How Carbolic Acid Supports Advancements in Liquid Crystal Displays

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LCD Technology Evolution

Liquid Crystal Display (LCD) technology has undergone a remarkable evolution since its inception in the 1960s. The journey began with the discovery of liquid crystals in 1888 by Austrian botanist Friedrich Reinitzer, but it wasn't until the late 1960s that the first practical LCD devices were developed. The initial LCDs were monochrome and had limited applications, primarily used in digital watches and calculators.

The 1970s saw significant advancements in LCD technology, with the introduction of twisted nematic (TN) LCDs. This innovation greatly improved the display quality and response time, paving the way for larger screens and more diverse applications. The 1980s marked a crucial turning point with the development of thin-film transistor (TFT) technology, which allowed for active-matrix addressing and dramatically enhanced image quality.

In the 1990s, LCD technology began to challenge the dominance of cathode-ray tube (CRT) displays in computer monitors and televisions. This period saw rapid improvements in color reproduction, viewing angles, and screen sizes. The introduction of in-plane switching (IPS) technology in the mid-1990s further improved color accuracy and viewing angles, addressing some of the limitations of TN displays.

The early 2000s witnessed the widespread adoption of LCD technology in consumer electronics, particularly in flat-panel televisions and computer monitors. This era also saw the development of LED backlighting, which replaced traditional fluorescent lamps, resulting in thinner displays with improved energy efficiency and color performance.

More recent advancements have focused on increasing resolution, with the introduction of Full HD, 4K, and even 8K displays. Additionally, high refresh rates and adaptive sync technologies have enhanced the gaming and multimedia experience. The development of quantum dot technology has further improved color accuracy and brightness, pushing the boundaries of what LCD displays can achieve.

Throughout this evolution, carbolic acid, also known as phenol, has played a crucial role in supporting advancements in LCD technology. Its primary contribution has been in the production of high-quality liquid crystal materials and the manufacturing processes of LCD panels. Carbolic acid derivatives are used in the synthesis of various liquid crystal compounds, helping to optimize their physical and chemical properties for improved display performance.

As LCD technology continues to evolve, researchers are exploring new materials and techniques to overcome current limitations and push the boundaries of display technology. The ongoing development of micro-LED and OLED technologies presents both challenges and opportunities for the future of LCD displays, driving further innovation in this field.

The 1970s saw significant advancements in LCD technology, with the introduction of twisted nematic (TN) LCDs. This innovation greatly improved the display quality and response time, paving the way for larger screens and more diverse applications. The 1980s marked a crucial turning point with the development of thin-film transistor (TFT) technology, which allowed for active-matrix addressing and dramatically enhanced image quality.

In the 1990s, LCD technology began to challenge the dominance of cathode-ray tube (CRT) displays in computer monitors and televisions. This period saw rapid improvements in color reproduction, viewing angles, and screen sizes. The introduction of in-plane switching (IPS) technology in the mid-1990s further improved color accuracy and viewing angles, addressing some of the limitations of TN displays.

The early 2000s witnessed the widespread adoption of LCD technology in consumer electronics, particularly in flat-panel televisions and computer monitors. This era also saw the development of LED backlighting, which replaced traditional fluorescent lamps, resulting in thinner displays with improved energy efficiency and color performance.

More recent advancements have focused on increasing resolution, with the introduction of Full HD, 4K, and even 8K displays. Additionally, high refresh rates and adaptive sync technologies have enhanced the gaming and multimedia experience. The development of quantum dot technology has further improved color accuracy and brightness, pushing the boundaries of what LCD displays can achieve.

Throughout this evolution, carbolic acid, also known as phenol, has played a crucial role in supporting advancements in LCD technology. Its primary contribution has been in the production of high-quality liquid crystal materials and the manufacturing processes of LCD panels. Carbolic acid derivatives are used in the synthesis of various liquid crystal compounds, helping to optimize their physical and chemical properties for improved display performance.

As LCD technology continues to evolve, researchers are exploring new materials and techniques to overcome current limitations and push the boundaries of display technology. The ongoing development of micro-LED and OLED technologies presents both challenges and opportunities for the future of LCD displays, driving further innovation in this field.

Carbolic Acid Market Analysis

The carbolic acid market, also known as the phenol market, has been experiencing significant growth due to its widespread applications across various industries, including the liquid crystal display (LCD) sector. The global phenol market size was valued at approximately 11.5 million tons in 2020 and is projected to grow at a compound annual growth rate (CAGR) of 3.5% from 2021 to 2028. This growth is primarily driven by the increasing demand for phenol derivatives in the production of bisphenol-A, which is a key component in the manufacturing of polycarbonate resins used in LCD screens.

The LCD industry has been a major contributor to the demand for carbolic acid, particularly in the production of advanced display technologies. As the consumer electronics market continues to expand, the demand for high-quality displays in smartphones, tablets, laptops, and televisions has surged, consequently boosting the carbolic acid market. The Asia-Pacific region, especially countries like China, Japan, and South Korea, dominates the LCD manufacturing industry and accounts for a significant share of the global carbolic acid consumption in this sector.

In recent years, there has been a shift towards more environmentally friendly and sustainable production methods in the carbolic acid market. This trend is driven by stringent regulations and growing consumer awareness regarding environmental issues. Manufacturers are investing in research and development to develop bio-based phenol production methods, which could potentially reshape the market landscape in the coming years.

The carbolic acid market is characterized by a high degree of consolidation, with a few major players dominating the global production. Key market players include Ineos Group, Mitsui Chemicals, LG Chem, and Solvay SA. These companies are actively engaged in capacity expansions, mergers, and acquisitions to strengthen their market position and meet the growing demand from various end-use industries, including LCD manufacturing.

Price volatility remains a significant challenge in the carbolic acid market, primarily due to fluctuations in raw material costs, particularly benzene. This volatility can impact the profitability of LCD manufacturers and potentially lead to supply chain disruptions. To mitigate these risks, many companies are focusing on vertical integration and long-term supply agreements with key raw material suppliers.

The future outlook for the carbolic acid market in relation to LCD technology remains positive, despite the emergence of alternative display technologies such as OLED. This is because LCD technology continues to evolve, with advancements in quantum dot technology and mini-LED backlighting systems that require high-performance materials like carbolic acid derivatives. As the demand for larger, higher-resolution displays grows, particularly in emerging markets, the carbolic acid market is expected to maintain its growth trajectory in the LCD sector for the foreseeable future.

The LCD industry has been a major contributor to the demand for carbolic acid, particularly in the production of advanced display technologies. As the consumer electronics market continues to expand, the demand for high-quality displays in smartphones, tablets, laptops, and televisions has surged, consequently boosting the carbolic acid market. The Asia-Pacific region, especially countries like China, Japan, and South Korea, dominates the LCD manufacturing industry and accounts for a significant share of the global carbolic acid consumption in this sector.

In recent years, there has been a shift towards more environmentally friendly and sustainable production methods in the carbolic acid market. This trend is driven by stringent regulations and growing consumer awareness regarding environmental issues. Manufacturers are investing in research and development to develop bio-based phenol production methods, which could potentially reshape the market landscape in the coming years.

The carbolic acid market is characterized by a high degree of consolidation, with a few major players dominating the global production. Key market players include Ineos Group, Mitsui Chemicals, LG Chem, and Solvay SA. These companies are actively engaged in capacity expansions, mergers, and acquisitions to strengthen their market position and meet the growing demand from various end-use industries, including LCD manufacturing.

Price volatility remains a significant challenge in the carbolic acid market, primarily due to fluctuations in raw material costs, particularly benzene. This volatility can impact the profitability of LCD manufacturers and potentially lead to supply chain disruptions. To mitigate these risks, many companies are focusing on vertical integration and long-term supply agreements with key raw material suppliers.

The future outlook for the carbolic acid market in relation to LCD technology remains positive, despite the emergence of alternative display technologies such as OLED. This is because LCD technology continues to evolve, with advancements in quantum dot technology and mini-LED backlighting systems that require high-performance materials like carbolic acid derivatives. As the demand for larger, higher-resolution displays grows, particularly in emerging markets, the carbolic acid market is expected to maintain its growth trajectory in the LCD sector for the foreseeable future.

Carbolic Acid in LCD: Current State

Carbolic acid, also known as phenol, plays a crucial role in the advancement of liquid crystal display (LCD) technology. The current state of carbolic acid in LCD manufacturing reflects a complex interplay of chemical processes and technological innovations. In recent years, the use of carbolic acid has become increasingly sophisticated, contributing to significant improvements in LCD performance and production efficiency.

One of the primary applications of carbolic acid in LCD technology is its role in the production of liquid crystal polymers. These polymers are essential components in the creation of advanced LCD panels, providing enhanced optical properties and improved durability. The unique molecular structure of carbolic acid allows for the synthesis of liquid crystal polymers with specific characteristics, tailored to meet the demanding requirements of modern display technologies.

Furthermore, carbolic acid serves as a key ingredient in the development of alignment layers for LCD panels. These layers are critical for ensuring proper orientation of liquid crystal molecules, which directly impacts the display's contrast, viewing angle, and overall image quality. The current state of alignment layer technology utilizing carbolic acid derivatives has led to remarkable advancements in LCD performance, particularly in terms of color accuracy and response times.

In the realm of LCD manufacturing, carbolic acid is also employed in the production of photoresist materials. These light-sensitive compounds are integral to the photolithography process, which is used to create intricate patterns on LCD substrates. The precision and reliability of carbolic acid-based photoresists have contributed to the miniaturization of LCD components, enabling the production of higher-resolution displays with improved pixel density.

Recent developments in carbolic acid applications for LCD technology have focused on enhancing environmental sustainability and reducing the carbon footprint of manufacturing processes. Researchers and industry leaders are exploring novel formulations and production methods that minimize the use of harmful chemicals while maintaining or improving the performance characteristics of LCD components.

The current state of carbolic acid in LCD technology also encompasses its role in the development of flexible and foldable displays. By incorporating carbolic acid derivatives into polymer substrates, manufacturers have been able to create bendable LCD panels that maintain their optical properties even when subjected to repeated flexing. This breakthrough has opened up new possibilities for innovative device designs and form factors in the consumer electronics market.

As the demand for higher-quality displays continues to grow across various industries, including consumer electronics, automotive, and medical devices, the importance of carbolic acid in LCD technology is expected to increase. Ongoing research and development efforts are focused on further optimizing the use of carbolic acid and its derivatives to address emerging challenges in display technology, such as improved energy efficiency, enhanced durability, and expanded color gamut.

One of the primary applications of carbolic acid in LCD technology is its role in the production of liquid crystal polymers. These polymers are essential components in the creation of advanced LCD panels, providing enhanced optical properties and improved durability. The unique molecular structure of carbolic acid allows for the synthesis of liquid crystal polymers with specific characteristics, tailored to meet the demanding requirements of modern display technologies.

Furthermore, carbolic acid serves as a key ingredient in the development of alignment layers for LCD panels. These layers are critical for ensuring proper orientation of liquid crystal molecules, which directly impacts the display's contrast, viewing angle, and overall image quality. The current state of alignment layer technology utilizing carbolic acid derivatives has led to remarkable advancements in LCD performance, particularly in terms of color accuracy and response times.

In the realm of LCD manufacturing, carbolic acid is also employed in the production of photoresist materials. These light-sensitive compounds are integral to the photolithography process, which is used to create intricate patterns on LCD substrates. The precision and reliability of carbolic acid-based photoresists have contributed to the miniaturization of LCD components, enabling the production of higher-resolution displays with improved pixel density.

Recent developments in carbolic acid applications for LCD technology have focused on enhancing environmental sustainability and reducing the carbon footprint of manufacturing processes. Researchers and industry leaders are exploring novel formulations and production methods that minimize the use of harmful chemicals while maintaining or improving the performance characteristics of LCD components.

The current state of carbolic acid in LCD technology also encompasses its role in the development of flexible and foldable displays. By incorporating carbolic acid derivatives into polymer substrates, manufacturers have been able to create bendable LCD panels that maintain their optical properties even when subjected to repeated flexing. This breakthrough has opened up new possibilities for innovative device designs and form factors in the consumer electronics market.

As the demand for higher-quality displays continues to grow across various industries, including consumer electronics, automotive, and medical devices, the importance of carbolic acid in LCD technology is expected to increase. Ongoing research and development efforts are focused on further optimizing the use of carbolic acid and its derivatives to address emerging challenges in display technology, such as improved energy efficiency, enhanced durability, and expanded color gamut.

Carbolic Acid Applications in LCDs

01 Historical use of carbolic acid in medical applications

Carbolic acid, also known as phenol, has been historically used in various medical applications, particularly as an antiseptic and disinfectant. Its use dates back to the late 19th and early 20th centuries, where it was employed in surgical procedures and wound care due to its antimicrobial properties.- Historical use in medical applications: Carbolic acid, also known as phenol, has been historically used in various medical applications. It was one of the earliest antiseptics used in surgery and wound treatment due to its ability to kill bacteria and other microorganisms. Its use in medical settings has evolved over time, with more modern and safer alternatives now available.

- Industrial and chemical applications: Carbolic acid finds extensive use in industrial and chemical processes. It serves as a precursor for many organic compounds and is utilized in the production of plastics, resins, and other synthetic materials. Its chemical properties make it valuable in various manufacturing processes and as a component in industrial formulations.

- Water treatment and disinfection: Carbolic acid has applications in water treatment and disinfection processes. It can be used to purify water and eliminate harmful microorganisms. However, its use in this context is limited due to its toxicity, and safer alternatives are often preferred in modern water treatment systems.

- Environmental and safety considerations: The use of carbolic acid requires careful handling and safety measures due to its corrosive and toxic nature. Environmental concerns have led to the development of containment systems, protective equipment, and disposal methods to minimize risks associated with its use and potential environmental impact.

- Research and development of derivatives: Ongoing research focuses on developing carbolic acid derivatives with improved properties and reduced toxicity. These efforts aim to create compounds that retain the beneficial aspects of carbolic acid while minimizing its negative effects, potentially leading to new applications in various fields.

02 Carbolic acid in modern disinfection and sterilization

In contemporary applications, carbolic acid continues to be utilized in disinfection and sterilization processes. It is incorporated into various cleaning and sanitizing products, particularly in industrial and healthcare settings, where its strong antimicrobial properties are beneficial for maintaining hygiene standards.Expand Specific Solutions03 Carbolic acid in water treatment systems

Carbolic acid finds application in water treatment systems, where it is used to purify and disinfect water supplies. Its ability to eliminate harmful microorganisms makes it an effective component in ensuring safe drinking water and in treating wastewater.Expand Specific Solutions04 Industrial applications of carbolic acid

Beyond its use in disinfection, carbolic acid has various industrial applications. It is used in the production of plastics, resins, and other synthetic materials. Additionally, it serves as a precursor in the manufacture of pharmaceuticals and as a component in certain industrial processes.Expand Specific Solutions05 Safety considerations and alternatives to carbolic acid

Due to the toxic nature of carbolic acid, there is ongoing research and development focused on safer alternatives and improved handling methods. This includes the development of less hazardous disinfectants, protective equipment for handling carbolic acid, and alternative compounds that can provide similar benefits with reduced risks.Expand Specific Solutions

Key LCD and Chemical Industry Players

The competition landscape for carbolic acid in liquid crystal displays (LCDs) is evolving rapidly, with the industry in a mature growth phase. The global LCD market size is substantial, projected to reach billions of dollars annually. Technologically, carbolic acid applications in LCDs are well-established, with companies like Nissan Chemical Corp., Merck Patent GmbH, and LG Display Co., Ltd. leading innovation. These firms, along with others such as BOE Technology Group and Samsung Electronics, are continually refining their technologies to enhance LCD performance and efficiency. The market is characterized by intense competition among established players and emerging companies, driving ongoing research and development efforts to improve LCD technology and expand its applications.

Merck Patent GmbH

Technical Solution: Merck Patent GmbH has developed advanced liquid crystal mixtures incorporating carbolic acid derivatives to enhance LCD performance. Their proprietary technology utilizes phenol-based compounds to improve the dielectric anisotropy and birefringence of liquid crystals[1]. This results in LCDs with faster response times, wider viewing angles, and improved contrast ratios. Merck's approach involves synthesizing novel carbolic acid-based liquid crystal molecules with optimized molecular structures to achieve specific electro-optical properties[2]. The company has also developed specialized manufacturing processes to ensure high purity and stability of these compounds, critical for long-term LCD performance[3].

Strengths: Industry-leading expertise in liquid crystal chemistry, extensive patent portfolio, and ability to tailor solutions for specific LCD applications. Weaknesses: Potential higher costs due to specialized synthesis processes and reliance on petroleum-derived precursors for carbolic acid production.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has integrated carbolic acid-based compounds into their advanced LCD technologies. Their approach focuses on using phenol derivatives to modify the alignment layers in LCD panels, improving molecular orientation and reducing image sticking[4]. Samsung has developed a proprietary surface treatment process using carbolic acid compounds to enhance the anchoring energy of liquid crystals, resulting in faster switching speeds and improved viewing angles[5]. Additionally, the company has incorporated carbolic acid-based additives into their color filter materials, leading to enhanced color gamut and improved light transmission efficiency in their LCD displays[6].

Strengths: Vertical integration allowing for seamless incorporation of new materials into display manufacturing, strong R&D capabilities in display technologies. Weaknesses: Potential environmental concerns related to the use of phenol-based compounds in large-scale production.

Carbolic Acid LCD Patents

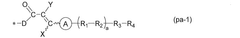

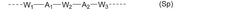

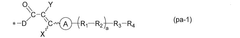

Liquid crystal aligning agent, liquid crystal alignment film, and liquid crystal display element

PatentWO2023054567A1

Innovation

- A liquid crystal aligning agent containing a compound with a photoalignable group and a thermally crosslinkable group, which reacts with a carboxy group to form a covalent bond, is used to create a liquid crystal alignment film. This agent, combined with polyamic acid and a solvent, provides excellent alignment and pretilt angle control, even at low exposure doses and short baking times, enhancing the stability and reliability of the liquid crystal display.

Liquid crystal aligning agent, liquid crystal alignment film, and liquid crystal display element

PatentWO2011136375A1

Innovation

- A liquid crystal aligning agent containing polyamic acid derived from specific diamine and tetracarboxylic dianhydride components, optimizing diamine composition to achieve low volume resistivity stability, improved rubbing resistance, high transmittance, and controlled ion density, thereby enhancing display quality.

Environmental Impact of Carbolic Acid Use

The use of carbolic acid in the production of liquid crystal displays (LCDs) has raised significant environmental concerns due to its potential impact on ecosystems and human health. As LCD technology continues to advance, the demand for carbolic acid in manufacturing processes has increased, necessitating a closer examination of its environmental footprint.

Carbolic acid, also known as phenol, is a toxic compound that can have severe effects on aquatic life if released into water bodies. Even at low concentrations, it can cause mortality in fish and other aquatic organisms. The production and disposal of LCD components containing carbolic acid residues pose risks of contamination to soil and groundwater if not properly managed.

Air pollution is another environmental concern associated with carbolic acid use in LCD manufacturing. Volatile organic compounds (VOCs) released during production processes can contribute to smog formation and negatively impact air quality. This is particularly problematic in areas with high concentrations of LCD manufacturing facilities.

The energy-intensive nature of carbolic acid production also contributes to its environmental impact. The process typically involves the cumene process, which requires significant energy inputs and generates greenhouse gas emissions. As the demand for LCDs grows, the carbon footprint associated with carbolic acid production is likely to increase unless more sustainable manufacturing methods are developed.

Waste management is a critical aspect of mitigating the environmental impact of carbolic acid use in LCD production. Proper treatment and disposal of waste containing carbolic acid residues are essential to prevent environmental contamination. Many countries have implemented strict regulations governing the handling and disposal of phenolic compounds, but enforcement remains a challenge in some regions.

Efforts to reduce the environmental impact of carbolic acid in LCD manufacturing have led to research into alternative materials and production methods. Some companies are exploring bio-based alternatives to carbolic acid, while others are focusing on improving recycling techniques for LCD components to minimize waste generation.

The development of more efficient LCD technologies that require less carbolic acid or utilize it more effectively could also help reduce environmental impacts. This includes advancements in manufacturing processes that minimize chemical usage and improve yield rates, thereby reducing waste generation and resource consumption.

As the electronics industry continues to evolve, there is a growing emphasis on lifecycle assessments and circular economy principles. These approaches consider the environmental impact of carbolic acid and other materials used in LCD production from cradle to grave, encouraging more sustainable practices throughout the supply chain.

Carbolic acid, also known as phenol, is a toxic compound that can have severe effects on aquatic life if released into water bodies. Even at low concentrations, it can cause mortality in fish and other aquatic organisms. The production and disposal of LCD components containing carbolic acid residues pose risks of contamination to soil and groundwater if not properly managed.

Air pollution is another environmental concern associated with carbolic acid use in LCD manufacturing. Volatile organic compounds (VOCs) released during production processes can contribute to smog formation and negatively impact air quality. This is particularly problematic in areas with high concentrations of LCD manufacturing facilities.

The energy-intensive nature of carbolic acid production also contributes to its environmental impact. The process typically involves the cumene process, which requires significant energy inputs and generates greenhouse gas emissions. As the demand for LCDs grows, the carbon footprint associated with carbolic acid production is likely to increase unless more sustainable manufacturing methods are developed.

Waste management is a critical aspect of mitigating the environmental impact of carbolic acid use in LCD production. Proper treatment and disposal of waste containing carbolic acid residues are essential to prevent environmental contamination. Many countries have implemented strict regulations governing the handling and disposal of phenolic compounds, but enforcement remains a challenge in some regions.

Efforts to reduce the environmental impact of carbolic acid in LCD manufacturing have led to research into alternative materials and production methods. Some companies are exploring bio-based alternatives to carbolic acid, while others are focusing on improving recycling techniques for LCD components to minimize waste generation.

The development of more efficient LCD technologies that require less carbolic acid or utilize it more effectively could also help reduce environmental impacts. This includes advancements in manufacturing processes that minimize chemical usage and improve yield rates, thereby reducing waste generation and resource consumption.

As the electronics industry continues to evolve, there is a growing emphasis on lifecycle assessments and circular economy principles. These approaches consider the environmental impact of carbolic acid and other materials used in LCD production from cradle to grave, encouraging more sustainable practices throughout the supply chain.

Cost-Benefit Analysis of Carbolic Acid in LCDs

The cost-benefit analysis of carbolic acid in Liquid Crystal Displays (LCDs) reveals a complex interplay of economic factors and technological advantages. Carbolic acid, also known as phenol, plays a crucial role in the production of various LCD components, particularly in the synthesis of liquid crystal materials and the manufacturing of polarizers.

From a cost perspective, carbolic acid is relatively inexpensive compared to other specialty chemicals used in LCD production. Its widespread availability and established production processes contribute to its cost-effectiveness. The use of carbolic acid in LCD manufacturing can lead to significant reductions in overall production expenses, potentially lowering the final cost of LCD panels for consumers.

However, the benefits of using carbolic acid extend beyond mere cost savings. The chemical properties of carbolic acid make it an excellent precursor for creating high-performance liquid crystal molecules. These molecules are essential for achieving superior display characteristics, such as improved contrast ratios, faster response times, and wider viewing angles. The resulting enhancement in display quality can justify the use of carbolic acid even if its cost were to increase moderately.

Furthermore, carbolic acid's role in polarizer production is noteworthy. Polarizers are critical components in LCDs, responsible for controlling light transmission and improving overall display performance. The use of carbolic acid in polarizer manufacturing processes can lead to more efficient and durable polarizers, potentially extending the lifespan of LCD panels and reducing long-term replacement costs for consumers.

Despite these advantages, it is important to consider potential drawbacks. Carbolic acid is a hazardous substance that requires careful handling and disposal. The implementation of safety measures and environmental controls can add to the overall production costs. Additionally, regulatory compliance related to the use of carbolic acid may vary across different regions, potentially impacting the global supply chain and manufacturing strategies of LCD producers.

In conclusion, the cost-benefit analysis of carbolic acid in LCDs demonstrates a favorable balance. The economic benefits derived from its use, coupled with the technological advantages it brings to LCD performance, generally outweigh the associated costs and challenges. As the LCD industry continues to evolve, the role of carbolic acid is likely to remain significant, driving further innovations in display technology while maintaining cost-effectiveness.

From a cost perspective, carbolic acid is relatively inexpensive compared to other specialty chemicals used in LCD production. Its widespread availability and established production processes contribute to its cost-effectiveness. The use of carbolic acid in LCD manufacturing can lead to significant reductions in overall production expenses, potentially lowering the final cost of LCD panels for consumers.

However, the benefits of using carbolic acid extend beyond mere cost savings. The chemical properties of carbolic acid make it an excellent precursor for creating high-performance liquid crystal molecules. These molecules are essential for achieving superior display characteristics, such as improved contrast ratios, faster response times, and wider viewing angles. The resulting enhancement in display quality can justify the use of carbolic acid even if its cost were to increase moderately.

Furthermore, carbolic acid's role in polarizer production is noteworthy. Polarizers are critical components in LCDs, responsible for controlling light transmission and improving overall display performance. The use of carbolic acid in polarizer manufacturing processes can lead to more efficient and durable polarizers, potentially extending the lifespan of LCD panels and reducing long-term replacement costs for consumers.

Despite these advantages, it is important to consider potential drawbacks. Carbolic acid is a hazardous substance that requires careful handling and disposal. The implementation of safety measures and environmental controls can add to the overall production costs. Additionally, regulatory compliance related to the use of carbolic acid may vary across different regions, potentially impacting the global supply chain and manufacturing strategies of LCD producers.

In conclusion, the cost-benefit analysis of carbolic acid in LCDs demonstrates a favorable balance. The economic benefits derived from its use, coupled with the technological advantages it brings to LCD performance, generally outweigh the associated costs and challenges. As the LCD industry continues to evolve, the role of carbolic acid is likely to remain significant, driving further innovations in display technology while maintaining cost-effectiveness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!