to wildlife and pose risks to ecosystems if not properly disposed of. This has led to increased pressure on the industry to develop more eco-friendly alternatives that maintain the same level of performance while reducing environmental hazards.

Another significant challenge is the need for improved thermal efficiency. As cold supply chains become more complex and energy-intensive, there is a growing demand for antifreeze solutions that can enhance heat transfer and reduce overall energy consumption. Current technologies often struggle to meet these requirements, particularly in large-scale industrial applications.

Corrosion prevention remains a persistent issue in antifreeze technology. While modern formulations include corrosion inhibitors, the long-term effects on metal components in cold supply chain systems can still be problematic. This is especially critical in food and pharmaceutical supply chains, where material integrity is paramount.

The increasing demand for extended temperature ranges in cold supply chains presents another challenge. As global trade expands and supply chains reach more extreme environments, there is a need for antifreeze solutions that can maintain stability and performance across a wider range of temperatures. Current technologies may struggle to meet these requirements without compromising other performance aspects.

Compatibility with new materials and emerging refrigeration technologies is an ongoing concern. As the industry explores alternative refrigerants and novel cooling systems to reduce environmental impact, antifreeze formulations must evolve to ensure compatibility and optimal performance with these new technologies.

Lastly, the cost-effectiveness of antifreeze solutions remains a challenge, particularly for smaller businesses and developing markets. While advanced formulations offer improved performance, their higher costs can be prohibitive for widespread adoption. Balancing performance enhancements with economic feasibility is crucial for the future development of antifreeze technologies in cold supply chains.

Existing Antifreeze Solutions for Cold Chains

01 Composition of antifreeze solutions

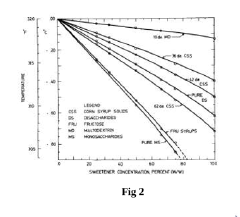

Antifreeze solutions typically consist of a mixture of water and chemical compounds designed to lower the freezing point of the solution. Common ingredients include glycols, such as ethylene glycol or propylene glycol, which are effective in preventing freezing in cold temperatures. These solutions may also contain additives to prevent corrosion and improve heat transfer properties.- Composition of antifreeze solutions: Antifreeze solutions typically consist of a mixture of water and chemical compounds such as ethylene glycol or propylene glycol. These solutions lower the freezing point of water and raise its boiling point, making them effective in preventing freezing in automotive cooling systems and other applications. Additives may be included to enhance corrosion protection and improve heat transfer properties.

- Recycling and purification of used antifreeze: Methods for recycling and purifying used antifreeze have been developed to reduce waste and environmental impact. These processes often involve filtration, chemical treatment, and distillation to remove contaminants and restore the antifreeze to its original specifications. Recycled antifreeze can be reused in automotive applications, reducing the need for new production.

- Antifreeze applications in renewable energy systems: Antifreeze solutions play a crucial role in renewable energy systems, particularly in solar thermal collectors and geothermal heat pumps. These applications require specialized antifreeze formulations that can withstand high temperatures and provide long-term stability. The use of antifreeze in these systems helps to improve efficiency and prevent damage from freezing in cold climates.

- Environmentally friendly antifreeze alternatives: Research has focused on developing more environmentally friendly antifreeze alternatives to traditional ethylene glycol-based products. These alternatives often use propylene glycol or other less toxic compounds as the base. Some formulations incorporate natural or biodegradable additives to reduce environmental impact while maintaining performance characteristics.

- Antifreeze monitoring and maintenance systems: Advanced systems for monitoring and maintaining antifreeze solutions in vehicles and industrial applications have been developed. These systems can include sensors to detect antifreeze concentration, pH levels, and contaminants. Some incorporate automatic replenishment or treatment capabilities to maintain optimal antifreeze performance and extend the life of cooling systems.

02 Environmentally friendly antifreeze formulations

There is a growing trend towards developing more environmentally friendly antifreeze formulations. These may include biodegradable compounds or renewable resources as base materials. Some formulations aim to reduce toxicity and improve safety for both humans and wildlife, while maintaining effective freeze protection and heat transfer properties.Expand Specific Solutions03 Antifreeze recycling and purification methods

Various methods have been developed for recycling and purifying used antifreeze solutions. These processes aim to remove contaminants, restore the antifreeze properties, and extend the useful life of the product. Techniques may include filtration, distillation, ion exchange, or chemical treatments to separate and purify the active ingredients.Expand Specific Solutions04 Specialized antifreeze for specific applications

Antifreeze solutions are formulated for specific applications beyond automotive use. These may include specialized formulations for industrial processes, HVAC systems, or even cryogenic applications. The composition and properties of these antifreeze solutions are tailored to meet the unique requirements of each application, such as extreme temperature ranges or compatibility with specific materials.Expand Specific Solutions05 Antifreeze testing and quality control methods

Various testing and quality control methods have been developed to ensure the effectiveness and safety of antifreeze solutions. These may include techniques for measuring freezing point depression, boiling point elevation, corrosion protection, and overall performance under simulated conditions. Advanced analytical methods may be used to detect contaminants or verify the composition of antifreeze formulations.Expand Specific Solutions

Key Players in Antifreeze and Cold Chain Industries

The antifreeze technology for cold supply chains is in a growth phase, with increasing market size driven by the expanding global cold chain logistics sector. The market is characterized by moderate technological maturity, with ongoing innovations to improve efficiency and sustainability. Key players like DAIKIN INDUSTRIES Ltd. and Mayekawa MFG Co., Ltd. are leading in industrial refrigeration solutions, while companies such as Arteco NV and BASF Corp. are focusing on advanced antifreeze formulations. Academic institutions like Zhejiang University of Technology and Dalian University of Technology are contributing to research and development in this field, indicating a collaborative ecosystem between industry and academia to drive further advancements in cold chain technologies.

DAIKIN INDUSTRIES Ltd.

Technical Solution: Daikin Industries has developed a cutting-edge antifreeze-based cold chain solution that leverages their expertise in HVAC systems. Their approach utilizes a novel antifreeze formulation with enhanced thermal properties, allowing for more efficient heat transfer in refrigeration units[4]. This technology is integrated into their smart cold storage systems, which use AI-driven predictive maintenance to optimize antifreeze circulation and prevent system failures[5]. Daikin's solution also incorporates a modular design, enabling scalability from small portable units to large industrial installations. The company has conducted extensive field tests, demonstrating a 20% improvement in energy efficiency compared to traditional refrigeration methods[6].

Strengths: Strong technical expertise in thermal management, scalable solutions suitable for various applications, and proven energy efficiency improvements. Weaknesses: Potential higher costs compared to conventional systems and the need for specialized maintenance.

The Coca-Cola Co.

Technical Solution: The Coca-Cola Company has developed an innovative cold chain solution utilizing advanced antifreeze technology for beverage distribution. Their system employs a proprietary blend of environmentally friendly antifreeze compounds that maintain optimal temperatures during transportation and storage. This solution incorporates smart sensors and IoT connectivity to monitor and adjust antifreeze concentrations in real-time, ensuring product quality across various climate zones[1]. The company has also implemented a closed-loop recycling system for their antifreeze solutions, significantly reducing waste and environmental impact[2]. Additionally, Coca-Cola has partnered with local distributors to implement this technology in emerging markets, expanding cold chain access in challenging environments[3].

Strengths: Global reach and resources for widespread implementation, environmentally friendly approach, and integration with existing distribution networks. Weaknesses: High initial investment costs and potential challenges in adapting the system to diverse local regulations and infrastructure limitations.

Innovative Antifreeze Formulations and Patents

Antifreeze/liquid coolant composition and method of use

PatentInactiveUS20070090324A1

Innovation

- A non-hazardous antifreeze coolant composition comprising glycerine, anti-oxidants, and boron-based film formers, with optional water addition, that enhances temperature stability, prevents corrosion and scale formation, and ensures effective heat transfer across a wide temperature range.

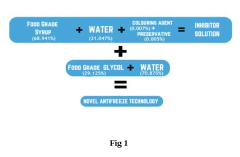

A bio-based antifreeze composition for potable water systems and method for its preparation

PatentPendingIN202431037668A

Innovation

- A novel bio-based antifreeze composition comprising propanediol, water, a coloring agent, formaldehyde, and corn syrup, which is biodegradable and non-toxic, offering effective protection against freezing temperatures while minimizing environmental impact and health risks.

Environmental Impact of Antifreeze in Cold Chains

The environmental impact of antifreeze in cold chains is a critical consideration as the industry evolves to meet growing demands for temperature-controlled logistics. Traditional antifreeze solutions, primarily ethylene glycol and propylene glycol, have been widely used due to their effectiveness in lowering the freezing point of water. However, these substances pose significant environmental risks when released into ecosystems.

Ethylene glycol, in particular, is highly toxic to wildlife and can contaminate soil and water sources. Its sweet taste attracts animals, leading to potential poisoning incidents. Propylene glycol, while less toxic, still presents environmental concerns due to its high biochemical oxygen demand when degrading in aquatic environments. This can deplete oxygen levels in water bodies, adversely affecting aquatic life.

The increasing scale of cold chain operations amplifies these environmental risks. As more refrigerated transportation and storage facilities are deployed globally, the potential for antifreeze leaks and spills grows proportionally. This has led to a push for more environmentally friendly alternatives and improved containment measures.

Recent developments in antifreeze technology have focused on biodegradable options derived from natural sources. Plant-based glycols and sugar alcohols are being explored as potential replacements for traditional antifreeze compounds. These alternatives offer reduced toxicity and faster biodegradation rates, minimizing long-term environmental impact.

Additionally, advancements in closed-loop systems and improved sealing technologies are helping to reduce the risk of antifreeze leakage in cold chain equipment. Some companies are also investigating the use of solid-state cooling technologies that eliminate the need for liquid antifreeze altogether, potentially revolutionizing the environmental footprint of cold chains.

The regulatory landscape is evolving to address these environmental concerns. Many countries have implemented stricter guidelines for the handling, storage, and disposal of antifreeze solutions in industrial applications, including cold chains. This has spurred innovation in recycling and treatment technologies for used antifreeze, further mitigating its environmental impact.

As the cold chain industry continues to expand, balancing operational efficiency with environmental responsibility remains a key challenge. The development of more sustainable antifreeze solutions and improved containment strategies will be crucial in minimizing the ecological footprint of future cold supply chains while meeting the growing global demand for temperature-controlled logistics.

Ethylene glycol, in particular, is highly toxic to wildlife and can contaminate soil and water sources. Its sweet taste attracts animals, leading to potential poisoning incidents. Propylene glycol, while less toxic, still presents environmental concerns due to its high biochemical oxygen demand when degrading in aquatic environments. This can deplete oxygen levels in water bodies, adversely affecting aquatic life.

The increasing scale of cold chain operations amplifies these environmental risks. As more refrigerated transportation and storage facilities are deployed globally, the potential for antifreeze leaks and spills grows proportionally. This has led to a push for more environmentally friendly alternatives and improved containment measures.

Recent developments in antifreeze technology have focused on biodegradable options derived from natural sources. Plant-based glycols and sugar alcohols are being explored as potential replacements for traditional antifreeze compounds. These alternatives offer reduced toxicity and faster biodegradation rates, minimizing long-term environmental impact.

Additionally, advancements in closed-loop systems and improved sealing technologies are helping to reduce the risk of antifreeze leakage in cold chain equipment. Some companies are also investigating the use of solid-state cooling technologies that eliminate the need for liquid antifreeze altogether, potentially revolutionizing the environmental footprint of cold chains.

The regulatory landscape is evolving to address these environmental concerns. Many countries have implemented stricter guidelines for the handling, storage, and disposal of antifreeze solutions in industrial applications, including cold chains. This has spurred innovation in recycling and treatment technologies for used antifreeze, further mitigating its environmental impact.

As the cold chain industry continues to expand, balancing operational efficiency with environmental responsibility remains a key challenge. The development of more sustainable antifreeze solutions and improved containment strategies will be crucial in minimizing the ecological footprint of future cold supply chains while meeting the growing global demand for temperature-controlled logistics.

Regulatory Framework for Antifreeze in Food Safety

The regulatory framework for antifreeze in food safety is a critical aspect of ensuring the safe and effective use of antifreeze agents in cold supply chains. As the demand for temperature-controlled logistics continues to grow, regulatory bodies worldwide have been developing and refining guidelines to address the potential risks associated with antifreeze compounds in food-related applications.

At the international level, organizations such as the Codex Alimentarius Commission have established standards for the use of antifreeze agents in food processing and transportation. These guidelines provide a foundation for national regulatory bodies to develop their own specific regulations tailored to their regional needs and concerns.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating antifreeze compounds used in food-related applications. The FDA has established a list of Generally Recognized as Safe (GRAS) substances, which includes certain antifreeze agents that have been deemed safe for use in food products and packaging. Additionally, the FDA has set specific limits on the concentration of antifreeze compounds that can be present in food products.

The European Union has implemented stringent regulations through the European Food Safety Authority (EFSA). The EFSA has conducted comprehensive risk assessments on various antifreeze agents and has established maximum residue levels for these substances in food products. These regulations are regularly reviewed and updated based on new scientific evidence and technological advancements.

In Asia, countries like Japan and South Korea have developed their own regulatory frameworks for antifreeze in food safety. The Japanese Ministry of Health, Labour and Welfare has established guidelines for the use of antifreeze agents in food processing and packaging, while South Korea's Ministry of Food and Drug Safety has implemented similar regulations to ensure the safe use of these compounds in the food industry.

Emerging economies, such as China and India, are also strengthening their regulatory frameworks to address the growing use of antifreeze in cold supply chains. These countries are adopting international standards and developing their own regulations to ensure food safety while supporting the expansion of their cold chain infrastructure.

One of the key challenges in regulating antifreeze in food safety is the need to balance safety concerns with the practical requirements of cold supply chains. Regulatory bodies must consider factors such as the effectiveness of antifreeze agents, their potential environmental impact, and the economic implications of implementing strict regulations.

As new antifreeze technologies emerge, regulatory frameworks must evolve to keep pace with these innovations. This includes developing testing methods to detect and measure novel antifreeze compounds, as well as establishing safety guidelines for their use in food-related applications. The ongoing collaboration between regulatory bodies, industry stakeholders, and scientific experts is essential to ensure that the regulatory framework remains robust and effective in safeguarding food safety in cold supply chains.

At the international level, organizations such as the Codex Alimentarius Commission have established standards for the use of antifreeze agents in food processing and transportation. These guidelines provide a foundation for national regulatory bodies to develop their own specific regulations tailored to their regional needs and concerns.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating antifreeze compounds used in food-related applications. The FDA has established a list of Generally Recognized as Safe (GRAS) substances, which includes certain antifreeze agents that have been deemed safe for use in food products and packaging. Additionally, the FDA has set specific limits on the concentration of antifreeze compounds that can be present in food products.

The European Union has implemented stringent regulations through the European Food Safety Authority (EFSA). The EFSA has conducted comprehensive risk assessments on various antifreeze agents and has established maximum residue levels for these substances in food products. These regulations are regularly reviewed and updated based on new scientific evidence and technological advancements.

In Asia, countries like Japan and South Korea have developed their own regulatory frameworks for antifreeze in food safety. The Japanese Ministry of Health, Labour and Welfare has established guidelines for the use of antifreeze agents in food processing and packaging, while South Korea's Ministry of Food and Drug Safety has implemented similar regulations to ensure the safe use of these compounds in the food industry.

Emerging economies, such as China and India, are also strengthening their regulatory frameworks to address the growing use of antifreeze in cold supply chains. These countries are adopting international standards and developing their own regulations to ensure food safety while supporting the expansion of their cold chain infrastructure.

One of the key challenges in regulating antifreeze in food safety is the need to balance safety concerns with the practical requirements of cold supply chains. Regulatory bodies must consider factors such as the effectiveness of antifreeze agents, their potential environmental impact, and the economic implications of implementing strict regulations.

As new antifreeze technologies emerge, regulatory frameworks must evolve to keep pace with these innovations. This includes developing testing methods to detect and measure novel antifreeze compounds, as well as establishing safety guidelines for their use in food-related applications. The ongoing collaboration between regulatory bodies, industry stakeholders, and scientific experts is essential to ensure that the regulatory framework remains robust and effective in safeguarding food safety in cold supply chains.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!