How Ethyl Acetate Aids in Developing Safer Functional Products?

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate Background and Safety Objectives

Ethyl acetate, a versatile organic compound, has played a significant role in the development of safer functional products across various industries. This colorless liquid ester, with its characteristic sweet odor, has been utilized for decades due to its unique properties and relatively low toxicity compared to many other solvents.

The evolution of ethyl acetate in industrial applications can be traced back to the early 20th century when it was primarily used as a solvent in the production of nitrocellulose lacquers. As safety concerns grew in the chemical industry, ethyl acetate emerged as a safer alternative to more hazardous solvents, marking the beginning of its journey towards becoming a key component in developing safer functional products.

In recent years, the focus on sustainability and environmental safety has further propelled the use of ethyl acetate. Its biodegradability and low environmental impact have made it an attractive option for manufacturers seeking to reduce their ecological footprint while maintaining product efficacy. This shift aligns with global initiatives to minimize the use of volatile organic compounds (VOCs) and promote greener chemistry practices.

The safety objectives associated with ethyl acetate usage in product development are multifaceted. Primarily, it aims to reduce exposure risks for both workers and consumers. Unlike many of its counterparts, ethyl acetate has a lower acute toxicity profile, making it safer to handle in manufacturing processes. Additionally, its rapid evaporation rate contributes to reduced long-term exposure in end-use products.

Another critical safety objective is the replacement of more harmful solvents in existing formulations. By substituting ethyl acetate for solvents with higher toxicity or environmental persistence, manufacturers can significantly improve the safety profile of their products without compromising functionality. This substitution strategy has been particularly effective in industries such as coatings, adhesives, and personal care products.

The development of safer functional products using ethyl acetate also extends to improving product stability and shelf life. Its excellent solvency properties allow for better dispersion of active ingredients, potentially reducing the need for additional stabilizers or preservatives that may pose safety concerns. This aspect is particularly valuable in the pharmaceutical and food industries, where product integrity and safety are paramount.

As research continues, the potential of ethyl acetate in developing novel, safer formulations is being explored. Scientists and engineers are investigating its use in advanced drug delivery systems, eco-friendly pesticides, and innovative cleaning solutions. These developments aim to further enhance product safety while meeting the growing consumer demand for effective and environmentally responsible products.

The evolution of ethyl acetate in industrial applications can be traced back to the early 20th century when it was primarily used as a solvent in the production of nitrocellulose lacquers. As safety concerns grew in the chemical industry, ethyl acetate emerged as a safer alternative to more hazardous solvents, marking the beginning of its journey towards becoming a key component in developing safer functional products.

In recent years, the focus on sustainability and environmental safety has further propelled the use of ethyl acetate. Its biodegradability and low environmental impact have made it an attractive option for manufacturers seeking to reduce their ecological footprint while maintaining product efficacy. This shift aligns with global initiatives to minimize the use of volatile organic compounds (VOCs) and promote greener chemistry practices.

The safety objectives associated with ethyl acetate usage in product development are multifaceted. Primarily, it aims to reduce exposure risks for both workers and consumers. Unlike many of its counterparts, ethyl acetate has a lower acute toxicity profile, making it safer to handle in manufacturing processes. Additionally, its rapid evaporation rate contributes to reduced long-term exposure in end-use products.

Another critical safety objective is the replacement of more harmful solvents in existing formulations. By substituting ethyl acetate for solvents with higher toxicity or environmental persistence, manufacturers can significantly improve the safety profile of their products without compromising functionality. This substitution strategy has been particularly effective in industries such as coatings, adhesives, and personal care products.

The development of safer functional products using ethyl acetate also extends to improving product stability and shelf life. Its excellent solvency properties allow for better dispersion of active ingredients, potentially reducing the need for additional stabilizers or preservatives that may pose safety concerns. This aspect is particularly valuable in the pharmaceutical and food industries, where product integrity and safety are paramount.

As research continues, the potential of ethyl acetate in developing novel, safer formulations is being explored. Scientists and engineers are investigating its use in advanced drug delivery systems, eco-friendly pesticides, and innovative cleaning solutions. These developments aim to further enhance product safety while meeting the growing consumer demand for effective and environmentally responsible products.

Market Demand for Safer Functional Products

The market demand for safer functional products has been steadily increasing in recent years, driven by growing consumer awareness of health and environmental concerns. This trend is particularly evident in industries such as personal care, household cleaning, and industrial applications, where traditional products often contain harsh chemicals or potentially harmful ingredients.

Consumers are increasingly seeking alternatives that offer the same or better functionality while minimizing potential risks to their health and the environment. This shift in consumer preferences has created a significant opportunity for products that incorporate safer ingredients, such as ethyl acetate, which can provide similar performance characteristics to more hazardous substances.

In the personal care industry, there is a strong demand for safer cosmetics, skincare, and hair care products. Consumers are looking for formulations that are free from parabens, phthalates, and other controversial ingredients. Ethyl acetate, when used as a solvent or fragrance ingredient, can help meet this demand by offering a safer alternative to some traditional chemicals.

The household cleaning sector has also seen a surge in demand for eco-friendly and non-toxic products. Consumers are increasingly concerned about the potential health impacts of harsh cleaning chemicals, especially in homes with children or pets. Ethyl acetate's low toxicity and biodegradability make it an attractive option for manufacturers looking to develop safer cleaning solutions that meet consumer expectations.

In industrial applications, there is growing pressure from regulators and stakeholders to reduce the use of volatile organic compounds (VOCs) and other hazardous substances. This has led to increased demand for safer solvents and chemicals in manufacturing processes, coatings, and adhesives. Ethyl acetate's relatively low toxicity and environmental impact position it as a viable alternative in many industrial applications.

The market for safer functional products is not limited to consumer goods. There is also significant demand in the pharmaceutical and food industries for safer excipients and processing aids. Ethyl acetate's status as a generally recognized as safe (GRAS) substance by the FDA makes it an attractive option for these applications.

As sustainability becomes an increasingly important factor in consumer purchasing decisions, the demand for products made with safer, more environmentally friendly ingredients is expected to continue growing. This trend presents a significant opportunity for manufacturers who can effectively incorporate safer alternatives like ethyl acetate into their product formulations while maintaining or improving product performance.

Consumers are increasingly seeking alternatives that offer the same or better functionality while minimizing potential risks to their health and the environment. This shift in consumer preferences has created a significant opportunity for products that incorporate safer ingredients, such as ethyl acetate, which can provide similar performance characteristics to more hazardous substances.

In the personal care industry, there is a strong demand for safer cosmetics, skincare, and hair care products. Consumers are looking for formulations that are free from parabens, phthalates, and other controversial ingredients. Ethyl acetate, when used as a solvent or fragrance ingredient, can help meet this demand by offering a safer alternative to some traditional chemicals.

The household cleaning sector has also seen a surge in demand for eco-friendly and non-toxic products. Consumers are increasingly concerned about the potential health impacts of harsh cleaning chemicals, especially in homes with children or pets. Ethyl acetate's low toxicity and biodegradability make it an attractive option for manufacturers looking to develop safer cleaning solutions that meet consumer expectations.

In industrial applications, there is growing pressure from regulators and stakeholders to reduce the use of volatile organic compounds (VOCs) and other hazardous substances. This has led to increased demand for safer solvents and chemicals in manufacturing processes, coatings, and adhesives. Ethyl acetate's relatively low toxicity and environmental impact position it as a viable alternative in many industrial applications.

The market for safer functional products is not limited to consumer goods. There is also significant demand in the pharmaceutical and food industries for safer excipients and processing aids. Ethyl acetate's status as a generally recognized as safe (GRAS) substance by the FDA makes it an attractive option for these applications.

As sustainability becomes an increasingly important factor in consumer purchasing decisions, the demand for products made with safer, more environmentally friendly ingredients is expected to continue growing. This trend presents a significant opportunity for manufacturers who can effectively incorporate safer alternatives like ethyl acetate into their product formulations while maintaining or improving product performance.

Current Applications and Challenges

Ethyl acetate has emerged as a versatile and safer alternative in the development of functional products across various industries. Its current applications span a wide range of sectors, including cosmetics, pharmaceuticals, food and beverages, and industrial manufacturing. In the cosmetics industry, ethyl acetate is widely used as a solvent in nail polish removers, offering a less harsh option compared to traditional acetone-based products. It also finds application in fragrances and perfumes due to its pleasant, fruity odor and ability to dissolve essential oils effectively.

In the pharmaceutical sector, ethyl acetate plays a crucial role in the production of various medications. It serves as an extraction solvent in the manufacture of antibiotics and other active pharmaceutical ingredients. Its low toxicity and high selectivity make it an ideal choice for pharmaceutical processes where purity is paramount. Additionally, ethyl acetate is utilized in the production of controlled-release drug delivery systems, contributing to the development of more efficient and targeted medications.

The food and beverage industry has also embraced ethyl acetate for its safety profile and functional properties. It is commonly used as a flavoring agent, imparting a fruity essence to various products. Moreover, ethyl acetate serves as an extraction solvent in the decaffeination of coffee and tea, offering a safer alternative to methylene chloride, which has raised health concerns.

In industrial applications, ethyl acetate has found its place as a cleaning agent and degreaser. Its ability to dissolve a wide range of substances without leaving residues makes it valuable in electronics manufacturing and precision cleaning processes. Furthermore, it is employed in the production of adhesives, coatings, and inks, contributing to the development of eco-friendlier formulations.

Despite its numerous advantages, the use of ethyl acetate in developing safer functional products faces several challenges. One primary concern is its high volatility, which can lead to rapid evaporation and potential flammability risks. This characteristic necessitates careful handling and storage procedures, as well as the implementation of proper ventilation systems in manufacturing facilities. Additionally, while ethyl acetate is generally considered safe, prolonged exposure to high concentrations can cause respiratory irritation and other health issues, requiring stringent workplace safety measures.

Another challenge lies in the optimization of ethyl acetate-based formulations to achieve desired performance characteristics. Balancing the solvent properties of ethyl acetate with other ingredients to maintain product stability and efficacy can be complex, particularly in cosmetic and pharmaceutical applications. Furthermore, the cost of ethyl acetate, although competitive, can fluctuate based on raw material prices and market demand, potentially impacting product pricing and profitability.

In the pharmaceutical sector, ethyl acetate plays a crucial role in the production of various medications. It serves as an extraction solvent in the manufacture of antibiotics and other active pharmaceutical ingredients. Its low toxicity and high selectivity make it an ideal choice for pharmaceutical processes where purity is paramount. Additionally, ethyl acetate is utilized in the production of controlled-release drug delivery systems, contributing to the development of more efficient and targeted medications.

The food and beverage industry has also embraced ethyl acetate for its safety profile and functional properties. It is commonly used as a flavoring agent, imparting a fruity essence to various products. Moreover, ethyl acetate serves as an extraction solvent in the decaffeination of coffee and tea, offering a safer alternative to methylene chloride, which has raised health concerns.

In industrial applications, ethyl acetate has found its place as a cleaning agent and degreaser. Its ability to dissolve a wide range of substances without leaving residues makes it valuable in electronics manufacturing and precision cleaning processes. Furthermore, it is employed in the production of adhesives, coatings, and inks, contributing to the development of eco-friendlier formulations.

Despite its numerous advantages, the use of ethyl acetate in developing safer functional products faces several challenges. One primary concern is its high volatility, which can lead to rapid evaporation and potential flammability risks. This characteristic necessitates careful handling and storage procedures, as well as the implementation of proper ventilation systems in manufacturing facilities. Additionally, while ethyl acetate is generally considered safe, prolonged exposure to high concentrations can cause respiratory irritation and other health issues, requiring stringent workplace safety measures.

Another challenge lies in the optimization of ethyl acetate-based formulations to achieve desired performance characteristics. Balancing the solvent properties of ethyl acetate with other ingredients to maintain product stability and efficacy can be complex, particularly in cosmetic and pharmaceutical applications. Furthermore, the cost of ethyl acetate, although competitive, can fluctuate based on raw material prices and market demand, potentially impacting product pricing and profitability.

Existing Safety Enhancement Solutions

01 Safety measures in industrial processes

Ethyl acetate safety in industrial processes involves implementing proper handling procedures, ventilation systems, and protective equipment. Measures include using closed systems, monitoring vapor concentrations, and providing adequate training for workers to minimize exposure risks and prevent accidents.- Safety measures in industrial processes: Ethyl acetate is commonly used in industrial processes, and safety measures are crucial. These include proper ventilation systems, use of protective equipment, and implementation of safety protocols to minimize exposure risks and prevent accidents during handling and storage.

- Environmental impact and disposal: The environmental impact of ethyl acetate and its proper disposal are important safety considerations. Techniques for reducing emissions, treating waste, and implementing environmentally friendly disposal methods are essential to minimize ecological risks associated with its use.

- Health effects and exposure limits: Understanding the health effects of ethyl acetate exposure and establishing appropriate exposure limits are crucial for worker safety. This includes studying short-term and long-term health impacts, setting occupational exposure limits, and implementing monitoring systems to ensure compliance.

- Fire and explosion prevention: Ethyl acetate is flammable, necessitating fire and explosion prevention measures. This involves proper storage techniques, use of fire-resistant materials, implementation of fire suppression systems, and development of emergency response protocols to mitigate risks in industrial settings.

- Safe handling and transportation: Ensuring safe handling and transportation of ethyl acetate is essential to prevent accidents and spills. This includes proper packaging, labeling, and transportation protocols, as well as training for personnel involved in handling and transporting the chemical.

02 Environmental impact and disposal

Proper disposal and management of ethyl acetate waste are crucial for environmental safety. This includes implementing recycling processes, using specialized treatment methods, and adhering to regulations for safe disposal to minimize environmental contamination and reduce potential health hazards.Expand Specific Solutions03 Fire and explosion prevention

Ethyl acetate is highly flammable, necessitating specific fire and explosion prevention measures. These include proper storage in fire-resistant containers, implementing adequate fire suppression systems, and maintaining safe distances from ignition sources in industrial settings.Expand Specific Solutions04 Personal protective equipment and handling

Ensuring worker safety when handling ethyl acetate involves using appropriate personal protective equipment (PPE) such as chemical-resistant gloves, safety goggles, and respiratory protection. Proper training on handling procedures and emergency response is also essential to minimize exposure risks.Expand Specific Solutions05 Safety in chemical reactions and processes

When using ethyl acetate in chemical reactions and processes, safety considerations include controlling reaction conditions, monitoring temperature and pressure, and implementing fail-safe mechanisms. Proper equipment design and maintenance are crucial to prevent leaks, spills, and other potential hazards.Expand Specific Solutions

Key Industry Players and Manufacturers

The development of safer functional products using ethyl acetate is in a mature phase, with a substantial global market driven by increasing demand for eco-friendly and high-performance materials. The technology's maturity is evident from the involvement of major chemical companies like Celanese International Corp., Eastman Chemical Co., and SABIC Global Technologies BV. These industry leaders, along with specialized firms such as Nantong Acetic Acid Chemical Co., Ltd., are continuously innovating to improve product safety and functionality. The competitive landscape is characterized by a mix of established players and niche manufacturers, with research institutions like the University of California and Rice University contributing to advancements in the field.

Celanese International Corp.

Technical Solution: Celanese has developed a proprietary process for producing high-purity ethyl acetate using advanced catalysts and reactive distillation technology. Their method achieves conversion rates of over 99% and selectivity exceeding 99.9%[1]. The company has also introduced bio-based ethyl acetate derived from sustainable feedstocks, reducing carbon footprint by up to 50% compared to conventional petrochemical routes[2]. Celanese's ethyl acetate is used in a wide range of functional products, including low-VOC paints, adhesives, and pharmaceutical coatings, enhancing safety and performance[3].

Strengths: High-purity product, sustainable bio-based option, versatile applications. Weaknesses: Potentially higher production costs for bio-based version, reliance on specific feedstocks.

Eastman Chemical Co.

Technical Solution: Eastman has innovated in the field of ethyl acetate production and application, focusing on developing safer functional products. They have introduced a novel solvent system incorporating ethyl acetate for use in coatings and inks, which reduces VOC emissions by up to 30% compared to traditional formulations[4]. Eastman's ethyl acetate-based products also feature improved drying times and film formation properties. The company has further developed a range of ethyl acetate-based adhesives that are free from harmful phthalates and offer enhanced bonding strength for various substrates[5].

Strengths: Reduced VOC emissions, improved product performance, phthalate-free formulations. Weaknesses: May require reformulation of existing products, potential cost increases for specialized formulations.

Innovations in Ethyl Acetate Formulations

Chemical for the treatment, prevention and control of virus's diseases, bacterial diseases, cardiovascular diseases and lipids

PatentPendingCA3109802A1

Innovation

- Ethyl acetate (CH3C00C2H5) is used as the active substance in combination with pharmaceutical and/or dermatological acceptable auxiliary agents, formulated into forms such as dermal patches, creams, ointments, and solutions for transdermal, topical, or other applications.

Method for producing ethyl acetate

PatentPendingUS20250002441A1

Innovation

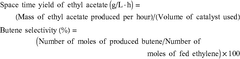

- Controlling the palladium content in the catalyst within the range of 0.1 to 14 ppb by mass in a heteropolyacid or its salt supported on a carrier, such as silica, suppresses side reactions and ensures stable long-term operation.

Regulatory Framework for Ethyl Acetate Use

The regulatory framework for ethyl acetate use is a critical aspect of ensuring the safe development and application of functional products. Globally, various regulatory bodies have established guidelines and standards for the use of ethyl acetate in consumer and industrial products.

In the United States, the Food and Drug Administration (FDA) regulates ethyl acetate as a food additive and solvent. It is classified as "Generally Recognized as Safe" (GRAS) when used in accordance with good manufacturing practices. The Environmental Protection Agency (EPA) also oversees its use under the Toxic Substances Control Act (TSCA), setting limits for environmental release and workplace exposure.

The European Union has implemented comprehensive regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) program. Under REACH, manufacturers and importers must register ethyl acetate and provide safety data. The European Chemicals Agency (ECHA) has established specific guidelines for its use in various applications, including cosmetics and food contact materials.

In Asia, countries like Japan and South Korea have their own regulatory frameworks. Japan's Ministry of Health, Labour and Welfare regulates ethyl acetate in food and cosmetic applications, while the Korean Food and Drug Administration oversees its use in similar contexts.

International organizations also play a role in shaping the regulatory landscape. The World Health Organization (WHO) provides guidelines on the safe use of ethyl acetate in pharmaceutical applications. The International Organization for Standardization (ISO) has developed standards for testing and quality control of ethyl acetate in various industrial processes.

Occupational safety regulations are another crucial aspect of the framework. Many countries have established permissible exposure limits (PELs) for ethyl acetate in workplace environments. For instance, the U.S. Occupational Safety and Health Administration (OSHA) has set a PEL of 400 parts per million (ppm) for an 8-hour workday.

As sustainability becomes increasingly important, regulations are evolving to address environmental concerns. Many jurisdictions now require manufacturers to implement proper disposal and recycling procedures for ethyl acetate-containing products and waste.

The regulatory framework also extends to labeling and packaging requirements. Products containing ethyl acetate must often include specific hazard warnings and handling instructions, as mandated by agencies such as the U.S. Consumer Product Safety Commission and the EU's Classification, Labeling, and Packaging (CLP) Regulation.

In the United States, the Food and Drug Administration (FDA) regulates ethyl acetate as a food additive and solvent. It is classified as "Generally Recognized as Safe" (GRAS) when used in accordance with good manufacturing practices. The Environmental Protection Agency (EPA) also oversees its use under the Toxic Substances Control Act (TSCA), setting limits for environmental release and workplace exposure.

The European Union has implemented comprehensive regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) program. Under REACH, manufacturers and importers must register ethyl acetate and provide safety data. The European Chemicals Agency (ECHA) has established specific guidelines for its use in various applications, including cosmetics and food contact materials.

In Asia, countries like Japan and South Korea have their own regulatory frameworks. Japan's Ministry of Health, Labour and Welfare regulates ethyl acetate in food and cosmetic applications, while the Korean Food and Drug Administration oversees its use in similar contexts.

International organizations also play a role in shaping the regulatory landscape. The World Health Organization (WHO) provides guidelines on the safe use of ethyl acetate in pharmaceutical applications. The International Organization for Standardization (ISO) has developed standards for testing and quality control of ethyl acetate in various industrial processes.

Occupational safety regulations are another crucial aspect of the framework. Many countries have established permissible exposure limits (PELs) for ethyl acetate in workplace environments. For instance, the U.S. Occupational Safety and Health Administration (OSHA) has set a PEL of 400 parts per million (ppm) for an 8-hour workday.

As sustainability becomes increasingly important, regulations are evolving to address environmental concerns. Many jurisdictions now require manufacturers to implement proper disposal and recycling procedures for ethyl acetate-containing products and waste.

The regulatory framework also extends to labeling and packaging requirements. Products containing ethyl acetate must often include specific hazard warnings and handling instructions, as mandated by agencies such as the U.S. Consumer Product Safety Commission and the EU's Classification, Labeling, and Packaging (CLP) Regulation.

Environmental Impact Assessment

The environmental impact assessment of ethyl acetate in the development of safer functional products is a critical aspect that requires thorough examination. Ethyl acetate, while offering numerous benefits in product formulation, also presents potential environmental concerns that must be carefully evaluated and mitigated.

One of the primary environmental considerations is the volatile organic compound (VOC) emissions associated with ethyl acetate use. As a solvent, ethyl acetate can contribute to air pollution when released into the atmosphere. However, compared to many other solvents, ethyl acetate has a relatively low photochemical reactivity, which means it has a reduced potential for forming ground-level ozone. This characteristic makes it a more environmentally friendly option in many applications.

Water pollution is another area of concern when assessing the environmental impact of ethyl acetate. Although it is not highly soluble in water, any release into aquatic ecosystems could potentially affect water quality and aquatic life. Fortunately, ethyl acetate is biodegradable and does not persist in the environment for extended periods, which helps to mitigate long-term ecological risks.

The production process of ethyl acetate also warrants consideration in the environmental impact assessment. Traditional methods of ethyl acetate synthesis involve the reaction of ethanol with acetic acid, which can be energy-intensive and generate waste products. However, advancements in green chemistry have led to more sustainable production methods, such as the use of biocatalysts or renewable feedstocks, which can significantly reduce the environmental footprint of ethyl acetate manufacturing.

In terms of waste management, ethyl acetate presents both challenges and opportunities. While it is important to prevent the release of ethyl acetate into the environment, its high volatility allows for effective recovery and recycling in many industrial processes. This recyclability can lead to reduced waste generation and more efficient use of resources in product development and manufacturing.

The lifecycle analysis of products containing ethyl acetate is an essential component of the environmental impact assessment. This includes evaluating the sourcing of raw materials, production processes, product use, and end-of-life disposal or recycling. By considering the entire lifecycle, manufacturers can identify areas for improvement and implement strategies to minimize environmental impacts throughout the product's existence.

When used in the development of safer functional products, ethyl acetate can contribute to reducing the overall environmental impact by replacing more harmful substances. Its low toxicity and biodegradability make it a suitable alternative to many traditional solvents that pose greater risks to human health and the environment. This substitution can lead to safer working conditions, reduced environmental contamination, and improved product sustainability profiles.

One of the primary environmental considerations is the volatile organic compound (VOC) emissions associated with ethyl acetate use. As a solvent, ethyl acetate can contribute to air pollution when released into the atmosphere. However, compared to many other solvents, ethyl acetate has a relatively low photochemical reactivity, which means it has a reduced potential for forming ground-level ozone. This characteristic makes it a more environmentally friendly option in many applications.

Water pollution is another area of concern when assessing the environmental impact of ethyl acetate. Although it is not highly soluble in water, any release into aquatic ecosystems could potentially affect water quality and aquatic life. Fortunately, ethyl acetate is biodegradable and does not persist in the environment for extended periods, which helps to mitigate long-term ecological risks.

The production process of ethyl acetate also warrants consideration in the environmental impact assessment. Traditional methods of ethyl acetate synthesis involve the reaction of ethanol with acetic acid, which can be energy-intensive and generate waste products. However, advancements in green chemistry have led to more sustainable production methods, such as the use of biocatalysts or renewable feedstocks, which can significantly reduce the environmental footprint of ethyl acetate manufacturing.

In terms of waste management, ethyl acetate presents both challenges and opportunities. While it is important to prevent the release of ethyl acetate into the environment, its high volatility allows for effective recovery and recycling in many industrial processes. This recyclability can lead to reduced waste generation and more efficient use of resources in product development and manufacturing.

The lifecycle analysis of products containing ethyl acetate is an essential component of the environmental impact assessment. This includes evaluating the sourcing of raw materials, production processes, product use, and end-of-life disposal or recycling. By considering the entire lifecycle, manufacturers can identify areas for improvement and implement strategies to minimize environmental impacts throughout the product's existence.

When used in the development of safer functional products, ethyl acetate can contribute to reducing the overall environmental impact by replacing more harmful substances. Its low toxicity and biodegradability make it a suitable alternative to many traditional solvents that pose greater risks to human health and the environment. This substitution can lead to safer working conditions, reduced environmental contamination, and improved product sustainability profiles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!