How Ethyl Acetate Enhances Polymer Resilience?

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate in Polymers

Ethyl acetate plays a crucial role in enhancing polymer resilience through various mechanisms. As a solvent, it facilitates the dissolution and blending of polymer components, allowing for more uniform distribution of additives and reinforcing agents within the polymer matrix. This improved dispersion leads to enhanced mechanical properties and overall resilience of the final polymer product.

The interaction between ethyl acetate and polymer chains contributes to the modification of the polymer's molecular structure. By temporarily swelling the polymer, ethyl acetate enables greater molecular mobility, which can result in improved chain alignment and increased crystallinity in semi-crystalline polymers. This structural reorganization often leads to enhanced tensile strength, impact resistance, and overall durability of the polymer.

Furthermore, ethyl acetate acts as a plasticizer in certain polymer systems, increasing the flexibility and toughness of the material. By reducing the intermolecular forces between polymer chains, it lowers the glass transition temperature and improves the polymer's ability to absorb and dissipate energy under stress. This plasticizing effect is particularly beneficial in applications requiring high impact resistance and flexibility.

In the context of polymer processing, ethyl acetate's low boiling point and high volatility make it an excellent choice for solution casting and other solvent-based fabrication methods. Its rapid evaporation allows for quick solidification of polymer films or coatings, resulting in improved surface properties and enhanced resistance to environmental factors.

Ethyl acetate also plays a role in the synthesis of certain polymers, acting as a chain transfer agent or reaction medium. In these cases, it can influence the molecular weight distribution and branching of the polymer, which in turn affects the material's resilience and mechanical properties.

The use of ethyl acetate in polymer formulations can lead to improved adhesion properties, particularly in applications involving coatings or multi-layer structures. By promoting better interfacial bonding between different polymer layers or between the polymer and substrate, ethyl acetate enhances the overall structural integrity and resilience of composite materials.

It is worth noting that the specific effects of ethyl acetate on polymer resilience can vary depending on the type of polymer, the concentration of ethyl acetate used, and the processing conditions. Careful optimization of these parameters is essential to achieve the desired enhancement in polymer properties without compromising other important characteristics.

The interaction between ethyl acetate and polymer chains contributes to the modification of the polymer's molecular structure. By temporarily swelling the polymer, ethyl acetate enables greater molecular mobility, which can result in improved chain alignment and increased crystallinity in semi-crystalline polymers. This structural reorganization often leads to enhanced tensile strength, impact resistance, and overall durability of the polymer.

Furthermore, ethyl acetate acts as a plasticizer in certain polymer systems, increasing the flexibility and toughness of the material. By reducing the intermolecular forces between polymer chains, it lowers the glass transition temperature and improves the polymer's ability to absorb and dissipate energy under stress. This plasticizing effect is particularly beneficial in applications requiring high impact resistance and flexibility.

In the context of polymer processing, ethyl acetate's low boiling point and high volatility make it an excellent choice for solution casting and other solvent-based fabrication methods. Its rapid evaporation allows for quick solidification of polymer films or coatings, resulting in improved surface properties and enhanced resistance to environmental factors.

Ethyl acetate also plays a role in the synthesis of certain polymers, acting as a chain transfer agent or reaction medium. In these cases, it can influence the molecular weight distribution and branching of the polymer, which in turn affects the material's resilience and mechanical properties.

The use of ethyl acetate in polymer formulations can lead to improved adhesion properties, particularly in applications involving coatings or multi-layer structures. By promoting better interfacial bonding between different polymer layers or between the polymer and substrate, ethyl acetate enhances the overall structural integrity and resilience of composite materials.

It is worth noting that the specific effects of ethyl acetate on polymer resilience can vary depending on the type of polymer, the concentration of ethyl acetate used, and the processing conditions. Careful optimization of these parameters is essential to achieve the desired enhancement in polymer properties without compromising other important characteristics.

Market Demand Analysis

The market demand for polymer materials with enhanced resilience has been steadily increasing across various industries. This growing interest is driven by the need for more durable, flexible, and long-lasting materials in applications ranging from automotive and aerospace to consumer electronics and packaging.

In the automotive sector, there is a significant push towards lightweight materials that can withstand harsh environmental conditions and mechanical stress. Ethyl acetate-enhanced polymers offer improved resilience, potentially reducing the need for frequent replacements and maintenance of vehicle components. This aligns with the industry's focus on sustainability and cost-effectiveness.

The aerospace industry also presents a substantial market opportunity for resilient polymers. With the demand for more fuel-efficient aircraft, manufacturers are seeking materials that can maintain their structural integrity under extreme temperature variations and mechanical loads. Ethyl acetate-enhanced polymers could provide a solution to these challenges, potentially leading to longer-lasting and safer aircraft components.

In the consumer electronics market, there is a growing demand for devices that can withstand daily wear and tear. Smartphones, tablets, and wearable devices require materials that can resist scratches, impacts, and bending. Polymers with enhanced resilience through ethyl acetate treatment could significantly improve the durability and lifespan of these products, addressing consumer concerns about device longevity.

The packaging industry is another sector showing increased interest in resilient polymers. With the rise of e-commerce and the need for more robust packaging solutions, materials that can withstand shipping stresses while maintaining their protective properties are in high demand. Ethyl acetate-enhanced polymers could provide improved performance in this area, potentially reducing packaging waste and improving product protection during transit.

Market analysis indicates that the global demand for high-performance polymers is expected to grow significantly in the coming years. Factors such as urbanization, industrialization, and technological advancements are driving this growth. The ability of ethyl acetate to enhance polymer resilience positions it as a key player in meeting this increasing demand.

Furthermore, the trend towards sustainable and environmentally friendly materials is influencing market preferences. If ethyl acetate-enhanced polymers can demonstrate improved recyclability or biodegradability alongside their enhanced resilience, they could capture a larger market share in industries prioritizing eco-friendly solutions.

In conclusion, the market demand for polymers with enhanced resilience is robust and diverse, spanning multiple industries. The potential of ethyl acetate to improve polymer performance aligns well with current market needs and future trends, suggesting a promising outlook for this technology in various applications.

In the automotive sector, there is a significant push towards lightweight materials that can withstand harsh environmental conditions and mechanical stress. Ethyl acetate-enhanced polymers offer improved resilience, potentially reducing the need for frequent replacements and maintenance of vehicle components. This aligns with the industry's focus on sustainability and cost-effectiveness.

The aerospace industry also presents a substantial market opportunity for resilient polymers. With the demand for more fuel-efficient aircraft, manufacturers are seeking materials that can maintain their structural integrity under extreme temperature variations and mechanical loads. Ethyl acetate-enhanced polymers could provide a solution to these challenges, potentially leading to longer-lasting and safer aircraft components.

In the consumer electronics market, there is a growing demand for devices that can withstand daily wear and tear. Smartphones, tablets, and wearable devices require materials that can resist scratches, impacts, and bending. Polymers with enhanced resilience through ethyl acetate treatment could significantly improve the durability and lifespan of these products, addressing consumer concerns about device longevity.

The packaging industry is another sector showing increased interest in resilient polymers. With the rise of e-commerce and the need for more robust packaging solutions, materials that can withstand shipping stresses while maintaining their protective properties are in high demand. Ethyl acetate-enhanced polymers could provide improved performance in this area, potentially reducing packaging waste and improving product protection during transit.

Market analysis indicates that the global demand for high-performance polymers is expected to grow significantly in the coming years. Factors such as urbanization, industrialization, and technological advancements are driving this growth. The ability of ethyl acetate to enhance polymer resilience positions it as a key player in meeting this increasing demand.

Furthermore, the trend towards sustainable and environmentally friendly materials is influencing market preferences. If ethyl acetate-enhanced polymers can demonstrate improved recyclability or biodegradability alongside their enhanced resilience, they could capture a larger market share in industries prioritizing eco-friendly solutions.

In conclusion, the market demand for polymers with enhanced resilience is robust and diverse, spanning multiple industries. The potential of ethyl acetate to improve polymer performance aligns well with current market needs and future trends, suggesting a promising outlook for this technology in various applications.

Current Challenges

The enhancement of polymer resilience through the use of ethyl acetate faces several significant challenges in both research and practical applications. One of the primary obstacles is achieving consistent and uniform distribution of ethyl acetate within the polymer matrix. Uneven dispersion can lead to localized areas of weakness or excessive plasticization, compromising the overall mechanical properties of the material.

Another challenge lies in maintaining the stability of the ethyl acetate-polymer system over time. Environmental factors such as temperature fluctuations, humidity, and exposure to UV radiation can potentially cause the ethyl acetate to leach out of the polymer, gradually reducing its effectiveness in enhancing resilience. This issue is particularly critical for applications requiring long-term durability and consistent performance.

The optimization of ethyl acetate concentration presents a delicate balance. While higher concentrations may lead to improved resilience, they can also negatively impact other essential properties of the polymer, such as tensile strength or thermal stability. Finding the optimal concentration that maximizes resilience without compromising other crucial characteristics remains a significant challenge for researchers and material scientists.

Furthermore, the interaction between ethyl acetate and different polymer types varies considerably. What works well for one polymer may not be suitable for another, necessitating extensive research and testing for each specific polymer-ethyl acetate combination. This variability complicates the development of universal solutions and requires tailored approaches for different polymer systems.

The environmental impact of using ethyl acetate in polymer production is also a growing concern. As sustainability becomes increasingly important in materials science, researchers must address the potential environmental consequences of ethyl acetate usage, including its production, incorporation into polymers, and end-of-life disposal or recycling of the enhanced materials.

Scalability and cost-effectiveness present additional hurdles in the widespread adoption of ethyl acetate for polymer resilience enhancement. While laboratory-scale experiments may show promising results, translating these findings into large-scale industrial processes while maintaining economic viability remains challenging. The additional processing steps and materials required may increase production costs, potentially limiting the commercial feasibility of this approach.

Lastly, regulatory compliance and safety considerations pose ongoing challenges. As with any chemical additive, the use of ethyl acetate in polymer production must adhere to strict safety standards and regulations. Ensuring that the enhanced polymers meet all necessary safety criteria, particularly for applications in sensitive areas such as food packaging or medical devices, requires rigorous testing and validation processes.

Another challenge lies in maintaining the stability of the ethyl acetate-polymer system over time. Environmental factors such as temperature fluctuations, humidity, and exposure to UV radiation can potentially cause the ethyl acetate to leach out of the polymer, gradually reducing its effectiveness in enhancing resilience. This issue is particularly critical for applications requiring long-term durability and consistent performance.

The optimization of ethyl acetate concentration presents a delicate balance. While higher concentrations may lead to improved resilience, they can also negatively impact other essential properties of the polymer, such as tensile strength or thermal stability. Finding the optimal concentration that maximizes resilience without compromising other crucial characteristics remains a significant challenge for researchers and material scientists.

Furthermore, the interaction between ethyl acetate and different polymer types varies considerably. What works well for one polymer may not be suitable for another, necessitating extensive research and testing for each specific polymer-ethyl acetate combination. This variability complicates the development of universal solutions and requires tailored approaches for different polymer systems.

The environmental impact of using ethyl acetate in polymer production is also a growing concern. As sustainability becomes increasingly important in materials science, researchers must address the potential environmental consequences of ethyl acetate usage, including its production, incorporation into polymers, and end-of-life disposal or recycling of the enhanced materials.

Scalability and cost-effectiveness present additional hurdles in the widespread adoption of ethyl acetate for polymer resilience enhancement. While laboratory-scale experiments may show promising results, translating these findings into large-scale industrial processes while maintaining economic viability remains challenging. The additional processing steps and materials required may increase production costs, potentially limiting the commercial feasibility of this approach.

Lastly, regulatory compliance and safety considerations pose ongoing challenges. As with any chemical additive, the use of ethyl acetate in polymer production must adhere to strict safety standards and regulations. Ensuring that the enhanced polymers meet all necessary safety criteria, particularly for applications in sensitive areas such as food packaging or medical devices, requires rigorous testing and validation processes.

Existing Enhancement Methods

01 Ethyl acetate production methods

Various methods for producing ethyl acetate with improved resilience are described. These include esterification of ethanol and acetic acid, dehydrogenation of ethanol, and catalytic processes. The focus is on enhancing yield, purity, and efficiency of ethyl acetate production while maintaining product stability.- Ethyl acetate production methods: Various methods for producing ethyl acetate with improved resilience are described. These include esterification processes, catalytic reactions, and distillation techniques. The focus is on enhancing yield, purity, and efficiency of ethyl acetate production while maintaining its stability and quality.

- Ethyl acetate as a solvent in resilient formulations: Ethyl acetate is utilized as a solvent in various resilient formulations, including coatings, adhesives, and polymer compositions. Its properties contribute to the overall resilience and durability of the final products, making it a valuable component in these applications.

- Ethyl acetate recovery and purification: Techniques for recovering and purifying ethyl acetate are developed to enhance its resilience and reusability. These methods include distillation, extraction, and membrane separation processes, aimed at maintaining the quality and properties of ethyl acetate for prolonged use.

- Ethyl acetate in resilient polymer compositions: Ethyl acetate is incorporated into polymer compositions to enhance their resilience and other physical properties. It serves as a solvent or additive in the formulation of resilient materials such as elastomers, adhesives, and coatings, contributing to their flexibility and durability.

- Ethyl acetate stability in various applications: Research focuses on improving the stability and resilience of ethyl acetate in various applications. This includes developing stabilizers, optimizing storage conditions, and enhancing its compatibility with other materials to maintain its effectiveness and properties over time.

02 Ethyl acetate purification techniques

Purification techniques are crucial for enhancing the resilience of ethyl acetate. Methods such as distillation, extraction, and membrane separation are employed to remove impurities and increase the purity of ethyl acetate. These processes contribute to improved stability and quality of the final product.Expand Specific Solutions03 Stabilization additives for ethyl acetate

Various additives are used to enhance the stability and resilience of ethyl acetate. These may include antioxidants, pH stabilizers, and moisture scavengers. The incorporation of these additives helps to prevent degradation and maintain the quality of ethyl acetate during storage and use.Expand Specific Solutions04 Ethyl acetate-based formulations

Formulations incorporating ethyl acetate are developed with a focus on resilience. These may include coatings, adhesives, and solvents. The formulations are designed to maintain stability and performance under various environmental conditions, enhancing the overall resilience of ethyl acetate-containing products.Expand Specific Solutions05 Testing and quality control of ethyl acetate

Methods for testing and quality control of ethyl acetate are developed to ensure its resilience. These include analytical techniques for purity assessment, stability testing protocols, and performance evaluation under different conditions. Such measures help in maintaining consistent quality and resilience of ethyl acetate products.Expand Specific Solutions

Key Industry Players

The ethyl acetate polymer resilience enhancement market is in a growth phase, driven by increasing demand for high-performance materials across various industries. The market size is expanding, with major players like DuPont de Nemours, LG Chem, and Eastman Chemical Co. investing in research and development. The technology is maturing, with companies such as China Petroleum & Chemical Corp. and Sinopec Research Institute of Petroleum Processing contributing to advancements. However, the field remains competitive, with emerging players like Kingfa Sci. & Tech. Co., Ltd. and ARLANXEO Deutschland GmbH also making significant strides in developing innovative solutions for improved polymer resilience using ethyl acetate.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a proprietary process for incorporating ethyl acetate into polymer matrices to enhance resilience. Their method involves a controlled solvent-based technique that allows for uniform distribution of ethyl acetate within the polymer structure. This process creates micro-voids that act as energy absorbers, improving the material's ability to withstand impacts and recover from deformation[1]. DuPont's approach also includes a post-treatment step that stabilizes the ethyl acetate within the polymer, preventing leaching and ensuring long-term performance[3].

Strengths: Uniform distribution of ethyl acetate, improved impact resistance, and long-term stability. Weaknesses: Potentially higher production costs and complexity in manufacturing process.

LG Chem Ltd.

Technical Solution: LG Chem has developed a unique approach to enhancing polymer resilience using ethyl acetate as a key component in their advanced polymer blending technology. Their method involves a controlled reactive extrusion process where ethyl acetate is introduced at specific stages of polymer compounding[7]. This process allows for the formation of transient crosslinks between polymer chains, mediated by ethyl acetate molecules. These dynamic crosslinks provide enhanced elasticity and recovery properties to the polymer. LG Chem's technique also incorporates a proprietary cooling and annealing process that optimizes the distribution and interaction of ethyl acetate within the polymer matrix[8].

Strengths: Formation of dynamic crosslinks, enhanced elasticity and recovery properties. Weaknesses: Precise control required during extrusion process, potential for batch-to-batch variability.

Core Innovations

Homogeneous plastic webs or sheets, their use and process of their preparation

PatentInactiveEP0617083A1

Innovation

- The development of plastic sheets or panels using a polymeric binder containing ethylene-alkyl acrylate copolymers, which eliminates the need for plasticizers, enhances wear resistance, and maintains stability at higher temperatures, while being less hazardous and more environmentally friendly.

Glass fiber-reinforced polycarbonate flame-retardant resin composition

PatentActiveUS20140114001A1

Innovation

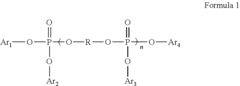

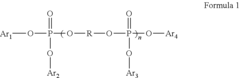

- A glass fiber-reinforced polycarbonate flame-retardant resin composition combining 50-75% polycarbonate with a rubber-modified styrene-based graft copolymer, 3-10% copolymer of aromatic vinyl and vinyl cyan compounds, 1-10% ethylene acrylate-based copolymer, and 10-25% glass fiber, along with 5-20% aromatic phosphate ester-based compound, to enhance flowability, impact resistance, and appearance while ensuring flame retardancy.

Environmental Impact

The use of ethyl acetate in enhancing polymer resilience has significant environmental implications that warrant careful consideration. While this chemical compound offers notable benefits in improving the durability and performance of polymers, its production, application, and disposal processes can impact the environment in various ways.

Ethyl acetate is primarily synthesized through the esterification of ethanol and acetic acid, a process that requires energy input and may contribute to greenhouse gas emissions. However, compared to some alternative solvents, ethyl acetate's production generally has a lower carbon footprint. Additionally, it can be derived from renewable resources, such as biomass, potentially reducing its overall environmental impact.

In terms of air quality, ethyl acetate is classified as a volatile organic compound (VOC). When used in polymer manufacturing or application processes, it can evaporate and contribute to the formation of ground-level ozone, a key component of smog. This aspect necessitates proper ventilation and emission control measures in industrial settings to minimize air pollution.

Water pollution is another concern associated with ethyl acetate usage. Although it has low water solubility, improper handling or disposal can lead to contamination of water bodies. However, ethyl acetate's relatively rapid biodegradability in aquatic environments mitigates long-term ecological risks compared to more persistent chemicals.

From a toxicity perspective, ethyl acetate exhibits low acute toxicity to aquatic organisms and terrestrial wildlife. This characteristic makes it a more environmentally friendly option compared to some alternative solvents used in polymer processing. Nevertheless, chronic exposure studies on various ecosystems are limited, warranting further research to fully understand its long-term ecological effects.

The enhanced resilience of polymers treated with ethyl acetate can indirectly benefit the environment by extending product lifespans and reducing the frequency of replacement. This potentially leads to decreased waste generation and resource consumption over time. However, the improved durability may also complicate end-of-life management and recycling processes for these materials.

In the context of circular economy principles, the use of ethyl acetate in polymer resilience enhancement presents both opportunities and challenges. While it contributes to creating more durable products, the presence of this compound may affect the recyclability or biodegradability of the polymers. Developing effective recycling technologies that can handle ethyl acetate-treated polymers is crucial for minimizing environmental impact and promoting sustainable material use.

Ethyl acetate is primarily synthesized through the esterification of ethanol and acetic acid, a process that requires energy input and may contribute to greenhouse gas emissions. However, compared to some alternative solvents, ethyl acetate's production generally has a lower carbon footprint. Additionally, it can be derived from renewable resources, such as biomass, potentially reducing its overall environmental impact.

In terms of air quality, ethyl acetate is classified as a volatile organic compound (VOC). When used in polymer manufacturing or application processes, it can evaporate and contribute to the formation of ground-level ozone, a key component of smog. This aspect necessitates proper ventilation and emission control measures in industrial settings to minimize air pollution.

Water pollution is another concern associated with ethyl acetate usage. Although it has low water solubility, improper handling or disposal can lead to contamination of water bodies. However, ethyl acetate's relatively rapid biodegradability in aquatic environments mitigates long-term ecological risks compared to more persistent chemicals.

From a toxicity perspective, ethyl acetate exhibits low acute toxicity to aquatic organisms and terrestrial wildlife. This characteristic makes it a more environmentally friendly option compared to some alternative solvents used in polymer processing. Nevertheless, chronic exposure studies on various ecosystems are limited, warranting further research to fully understand its long-term ecological effects.

The enhanced resilience of polymers treated with ethyl acetate can indirectly benefit the environment by extending product lifespans and reducing the frequency of replacement. This potentially leads to decreased waste generation and resource consumption over time. However, the improved durability may also complicate end-of-life management and recycling processes for these materials.

In the context of circular economy principles, the use of ethyl acetate in polymer resilience enhancement presents both opportunities and challenges. While it contributes to creating more durable products, the presence of this compound may affect the recyclability or biodegradability of the polymers. Developing effective recycling technologies that can handle ethyl acetate-treated polymers is crucial for minimizing environmental impact and promoting sustainable material use.

Regulatory Compliance

The regulatory landscape surrounding the use of ethyl acetate in polymer manufacturing is complex and multifaceted. As a solvent and plasticizer, ethyl acetate is subject to various regulations and standards across different jurisdictions. In the United States, the Environmental Protection Agency (EPA) regulates ethyl acetate under the Toxic Substances Control Act (TSCA), which requires manufacturers to report production volumes, uses, and potential environmental and health impacts.

The Food and Drug Administration (FDA) also plays a crucial role in regulating ethyl acetate when used in food packaging materials or medical devices. The FDA has established specific migration limits for ethyl acetate in food contact materials to ensure consumer safety. In the European Union, ethyl acetate is regulated under the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which mandates thorough safety assessments and registration of chemical substances.

Occupational safety regulations are another critical aspect of compliance when using ethyl acetate in polymer manufacturing. The Occupational Safety and Health Administration (OSHA) in the United States has set permissible exposure limits (PELs) for ethyl acetate in the workplace, requiring proper ventilation and personal protective equipment for workers handling the substance.

Environmental regulations also come into play, as ethyl acetate is classified as a volatile organic compound (VOC). Many countries and regions have implemented strict VOC emission controls to reduce air pollution. Manufacturers must adhere to these regulations by implementing appropriate emission control technologies and monitoring systems.

Quality standards such as ISO 9001 and industry-specific certifications may also apply to the use of ethyl acetate in polymer production. These standards ensure consistent product quality and may include specific requirements for the handling and use of solvents like ethyl acetate.

As sustainability becomes increasingly important, regulations promoting the use of bio-based and recyclable materials are emerging. This trend may impact the use of ethyl acetate in polymer manufacturing, potentially favoring bio-based alternatives or processes that minimize solvent use.

Compliance with these diverse regulations requires a comprehensive approach, including thorough documentation, regular audits, and ongoing monitoring of regulatory changes. Manufacturers must also consider the global nature of supply chains, as regulations may vary significantly between countries and regions. Staying informed about evolving regulatory requirements and proactively adapting manufacturing processes is essential for maintaining compliance and ensuring the continued use of ethyl acetate in enhancing polymer resilience.

The Food and Drug Administration (FDA) also plays a crucial role in regulating ethyl acetate when used in food packaging materials or medical devices. The FDA has established specific migration limits for ethyl acetate in food contact materials to ensure consumer safety. In the European Union, ethyl acetate is regulated under the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which mandates thorough safety assessments and registration of chemical substances.

Occupational safety regulations are another critical aspect of compliance when using ethyl acetate in polymer manufacturing. The Occupational Safety and Health Administration (OSHA) in the United States has set permissible exposure limits (PELs) for ethyl acetate in the workplace, requiring proper ventilation and personal protective equipment for workers handling the substance.

Environmental regulations also come into play, as ethyl acetate is classified as a volatile organic compound (VOC). Many countries and regions have implemented strict VOC emission controls to reduce air pollution. Manufacturers must adhere to these regulations by implementing appropriate emission control technologies and monitoring systems.

Quality standards such as ISO 9001 and industry-specific certifications may also apply to the use of ethyl acetate in polymer production. These standards ensure consistent product quality and may include specific requirements for the handling and use of solvents like ethyl acetate.

As sustainability becomes increasingly important, regulations promoting the use of bio-based and recyclable materials are emerging. This trend may impact the use of ethyl acetate in polymer manufacturing, potentially favoring bio-based alternatives or processes that minimize solvent use.

Compliance with these diverse regulations requires a comprehensive approach, including thorough documentation, regular audits, and ongoing monitoring of regulatory changes. Manufacturers must also consider the global nature of supply chains, as regulations may vary significantly between countries and regions. Staying informed about evolving regulatory requirements and proactively adapting manufacturing processes is essential for maintaining compliance and ensuring the continued use of ethyl acetate in enhancing polymer resilience.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!