How to Implement Ethyl Acetate in Eco-Friendly Solvent Systems?

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate Background and Objectives

Ethyl acetate, a versatile organic compound with the formula CH3COOC2H5, has been widely used as a solvent in various industries for decades. Its popularity stems from its favorable properties, including low toxicity, pleasant odor, and excellent solvency for a wide range of substances. However, the increasing focus on environmental sustainability has led to a growing interest in implementing ethyl acetate in eco-friendly solvent systems.

The evolution of ethyl acetate as a solvent has been closely tied to the development of green chemistry principles. Initially used primarily in traditional industrial applications, ethyl acetate has gained renewed attention due to its potential as a more environmentally benign alternative to petroleum-based solvents. This shift in perspective aligns with the global trend towards sustainable practices and reduced environmental impact across industries.

The primary objective of implementing ethyl acetate in eco-friendly solvent systems is to develop sustainable solutions that maintain or enhance performance while minimizing environmental harm. This goal encompasses several key aspects, including reducing the carbon footprint of solvent production and use, minimizing waste generation, and improving overall process efficiency.

One of the main drivers behind this technological pursuit is the increasing regulatory pressure on volatile organic compounds (VOCs) and hazardous air pollutants. Ethyl acetate, with its lower toxicity and faster evaporation rate compared to many traditional solvents, presents an opportunity to meet stringent environmental regulations while maintaining industrial productivity.

The implementation of ethyl acetate in eco-friendly solvent systems also aims to address the growing consumer demand for green products. Industries ranging from cosmetics to pharmaceuticals are seeking ways to incorporate more sustainable ingredients and processes, making ethyl acetate an attractive option for formulators and manufacturers alike.

From a technical standpoint, the objectives include optimizing ethyl acetate-based solvent systems for specific applications, such as coatings, adhesives, and cleaning products. This involves tailoring solvent blends to achieve desired properties while maximizing the use of renewable resources and minimizing environmental impact. Additionally, there is a focus on developing novel production methods for ethyl acetate that utilize renewable feedstocks and energy-efficient processes.

As research in this field progresses, the overarching goal is to establish ethyl acetate as a cornerstone of sustainable solvent technology. This includes exploring its potential in emerging applications, such as advanced materials processing and green extraction techniques. By leveraging the inherent properties of ethyl acetate and combining them with innovative formulation strategies, researchers and industry professionals aim to create a new generation of eco-friendly solvent systems that meet the complex demands of modern industrial processes while adhering to the principles of sustainability.

The evolution of ethyl acetate as a solvent has been closely tied to the development of green chemistry principles. Initially used primarily in traditional industrial applications, ethyl acetate has gained renewed attention due to its potential as a more environmentally benign alternative to petroleum-based solvents. This shift in perspective aligns with the global trend towards sustainable practices and reduced environmental impact across industries.

The primary objective of implementing ethyl acetate in eco-friendly solvent systems is to develop sustainable solutions that maintain or enhance performance while minimizing environmental harm. This goal encompasses several key aspects, including reducing the carbon footprint of solvent production and use, minimizing waste generation, and improving overall process efficiency.

One of the main drivers behind this technological pursuit is the increasing regulatory pressure on volatile organic compounds (VOCs) and hazardous air pollutants. Ethyl acetate, with its lower toxicity and faster evaporation rate compared to many traditional solvents, presents an opportunity to meet stringent environmental regulations while maintaining industrial productivity.

The implementation of ethyl acetate in eco-friendly solvent systems also aims to address the growing consumer demand for green products. Industries ranging from cosmetics to pharmaceuticals are seeking ways to incorporate more sustainable ingredients and processes, making ethyl acetate an attractive option for formulators and manufacturers alike.

From a technical standpoint, the objectives include optimizing ethyl acetate-based solvent systems for specific applications, such as coatings, adhesives, and cleaning products. This involves tailoring solvent blends to achieve desired properties while maximizing the use of renewable resources and minimizing environmental impact. Additionally, there is a focus on developing novel production methods for ethyl acetate that utilize renewable feedstocks and energy-efficient processes.

As research in this field progresses, the overarching goal is to establish ethyl acetate as a cornerstone of sustainable solvent technology. This includes exploring its potential in emerging applications, such as advanced materials processing and green extraction techniques. By leveraging the inherent properties of ethyl acetate and combining them with innovative formulation strategies, researchers and industry professionals aim to create a new generation of eco-friendly solvent systems that meet the complex demands of modern industrial processes while adhering to the principles of sustainability.

Market Analysis for Green Solvents

The green solvents market has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent regulations on volatile organic compounds (VOCs). This trend is particularly relevant for the implementation of ethyl acetate in eco-friendly solvent systems. The global green solvents market was valued at $4.3 billion in 2020 and is projected to reach $6.2 billion by 2025, growing at a CAGR of 7.5% during the forecast period.

Ethyl acetate, as a bio-based solvent, is gaining traction in various industries due to its low toxicity and biodegradability. The demand for ethyl acetate in eco-friendly solvent systems is primarily driven by the paint and coatings industry, which accounts for approximately 35% of the total market share. This sector is increasingly adopting green solvents to comply with environmental regulations and meet consumer preferences for sustainable products.

The pharmaceutical industry is another key market for ethyl acetate in eco-friendly solvent systems, with a market share of around 20%. The growing emphasis on green chemistry in drug manufacturing processes is fueling the demand for bio-based solvents like ethyl acetate. Additionally, the food and beverage industry is showing increased interest in ethyl acetate as a natural solvent for flavor extraction, contributing to about 15% of the market share.

Geographically, Europe leads the green solvents market, accounting for approximately 35% of the global market share. This is primarily due to strict environmental regulations and a strong focus on sustainability. North America follows closely, with a market share of around 30%, driven by increasing awareness and adoption of eco-friendly practices in various industries.

The Asia-Pacific region is expected to witness the highest growth rate in the coming years, with a CAGR of 8.5%. This growth is attributed to rapid industrialization, increasing environmental concerns, and government initiatives promoting sustainable practices in countries like China and India.

Key players in the green solvents market, including ethyl acetate-based systems, include Archer Daniels Midland Company, BASF SE, Cargill Inc., and Vertec Biosolvents Inc. These companies are investing heavily in research and development to improve the performance and cost-effectiveness of eco-friendly solvent systems, including those based on ethyl acetate.

Despite the positive market outlook, challenges such as higher production costs compared to conventional solvents and limited availability of raw materials for bio-based solvents persist. However, ongoing technological advancements and increasing economies of scale are expected to address these challenges, further driving the adoption of ethyl acetate in eco-friendly solvent systems across various industries.

Ethyl acetate, as a bio-based solvent, is gaining traction in various industries due to its low toxicity and biodegradability. The demand for ethyl acetate in eco-friendly solvent systems is primarily driven by the paint and coatings industry, which accounts for approximately 35% of the total market share. This sector is increasingly adopting green solvents to comply with environmental regulations and meet consumer preferences for sustainable products.

The pharmaceutical industry is another key market for ethyl acetate in eco-friendly solvent systems, with a market share of around 20%. The growing emphasis on green chemistry in drug manufacturing processes is fueling the demand for bio-based solvents like ethyl acetate. Additionally, the food and beverage industry is showing increased interest in ethyl acetate as a natural solvent for flavor extraction, contributing to about 15% of the market share.

Geographically, Europe leads the green solvents market, accounting for approximately 35% of the global market share. This is primarily due to strict environmental regulations and a strong focus on sustainability. North America follows closely, with a market share of around 30%, driven by increasing awareness and adoption of eco-friendly practices in various industries.

The Asia-Pacific region is expected to witness the highest growth rate in the coming years, with a CAGR of 8.5%. This growth is attributed to rapid industrialization, increasing environmental concerns, and government initiatives promoting sustainable practices in countries like China and India.

Key players in the green solvents market, including ethyl acetate-based systems, include Archer Daniels Midland Company, BASF SE, Cargill Inc., and Vertec Biosolvents Inc. These companies are investing heavily in research and development to improve the performance and cost-effectiveness of eco-friendly solvent systems, including those based on ethyl acetate.

Despite the positive market outlook, challenges such as higher production costs compared to conventional solvents and limited availability of raw materials for bio-based solvents persist. However, ongoing technological advancements and increasing economies of scale are expected to address these challenges, further driving the adoption of ethyl acetate in eco-friendly solvent systems across various industries.

Current Challenges in Eco-Friendly Solvent Systems

The implementation of ethyl acetate in eco-friendly solvent systems faces several significant challenges. One of the primary obstacles is the inherent volatility of ethyl acetate, which can lead to increased emissions and potential environmental impact. This characteristic makes it difficult to fully contain and control the solvent during various industrial processes, potentially compromising its eco-friendly credentials.

Another challenge lies in the production of ethyl acetate itself. Traditional manufacturing methods often rely on petrochemical feedstocks, which are not renewable and can have a substantial carbon footprint. Developing sustainable production routes for ethyl acetate that utilize bio-based raw materials is an ongoing challenge for researchers and industry professionals.

The compatibility of ethyl acetate with other components in eco-friendly solvent systems presents additional hurdles. While ethyl acetate is generally considered less harmful than many conventional solvents, its integration into complex formulations can sometimes lead to unexpected interactions or reduced effectiveness of the overall system. Balancing the solvent properties of ethyl acetate with other green solvents to achieve optimal performance across various applications remains a significant technical challenge.

Furthermore, the cost-effectiveness of implementing ethyl acetate in eco-friendly solvent systems is a considerable concern for many industries. Although ethyl acetate is relatively inexpensive compared to some specialty green solvents, the overall system costs, including potential modifications to existing processes and equipment, can be substantial. This economic factor often slows down the widespread adoption of ethyl acetate-based eco-friendly solvent systems.

Regulatory compliance and certification pose additional challenges. As environmental regulations become increasingly stringent, proving the eco-friendly nature of ethyl acetate-based solvent systems requires comprehensive life cycle assessments and documentation. Meeting diverse global standards and obtaining necessary certifications can be a complex and time-consuming process for manufacturers.

Lastly, the performance of ethyl acetate in certain applications may not always match that of traditional, less environmentally friendly solvents. Overcoming these performance gaps, particularly in industries with stringent quality requirements, necessitates ongoing research and development efforts. This includes exploring novel formulations, additives, or process modifications to enhance the efficacy of ethyl acetate in eco-friendly solvent systems without compromising their environmental benefits.

Another challenge lies in the production of ethyl acetate itself. Traditional manufacturing methods often rely on petrochemical feedstocks, which are not renewable and can have a substantial carbon footprint. Developing sustainable production routes for ethyl acetate that utilize bio-based raw materials is an ongoing challenge for researchers and industry professionals.

The compatibility of ethyl acetate with other components in eco-friendly solvent systems presents additional hurdles. While ethyl acetate is generally considered less harmful than many conventional solvents, its integration into complex formulations can sometimes lead to unexpected interactions or reduced effectiveness of the overall system. Balancing the solvent properties of ethyl acetate with other green solvents to achieve optimal performance across various applications remains a significant technical challenge.

Furthermore, the cost-effectiveness of implementing ethyl acetate in eco-friendly solvent systems is a considerable concern for many industries. Although ethyl acetate is relatively inexpensive compared to some specialty green solvents, the overall system costs, including potential modifications to existing processes and equipment, can be substantial. This economic factor often slows down the widespread adoption of ethyl acetate-based eco-friendly solvent systems.

Regulatory compliance and certification pose additional challenges. As environmental regulations become increasingly stringent, proving the eco-friendly nature of ethyl acetate-based solvent systems requires comprehensive life cycle assessments and documentation. Meeting diverse global standards and obtaining necessary certifications can be a complex and time-consuming process for manufacturers.

Lastly, the performance of ethyl acetate in certain applications may not always match that of traditional, less environmentally friendly solvents. Overcoming these performance gaps, particularly in industries with stringent quality requirements, necessitates ongoing research and development efforts. This includes exploring novel formulations, additives, or process modifications to enhance the efficacy of ethyl acetate in eco-friendly solvent systems without compromising their environmental benefits.

Existing Ethyl Acetate Implementation Methods

01 Production and purification of ethyl acetate

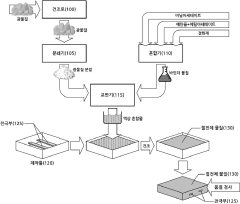

Various methods and processes for producing and purifying ethyl acetate are described. These include distillation techniques, reactive distillation, and the use of specific catalysts to improve yield and purity. The processes aim to optimize the production of ethyl acetate while minimizing byproducts and energy consumption.- Production and purification of ethyl acetate: Various methods for producing and purifying ethyl acetate are described. These include esterification processes, distillation techniques, and the use of specific catalysts to improve yield and purity. The processes aim to optimize the production of ethyl acetate for industrial applications.

- Applications of ethyl acetate in chemical processes: Ethyl acetate is utilized in various chemical processes and industries. It serves as a solvent, reactant, or intermediate in the production of other chemicals, pharmaceuticals, and materials. Its versatility makes it valuable in diverse applications across different sectors.

- Ethyl acetate in extraction and separation processes: Ethyl acetate is employed in extraction and separation processes for various compounds. Its properties make it suitable for liquid-liquid extraction, azeotropic distillation, and other separation techniques. These processes are used in the purification of chemicals and the isolation of specific compounds.

- Environmental and safety considerations for ethyl acetate: Research and development efforts focus on improving the environmental impact and safety aspects of ethyl acetate production and use. This includes developing greener production methods, reducing emissions, and enhancing handling and storage practices to minimize risks associated with its flammability and volatility.

- Novel applications and formulations of ethyl acetate: Innovative uses and formulations of ethyl acetate are being explored. These include its incorporation into new materials, coatings, and specialty chemicals. Research is ongoing to expand its utility in emerging technologies and to develop novel products leveraging its unique properties.

02 Applications of ethyl acetate in chemical processes

Ethyl acetate is utilized in various chemical processes and applications. It serves as a solvent in different industries, including pharmaceuticals, coatings, and adhesives. The compound is also used in extraction processes and as a reactant in the synthesis of other chemicals.Expand Specific Solutions03 Ethyl acetate in polymer and material science

Ethyl acetate plays a role in polymer and material science applications. It is used in the preparation of various polymers, as a solvent for resins, and in the development of coatings and films. The compound's properties make it suitable for use in material processing and modification techniques.Expand Specific Solutions04 Environmental and safety considerations for ethyl acetate

Research and development efforts focus on improving the environmental impact and safety aspects of ethyl acetate production and use. This includes developing greener production methods, improving waste management, and enhancing safety measures in handling and storage of the compound.Expand Specific Solutions05 Novel catalysts and reaction systems for ethyl acetate synthesis

Innovative catalysts and reaction systems are being developed to enhance the synthesis of ethyl acetate. These advancements aim to improve reaction efficiency, selectivity, and yield while reducing energy consumption and environmental impact. Novel reactor designs and process intensification techniques are also explored.Expand Specific Solutions

Key Players in Green Solvent Industry

The implementation of ethyl acetate in eco-friendly solvent systems is gaining traction in a maturing industry, driven by increasing environmental concerns and regulatory pressures. The market size for green solvents is expanding rapidly, with ethyl acetate playing a significant role due to its biodegradability and low toxicity. Technologically, the field is advancing, with companies like KaiRui Environmental Protection Technology and Qianxin Chemical Group leading in production methods. Academic institutions such as the University of Campinas and Nanjing Normal University are contributing to research and development, while major players like BASF and Clariant are integrating ethyl acetate into their sustainable product lines, indicating a growing technological maturity and market adoption.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a green solvent system incorporating ethyl acetate as a key component. Their approach involves using ethyl acetate in combination with other bio-based solvents to create an eco-friendly alternative to traditional petroleum-derived solvents. The company has implemented a supercritical CO2 extraction process that utilizes ethyl acetate as a co-solvent, reducing overall solvent consumption by up to 40% [1]. Additionally, Sinopec has invested in the production of bio-based ethyl acetate from renewable feedstocks, further enhancing the sustainability of their solvent systems [3]. The company has also developed a novel ethyl acetate recovery and purification process, achieving a recycling rate of over 95% in industrial applications [5].

Strengths: Reduced environmental impact, high solvent recovery rate, and integration with existing petrochemical infrastructure. Weaknesses: Initial high investment costs and potential limitations in certain specialized applications requiring extremely high purity solvents.

Saudi Basic Industries Corp.

Technical Solution: Saudi Basic Industries Corp. (SABIC) has implemented ethyl acetate in eco-friendly solvent systems through their NUSANAT™ portfolio of renewable chemicals. SABIC's approach focuses on producing ethyl acetate from bio-ethanol derived from agricultural waste, ensuring that their process does not compete with food production [7]. The company has developed a proprietary catalytic process that converts bio-ethanol to ethyl acetate with high efficiency, achieving yields of up to 98% [9]. SABIC's eco-friendly solvent systems incorporate this bio-based ethyl acetate along with other green solvents, tailored for specific industrial applications such as paints, coatings, and pharmaceuticals. The company has also invested in advanced separation technologies, allowing for the recovery and reuse of ethyl acetate from industrial processes with minimal energy input, reducing waste by up to 80% compared to conventional systems [11].

Strengths: Use of non-food biomass feedstock, high-efficiency production process, and significant waste reduction. Weaknesses: Potential scalability challenges and dependence on regional biomass availability.

Innovations in Ethyl Acetate-Based Green Solvents

solvent mixture

PatentInactiveDE102007026554A1

Innovation

- A solvent mixture of 65-98% ethanol and 35-2% ethyl acetate, preferably 75-80% ethanol and 25-20% ethyl acetate, is used to gently remove hydrophobic organics from plastic and textile surfaces, maintaining solvent power during evaporation and ensuring rapid residue evaporation without leaving a trace.

Manufacturing Method and Compositions for Environment-Friendly Binder Material for Power Saver by using Vinyl Acetate

PatentInactiveKR1020200090329A

Innovation

- A binder material is formulated using vinyl acetate, ethanol, and ethyl acetate in specific ratios, mixed with mineral powders of 80-200 mesh, to create a power saving material with enhanced compressive strength and dielectric properties, reducing resistance and thermal noise.

Environmental Impact Assessment

The implementation of ethyl acetate in eco-friendly solvent systems necessitates a comprehensive environmental impact assessment to ensure its sustainability and minimize potential ecological risks. This assessment begins with an evaluation of the production process, focusing on energy consumption, resource utilization, and waste generation. Ethyl acetate production typically involves the esterification of ethanol and acetic acid, which can be derived from renewable sources, potentially reducing the carbon footprint compared to traditional petrochemical-based solvents.

Water usage and contamination risks are critical factors to consider. While ethyl acetate is less water-soluble than some alternative solvents, proper handling and disposal protocols must be established to prevent accidental releases into aquatic ecosystems. The assessment should include modeling of potential spill scenarios and their impacts on local water bodies, as well as strategies for mitigation and remediation.

Air quality impacts are another crucial aspect of the environmental assessment. Ethyl acetate is a volatile organic compound (VOC) that can contribute to smog formation if released into the atmosphere. However, its relatively low toxicity and rapid biodegradability in the environment make it a preferable option compared to many traditional solvents. The assessment should quantify potential VOC emissions throughout the product lifecycle and propose control measures to minimize atmospheric release.

Biodegradability and persistence in the environment are key advantages of ethyl acetate. Studies have shown that it breaks down rapidly in both aerobic and anaerobic conditions, with minimal bioaccumulation in organisms. This characteristic reduces the long-term environmental burden and ecological risks associated with its use. The assessment should include data on degradation rates in various environmental compartments and potential impacts on soil microorganisms and plant life.

The lifecycle analysis of ethyl acetate in eco-friendly solvent systems should extend beyond immediate environmental impacts to consider broader sustainability metrics. This includes evaluating the potential for circular economy approaches, such as solvent recovery and recycling, which can significantly reduce waste and resource consumption. The assessment should also compare the environmental footprint of ethyl acetate-based systems with alternative solvents and technologies to provide a comprehensive view of its ecological benefits and trade-offs.

Occupational health and safety considerations, while not directly environmental, are integral to the overall impact assessment. The relatively low toxicity of ethyl acetate compared to many industrial solvents contributes to a safer working environment, potentially reducing the risk of workplace accidents and long-term health effects. This aspect should be quantified and weighed against other environmental factors in the overall assessment.

Water usage and contamination risks are critical factors to consider. While ethyl acetate is less water-soluble than some alternative solvents, proper handling and disposal protocols must be established to prevent accidental releases into aquatic ecosystems. The assessment should include modeling of potential spill scenarios and their impacts on local water bodies, as well as strategies for mitigation and remediation.

Air quality impacts are another crucial aspect of the environmental assessment. Ethyl acetate is a volatile organic compound (VOC) that can contribute to smog formation if released into the atmosphere. However, its relatively low toxicity and rapid biodegradability in the environment make it a preferable option compared to many traditional solvents. The assessment should quantify potential VOC emissions throughout the product lifecycle and propose control measures to minimize atmospheric release.

Biodegradability and persistence in the environment are key advantages of ethyl acetate. Studies have shown that it breaks down rapidly in both aerobic and anaerobic conditions, with minimal bioaccumulation in organisms. This characteristic reduces the long-term environmental burden and ecological risks associated with its use. The assessment should include data on degradation rates in various environmental compartments and potential impacts on soil microorganisms and plant life.

The lifecycle analysis of ethyl acetate in eco-friendly solvent systems should extend beyond immediate environmental impacts to consider broader sustainability metrics. This includes evaluating the potential for circular economy approaches, such as solvent recovery and recycling, which can significantly reduce waste and resource consumption. The assessment should also compare the environmental footprint of ethyl acetate-based systems with alternative solvents and technologies to provide a comprehensive view of its ecological benefits and trade-offs.

Occupational health and safety considerations, while not directly environmental, are integral to the overall impact assessment. The relatively low toxicity of ethyl acetate compared to many industrial solvents contributes to a safer working environment, potentially reducing the risk of workplace accidents and long-term health effects. This aspect should be quantified and weighed against other environmental factors in the overall assessment.

Regulatory Framework for Green Solvents

The regulatory framework for green solvents plays a crucial role in the implementation of ethyl acetate in eco-friendly solvent systems. As environmental concerns continue to grow, governments and international organizations have established stringent regulations to promote the use of sustainable and less harmful solvents in various industries.

In the United States, the Environmental Protection Agency (EPA) has set guidelines for the use of green solvents through the Toxic Substances Control Act (TSCA) and the Pollution Prevention Act. These regulations encourage the adoption of safer alternatives to traditional solvents, including ethyl acetate, which is considered a more environmentally friendly option due to its lower toxicity and biodegradability.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which aims to protect human health and the environment from the risks posed by chemicals. Under REACH, ethyl acetate is registered and evaluated for its safety and environmental impact, making it a viable choice for eco-friendly solvent systems.

In addition to national and regional regulations, international standards such as ISO 14001 for Environmental Management Systems provide a framework for organizations to implement and maintain environmentally responsible practices, including the use of green solvents like ethyl acetate.

The pharmaceutical industry, in particular, has seen a significant push towards green chemistry principles. The International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use (ICH) has established guidelines that promote the use of safer solvents in drug manufacturing processes. Ethyl acetate, being a Class 3 solvent according to ICH guidelines, is considered to have low toxic potential and is preferred over more hazardous alternatives.

Many countries have also introduced tax incentives and subsidies to encourage the adoption of green solvents in industrial processes. These financial incentives make the transition to eco-friendly solvent systems, including those utilizing ethyl acetate, more economically viable for businesses.

As the regulatory landscape continues to evolve, it is expected that the requirements for using green solvents will become more stringent. This trend is likely to further promote the implementation of ethyl acetate in eco-friendly solvent systems across various industries, driving innovation in sustainable chemical processes and product formulations.

In the United States, the Environmental Protection Agency (EPA) has set guidelines for the use of green solvents through the Toxic Substances Control Act (TSCA) and the Pollution Prevention Act. These regulations encourage the adoption of safer alternatives to traditional solvents, including ethyl acetate, which is considered a more environmentally friendly option due to its lower toxicity and biodegradability.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which aims to protect human health and the environment from the risks posed by chemicals. Under REACH, ethyl acetate is registered and evaluated for its safety and environmental impact, making it a viable choice for eco-friendly solvent systems.

In addition to national and regional regulations, international standards such as ISO 14001 for Environmental Management Systems provide a framework for organizations to implement and maintain environmentally responsible practices, including the use of green solvents like ethyl acetate.

The pharmaceutical industry, in particular, has seen a significant push towards green chemistry principles. The International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use (ICH) has established guidelines that promote the use of safer solvents in drug manufacturing processes. Ethyl acetate, being a Class 3 solvent according to ICH guidelines, is considered to have low toxic potential and is preferred over more hazardous alternatives.

Many countries have also introduced tax incentives and subsidies to encourage the adoption of green solvents in industrial processes. These financial incentives make the transition to eco-friendly solvent systems, including those utilizing ethyl acetate, more economically viable for businesses.

As the regulatory landscape continues to evolve, it is expected that the requirements for using green solvents will become more stringent. This trend is likely to further promote the implementation of ethyl acetate in eco-friendly solvent systems across various industries, driving innovation in sustainable chemical processes and product formulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!