How Circular Economy Concepts Affect V12 Engines Manufacturing

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V12 Engine Evolution and Circular Economy Goals

The evolution of V12 engines has been a testament to automotive engineering prowess, with these powerplants long symbolizing the pinnacle of performance and luxury. However, the advent of circular economy concepts is reshaping the manufacturing landscape, including that of V12 engines. This intersection presents both challenges and opportunities for the automotive industry.

Historically, V12 engines have been developed with a focus on power, smoothness, and prestige. From their early applications in aviation to their adoption in high-end automobiles, V12s have undergone significant refinements in materials, design, and efficiency. The technological trajectory has been largely linear, emphasizing incremental improvements in power output, fuel efficiency, and emissions control.

As circular economy principles gain traction, the goals for V12 engine manufacturing are being redefined. The primary objective is shifting from purely performance-driven metrics to a more holistic approach that considers the entire lifecycle of the engine. This includes design for disassembly, use of recyclable materials, and minimization of waste throughout the production process.

The circular economy concept aims to create a closed-loop system where resources are used, recovered, and regenerated, reducing the environmental impact of manufacturing. For V12 engines, this translates to several key goals: extending engine lifespan through improved durability and repairability, increasing the use of recycled materials in production, and designing components that can be easily recycled at the end of the engine's life.

Another crucial aspect is the reduction of energy consumption and emissions during the manufacturing process. This aligns with broader sustainability targets and regulatory pressures facing the automotive industry. Manufacturers are now exploring innovative production techniques that minimize resource use and environmental impact while maintaining the high standards expected of V12 engines.

The integration of circular economy principles also extends to the supply chain, with a focus on sourcing sustainable materials and components. This includes the development of new alloys and composites that offer the required performance characteristics while being more environmentally friendly and easier to recycle.

As V12 engines continue to evolve, the industry faces the challenge of balancing traditional performance expectations with new sustainability imperatives. This evolution may lead to hybrid or even fully electric V12 configurations, where the iconic V12 layout is preserved for its brand value and driving experience, but powered by more sustainable energy sources.

In conclusion, the future of V12 engine manufacturing lies in harmonizing the rich heritage of these powerplants with the forward-thinking principles of the circular economy. This convergence will likely result in V12 engines that not only deliver exceptional performance but also set new standards for sustainability in high-end automotive engineering.

Historically, V12 engines have been developed with a focus on power, smoothness, and prestige. From their early applications in aviation to their adoption in high-end automobiles, V12s have undergone significant refinements in materials, design, and efficiency. The technological trajectory has been largely linear, emphasizing incremental improvements in power output, fuel efficiency, and emissions control.

As circular economy principles gain traction, the goals for V12 engine manufacturing are being redefined. The primary objective is shifting from purely performance-driven metrics to a more holistic approach that considers the entire lifecycle of the engine. This includes design for disassembly, use of recyclable materials, and minimization of waste throughout the production process.

The circular economy concept aims to create a closed-loop system where resources are used, recovered, and regenerated, reducing the environmental impact of manufacturing. For V12 engines, this translates to several key goals: extending engine lifespan through improved durability and repairability, increasing the use of recycled materials in production, and designing components that can be easily recycled at the end of the engine's life.

Another crucial aspect is the reduction of energy consumption and emissions during the manufacturing process. This aligns with broader sustainability targets and regulatory pressures facing the automotive industry. Manufacturers are now exploring innovative production techniques that minimize resource use and environmental impact while maintaining the high standards expected of V12 engines.

The integration of circular economy principles also extends to the supply chain, with a focus on sourcing sustainable materials and components. This includes the development of new alloys and composites that offer the required performance characteristics while being more environmentally friendly and easier to recycle.

As V12 engines continue to evolve, the industry faces the challenge of balancing traditional performance expectations with new sustainability imperatives. This evolution may lead to hybrid or even fully electric V12 configurations, where the iconic V12 layout is preserved for its brand value and driving experience, but powered by more sustainable energy sources.

In conclusion, the future of V12 engine manufacturing lies in harmonizing the rich heritage of these powerplants with the forward-thinking principles of the circular economy. This convergence will likely result in V12 engines that not only deliver exceptional performance but also set new standards for sustainability in high-end automotive engineering.

Market Demand for Sustainable V12 Engines

The market demand for sustainable V12 engines is undergoing a significant transformation as the automotive industry grapples with environmental concerns and regulatory pressures. Traditionally, V12 engines have been synonymous with luxury, performance, and prestige, primarily found in high-end sports cars, luxury sedans, and exclusive supercars. However, the growing emphasis on sustainability and environmental responsibility has created a new paradigm in the market.

Consumers are increasingly seeking vehicles that offer both performance and sustainability, leading to a shift in demand towards more eco-friendly alternatives. This trend has prompted manufacturers to explore innovative solutions for V12 engines that align with circular economy principles. The market is witnessing a growing interest in sustainable V12 engines that incorporate recycled materials, utilize advanced manufacturing processes to reduce waste, and are designed for easier disassembly and recycling at the end of their lifecycle.

Despite the overall decline in demand for large displacement engines due to stringent emissions regulations, there remains a niche market for sustainable V12 engines. This segment primarily consists of ultra-luxury vehicle manufacturers and high-performance car brands that cater to environmentally conscious affluent consumers. These buyers are willing to pay a premium for vehicles that combine the prestige and power of a V12 engine with sustainable manufacturing practices.

The market demand is also being driven by the automotive industry's commitment to reducing its carbon footprint. Many luxury car manufacturers have pledged to achieve carbon neutrality in their operations, including the production of engines. This has led to increased investment in research and development of sustainable manufacturing processes for V12 engines, focusing on reducing energy consumption, minimizing waste, and incorporating recycled materials.

Furthermore, there is a growing interest in the aftermarket and restoration sectors for sustainable solutions to maintain and upgrade existing V12 engines. This includes the development of remanufacturing processes that extend the lifespan of these engines while improving their environmental performance. The demand for such services is particularly strong among collectors and enthusiasts who wish to preserve classic vehicles while reducing their environmental impact.

In response to these market trends, manufacturers are exploring various technologies to enhance the sustainability of V12 engines. This includes the development of hybrid V12 powertrains, the use of sustainable biofuels, and the implementation of advanced engine management systems to optimize fuel efficiency and reduce emissions. The market is also seeing increased demand for V12 engines designed with modular components that facilitate easier repairs, upgrades, and eventual recycling.

Consumers are increasingly seeking vehicles that offer both performance and sustainability, leading to a shift in demand towards more eco-friendly alternatives. This trend has prompted manufacturers to explore innovative solutions for V12 engines that align with circular economy principles. The market is witnessing a growing interest in sustainable V12 engines that incorporate recycled materials, utilize advanced manufacturing processes to reduce waste, and are designed for easier disassembly and recycling at the end of their lifecycle.

Despite the overall decline in demand for large displacement engines due to stringent emissions regulations, there remains a niche market for sustainable V12 engines. This segment primarily consists of ultra-luxury vehicle manufacturers and high-performance car brands that cater to environmentally conscious affluent consumers. These buyers are willing to pay a premium for vehicles that combine the prestige and power of a V12 engine with sustainable manufacturing practices.

The market demand is also being driven by the automotive industry's commitment to reducing its carbon footprint. Many luxury car manufacturers have pledged to achieve carbon neutrality in their operations, including the production of engines. This has led to increased investment in research and development of sustainable manufacturing processes for V12 engines, focusing on reducing energy consumption, minimizing waste, and incorporating recycled materials.

Furthermore, there is a growing interest in the aftermarket and restoration sectors for sustainable solutions to maintain and upgrade existing V12 engines. This includes the development of remanufacturing processes that extend the lifespan of these engines while improving their environmental performance. The demand for such services is particularly strong among collectors and enthusiasts who wish to preserve classic vehicles while reducing their environmental impact.

In response to these market trends, manufacturers are exploring various technologies to enhance the sustainability of V12 engines. This includes the development of hybrid V12 powertrains, the use of sustainable biofuels, and the implementation of advanced engine management systems to optimize fuel efficiency and reduce emissions. The market is also seeing increased demand for V12 engines designed with modular components that facilitate easier repairs, upgrades, and eventual recycling.

Circular Economy Challenges in V12 Manufacturing

The implementation of circular economy concepts in V12 engine manufacturing presents several significant challenges. One of the primary obstacles is the complex nature of V12 engines, which are composed of numerous intricate parts and materials. This complexity makes it difficult to design for disassembly and recycling, key principles of the circular economy.

Material selection poses another challenge. V12 engines typically use a variety of metals, alloys, and composite materials, each chosen for specific performance characteristics. Transitioning to more recyclable or biodegradable materials while maintaining the high performance and durability expected from V12 engines is a formidable task. Engineers must balance material circularity with the stringent requirements of power, efficiency, and longevity.

The long lifespan of V12 engines also complicates circular economy implementation. These engines are often designed to last for decades, which means that the materials and components used in their production may not re-enter the circular system for an extended period. This long lifecycle can hinder the rapid adoption of new, more sustainable materials and designs.

Manufacturing processes for V12 engines are highly specialized and optimized for current designs. Adapting these processes to incorporate circular economy principles, such as using recycled materials or designing for easier disassembly, may require significant retooling and investment. This can be a substantial barrier for manufacturers, especially given the relatively low production volumes of V12 engines.

Energy consumption during the manufacturing process is another area of concern. V12 engines require precision machining and assembly, which are energy-intensive processes. Implementing circular economy concepts often involves additional processing steps, such as sorting and cleaning recycled materials, which can further increase energy consumption and potentially offset some of the environmental benefits.

Supply chain management presents yet another challenge. Establishing a circular supply chain for V12 engine components requires coordination among multiple stakeholders, including suppliers, manufacturers, and recyclers. Ensuring a consistent supply of high-quality recycled materials that meet the exacting standards of V12 engine production can be difficult, especially given the global nature of automotive supply chains.

Lastly, regulatory compliance and certification pose significant hurdles. V12 engines must meet strict emissions and safety standards. Incorporating recycled materials or redesigning components to align with circular economy principles may require extensive testing and recertification, adding time and cost to the development process. Balancing these regulatory requirements with circular economy goals is a complex task that requires careful navigation by manufacturers.

Material selection poses another challenge. V12 engines typically use a variety of metals, alloys, and composite materials, each chosen for specific performance characteristics. Transitioning to more recyclable or biodegradable materials while maintaining the high performance and durability expected from V12 engines is a formidable task. Engineers must balance material circularity with the stringent requirements of power, efficiency, and longevity.

The long lifespan of V12 engines also complicates circular economy implementation. These engines are often designed to last for decades, which means that the materials and components used in their production may not re-enter the circular system for an extended period. This long lifecycle can hinder the rapid adoption of new, more sustainable materials and designs.

Manufacturing processes for V12 engines are highly specialized and optimized for current designs. Adapting these processes to incorporate circular economy principles, such as using recycled materials or designing for easier disassembly, may require significant retooling and investment. This can be a substantial barrier for manufacturers, especially given the relatively low production volumes of V12 engines.

Energy consumption during the manufacturing process is another area of concern. V12 engines require precision machining and assembly, which are energy-intensive processes. Implementing circular economy concepts often involves additional processing steps, such as sorting and cleaning recycled materials, which can further increase energy consumption and potentially offset some of the environmental benefits.

Supply chain management presents yet another challenge. Establishing a circular supply chain for V12 engine components requires coordination among multiple stakeholders, including suppliers, manufacturers, and recyclers. Ensuring a consistent supply of high-quality recycled materials that meet the exacting standards of V12 engine production can be difficult, especially given the global nature of automotive supply chains.

Lastly, regulatory compliance and certification pose significant hurdles. V12 engines must meet strict emissions and safety standards. Incorporating recycled materials or redesigning components to align with circular economy principles may require extensive testing and recertification, adding time and cost to the development process. Balancing these regulatory requirements with circular economy goals is a complex task that requires careful navigation by manufacturers.

Current Circular Solutions in V12 Manufacturing

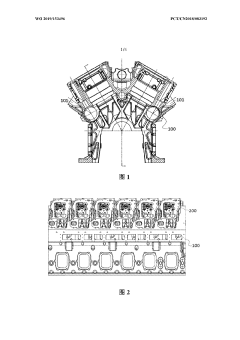

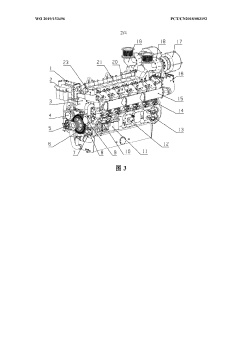

01 V12 Engine Design and Configuration

V12 engines are typically designed with two banks of six cylinders arranged in a V-shape. This configuration allows for a compact engine design while providing high power output and smooth operation. The V12 layout is often used in high-performance and luxury vehicles due to its balance of power and refinement.- V12 Engine Design and Configuration: V12 engines are characterized by their unique configuration of twelve cylinders arranged in two banks of six, forming a V shape. This design offers a balance of power, smoothness, and compact packaging, making it popular in high-performance and luxury vehicles. The V12 layout allows for excellent power output and torque characteristics while maintaining a relatively compact size compared to inline configurations.

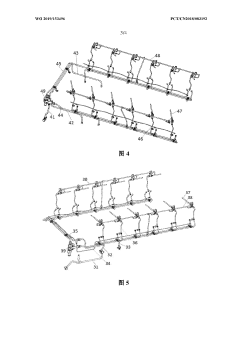

- Performance Optimization in V12 Engines: Various techniques are employed to optimize the performance of V12 engines, including advanced fuel injection systems, variable valve timing, and turbocharging or supercharging. These technologies help improve power output, fuel efficiency, and emissions control. Engine management systems play a crucial role in coordinating these features to achieve optimal performance across different operating conditions.

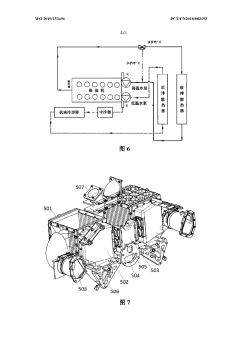

- Cooling and Lubrication Systems for V12 Engines: Effective cooling and lubrication are critical for the reliable operation of V12 engines due to their high power output and complex design. Advanced cooling systems may include precision-controlled coolant flow and oil cooling mechanisms. Lubrication systems are designed to ensure proper oil distribution to all critical components, even under high-stress conditions such as high-speed operation or heavy loads.

- Manufacturing and Assembly Processes for V12 Engines: The production of V12 engines involves sophisticated manufacturing and assembly processes to ensure precision and reliability. This may include advanced casting techniques for engine blocks, precision machining of components, and carefully controlled assembly procedures. Quality control measures are implemented throughout the manufacturing process to maintain tight tolerances and ensure optimal engine performance.

- Electronic Control and Diagnostics in V12 Engines: Modern V12 engines incorporate advanced electronic control systems for engine management, performance optimization, and diagnostics. These systems may include real-time monitoring of engine parameters, adaptive control algorithms, and sophisticated diagnostic capabilities. Such features allow for precise control of engine operation, improved fuel efficiency, and easier maintenance through early detection of potential issues.

02 Engine Control Systems for V12 Engines

Modern V12 engines incorporate advanced control systems to optimize performance, fuel efficiency, and emissions. These systems may include electronic fuel injection, variable valve timing, and sophisticated engine management computers to precisely control various engine parameters.Expand Specific Solutions03 Turbocharging and Supercharging V12 Engines

To further enhance power output and efficiency, many V12 engines employ forced induction systems such as turbochargers or superchargers. These systems compress the intake air, allowing for increased fuel combustion and power generation while potentially improving fuel economy.Expand Specific Solutions04 Historical Development of V12 Engines

The development of V12 engines dates back to the early 20th century, with various applications in aviation, marine, and automotive industries. Early designs focused on achieving high power output for specialized applications, while later developments aimed to improve efficiency and reliability for broader use.Expand Specific Solutions05 Manufacturing and Assembly Techniques for V12 Engines

The production of V12 engines involves specialized manufacturing and assembly techniques to ensure precision, durability, and performance. This may include advanced casting methods for engine blocks, precision machining of components, and carefully controlled assembly processes to maintain tight tolerances and balance.Expand Specific Solutions

Key Players in Sustainable V12 Production

The circular economy's impact on V12 engine manufacturing is at an early stage, with the market still developing. The technology's maturity varies among key players, with established automotive giants like BMW, Mercedes-Benz, and Toyota leading in research and implementation. Emerging companies such as Delphi Technology and BRP-Rotax are also making strides. The market size is growing as manufacturers increasingly adopt circular principles to reduce waste and improve resource efficiency. However, full integration of circular economy concepts in V12 engine production remains a challenge, requiring significant investment and innovation from industry players.

Bayerische Motoren Werke AG

Technical Solution: BMW has implemented a comprehensive circular economy strategy for V12 engine manufacturing. They focus on sustainable material sourcing, utilizing up to 30% recycled aluminum in engine components[1]. The company has developed advanced disassembly techniques to facilitate easier recycling of engine parts at end-of-life. BMW also employs a closed-loop system for coolants and lubricants used in the manufacturing process, reducing waste by up to 90%[2]. Additionally, they have implemented energy-efficient production methods, including heat recovery systems that capture and reuse waste heat from the manufacturing process, reducing overall energy consumption by approximately 20%[3].

Strengths: Reduced raw material costs, improved brand image, and decreased environmental impact. Weaknesses: Higher initial investment costs and potential challenges in maintaining consistent quality with recycled materials.

Caterpillar, Inc.

Technical Solution: Caterpillar has embraced circular economy concepts in their V12 engine manufacturing through their "Reman" program. This initiative focuses on remanufacturing end-of-life engines, reducing raw material usage by up to 85% compared to new production[8]. They employ advanced cleaning and restoration techniques to bring used components back to original specifications. Caterpillar has also developed a proprietary core management system that tracks and recovers used engines and components globally. In their manufacturing process, they utilize additive manufacturing techniques for certain parts, reducing material waste by up to 90% compared to traditional machining methods[9]. The company has also implemented a closed-loop system for metalworking fluids, extending their life and reducing disposal needs.

Strengths: Significant reduction in raw material costs, extended product life cycles, and reduced waste. Weaknesses: Dependence on the return of used engines and potential quality perception issues with remanufactured products.

Innovative Circular Technologies for V12 Engines

V-type 12-cylinder diesel engine

PatentWO2019153496A1

Innovation

- It adopts a V-shaped 12-cylinder diesel engine design, including a V-shaped cylinder block, 12 single cylinder heads, an electronically controlled single pump diesel supply system, an air intake system and a high and low temperature water separate cooling system to achieve double-sided oil supply, supercharged cooling and Classified cooling to improve the power and performance of diesel engines.

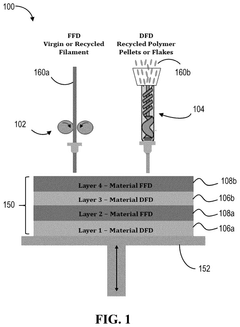

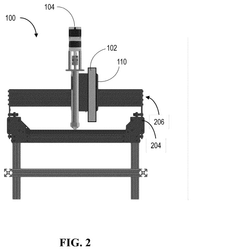

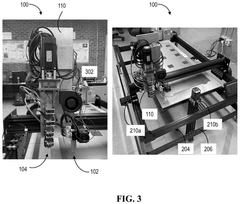

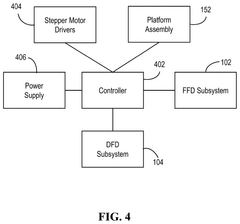

System for hybrid high-throughput additive deposition modelling, and a method for operating thereof

PatentPendingUS20250083377A1

Innovation

- A hybrid additive deposition system combining fused filament deposition (FFD) and direct fused deposition (DFD) modeling, capable of using both virgin and recycled plastics, and suitable for multicomponent and multi-material printing of thermoplastic materials.

Environmental Regulations Impact on V12 Production

Environmental regulations have significantly impacted the production of V12 engines, particularly in the context of circular economy concepts. These regulations, driven by increasing concerns over climate change and resource depletion, have forced manufacturers to reassess their production processes and adapt to more sustainable practices.

One of the primary impacts has been the need for manufacturers to reduce the carbon footprint of V12 engine production. This has led to the implementation of more energy-efficient manufacturing processes and the use of renewable energy sources in production facilities. Companies have invested in advanced technologies such as smart manufacturing systems and energy recovery systems to minimize waste and optimize resource utilization.

The regulations have also pushed manufacturers to focus on the use of recycled materials in V12 engine production. This shift has necessitated the development of new supply chain strategies to source high-quality recycled materials that meet the stringent performance requirements of V12 engines. As a result, manufacturers have had to establish partnerships with recycling facilities and invest in advanced material sorting and processing technologies.

Furthermore, environmental regulations have prompted V12 engine manufacturers to design for disassembly and recyclability. This approach ensures that at the end of an engine's life cycle, its components can be easily separated and recycled. Consequently, manufacturers have had to redesign certain engine components and rethink material choices to facilitate easier recycling without compromising performance.

The regulations have also led to increased focus on the reduction of harmful emissions during the production process. This has resulted in the adoption of cleaner production technologies, such as low-VOC paints and coatings, and the implementation of advanced filtration systems in manufacturing facilities. These measures have not only helped companies comply with regulations but have also improved the overall environmental performance of their operations.

Another significant impact has been the emphasis on extended producer responsibility. Manufacturers are now required to take responsibility for the entire lifecycle of their products, including disposal and recycling. This has led to the development of take-back programs and the establishment of recycling facilities specifically designed for V12 engines and their components.

The stringent environmental regulations have also driven innovation in V12 engine design. Manufacturers have been compelled to develop more fuel-efficient engines with reduced emissions, leading to advancements in technologies such as direct injection, variable valve timing, and cylinder deactivation. These innovations not only help meet regulatory requirements but also improve the overall performance and efficiency of V12 engines.

In conclusion, environmental regulations have fundamentally transformed the landscape of V12 engine manufacturing. While presenting challenges, these regulations have also spurred innovation and pushed the industry towards more sustainable practices, aligning with circular economy principles and contributing to a more environmentally responsible automotive sector.

One of the primary impacts has been the need for manufacturers to reduce the carbon footprint of V12 engine production. This has led to the implementation of more energy-efficient manufacturing processes and the use of renewable energy sources in production facilities. Companies have invested in advanced technologies such as smart manufacturing systems and energy recovery systems to minimize waste and optimize resource utilization.

The regulations have also pushed manufacturers to focus on the use of recycled materials in V12 engine production. This shift has necessitated the development of new supply chain strategies to source high-quality recycled materials that meet the stringent performance requirements of V12 engines. As a result, manufacturers have had to establish partnerships with recycling facilities and invest in advanced material sorting and processing technologies.

Furthermore, environmental regulations have prompted V12 engine manufacturers to design for disassembly and recyclability. This approach ensures that at the end of an engine's life cycle, its components can be easily separated and recycled. Consequently, manufacturers have had to redesign certain engine components and rethink material choices to facilitate easier recycling without compromising performance.

The regulations have also led to increased focus on the reduction of harmful emissions during the production process. This has resulted in the adoption of cleaner production technologies, such as low-VOC paints and coatings, and the implementation of advanced filtration systems in manufacturing facilities. These measures have not only helped companies comply with regulations but have also improved the overall environmental performance of their operations.

Another significant impact has been the emphasis on extended producer responsibility. Manufacturers are now required to take responsibility for the entire lifecycle of their products, including disposal and recycling. This has led to the development of take-back programs and the establishment of recycling facilities specifically designed for V12 engines and their components.

The stringent environmental regulations have also driven innovation in V12 engine design. Manufacturers have been compelled to develop more fuel-efficient engines with reduced emissions, leading to advancements in technologies such as direct injection, variable valve timing, and cylinder deactivation. These innovations not only help meet regulatory requirements but also improve the overall performance and efficiency of V12 engines.

In conclusion, environmental regulations have fundamentally transformed the landscape of V12 engine manufacturing. While presenting challenges, these regulations have also spurred innovation and pushed the industry towards more sustainable practices, aligning with circular economy principles and contributing to a more environmentally responsible automotive sector.

Life Cycle Assessment of V12 Engines

Life Cycle Assessment (LCA) of V12 engines is a comprehensive approach to evaluating the environmental impacts associated with all stages of these powerful engines' existence. This assessment begins with the extraction of raw materials and extends through manufacturing, use, and eventual disposal or recycling. For V12 engines, which are known for their high performance and luxury applications, the LCA process is particularly crucial due to their significant resource requirements and environmental footprint.

The manufacturing phase of V12 engines involves complex processes and a wide array of materials. High-grade metals, including aluminum alloys, steel, and sometimes exotic materials like titanium, are extensively used. The production of these materials and their subsequent machining into engine components contribute substantially to the overall environmental impact. Advanced manufacturing techniques, such as precision casting and CNC machining, while ensuring high quality, often require considerable energy input.

During the use phase, V12 engines are notorious for their fuel consumption and emissions. This stage typically accounts for the largest portion of the engine's environmental impact over its lifetime. The extended service life of many V12 engines, particularly in luxury and high-performance vehicles, means that this use phase can span decades, amplifying its significance in the LCA.

End-of-life considerations for V12 engines present both challenges and opportunities. The complexity of these engines, with their numerous components and varied materials, can make disassembly and recycling more difficult. However, the high-quality materials used in their construction often retain significant value, incentivizing recycling efforts.

Recent advancements in LCA methodologies have allowed for more nuanced evaluations of V12 engines. These include considerations of regional energy mixes in manufacturing locations, the impact of different driving conditions on emissions, and the potential for remanufacturing or repurposing engine components. Such detailed analyses provide valuable insights for manufacturers, policymakers, and consumers alike.

The LCA of V12 engines also highlights areas for potential improvement. This includes exploring more sustainable material sourcing, implementing energy-efficient manufacturing processes, and developing technologies to reduce emissions and improve fuel efficiency during the use phase. Additionally, designing for easier disassembly and recycling at the end of life can significantly enhance the overall sustainability profile of these engines.

The manufacturing phase of V12 engines involves complex processes and a wide array of materials. High-grade metals, including aluminum alloys, steel, and sometimes exotic materials like titanium, are extensively used. The production of these materials and their subsequent machining into engine components contribute substantially to the overall environmental impact. Advanced manufacturing techniques, such as precision casting and CNC machining, while ensuring high quality, often require considerable energy input.

During the use phase, V12 engines are notorious for their fuel consumption and emissions. This stage typically accounts for the largest portion of the engine's environmental impact over its lifetime. The extended service life of many V12 engines, particularly in luxury and high-performance vehicles, means that this use phase can span decades, amplifying its significance in the LCA.

End-of-life considerations for V12 engines present both challenges and opportunities. The complexity of these engines, with their numerous components and varied materials, can make disassembly and recycling more difficult. However, the high-quality materials used in their construction often retain significant value, incentivizing recycling efforts.

Recent advancements in LCA methodologies have allowed for more nuanced evaluations of V12 engines. These include considerations of regional energy mixes in manufacturing locations, the impact of different driving conditions on emissions, and the potential for remanufacturing or repurposing engine components. Such detailed analyses provide valuable insights for manufacturers, policymakers, and consumers alike.

The LCA of V12 engines also highlights areas for potential improvement. This includes exploring more sustainable material sourcing, implementing energy-efficient manufacturing processes, and developing technologies to reduce emissions and improve fuel efficiency during the use phase. Additionally, designing for easier disassembly and recycling at the end of life can significantly enhance the overall sustainability profile of these engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!