How Dimethyl Ether Improves LPG Fuel Alternatives?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME and LPG Background

Dimethyl ether (DME) and liquefied petroleum gas (LPG) are two important fuel alternatives that have gained significant attention in recent years. LPG, a mixture of propane and butane, has been widely used as a cooking and heating fuel for decades. It has also found applications in the automotive sector as an alternative to gasoline and diesel. DME, on the other hand, is a newer entrant in the fuel market, offering promising characteristics that could potentially improve upon LPG's performance.

LPG's history dates back to the early 20th century when it was first discovered as a byproduct of petroleum refining. Its popularity grew rapidly due to its clean-burning properties and ease of storage and transportation. LPG quickly became a staple fuel for residential and commercial applications, particularly in regions with limited access to natural gas infrastructure.

DME, while less established than LPG, has a history that spans several decades. It was first synthesized in the 1930s but only gained attention as a potential fuel in the 1990s. DME is typically produced from natural gas, coal, or biomass through a process of methanol dehydration. Its chemical properties make it an attractive alternative to conventional fuels, particularly in diesel engines.

The growing interest in DME as an LPG alternative stems from several factors. Firstly, DME has a higher cetane number than LPG, which translates to better ignition quality in compression ignition engines. This property makes DME particularly suitable for use in diesel engines without significant modifications. Secondly, DME produces lower emissions of particulate matter and nitrogen oxides compared to conventional diesel fuel, addressing key environmental concerns associated with diesel engines.

Furthermore, DME's physical properties allow for easier handling and storage compared to LPG. It can be liquefied at relatively low pressures, similar to LPG, but with the added advantage of being non-corrosive to metals. This characteristic simplifies storage and distribution infrastructure requirements, potentially reducing overall system costs.

The evolution of DME as an LPG alternative is closely tied to the global push for cleaner and more sustainable energy sources. As countries worldwide seek to reduce their carbon footprint and improve air quality, alternative fuels like DME have gained traction. The technology for DME production has also advanced significantly, with improvements in efficiency and cost-effectiveness making it increasingly competitive with traditional fuels.

In recent years, several pilot projects and commercial applications have demonstrated the viability of DME as a fuel alternative. These initiatives have spanned various sectors, including transportation, power generation, and domestic use, showcasing the versatility of DME as a potential replacement or complement to LPG in multiple applications.

LPG's history dates back to the early 20th century when it was first discovered as a byproduct of petroleum refining. Its popularity grew rapidly due to its clean-burning properties and ease of storage and transportation. LPG quickly became a staple fuel for residential and commercial applications, particularly in regions with limited access to natural gas infrastructure.

DME, while less established than LPG, has a history that spans several decades. It was first synthesized in the 1930s but only gained attention as a potential fuel in the 1990s. DME is typically produced from natural gas, coal, or biomass through a process of methanol dehydration. Its chemical properties make it an attractive alternative to conventional fuels, particularly in diesel engines.

The growing interest in DME as an LPG alternative stems from several factors. Firstly, DME has a higher cetane number than LPG, which translates to better ignition quality in compression ignition engines. This property makes DME particularly suitable for use in diesel engines without significant modifications. Secondly, DME produces lower emissions of particulate matter and nitrogen oxides compared to conventional diesel fuel, addressing key environmental concerns associated with diesel engines.

Furthermore, DME's physical properties allow for easier handling and storage compared to LPG. It can be liquefied at relatively low pressures, similar to LPG, but with the added advantage of being non-corrosive to metals. This characteristic simplifies storage and distribution infrastructure requirements, potentially reducing overall system costs.

The evolution of DME as an LPG alternative is closely tied to the global push for cleaner and more sustainable energy sources. As countries worldwide seek to reduce their carbon footprint and improve air quality, alternative fuels like DME have gained traction. The technology for DME production has also advanced significantly, with improvements in efficiency and cost-effectiveness making it increasingly competitive with traditional fuels.

In recent years, several pilot projects and commercial applications have demonstrated the viability of DME as a fuel alternative. These initiatives have spanned various sectors, including transportation, power generation, and domestic use, showcasing the versatility of DME as a potential replacement or complement to LPG in multiple applications.

Market Analysis for DME

The market for Dimethyl Ether (DME) as an alternative to Liquefied Petroleum Gas (LPG) is experiencing significant growth and transformation. This shift is driven by the increasing global demand for cleaner and more sustainable fuel options. DME offers several advantages over traditional LPG, including lower emissions, higher energy efficiency, and compatibility with existing LPG infrastructure.

The global DME market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) expected to exceed 10% through 2030. This growth is primarily fueled by the rising adoption of DME in various applications, including domestic cooking, industrial processes, and transportation. The Asia-Pacific region, particularly China and India, is anticipated to be the largest and fastest-growing market for DME due to their large populations and increasing focus on reducing air pollution.

In the domestic cooking sector, DME is gaining traction as a cleaner alternative to traditional LPG. Countries with large rural populations, such as India and Indonesia, are showing increased interest in DME as a cooking fuel due to its lower cost and reduced environmental impact. This shift is supported by government initiatives aimed at reducing dependence on imported LPG and promoting cleaner fuel alternatives.

The industrial sector is another key driver of DME market growth. DME's properties make it an attractive option for various industrial applications, including power generation, chemical manufacturing, and spray propellants. The automotive industry is also exploring DME as a potential fuel for heavy-duty vehicles, with several pilot projects underway in Europe and North America.

However, the DME market faces challenges in terms of production capacity and distribution infrastructure. While DME can be produced from various feedstocks, including natural gas, coal, and biomass, current production levels are limited. Investments in production facilities and distribution networks are crucial for meeting the growing demand and realizing the full potential of DME as an LPG alternative.

Regulatory support and government incentives play a significant role in shaping the DME market. Countries with stringent emissions regulations and targets for renewable energy adoption are likely to see faster growth in DME usage. For instance, the European Union's Renewable Energy Directive II (RED II) recognizes DME as a renewable fuel when produced from biomass, potentially boosting its adoption in the region.

The competitive landscape of the DME market is evolving, with both established energy companies and new entrants investing in DME production and technology. Partnerships between fuel producers, technology providers, and end-users are becoming increasingly common, driving innovation and market expansion.

The global DME market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) expected to exceed 10% through 2030. This growth is primarily fueled by the rising adoption of DME in various applications, including domestic cooking, industrial processes, and transportation. The Asia-Pacific region, particularly China and India, is anticipated to be the largest and fastest-growing market for DME due to their large populations and increasing focus on reducing air pollution.

In the domestic cooking sector, DME is gaining traction as a cleaner alternative to traditional LPG. Countries with large rural populations, such as India and Indonesia, are showing increased interest in DME as a cooking fuel due to its lower cost and reduced environmental impact. This shift is supported by government initiatives aimed at reducing dependence on imported LPG and promoting cleaner fuel alternatives.

The industrial sector is another key driver of DME market growth. DME's properties make it an attractive option for various industrial applications, including power generation, chemical manufacturing, and spray propellants. The automotive industry is also exploring DME as a potential fuel for heavy-duty vehicles, with several pilot projects underway in Europe and North America.

However, the DME market faces challenges in terms of production capacity and distribution infrastructure. While DME can be produced from various feedstocks, including natural gas, coal, and biomass, current production levels are limited. Investments in production facilities and distribution networks are crucial for meeting the growing demand and realizing the full potential of DME as an LPG alternative.

Regulatory support and government incentives play a significant role in shaping the DME market. Countries with stringent emissions regulations and targets for renewable energy adoption are likely to see faster growth in DME usage. For instance, the European Union's Renewable Energy Directive II (RED II) recognizes DME as a renewable fuel when produced from biomass, potentially boosting its adoption in the region.

The competitive landscape of the DME market is evolving, with both established energy companies and new entrants investing in DME production and technology. Partnerships between fuel producers, technology providers, and end-users are becoming increasingly common, driving innovation and market expansion.

DME Technical Challenges

The adoption of dimethyl ether (DME) as an alternative to liquefied petroleum gas (LPG) faces several technical challenges that need to be addressed for widespread implementation. One of the primary obstacles is the compatibility of existing LPG infrastructure with DME. While DME shares similar physical properties with LPG, its chemical composition differs, requiring modifications to storage tanks, pipelines, and distribution systems to prevent material degradation and ensure proper sealing.

Another significant challenge lies in the development of efficient and cost-effective DME production methods. Current production processes, such as methanol dehydration or direct synthesis from syngas, need further optimization to achieve economies of scale comparable to LPG production. The energy intensity of DME production also remains a concern, as it impacts the overall environmental benefits of using DME as an alternative fuel.

The lower energy density of DME compared to LPG presents a challenge in terms of storage and transportation. This necessitates larger storage tanks and more frequent refueling, which may require adjustments to logistics and supply chain management. Additionally, the lower calorific value of DME means that higher volumes are needed to achieve the same energy output as LPG, potentially affecting the design of burners and combustion systems in end-use applications.

DME's higher vapor pressure compared to LPG poses challenges in terms of containment and safety. This requires the development of enhanced sealing technologies and pressure management systems to prevent leakage and ensure safe handling throughout the supply chain. Furthermore, the different combustion characteristics of DME may necessitate modifications to existing appliances and engines to optimize performance and emissions.

The lack of widespread standardization and regulations specific to DME as a fuel alternative presents regulatory challenges. Establishing comprehensive safety standards, handling protocols, and quality specifications for DME is crucial for its acceptance and integration into existing energy systems. This also extends to the need for training and certification programs for personnel involved in DME handling and distribution.

Lastly, the economic viability of DME as an LPG alternative remains a significant hurdle. The current cost of DME production, coupled with the required infrastructure investments, makes it challenging to compete with established LPG markets. Overcoming this challenge requires continued research and development to improve production efficiencies, as well as potential policy support and incentives to encourage adoption and investment in DME technologies.

Another significant challenge lies in the development of efficient and cost-effective DME production methods. Current production processes, such as methanol dehydration or direct synthesis from syngas, need further optimization to achieve economies of scale comparable to LPG production. The energy intensity of DME production also remains a concern, as it impacts the overall environmental benefits of using DME as an alternative fuel.

The lower energy density of DME compared to LPG presents a challenge in terms of storage and transportation. This necessitates larger storage tanks and more frequent refueling, which may require adjustments to logistics and supply chain management. Additionally, the lower calorific value of DME means that higher volumes are needed to achieve the same energy output as LPG, potentially affecting the design of burners and combustion systems in end-use applications.

DME's higher vapor pressure compared to LPG poses challenges in terms of containment and safety. This requires the development of enhanced sealing technologies and pressure management systems to prevent leakage and ensure safe handling throughout the supply chain. Furthermore, the different combustion characteristics of DME may necessitate modifications to existing appliances and engines to optimize performance and emissions.

The lack of widespread standardization and regulations specific to DME as a fuel alternative presents regulatory challenges. Establishing comprehensive safety standards, handling protocols, and quality specifications for DME is crucial for its acceptance and integration into existing energy systems. This also extends to the need for training and certification programs for personnel involved in DME handling and distribution.

Lastly, the economic viability of DME as an LPG alternative remains a significant hurdle. The current cost of DME production, coupled with the required infrastructure investments, makes it challenging to compete with established LPG markets. Overcoming this challenge requires continued research and development to improve production efficiencies, as well as potential policy support and incentives to encourage adoption and investment in DME technologies.

Current DME Solutions

01 Catalytic conversion of methanol to dimethyl ether

Improving the process of converting methanol to dimethyl ether using catalysts. This involves optimizing catalyst composition, reaction conditions, and reactor design to enhance yield and selectivity. The process aims to increase efficiency and reduce byproduct formation in dimethyl ether production.- Catalytic synthesis of dimethyl ether: Improvements in the catalytic synthesis of dimethyl ether from syngas or methanol. This includes developing more efficient catalysts, optimizing reaction conditions, and enhancing the selectivity of the process to increase yield and reduce byproducts.

- Purification and separation techniques: Advancements in purification and separation methods for dimethyl ether production. This involves innovative distillation processes, membrane separation technologies, and other techniques to obtain high-purity dimethyl ether and remove impurities efficiently.

- Process integration and energy efficiency: Improvements in process integration and energy efficiency for dimethyl ether production. This includes heat integration, cogeneration systems, and optimized process designs to reduce energy consumption and improve overall process economics.

- Novel applications and formulations: Development of new applications and formulations for dimethyl ether. This includes its use as a clean fuel alternative, aerosol propellant, refrigerant, and in chemical synthesis. Improvements focus on enhancing performance and safety in these applications.

- Environmental and safety enhancements: Advancements in environmental and safety aspects of dimethyl ether production and use. This includes developing greener production processes, reducing emissions, improving storage and handling safety, and enhancing the overall sustainability of dimethyl ether as a chemical and fuel.

02 Purification and separation of dimethyl ether

Developing advanced methods for purifying and separating dimethyl ether from reaction mixtures. This includes techniques such as distillation, adsorption, and membrane separation to obtain high-purity dimethyl ether. The focus is on improving separation efficiency and reducing energy consumption in the purification process.Expand Specific Solutions03 Direct synthesis of dimethyl ether from syngas

Enhancing the direct synthesis of dimethyl ether from syngas (CO and H2). This involves developing bifunctional catalysts that can perform both methanol synthesis and dehydration in a single step. The aim is to improve conversion rates, selectivity, and overall process efficiency compared to traditional two-step processes.Expand Specific Solutions04 Dimethyl ether as a fuel additive or alternative fuel

Improving the use of dimethyl ether as a fuel additive or alternative fuel. This includes optimizing fuel blends, developing specialized engine components, and addressing storage and handling challenges. The goal is to enhance combustion efficiency, reduce emissions, and improve overall performance in various applications.Expand Specific Solutions05 Production of value-added chemicals from dimethyl ether

Developing new processes to convert dimethyl ether into higher-value chemicals. This involves exploring novel catalytic pathways, reaction conditions, and process designs to produce olefins, aromatics, or other valuable chemical intermediates from dimethyl ether. The focus is on expanding the utilization of dimethyl ether as a versatile chemical feedstock.Expand Specific Solutions

Key DME Industry Players

The development of dimethyl ether (DME) as an LPG fuel alternative is in its early stages, with the market still emerging. The global DME market size is projected to grow significantly in the coming years, driven by increasing demand for clean energy solutions. Technologically, DME production is advancing, but commercialization remains limited. Key players like China Petroleum & Chemical Corp., Indian Oil Corp. Ltd., and SK Innovation Co., Ltd. are investing in research and development to improve DME production efficiency and scalability. Universities such as the University of Southern California and Xi'an Jiaotong University are contributing to technological advancements through academic research. While progress is being made, widespread adoption of DME as an LPG alternative still faces challenges in terms of infrastructure development and cost-competitiveness.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a proprietary DME production technology using syngas derived from coal or natural gas. Their process involves a single-step synthesis method, which directly converts syngas to DME, improving efficiency and reducing production costs[1]. Sinopec has also invested in large-scale DME production facilities, with an annual capacity of over 1 million tons[2]. The company has conducted extensive research on DME as an LPG alternative, focusing on its application in household cooking and industrial heating. They have developed specialized DME-compatible burners and storage systems to facilitate the transition from LPG to DME[3].

Strengths: Established infrastructure for large-scale DME production; expertise in syngas-to-DME conversion. Weaknesses: Dependence on coal-based syngas may raise environmental concerns; requires significant investment in new distribution networks.

Indian Oil Corp. Ltd.

Technical Solution: Indian Oil Corp. Ltd. has been at the forefront of DME research and development in India. They have developed a novel process for DME production using bio-ethanol as a feedstock, which offers a more sustainable alternative to traditional fossil fuel-based methods[4]. The company has also conducted extensive field trials of DME-LPG blends in domestic and commercial applications, demonstrating up to 20% DME blending without significant modifications to existing LPG infrastructure[5]. Indian Oil has further invested in developing DME-compatible seals and gaskets to ensure the safe use of DME in existing LPG appliances, addressing one of the key challenges in DME adoption[6].

Strengths: Innovative bio-ethanol to DME production process; extensive field testing of DME-LPG blends. Weaknesses: Limited large-scale production capacity; reliance on government support for widespread adoption.

DME Core Technologies

Stockpiling methanol and/or dimethyl ether for fuel and energy reserves

PatentInactiveIN2777MUMNP2010A

Innovation

- Storing methanol and/or dimethyl ether in appropriate facilities, produced through the chemical recycling of carbon dioxide and methane, which offers a safe, economic, and environmentally friendly alternative fuel source that can be easily transported and stored, using methods such as reductive conversion and catalytic hydrogenation to produce methanol and dimethyl ether.

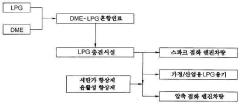

Dimethyl ether-liquefied petroleum gas mixed fuel composition and method for preparing the same

PatentInactiveKR1020070099512A

Innovation

- A mixed fuel composition of dimethyl ether (DME) and liquefied petroleum gas (LPG) is developed, allowing for use of existing LPG infrastructure and vehicles, with a mixing ratio of 1 to 99% by weight, and optionally including cetane number improvers and lubricity improvers.

Environmental Impact

The environmental impact of using dimethyl ether (DME) as an alternative to liquefied petroleum gas (LPG) is a critical consideration in the ongoing search for cleaner fuel options. DME offers several environmental advantages over traditional LPG, particularly in terms of emissions reduction and overall ecological footprint.

One of the primary environmental benefits of DME is its lower carbon dioxide emissions compared to LPG. When burned, DME produces significantly less CO2, contributing to a reduction in greenhouse gas emissions. This characteristic makes DME an attractive option for countries and industries seeking to meet increasingly stringent carbon reduction targets and mitigate climate change impacts.

In addition to reduced carbon emissions, DME combustion results in lower levels of particulate matter and nitrogen oxides (NOx) compared to conventional LPG. This reduction in harmful pollutants can lead to improved air quality, especially in urban areas where air pollution from transportation and industrial activities is a major concern. The decreased emission of these pollutants can potentially reduce the incidence of respiratory diseases and other health issues associated with poor air quality.

DME's environmental advantages extend beyond its combustion characteristics. The production of DME can be achieved through various methods, including the use of renewable resources such as biomass. This potential for renewable production further enhances DME's environmental credentials, as it offers a pathway to reduce dependence on fossil fuels and promote a more sustainable energy ecosystem.

Another environmental benefit of DME is its non-toxicity and rapid biodegradability. Unlike some other fuel alternatives, DME does not persist in the environment or accumulate in living organisms. In the event of accidental release, DME quickly breaks down in the atmosphere without causing long-term environmental damage. This characteristic reduces the risk of soil and water contamination associated with fuel spills or leaks.

The use of DME as an LPG alternative also has implications for waste management and recycling. DME can be stored and transported using existing LPG infrastructure with minimal modifications, reducing the need for new equipment and the associated environmental impacts of manufacturing and disposing of specialized storage and distribution systems.

However, it is important to note that the full environmental impact of DME depends on its production method. While DME can be produced from renewable sources, it is currently primarily derived from natural gas or coal. The environmental benefits of DME are most pronounced when it is produced using renewable feedstocks or waste materials, as this approach minimizes the overall carbon footprint of the fuel lifecycle.

In conclusion, the adoption of DME as an alternative to LPG offers significant potential for reducing environmental impacts across various dimensions. From lower emissions to biodegradability and the potential for renewable production, DME presents a promising option for improving the ecological profile of fuel use in both industrial and consumer applications.

One of the primary environmental benefits of DME is its lower carbon dioxide emissions compared to LPG. When burned, DME produces significantly less CO2, contributing to a reduction in greenhouse gas emissions. This characteristic makes DME an attractive option for countries and industries seeking to meet increasingly stringent carbon reduction targets and mitigate climate change impacts.

In addition to reduced carbon emissions, DME combustion results in lower levels of particulate matter and nitrogen oxides (NOx) compared to conventional LPG. This reduction in harmful pollutants can lead to improved air quality, especially in urban areas where air pollution from transportation and industrial activities is a major concern. The decreased emission of these pollutants can potentially reduce the incidence of respiratory diseases and other health issues associated with poor air quality.

DME's environmental advantages extend beyond its combustion characteristics. The production of DME can be achieved through various methods, including the use of renewable resources such as biomass. This potential for renewable production further enhances DME's environmental credentials, as it offers a pathway to reduce dependence on fossil fuels and promote a more sustainable energy ecosystem.

Another environmental benefit of DME is its non-toxicity and rapid biodegradability. Unlike some other fuel alternatives, DME does not persist in the environment or accumulate in living organisms. In the event of accidental release, DME quickly breaks down in the atmosphere without causing long-term environmental damage. This characteristic reduces the risk of soil and water contamination associated with fuel spills or leaks.

The use of DME as an LPG alternative also has implications for waste management and recycling. DME can be stored and transported using existing LPG infrastructure with minimal modifications, reducing the need for new equipment and the associated environmental impacts of manufacturing and disposing of specialized storage and distribution systems.

However, it is important to note that the full environmental impact of DME depends on its production method. While DME can be produced from renewable sources, it is currently primarily derived from natural gas or coal. The environmental benefits of DME are most pronounced when it is produced using renewable feedstocks or waste materials, as this approach minimizes the overall carbon footprint of the fuel lifecycle.

In conclusion, the adoption of DME as an alternative to LPG offers significant potential for reducing environmental impacts across various dimensions. From lower emissions to biodegradability and the potential for renewable production, DME presents a promising option for improving the ecological profile of fuel use in both industrial and consumer applications.

Regulatory Framework

The regulatory framework surrounding dimethyl ether (DME) as an LPG fuel alternative is complex and evolving. As DME gains traction as a cleaner and more efficient fuel option, governments and regulatory bodies are adapting existing regulations and developing new ones to ensure its safe and sustainable use.

At the international level, organizations such as the International Maritime Organization (IMO) and the United Nations Economic Commission for Europe (UNECE) are working to establish global standards for DME as a fuel. These efforts aim to harmonize regulations across countries and facilitate the widespread adoption of DME in various applications, including automotive and industrial sectors.

In the United States, the Environmental Protection Agency (EPA) has recognized DME as an alternative fuel under the Renewable Fuel Standard (RFS) program. This designation allows DME producers to generate Renewable Identification Numbers (RINs), providing economic incentives for its production and use. Additionally, the Department of Energy (DOE) has included DME in its research and development programs for alternative fuels, further supporting its integration into the energy landscape.

The European Union has also taken steps to incorporate DME into its regulatory framework. The Renewable Energy Directive (RED II) includes DME as a renewable fuel option, encouraging its use in transportation and other sectors. European countries are individually adapting their national regulations to accommodate DME, with some nations offering tax incentives or subsidies to promote its adoption.

Safety regulations play a crucial role in the regulatory framework for DME. Given its properties as a pressurized gas, storage and handling regulations are being developed or modified to ensure safe use. These regulations cover aspects such as tank design, filling procedures, and transportation requirements. The National Fire Protection Association (NFPA) in the United States, for example, has updated its codes to include specific provisions for DME.

Emissions regulations are another key area of focus. As DME offers lower emissions compared to traditional LPG and diesel fuels, regulators are adjusting emission standards to reflect its environmental benefits. This includes updating testing procedures and emission limits to accurately assess DME's performance in various applications.

The regulatory landscape for DME is dynamic, with ongoing efforts to address challenges and opportunities. As more countries recognize the potential of DME as an LPG fuel alternative, we can expect further refinement and expansion of regulations to support its widespread adoption while ensuring safety and environmental protection.

At the international level, organizations such as the International Maritime Organization (IMO) and the United Nations Economic Commission for Europe (UNECE) are working to establish global standards for DME as a fuel. These efforts aim to harmonize regulations across countries and facilitate the widespread adoption of DME in various applications, including automotive and industrial sectors.

In the United States, the Environmental Protection Agency (EPA) has recognized DME as an alternative fuel under the Renewable Fuel Standard (RFS) program. This designation allows DME producers to generate Renewable Identification Numbers (RINs), providing economic incentives for its production and use. Additionally, the Department of Energy (DOE) has included DME in its research and development programs for alternative fuels, further supporting its integration into the energy landscape.

The European Union has also taken steps to incorporate DME into its regulatory framework. The Renewable Energy Directive (RED II) includes DME as a renewable fuel option, encouraging its use in transportation and other sectors. European countries are individually adapting their national regulations to accommodate DME, with some nations offering tax incentives or subsidies to promote its adoption.

Safety regulations play a crucial role in the regulatory framework for DME. Given its properties as a pressurized gas, storage and handling regulations are being developed or modified to ensure safe use. These regulations cover aspects such as tank design, filling procedures, and transportation requirements. The National Fire Protection Association (NFPA) in the United States, for example, has updated its codes to include specific provisions for DME.

Emissions regulations are another key area of focus. As DME offers lower emissions compared to traditional LPG and diesel fuels, regulators are adjusting emission standards to reflect its environmental benefits. This includes updating testing procedures and emission limits to accurately assess DME's performance in various applications.

The regulatory landscape for DME is dynamic, with ongoing efforts to address challenges and opportunities. As more countries recognize the potential of DME as an LPG fuel alternative, we can expect further refinement and expansion of regulations to support its widespread adoption while ensuring safety and environmental protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!