How Ethyl Acetate Affects Performance in Coating Technologies?

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate in Coatings: Background and Objectives

Ethyl acetate has been a crucial component in coating technologies for decades, playing a significant role in enhancing performance and efficiency. The evolution of this solvent's application in coatings can be traced back to the early 20th century when the chemical industry began to explore its potential as a versatile organic compound.

Initially used primarily as a solvent in lacquers and varnishes, ethyl acetate's role in coating technologies has expanded significantly over time. Its low toxicity, high solvency power, and rapid evaporation rate have made it an attractive option for various coating applications, from industrial paints to consumer products.

The development of ethyl acetate in coatings has been driven by several factors, including environmental regulations, cost-effectiveness, and the need for improved coating performance. As environmental concerns grew in the latter half of the 20th century, ethyl acetate emerged as a more environmentally friendly alternative to many traditional solvents, aligning with the industry's shift towards more sustainable practices.

In recent years, the focus on ethyl acetate in coating technologies has intensified due to its potential to address key challenges in the industry. These challenges include the need for faster drying times, improved adhesion, enhanced durability, and reduced environmental impact. The ongoing research and development in this area aim to optimize the use of ethyl acetate to meet these evolving requirements.

The technical objectives for ethyl acetate in coating technologies are multifaceted. Researchers and industry professionals are working to enhance its compatibility with various coating formulations, improve its performance across different environmental conditions, and explore novel applications that leverage its unique properties. Additionally, there is a growing interest in developing ethyl acetate-based coating systems that can meet stringent regulatory standards while maintaining or improving coating quality.

As we look towards the future, the role of ethyl acetate in coating technologies is expected to continue evolving. Emerging trends such as nanotechnology, smart coatings, and bio-based materials are likely to intersect with ethyl acetate research, potentially leading to innovative solutions and applications. The ongoing pursuit of sustainability in the coatings industry also positions ethyl acetate as a key player in the development of eco-friendly coating technologies.

Understanding the background and objectives of ethyl acetate in coatings is crucial for predicting future developments and guiding research efforts. By examining its historical context, current applications, and future potential, we can better appreciate the significance of ethyl acetate in shaping the future of coating technologies and addressing the industry's evolving needs.

Initially used primarily as a solvent in lacquers and varnishes, ethyl acetate's role in coating technologies has expanded significantly over time. Its low toxicity, high solvency power, and rapid evaporation rate have made it an attractive option for various coating applications, from industrial paints to consumer products.

The development of ethyl acetate in coatings has been driven by several factors, including environmental regulations, cost-effectiveness, and the need for improved coating performance. As environmental concerns grew in the latter half of the 20th century, ethyl acetate emerged as a more environmentally friendly alternative to many traditional solvents, aligning with the industry's shift towards more sustainable practices.

In recent years, the focus on ethyl acetate in coating technologies has intensified due to its potential to address key challenges in the industry. These challenges include the need for faster drying times, improved adhesion, enhanced durability, and reduced environmental impact. The ongoing research and development in this area aim to optimize the use of ethyl acetate to meet these evolving requirements.

The technical objectives for ethyl acetate in coating technologies are multifaceted. Researchers and industry professionals are working to enhance its compatibility with various coating formulations, improve its performance across different environmental conditions, and explore novel applications that leverage its unique properties. Additionally, there is a growing interest in developing ethyl acetate-based coating systems that can meet stringent regulatory standards while maintaining or improving coating quality.

As we look towards the future, the role of ethyl acetate in coating technologies is expected to continue evolving. Emerging trends such as nanotechnology, smart coatings, and bio-based materials are likely to intersect with ethyl acetate research, potentially leading to innovative solutions and applications. The ongoing pursuit of sustainability in the coatings industry also positions ethyl acetate as a key player in the development of eco-friendly coating technologies.

Understanding the background and objectives of ethyl acetate in coatings is crucial for predicting future developments and guiding research efforts. By examining its historical context, current applications, and future potential, we can better appreciate the significance of ethyl acetate in shaping the future of coating technologies and addressing the industry's evolving needs.

Market Analysis of Ethyl Acetate-Based Coatings

The global market for ethyl acetate-based coatings has been experiencing steady growth, driven by increasing demand across various industries such as automotive, construction, and packaging. This growth is primarily attributed to the superior performance characteristics of ethyl acetate in coating technologies, including its fast evaporation rate, excellent solvency, and ability to enhance the overall quality of coatings.

In the automotive sector, ethyl acetate-based coatings have gained significant traction due to their ability to provide a high-gloss finish and improved durability. The automotive industry's shift towards more environmentally friendly coating solutions has further boosted the demand for ethyl acetate-based products, as they offer lower VOC emissions compared to traditional solvent-based coatings.

The construction industry has also emerged as a key consumer of ethyl acetate-based coatings, particularly in the production of protective and decorative coatings for both interior and exterior applications. The growing focus on sustainable building materials and the need for long-lasting, weather-resistant coatings have contributed to the increased adoption of ethyl acetate-based solutions in this sector.

The packaging industry represents another significant market for ethyl acetate-based coatings, especially in the food and beverage segment. The excellent adhesion properties and chemical resistance of these coatings make them ideal for use in flexible packaging materials, ensuring product safety and extended shelf life.

Geographically, Asia-Pacific has emerged as the largest market for ethyl acetate-based coatings, driven by rapid industrialization, urbanization, and increasing disposable incomes in countries like China and India. North America and Europe follow closely, with mature markets characterized by a strong focus on innovation and sustainability.

The market is expected to continue its growth trajectory in the coming years, with a compound annual growth rate projected to remain steady. This growth is likely to be fueled by ongoing technological advancements in coating formulations, increasing awareness of environmental regulations, and the expanding application scope of ethyl acetate-based coatings across various end-use industries.

However, the market also faces certain challenges, including volatility in raw material prices and the growing competition from alternative solvents and water-based coating technologies. To maintain their competitive edge, manufacturers are investing in research and development to enhance the performance characteristics of ethyl acetate-based coatings and explore new application areas.

In the automotive sector, ethyl acetate-based coatings have gained significant traction due to their ability to provide a high-gloss finish and improved durability. The automotive industry's shift towards more environmentally friendly coating solutions has further boosted the demand for ethyl acetate-based products, as they offer lower VOC emissions compared to traditional solvent-based coatings.

The construction industry has also emerged as a key consumer of ethyl acetate-based coatings, particularly in the production of protective and decorative coatings for both interior and exterior applications. The growing focus on sustainable building materials and the need for long-lasting, weather-resistant coatings have contributed to the increased adoption of ethyl acetate-based solutions in this sector.

The packaging industry represents another significant market for ethyl acetate-based coatings, especially in the food and beverage segment. The excellent adhesion properties and chemical resistance of these coatings make them ideal for use in flexible packaging materials, ensuring product safety and extended shelf life.

Geographically, Asia-Pacific has emerged as the largest market for ethyl acetate-based coatings, driven by rapid industrialization, urbanization, and increasing disposable incomes in countries like China and India. North America and Europe follow closely, with mature markets characterized by a strong focus on innovation and sustainability.

The market is expected to continue its growth trajectory in the coming years, with a compound annual growth rate projected to remain steady. This growth is likely to be fueled by ongoing technological advancements in coating formulations, increasing awareness of environmental regulations, and the expanding application scope of ethyl acetate-based coatings across various end-use industries.

However, the market also faces certain challenges, including volatility in raw material prices and the growing competition from alternative solvents and water-based coating technologies. To maintain their competitive edge, manufacturers are investing in research and development to enhance the performance characteristics of ethyl acetate-based coatings and explore new application areas.

Current Challenges in Ethyl Acetate Coating Technologies

The use of ethyl acetate in coating technologies presents several significant challenges that researchers and industry professionals are currently grappling with. One of the primary issues is the volatile nature of ethyl acetate, which leads to rapid evaporation during the coating process. This volatility can result in inconsistent film formation and difficulties in controlling the drying rate, ultimately affecting the quality and uniformity of the final coating.

Another challenge lies in the environmental and health concerns associated with ethyl acetate. Despite being less toxic than some other solvents, it still contributes to volatile organic compound (VOC) emissions. Stricter environmental regulations are pushing the industry to find ways to reduce VOC emissions, which is proving to be a complex task when balancing performance requirements with sustainability goals.

The flammability of ethyl acetate poses safety risks in manufacturing environments, necessitating stringent safety measures and specialized equipment. This not only increases production costs but also complicates the scaling up of coating processes, particularly in large industrial settings where the volume of solvent used is substantial.

Compatibility issues between ethyl acetate and certain substrate materials present another hurdle. Some plastics and rubbers may be degraded or dissolved by ethyl acetate, limiting its applicability in certain coating scenarios. This necessitates careful material selection and potentially the development of new, compatible substrate materials or protective underlayers.

The cost and availability of high-purity ethyl acetate for specialized coating applications is an ongoing concern. Fluctuations in raw material prices and supply chain disruptions can impact the consistency and affordability of coating formulations, pushing manufacturers to seek alternative solvents or develop more efficient purification methods.

Achieving optimal coating performance while addressing these challenges requires a delicate balance. Researchers are exploring ways to modify ethyl acetate-based formulations to enhance their properties, such as improving adhesion, increasing durability, and reducing drying times. However, these modifications often come with trade-offs that must be carefully managed.

The development of novel application techniques to maximize the benefits of ethyl acetate while minimizing its drawbacks is an active area of research. This includes investigating precision application methods, controlled atmosphere coating environments, and hybrid solvent systems that leverage the strengths of ethyl acetate while compensating for its limitations.

Another challenge lies in the environmental and health concerns associated with ethyl acetate. Despite being less toxic than some other solvents, it still contributes to volatile organic compound (VOC) emissions. Stricter environmental regulations are pushing the industry to find ways to reduce VOC emissions, which is proving to be a complex task when balancing performance requirements with sustainability goals.

The flammability of ethyl acetate poses safety risks in manufacturing environments, necessitating stringent safety measures and specialized equipment. This not only increases production costs but also complicates the scaling up of coating processes, particularly in large industrial settings where the volume of solvent used is substantial.

Compatibility issues between ethyl acetate and certain substrate materials present another hurdle. Some plastics and rubbers may be degraded or dissolved by ethyl acetate, limiting its applicability in certain coating scenarios. This necessitates careful material selection and potentially the development of new, compatible substrate materials or protective underlayers.

The cost and availability of high-purity ethyl acetate for specialized coating applications is an ongoing concern. Fluctuations in raw material prices and supply chain disruptions can impact the consistency and affordability of coating formulations, pushing manufacturers to seek alternative solvents or develop more efficient purification methods.

Achieving optimal coating performance while addressing these challenges requires a delicate balance. Researchers are exploring ways to modify ethyl acetate-based formulations to enhance their properties, such as improving adhesion, increasing durability, and reducing drying times. However, these modifications often come with trade-offs that must be carefully managed.

The development of novel application techniques to maximize the benefits of ethyl acetate while minimizing its drawbacks is an active area of research. This includes investigating precision application methods, controlled atmosphere coating environments, and hybrid solvent systems that leverage the strengths of ethyl acetate while compensating for its limitations.

Existing Ethyl Acetate Coating Formulations

01 Ethyl acetate as a solvent in chemical processes

Ethyl acetate is widely used as a solvent in various chemical processes due to its excellent solvency properties. It is particularly effective in dissolving a wide range of organic compounds and is commonly employed in extraction, purification, and synthesis reactions. Its low boiling point and relatively low toxicity make it a preferred choice in many industrial applications.- Ethyl acetate as a solvent in chemical processes: Ethyl acetate is widely used as a solvent in various chemical processes due to its excellent solvency properties. It is particularly effective in dissolving a wide range of organic compounds and is often employed in extraction, purification, and synthesis reactions. Its low boiling point and relatively low toxicity make it a preferred choice in many industrial applications.

- Ethyl acetate in coating and adhesive formulations: Ethyl acetate is a key component in many coating and adhesive formulations. Its fast evaporation rate and ability to dissolve various resins make it ideal for use in paints, varnishes, and adhesives. It contributes to improved drying times and film formation, enhancing the overall performance of these products.

- Ethyl acetate production and purification methods: Various methods have been developed to produce and purify ethyl acetate, focusing on improving yield and efficiency. These include esterification of ethanol with acetic acid, catalytic processes, and innovative separation techniques. Advancements in production methods aim to enhance the purity and reduce the environmental impact of ethyl acetate manufacturing.

- Ethyl acetate in pharmaceutical and food applications: Ethyl acetate finds applications in the pharmaceutical and food industries due to its low toxicity and pleasant odor. It is used as a solvent for drug formulations, as an extraction medium for natural products, and as a flavoring agent in food products. Its performance in these areas is characterized by its effectiveness and compliance with regulatory standards.

- Environmental and safety considerations of ethyl acetate: The performance of ethyl acetate is also evaluated in terms of its environmental impact and safety profile. While it is considered less harmful than many other organic solvents, proper handling and disposal methods are crucial. Research focuses on developing more sustainable production processes and exploring potential alternatives to improve its overall environmental performance.

02 Ethyl acetate in coating and adhesive formulations

Ethyl acetate is a key component in many coating and adhesive formulations. Its fast evaporation rate and ability to dissolve various resins make it ideal for use in paints, varnishes, and adhesives. It contributes to improved drying times, film formation, and overall performance of these products.Expand Specific Solutions03 Ethyl acetate production and purification methods

Various methods have been developed to produce and purify ethyl acetate, focusing on improving yield, efficiency, and product quality. These methods include esterification of ethanol and acetic acid, as well as advanced separation and purification techniques such as distillation and membrane processes.Expand Specific Solutions04 Ethyl acetate in pharmaceutical and personal care applications

Ethyl acetate finds applications in the pharmaceutical and personal care industries due to its low toxicity and pleasant odor. It is used as a solvent in the production of various drugs and as an ingredient in fragrances and cosmetic formulations. Its performance in these applications is characterized by its ability to dissolve active ingredients and its compatibility with other formulation components.Expand Specific Solutions05 Environmental and safety considerations of ethyl acetate

The performance of ethyl acetate is also evaluated in terms of its environmental impact and safety profile. While it is considered less harmful than many other organic solvents, proper handling and disposal procedures are necessary. Research focuses on developing more sustainable production methods and exploring potential alternatives to address environmental concerns.Expand Specific Solutions

Key Industry Players in Coating Solvents

The competitive landscape for ethyl acetate in coating technologies is characterized by a mature market with steady growth. The global market size is estimated to be in the billions of dollars, driven by increasing demand in various industries. Key players like Eastman Chemical, BASF Coatings, and PPG Industries dominate the market, leveraging their extensive R&D capabilities and global presence. The technology is well-established, with companies focusing on product innovations and sustainable solutions. Emerging players such as Rhodia Poliamida Brasil and Jiangmen Qianxin Chemical are also making strides, particularly in regional markets. The industry is witnessing a shift towards eco-friendly formulations, driving further research and development efforts among major manufacturers.

Eastman Chemical Co.

Technical Solution: Eastman Chemical Co. has developed advanced coating technologies utilizing ethyl acetate as a key solvent. Their approach involves optimizing the solvent blend to enhance coating performance and reduce environmental impact. The company has introduced a proprietary solvent system that incorporates ethyl acetate to improve film formation and drying characteristics[1]. This system allows for faster evaporation rates, resulting in quicker drying times and improved productivity in coating applications. Additionally, Eastman has engineered coating formulations that leverage ethyl acetate's solvency power to achieve better pigment dispersion and adhesion to various substrates[2].

Strengths: Improved drying times, enhanced film formation, better pigment dispersion. Weaknesses: Potential VOC emissions, flammability concerns, may require specialized handling and storage.

BASF Coatings GmbH

Technical Solution: BASF Coatings GmbH has integrated ethyl acetate into their eco-efficient coating solutions. Their approach focuses on balancing performance and sustainability. BASF has developed water-based coating systems that incorporate small amounts of ethyl acetate to improve coalescence and film formation[3]. This hybrid approach allows for reduced VOC emissions while maintaining the benefits of solvent-based systems. The company has also introduced a line of high-solids coatings that use ethyl acetate as a co-solvent to lower viscosity and improve application properties[4]. These formulations achieve higher film builds with fewer coats, reducing overall solvent use and improving efficiency.

Strengths: Reduced VOC emissions, improved coalescence in water-based systems, enhanced application properties. Weaknesses: Potential compatibility issues with some substrates, may require formulation adjustments for different climates.

Innovations in Ethyl Acetate Application Techniques

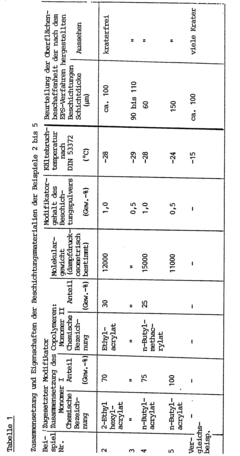

Coating powder of saponified ethylene/vinyl acetate copolymers, and their use

PatentInactiveEP0119427A2

Innovation

- Adding small amounts of polyalkyl (meth)acrylate resins to saponified ethylene-vinyl acetate copolymers improves their leveling properties, flexibility, and resistance to cracking at low temperatures, enhancing their utility and surface quality.

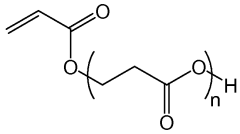

Coating formulation with enhanced metal adhesion

PatentWO2009013090A1

Innovation

- A coating formulation incorporating a resin system with ethylenically unsaturated monomers and polymeric components containing acid (meth)acrylates or polymerizable, multiply functionalized carboxylic acids, which enhances adhesion and drying speed, allowing for quick application and hardening on metal surfaces.

Environmental Impact of Ethyl Acetate in Coatings

The environmental impact of ethyl acetate in coatings is a critical consideration for the coating industry, given its widespread use and potential effects on ecosystems and human health. Ethyl acetate, a volatile organic compound (VOC), is commonly employed as a solvent in various coating formulations due to its excellent solvency properties and relatively low toxicity compared to other organic solvents.

When released into the atmosphere during coating application or drying processes, ethyl acetate can contribute to the formation of ground-level ozone and photochemical smog. These air pollutants can have adverse effects on both human respiratory health and plant life. However, the relatively short atmospheric half-life of ethyl acetate (approximately 5 days) means that it does not persist in the environment for extended periods, mitigating some long-term atmospheric impacts.

In aquatic environments, ethyl acetate exhibits low to moderate toxicity to fish and other aquatic organisms. Its high volatility and biodegradability contribute to its rapid removal from water systems, reducing the risk of long-term aquatic contamination. Nevertheless, accidental spills or improper disposal of coating waste containing ethyl acetate can lead to localized environmental issues and potential harm to aquatic ecosystems.

Soil contamination by ethyl acetate is generally considered a minor concern due to its high volatility and biodegradability. Microorganisms in soil can readily break down ethyl acetate, limiting its persistence and potential for groundwater contamination. However, large-scale spills or continuous release in industrial settings may still pose localized risks to soil ecosystems and potentially impact groundwater quality.

From a lifecycle perspective, the production of ethyl acetate involves petrochemical processes that contribute to carbon emissions and resource depletion. However, recent advancements in bio-based ethyl acetate production from renewable resources offer a more sustainable alternative, potentially reducing the overall environmental footprint of coatings that utilize this solvent.

Regulatory bodies worldwide have implemented measures to control VOC emissions from coatings, including limits on ethyl acetate content. These regulations have driven innovation in low-VOC and water-based coating technologies, reducing the reliance on solvents like ethyl acetate and mitigating their environmental impact. Additionally, improved application techniques and waste management practices in the coating industry have further minimized the release of ethyl acetate into the environment.

As the coating industry continues to evolve, balancing performance requirements with environmental considerations remains a key challenge. While ethyl acetate offers certain advantages in coating formulations, its environmental impact underscores the need for ongoing research into more sustainable alternatives and improved application methodologies to minimize its ecological footprint.

When released into the atmosphere during coating application or drying processes, ethyl acetate can contribute to the formation of ground-level ozone and photochemical smog. These air pollutants can have adverse effects on both human respiratory health and plant life. However, the relatively short atmospheric half-life of ethyl acetate (approximately 5 days) means that it does not persist in the environment for extended periods, mitigating some long-term atmospheric impacts.

In aquatic environments, ethyl acetate exhibits low to moderate toxicity to fish and other aquatic organisms. Its high volatility and biodegradability contribute to its rapid removal from water systems, reducing the risk of long-term aquatic contamination. Nevertheless, accidental spills or improper disposal of coating waste containing ethyl acetate can lead to localized environmental issues and potential harm to aquatic ecosystems.

Soil contamination by ethyl acetate is generally considered a minor concern due to its high volatility and biodegradability. Microorganisms in soil can readily break down ethyl acetate, limiting its persistence and potential for groundwater contamination. However, large-scale spills or continuous release in industrial settings may still pose localized risks to soil ecosystems and potentially impact groundwater quality.

From a lifecycle perspective, the production of ethyl acetate involves petrochemical processes that contribute to carbon emissions and resource depletion. However, recent advancements in bio-based ethyl acetate production from renewable resources offer a more sustainable alternative, potentially reducing the overall environmental footprint of coatings that utilize this solvent.

Regulatory bodies worldwide have implemented measures to control VOC emissions from coatings, including limits on ethyl acetate content. These regulations have driven innovation in low-VOC and water-based coating technologies, reducing the reliance on solvents like ethyl acetate and mitigating their environmental impact. Additionally, improved application techniques and waste management practices in the coating industry have further minimized the release of ethyl acetate into the environment.

As the coating industry continues to evolve, balancing performance requirements with environmental considerations remains a key challenge. While ethyl acetate offers certain advantages in coating formulations, its environmental impact underscores the need for ongoing research into more sustainable alternatives and improved application methodologies to minimize its ecological footprint.

Regulatory Compliance for Ethyl Acetate Usage

Regulatory compliance for ethyl acetate usage in coating technologies is a critical aspect that manufacturers and users must carefully consider. The use of ethyl acetate is subject to various regulations and guidelines set by governmental agencies and international organizations to ensure safety, environmental protection, and quality standards.

In the United States, the Environmental Protection Agency (EPA) regulates ethyl acetate under the Toxic Substances Control Act (TSCA). The EPA has established reporting requirements for manufacturers and importers of ethyl acetate, including the submission of chemical data reports and notifications of significant new uses. Additionally, the Occupational Safety and Health Administration (OSHA) has set permissible exposure limits (PELs) for ethyl acetate in the workplace to protect workers from potential health hazards.

The European Union (EU) regulates ethyl acetate under the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. Manufacturers and importers are required to register ethyl acetate with the European Chemicals Agency (ECHA) and provide safety data sheets to downstream users. The EU has also established specific limits for ethyl acetate in certain consumer products, such as cosmetics and food contact materials.

In the context of coating technologies, regulatory compliance extends to product-specific regulations. For instance, the use of ethyl acetate in food packaging coatings must comply with FDA regulations in the United States and EU food contact material regulations in Europe. These regulations set limits on the migration of ethyl acetate from the coating into food products.

Environmental regulations also play a significant role in the use of ethyl acetate in coating technologies. Many countries have implemented volatile organic compound (VOC) emission limits for industrial processes, including coating applications. Manufacturers must ensure that their coating formulations and application processes comply with these VOC regulations, which may require the use of low-VOC or VOC-free alternatives in some cases.

Proper handling, storage, and disposal of ethyl acetate are essential aspects of regulatory compliance. Safety data sheets (SDS) must be readily available, and personnel must be trained in the safe handling of the chemical. Storage facilities must meet specific requirements for flammable liquids, and disposal must follow hazardous waste regulations.

Compliance with these regulations requires ongoing monitoring and documentation. Companies using ethyl acetate in coating technologies must maintain records of usage, exposure assessments, and any incidents or near-misses. Regular audits and inspections may be necessary to ensure continued compliance with evolving regulations.

As regulations continue to evolve, staying informed about changes and updates is crucial for maintaining compliance. This may involve participating in industry associations, subscribing to regulatory updates, and engaging with regulatory agencies to understand and implement new requirements effectively.

In the United States, the Environmental Protection Agency (EPA) regulates ethyl acetate under the Toxic Substances Control Act (TSCA). The EPA has established reporting requirements for manufacturers and importers of ethyl acetate, including the submission of chemical data reports and notifications of significant new uses. Additionally, the Occupational Safety and Health Administration (OSHA) has set permissible exposure limits (PELs) for ethyl acetate in the workplace to protect workers from potential health hazards.

The European Union (EU) regulates ethyl acetate under the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. Manufacturers and importers are required to register ethyl acetate with the European Chemicals Agency (ECHA) and provide safety data sheets to downstream users. The EU has also established specific limits for ethyl acetate in certain consumer products, such as cosmetics and food contact materials.

In the context of coating technologies, regulatory compliance extends to product-specific regulations. For instance, the use of ethyl acetate in food packaging coatings must comply with FDA regulations in the United States and EU food contact material regulations in Europe. These regulations set limits on the migration of ethyl acetate from the coating into food products.

Environmental regulations also play a significant role in the use of ethyl acetate in coating technologies. Many countries have implemented volatile organic compound (VOC) emission limits for industrial processes, including coating applications. Manufacturers must ensure that their coating formulations and application processes comply with these VOC regulations, which may require the use of low-VOC or VOC-free alternatives in some cases.

Proper handling, storage, and disposal of ethyl acetate are essential aspects of regulatory compliance. Safety data sheets (SDS) must be readily available, and personnel must be trained in the safe handling of the chemical. Storage facilities must meet specific requirements for flammable liquids, and disposal must follow hazardous waste regulations.

Compliance with these regulations requires ongoing monitoring and documentation. Companies using ethyl acetate in coating technologies must maintain records of usage, exposure assessments, and any incidents or near-misses. Regular audits and inspections may be necessary to ensure continued compliance with evolving regulations.

As regulations continue to evolve, staying informed about changes and updates is crucial for maintaining compliance. This may involve participating in industry associations, subscribing to regulatory updates, and engaging with regulatory agencies to understand and implement new requirements effectively.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!