Pathways to Future Sustainability with Ethyl Acetate

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate Evolution

Ethyl acetate has undergone significant evolution since its discovery in the early 19th century. Initially synthesized through the esterification of ethanol and acetic acid, this process remained the primary production method for decades. The industrial revolution in the late 19th and early 20th centuries saw increased demand for ethyl acetate as a solvent in various applications, prompting research into more efficient production techniques.

The mid-20th century marked a pivotal point in ethyl acetate's evolution with the introduction of catalytic processes. The development of heterogeneous catalysts, particularly those based on zeolites and ion-exchange resins, revolutionized production efficiency and yield. This advancement allowed for continuous production processes, significantly reducing energy consumption and production costs.

In the 1970s and 1980s, environmental concerns led to further innovations in ethyl acetate production. The focus shifted towards greener synthesis routes, including the use of renewable feedstocks and bio-based production methods. Researchers began exploring the potential of utilizing agricultural waste and byproducts as raw materials, aligning with the growing emphasis on sustainability.

The late 20th and early 21st centuries saw the emergence of novel production techniques, such as reactive distillation and membrane reactors. These integrated processes combined reaction and separation steps, further improving efficiency and reducing energy requirements. Concurrently, advancements in biotechnology opened new avenues for ethyl acetate production, with engineered microorganisms capable of producing the compound through fermentation processes.

Recent years have witnessed a surge in research focused on circular economy principles applied to ethyl acetate production. This includes the development of closed-loop systems that minimize waste and maximize resource utilization. Additionally, the integration of artificial intelligence and machine learning in process optimization has led to smarter, more adaptive production systems.

Looking towards the future, the evolution of ethyl acetate production is likely to continue along several key pathways. These include further refinement of bio-based production methods, exploration of novel catalysts with enhanced selectivity and longevity, and the development of hybrid processes that combine the best aspects of chemical and biological production routes. The ongoing push for sustainability will likely drive innovations in carbon capture and utilization technologies, potentially incorporating CO2 as a feedstock in ethyl acetate synthesis.

The mid-20th century marked a pivotal point in ethyl acetate's evolution with the introduction of catalytic processes. The development of heterogeneous catalysts, particularly those based on zeolites and ion-exchange resins, revolutionized production efficiency and yield. This advancement allowed for continuous production processes, significantly reducing energy consumption and production costs.

In the 1970s and 1980s, environmental concerns led to further innovations in ethyl acetate production. The focus shifted towards greener synthesis routes, including the use of renewable feedstocks and bio-based production methods. Researchers began exploring the potential of utilizing agricultural waste and byproducts as raw materials, aligning with the growing emphasis on sustainability.

The late 20th and early 21st centuries saw the emergence of novel production techniques, such as reactive distillation and membrane reactors. These integrated processes combined reaction and separation steps, further improving efficiency and reducing energy requirements. Concurrently, advancements in biotechnology opened new avenues for ethyl acetate production, with engineered microorganisms capable of producing the compound through fermentation processes.

Recent years have witnessed a surge in research focused on circular economy principles applied to ethyl acetate production. This includes the development of closed-loop systems that minimize waste and maximize resource utilization. Additionally, the integration of artificial intelligence and machine learning in process optimization has led to smarter, more adaptive production systems.

Looking towards the future, the evolution of ethyl acetate production is likely to continue along several key pathways. These include further refinement of bio-based production methods, exploration of novel catalysts with enhanced selectivity and longevity, and the development of hybrid processes that combine the best aspects of chemical and biological production routes. The ongoing push for sustainability will likely drive innovations in carbon capture and utilization technologies, potentially incorporating CO2 as a feedstock in ethyl acetate synthesis.

Market Demand Analysis

The global market for ethyl acetate has been experiencing steady growth, driven by its versatile applications across various industries. As a key solvent and intermediate in the chemical industry, ethyl acetate's demand is closely tied to the performance of end-use sectors such as paints and coatings, adhesives, pharmaceuticals, and food packaging.

In recent years, the increasing focus on sustainability and environmental regulations has significantly influenced the market dynamics for ethyl acetate. The shift towards eco-friendly and low-VOC (volatile organic compound) products has created new opportunities for bio-based ethyl acetate, derived from renewable resources. This trend aligns with the growing consumer preference for sustainable products and the stringent environmental policies implemented by governments worldwide.

The paints and coatings industry remains the largest consumer of ethyl acetate, accounting for a substantial portion of the market demand. The robust growth in construction activities, particularly in emerging economies, continues to drive the consumption of ethyl acetate in this sector. Additionally, the automotive industry's recovery and the increasing demand for high-performance coatings have further bolstered the market.

The adhesives industry represents another significant market for ethyl acetate, with applications ranging from packaging to woodworking and consumer goods. The e-commerce boom and the subsequent increase in packaging requirements have positively impacted the demand for ethyl acetate-based adhesives. Furthermore, the growing trend of lightweight and fuel-efficient vehicles has led to an increased use of adhesives in automotive manufacturing, indirectly boosting ethyl acetate consumption.

In the pharmaceutical sector, ethyl acetate's role as a solvent in drug formulation and as an extraction medium has ensured a steady demand. The global health crisis has further emphasized the importance of pharmaceutical research and development, potentially leading to increased consumption of ethyl acetate in this sector.

The food and beverage industry also contributes significantly to the market demand for ethyl acetate. Its use as a flavoring agent and in the production of food packaging materials has seen consistent growth, driven by changing consumer lifestyles and the expansion of the processed food industry.

Geographically, Asia-Pacific remains the largest market for ethyl acetate, with China and India being the key consumers. The region's rapid industrialization, expanding manufacturing sector, and growing population have been the primary drivers of this demand. North America and Europe, while mature markets, continue to show steady demand, particularly in high-value applications and bio-based alternatives.

Looking ahead, the market for ethyl acetate is expected to continue its growth trajectory, with a particular emphasis on sustainable and bio-based alternatives. The increasing adoption of green technologies and the circular economy concept are likely to shape the future demand patterns for ethyl acetate, presenting both challenges and opportunities for industry players.

In recent years, the increasing focus on sustainability and environmental regulations has significantly influenced the market dynamics for ethyl acetate. The shift towards eco-friendly and low-VOC (volatile organic compound) products has created new opportunities for bio-based ethyl acetate, derived from renewable resources. This trend aligns with the growing consumer preference for sustainable products and the stringent environmental policies implemented by governments worldwide.

The paints and coatings industry remains the largest consumer of ethyl acetate, accounting for a substantial portion of the market demand. The robust growth in construction activities, particularly in emerging economies, continues to drive the consumption of ethyl acetate in this sector. Additionally, the automotive industry's recovery and the increasing demand for high-performance coatings have further bolstered the market.

The adhesives industry represents another significant market for ethyl acetate, with applications ranging from packaging to woodworking and consumer goods. The e-commerce boom and the subsequent increase in packaging requirements have positively impacted the demand for ethyl acetate-based adhesives. Furthermore, the growing trend of lightweight and fuel-efficient vehicles has led to an increased use of adhesives in automotive manufacturing, indirectly boosting ethyl acetate consumption.

In the pharmaceutical sector, ethyl acetate's role as a solvent in drug formulation and as an extraction medium has ensured a steady demand. The global health crisis has further emphasized the importance of pharmaceutical research and development, potentially leading to increased consumption of ethyl acetate in this sector.

The food and beverage industry also contributes significantly to the market demand for ethyl acetate. Its use as a flavoring agent and in the production of food packaging materials has seen consistent growth, driven by changing consumer lifestyles and the expansion of the processed food industry.

Geographically, Asia-Pacific remains the largest market for ethyl acetate, with China and India being the key consumers. The region's rapid industrialization, expanding manufacturing sector, and growing population have been the primary drivers of this demand. North America and Europe, while mature markets, continue to show steady demand, particularly in high-value applications and bio-based alternatives.

Looking ahead, the market for ethyl acetate is expected to continue its growth trajectory, with a particular emphasis on sustainable and bio-based alternatives. The increasing adoption of green technologies and the circular economy concept are likely to shape the future demand patterns for ethyl acetate, presenting both challenges and opportunities for industry players.

Technical Challenges

The production and use of ethyl acetate face several technical challenges that need to be addressed to ensure its future sustainability. One of the primary issues is the reliance on non-renewable feedstocks for its production. Currently, ethyl acetate is predominantly synthesized from petroleum-derived ethanol and acetic acid, which contributes to carbon emissions and resource depletion. Developing alternative, renewable feedstocks and production methods is crucial for long-term sustainability.

Energy efficiency in the manufacturing process presents another significant challenge. The traditional esterification reaction for ethyl acetate production requires high temperatures and pressures, leading to substantial energy consumption. Improving catalysts and reaction conditions to reduce energy requirements without compromising yield and purity is an ongoing area of research.

Purification and separation processes in ethyl acetate production also pose technical difficulties. The azeotropic nature of ethyl acetate-water mixtures complicates the separation process, often necessitating energy-intensive distillation techniques. Developing more efficient separation methods, such as advanced membrane technologies or novel azeotropic distillation approaches, could significantly enhance the overall sustainability of the production process.

The volatility of ethyl acetate presents challenges in both production and application. Its low boiling point leads to emissions during manufacturing and use, contributing to air pollution and potential health hazards. Implementing effective vapor recovery systems and exploring methods to reduce volatility without compromising functionality are important areas for technical innovation.

Recycling and circular economy integration pose additional challenges. While ethyl acetate can be recovered and reused in some applications, the process is often not economically viable or technically feasible at scale. Developing cost-effective recycling technologies and establishing closed-loop systems for ethyl acetate use in various industries are critical for improving its lifecycle sustainability.

Biodegradability and environmental impact remain concerns, particularly in applications where ethyl acetate may be released into the environment. Although it is considered less harmful than many other solvents, improving its biodegradability and reducing its potential ecological effects are important areas for research and development.

Lastly, the development of bio-based alternatives to ethyl acetate faces its own set of technical challenges. While promising, these alternatives often struggle to match the performance, cost-effectiveness, and scalability of traditional ethyl acetate. Overcoming these hurdles requires advancements in biotechnology, process engineering, and material science to create sustainable substitutes that can compete in the market.

Energy efficiency in the manufacturing process presents another significant challenge. The traditional esterification reaction for ethyl acetate production requires high temperatures and pressures, leading to substantial energy consumption. Improving catalysts and reaction conditions to reduce energy requirements without compromising yield and purity is an ongoing area of research.

Purification and separation processes in ethyl acetate production also pose technical difficulties. The azeotropic nature of ethyl acetate-water mixtures complicates the separation process, often necessitating energy-intensive distillation techniques. Developing more efficient separation methods, such as advanced membrane technologies or novel azeotropic distillation approaches, could significantly enhance the overall sustainability of the production process.

The volatility of ethyl acetate presents challenges in both production and application. Its low boiling point leads to emissions during manufacturing and use, contributing to air pollution and potential health hazards. Implementing effective vapor recovery systems and exploring methods to reduce volatility without compromising functionality are important areas for technical innovation.

Recycling and circular economy integration pose additional challenges. While ethyl acetate can be recovered and reused in some applications, the process is often not economically viable or technically feasible at scale. Developing cost-effective recycling technologies and establishing closed-loop systems for ethyl acetate use in various industries are critical for improving its lifecycle sustainability.

Biodegradability and environmental impact remain concerns, particularly in applications where ethyl acetate may be released into the environment. Although it is considered less harmful than many other solvents, improving its biodegradability and reducing its potential ecological effects are important areas for research and development.

Lastly, the development of bio-based alternatives to ethyl acetate faces its own set of technical challenges. While promising, these alternatives often struggle to match the performance, cost-effectiveness, and scalability of traditional ethyl acetate. Overcoming these hurdles requires advancements in biotechnology, process engineering, and material science to create sustainable substitutes that can compete in the market.

Current Green Solutions

01 Sustainable production methods

Various sustainable methods for producing ethyl acetate have been developed, including using renewable resources, improving process efficiency, and reducing waste. These methods aim to minimize environmental impact and increase the overall sustainability of ethyl acetate production.- Sustainable production methods: Various sustainable methods for producing ethyl acetate have been developed, including the use of renewable resources, improved catalytic processes, and more efficient reaction conditions. These methods aim to reduce environmental impact and increase overall sustainability of ethyl acetate production.

- Recycling and recovery techniques: Advanced recycling and recovery techniques have been implemented to improve the sustainability of ethyl acetate usage. These include methods for separating and purifying ethyl acetate from waste streams, as well as processes for regenerating and reusing the solvent in industrial applications.

- Bio-based ethyl acetate production: Research has focused on developing bio-based methods for producing ethyl acetate using renewable feedstocks such as biomass or agricultural waste. These processes often involve fermentation or enzymatic reactions to create more sustainable alternatives to traditional petrochemical-based production methods.

- Energy-efficient production processes: Innovations in energy-efficient production processes for ethyl acetate have been developed to reduce energy consumption and greenhouse gas emissions. These include optimized reaction conditions, improved heat integration, and the use of more efficient catalysts and equipment.

- Alternative applications and substitutes: Research has explored alternative applications for ethyl acetate and potential substitutes in various industries to improve overall sustainability. This includes the development of new formulations, alternative solvents, and novel uses that reduce environmental impact or improve resource efficiency.

02 Recycling and recovery techniques

Advanced recycling and recovery techniques have been implemented to improve the sustainability of ethyl acetate use. These include methods for separating and purifying ethyl acetate from waste streams, allowing for its reuse in industrial processes and reducing the need for new production.Expand Specific Solutions03 Bio-based ethyl acetate production

Research has focused on developing bio-based methods for producing ethyl acetate using renewable resources such as biomass or agricultural waste. These processes aim to reduce reliance on fossil fuels and decrease the carbon footprint of ethyl acetate production.Expand Specific Solutions04 Energy-efficient production processes

Innovations in energy-efficient production processes for ethyl acetate have been developed to reduce energy consumption and improve sustainability. These include optimized reaction conditions, improved catalysts, and more efficient separation techniques.Expand Specific Solutions05 Alternative solvents and substitutes

Research has been conducted on alternative solvents and substitutes for ethyl acetate in various applications. These alternatives aim to provide more sustainable options with reduced environmental impact while maintaining similar performance characteristics.Expand Specific Solutions

Industry Stakeholders

The ethyl acetate sustainability landscape is evolving rapidly, with the market in a growth phase driven by increasing demand for eco-friendly solvents. The global market size is projected to expand significantly, fueled by applications in various industries. Technologically, the field is advancing, with companies like Celanese, Eastman Chemical, and China Petroleum & Chemical Corp leading innovation. Research institutions such as Dalian Institute of Chemical Physics and Nanjing Tech University are contributing to technological advancements. Emerging players like LanzaTech and Avantium are introducing novel bio-based production methods, signaling a shift towards more sustainable practices. The competitive landscape is diverse, with established chemical giants competing alongside specialized biotech firms and academic institutions, fostering a dynamic environment for innovation and market growth.

Celanese International Corp.

Technical Solution: Celanese has developed an innovative VAntage® ethyl acetate production technology that offers significant sustainability benefits. The process utilizes a proprietary catalyst system that enables high selectivity and conversion rates, reducing byproduct formation and improving atom economy[1]. Celanese's technology incorporates advanced process control systems and heat recovery mechanisms, resulting in lower energy consumption compared to conventional methods[2]. The company has also implemented a closed-loop solvent recovery system, minimizing waste and reducing environmental impact[3]. Additionally, Celanese is investigating the use of bio-based feedstocks, including ethanol derived from agricultural waste, to further enhance the sustainability profile of their ethyl acetate production[4].

Strengths: High efficiency, reduced energy consumption, and potential for bio-based feedstocks. Weaknesses: Proprietary technology may limit widespread adoption, and initial capital investment could be high.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a sustainable ethyl acetate production process using bioethanol and acetic acid. The company employs a reactive distillation technology that combines reaction and separation in a single unit, improving efficiency and reducing energy consumption[1]. Their process utilizes a heterogeneous catalyst, which enhances selectivity and reduces waste generation[2]. Sinopec has also implemented a heat integration system, recovering waste heat from the process to further improve energy efficiency[3]. The company is exploring the use of biomass-derived acetic acid to create a fully bio-based ethyl acetate production route, aligning with circular economy principles[4].

Strengths: Integrated process design, improved energy efficiency, and potential for fully bio-based production. Weaknesses: Dependence on bioethanol availability and potential catalyst deactivation issues.

Key Innovations

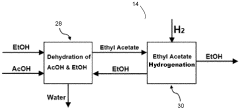

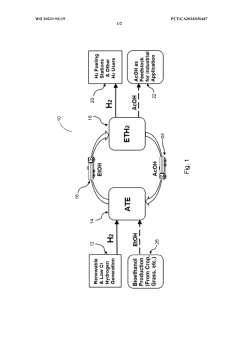

Process for the production of esters

PatentWO2012162321A2

Innovation

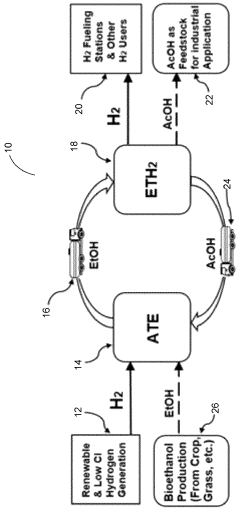

- A process involving anaerobic microbial fermentation of CO to produce ethanol and acetic acid, followed by an esterification reaction to form ethyl acetate, which can be optimized through continuous removal of water and use of reactive distillation to enhance conversion rates.

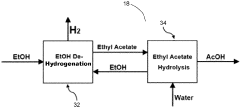

Systems and methods for storing, transporting, and supplying hydrogen

PatentWO2023193119A1

Innovation

- The use of acetic acid and ethanol as a liquid organic hydrogen carrier pair, where acetic acid is hydrogenated to form ethanol for storage and transportation, and ethanol is dehydrogenated to produce hydrogen, with acetic acid being reused, leveraging existing infrastructure and catalysts to enhance efficiency and safety.

Environmental Regulations

Environmental regulations play a crucial role in shaping the future sustainability of ethyl acetate production and usage. As global awareness of environmental issues continues to grow, governments and international organizations are implementing increasingly stringent regulations to mitigate the environmental impact of industrial processes and chemical products.

In the context of ethyl acetate, regulatory frameworks are evolving to address various aspects of its lifecycle, from production to disposal. One key area of focus is the reduction of volatile organic compound (VOC) emissions. Many countries have established strict limits on VOC emissions from industrial facilities, including those producing or using ethyl acetate. These regulations often require the implementation of advanced emission control technologies, such as thermal oxidizers or carbon adsorption systems, to minimize the release of ethyl acetate vapors into the atmosphere.

Water pollution prevention is another critical aspect of environmental regulations affecting ethyl acetate. Effluent discharge standards are becoming more stringent, necessitating improved wastewater treatment processes in ethyl acetate production facilities. This includes the implementation of advanced oxidation processes, membrane filtration, or biological treatment systems to ensure that wastewater meets increasingly strict quality parameters before release into the environment.

Waste management regulations are also evolving to promote the circular economy concept in the ethyl acetate industry. These regulations encourage the development of recycling and recovery processes for spent ethyl acetate, as well as the proper disposal of any waste products generated during its production or use. Extended producer responsibility (EPR) schemes are being implemented in some regions, making manufacturers responsible for the entire lifecycle of their products, including end-of-life management.

Energy efficiency and carbon footprint reduction are becoming increasingly important regulatory considerations. Many jurisdictions are implementing carbon pricing mechanisms or cap-and-trade systems that incentivize the adoption of more energy-efficient production processes and the use of renewable energy sources in ethyl acetate manufacturing.

Chemical safety regulations, such as REACH in the European Union and similar frameworks in other regions, are also impacting the ethyl acetate industry. These regulations require comprehensive safety assessments and documentation for chemical substances, including ethyl acetate, to ensure their safe use throughout the supply chain. This has led to increased investment in toxicological studies and the development of safer handling practices for ethyl acetate.

As environmental regulations continue to evolve, the ethyl acetate industry must adapt and innovate to ensure compliance while maintaining economic viability. This regulatory landscape is driving research and development efforts towards greener production methods, such as bio-based ethyl acetate synthesis, and the exploration of alternative solvents with reduced environmental impact. The future sustainability of ethyl acetate will largely depend on the industry's ability to align with and exceed these evolving regulatory requirements.

In the context of ethyl acetate, regulatory frameworks are evolving to address various aspects of its lifecycle, from production to disposal. One key area of focus is the reduction of volatile organic compound (VOC) emissions. Many countries have established strict limits on VOC emissions from industrial facilities, including those producing or using ethyl acetate. These regulations often require the implementation of advanced emission control technologies, such as thermal oxidizers or carbon adsorption systems, to minimize the release of ethyl acetate vapors into the atmosphere.

Water pollution prevention is another critical aspect of environmental regulations affecting ethyl acetate. Effluent discharge standards are becoming more stringent, necessitating improved wastewater treatment processes in ethyl acetate production facilities. This includes the implementation of advanced oxidation processes, membrane filtration, or biological treatment systems to ensure that wastewater meets increasingly strict quality parameters before release into the environment.

Waste management regulations are also evolving to promote the circular economy concept in the ethyl acetate industry. These regulations encourage the development of recycling and recovery processes for spent ethyl acetate, as well as the proper disposal of any waste products generated during its production or use. Extended producer responsibility (EPR) schemes are being implemented in some regions, making manufacturers responsible for the entire lifecycle of their products, including end-of-life management.

Energy efficiency and carbon footprint reduction are becoming increasingly important regulatory considerations. Many jurisdictions are implementing carbon pricing mechanisms or cap-and-trade systems that incentivize the adoption of more energy-efficient production processes and the use of renewable energy sources in ethyl acetate manufacturing.

Chemical safety regulations, such as REACH in the European Union and similar frameworks in other regions, are also impacting the ethyl acetate industry. These regulations require comprehensive safety assessments and documentation for chemical substances, including ethyl acetate, to ensure their safe use throughout the supply chain. This has led to increased investment in toxicological studies and the development of safer handling practices for ethyl acetate.

As environmental regulations continue to evolve, the ethyl acetate industry must adapt and innovate to ensure compliance while maintaining economic viability. This regulatory landscape is driving research and development efforts towards greener production methods, such as bio-based ethyl acetate synthesis, and the exploration of alternative solvents with reduced environmental impact. The future sustainability of ethyl acetate will largely depend on the industry's ability to align with and exceed these evolving regulatory requirements.

Life Cycle Assessment

Life Cycle Assessment (LCA) plays a crucial role in evaluating the environmental impact of ethyl acetate throughout its entire lifecycle. This comprehensive analysis encompasses raw material extraction, production processes, transportation, use phase, and end-of-life disposal or recycling. For ethyl acetate, the LCA begins with the sourcing of primary feedstocks, typically ethanol and acetic acid, which are derived from various sources including petrochemical and bio-based routes.

The production phase of ethyl acetate involves the esterification reaction between ethanol and acetic acid, catalyzed by strong acids. This process requires energy input and generates potential emissions, which are factored into the LCA. The environmental impact of different production methods, such as conventional batch processes versus continuous flow reactors, can be compared to identify more sustainable manufacturing routes.

Transportation and distribution of ethyl acetate contribute to the overall carbon footprint, with factors like distance, mode of transport, and packaging efficiency being key considerations. The use phase of ethyl acetate varies widely depending on its application, ranging from industrial solvents to consumer products. Each application may have distinct environmental implications that need to be assessed individually.

End-of-life scenarios for ethyl acetate include incineration, biodegradation, and potential recycling or recovery options. The LCA evaluates the environmental impacts of these disposal methods, considering factors such as energy recovery from incineration, greenhouse gas emissions, and the potential for circular economy approaches.

Water consumption and wastewater generation throughout the lifecycle are significant aspects of the LCA for ethyl acetate. This includes water used in production processes, cleaning operations, and potential contamination of water bodies during use or disposal. The assessment also considers the energy intensity of the entire lifecycle, identifying opportunities for energy efficiency improvements and the integration of renewable energy sources.

By conducting a thorough LCA, stakeholders can identify hotspots in the ethyl acetate lifecycle where environmental impacts are most significant. This information guides the development of targeted strategies to enhance sustainability, such as optimizing production processes, exploring bio-based feedstocks, improving energy efficiency, and implementing closed-loop recycling systems. The LCA results provide a foundation for making informed decisions about product design, manufacturing processes, and end-of-life management, ultimately contributing to more sustainable pathways for ethyl acetate in various industries.

The production phase of ethyl acetate involves the esterification reaction between ethanol and acetic acid, catalyzed by strong acids. This process requires energy input and generates potential emissions, which are factored into the LCA. The environmental impact of different production methods, such as conventional batch processes versus continuous flow reactors, can be compared to identify more sustainable manufacturing routes.

Transportation and distribution of ethyl acetate contribute to the overall carbon footprint, with factors like distance, mode of transport, and packaging efficiency being key considerations. The use phase of ethyl acetate varies widely depending on its application, ranging from industrial solvents to consumer products. Each application may have distinct environmental implications that need to be assessed individually.

End-of-life scenarios for ethyl acetate include incineration, biodegradation, and potential recycling or recovery options. The LCA evaluates the environmental impacts of these disposal methods, considering factors such as energy recovery from incineration, greenhouse gas emissions, and the potential for circular economy approaches.

Water consumption and wastewater generation throughout the lifecycle are significant aspects of the LCA for ethyl acetate. This includes water used in production processes, cleaning operations, and potential contamination of water bodies during use or disposal. The assessment also considers the energy intensity of the entire lifecycle, identifying opportunities for energy efficiency improvements and the integration of renewable energy sources.

By conducting a thorough LCA, stakeholders can identify hotspots in the ethyl acetate lifecycle where environmental impacts are most significant. This information guides the development of targeted strategies to enhance sustainability, such as optimizing production processes, exploring bio-based feedstocks, improving energy efficiency, and implementing closed-loop recycling systems. The LCA results provide a foundation for making informed decisions about product design, manufacturing processes, and end-of-life management, ultimately contributing to more sustainable pathways for ethyl acetate in various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!