Focus on Ethyl Acetate in Biodegradable Polymer Systems

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate in Biopolymers: Background and Objectives

Ethyl acetate has emerged as a significant component in the development of biodegradable polymer systems, marking a crucial intersection between sustainable materials science and environmental conservation efforts. The evolution of this technology can be traced back to the early 2000s when researchers began exploring alternatives to traditional petroleum-based plastics. The growing concern over plastic pollution and the depletion of fossil resources has driven the scientific community to investigate bio-based and biodegradable materials.

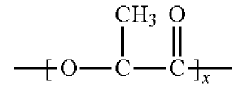

The primary objective of incorporating ethyl acetate into biopolymer systems is to enhance the processability and performance of biodegradable plastics while maintaining their environmentally friendly characteristics. Ethyl acetate, a naturally occurring ester, has gained attention due to its low toxicity, biodegradability, and potential to be derived from renewable resources. Its integration into biopolymer formulations aims to address key challenges in the field, such as improving material flexibility, reducing brittleness, and enhancing thermal stability.

The technological progression in this domain has been marked by several key milestones. Initially, ethyl acetate was primarily used as a solvent in the processing of biopolymers. However, recent advancements have expanded its role to that of a functional additive, capable of modifying the physical and chemical properties of the resulting materials. This shift has opened up new possibilities for tailoring biodegradable polymers to specific applications, ranging from packaging materials to biomedical devices.

As the field continues to evolve, researchers are exploring novel synthesis methods and polymer blends that incorporate ethyl acetate. The goal is to develop materials that not only degrade safely in the environment but also meet or exceed the performance standards of conventional plastics. This includes improving mechanical strength, barrier properties, and resistance to environmental factors such as moisture and temperature fluctuations.

The integration of ethyl acetate into biodegradable polymer systems aligns with broader sustainability trends and circular economy principles. It represents a step towards reducing the environmental impact of plastic production and waste management. As such, the technology is poised to play a crucial role in addressing global challenges related to plastic pollution and resource conservation.

Looking ahead, the field is expected to focus on optimizing the balance between material performance and biodegradability. This involves fine-tuning the molecular structure of biopolymers, developing more efficient production processes, and exploring synergistic effects with other bio-based additives. The ultimate aim is to create a new generation of materials that can seamlessly replace traditional plastics across a wide range of applications, without compromising on functionality or environmental sustainability.

The primary objective of incorporating ethyl acetate into biopolymer systems is to enhance the processability and performance of biodegradable plastics while maintaining their environmentally friendly characteristics. Ethyl acetate, a naturally occurring ester, has gained attention due to its low toxicity, biodegradability, and potential to be derived from renewable resources. Its integration into biopolymer formulations aims to address key challenges in the field, such as improving material flexibility, reducing brittleness, and enhancing thermal stability.

The technological progression in this domain has been marked by several key milestones. Initially, ethyl acetate was primarily used as a solvent in the processing of biopolymers. However, recent advancements have expanded its role to that of a functional additive, capable of modifying the physical and chemical properties of the resulting materials. This shift has opened up new possibilities for tailoring biodegradable polymers to specific applications, ranging from packaging materials to biomedical devices.

As the field continues to evolve, researchers are exploring novel synthesis methods and polymer blends that incorporate ethyl acetate. The goal is to develop materials that not only degrade safely in the environment but also meet or exceed the performance standards of conventional plastics. This includes improving mechanical strength, barrier properties, and resistance to environmental factors such as moisture and temperature fluctuations.

The integration of ethyl acetate into biodegradable polymer systems aligns with broader sustainability trends and circular economy principles. It represents a step towards reducing the environmental impact of plastic production and waste management. As such, the technology is poised to play a crucial role in addressing global challenges related to plastic pollution and resource conservation.

Looking ahead, the field is expected to focus on optimizing the balance between material performance and biodegradability. This involves fine-tuning the molecular structure of biopolymers, developing more efficient production processes, and exploring synergistic effects with other bio-based additives. The ultimate aim is to create a new generation of materials that can seamlessly replace traditional plastics across a wide range of applications, without compromising on functionality or environmental sustainability.

Market Analysis for Biodegradable Polymer Applications

The biodegradable polymer market has experienced significant growth in recent years, driven by increasing environmental concerns and regulatory pressures to reduce plastic waste. The global market for biodegradable polymers is projected to reach $7.1 billion by 2025, with a compound annual growth rate (CAGR) of 9.5% from 2020 to 2025. This growth is primarily attributed to the rising demand for sustainable packaging solutions across various industries, including food and beverage, healthcare, and consumer goods.

Within the biodegradable polymer market, ethyl acetate plays a crucial role as a solvent and processing aid in the production of various biodegradable polymer systems. The demand for ethyl acetate in this sector is expected to grow in tandem with the overall market expansion. Key applications of biodegradable polymers incorporating ethyl acetate include packaging films, disposable cutlery, and agricultural mulch films.

The packaging industry represents the largest end-use segment for biodegradable polymers, accounting for approximately 60% of the total market share. This is due to the increasing adoption of eco-friendly packaging materials by major brands and retailers in response to consumer preferences for sustainable products. The food and beverage sector, in particular, has shown strong interest in biodegradable polymer packaging solutions, with a focus on reducing single-use plastic waste.

Geographically, Europe leads the biodegradable polymer market, followed by North America and Asia-Pacific. Europe's dominance is attributed to stringent regulations on single-use plastics and a well-established infrastructure for composting and recycling. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing environmental awareness in countries like China and India.

The market for biodegradable polymers faces certain challenges, including higher production costs compared to conventional plastics and limited waste management infrastructure in some regions. However, ongoing research and development efforts are focused on improving the performance and cost-effectiveness of biodegradable polymer systems, which is expected to drive further market growth.

In conclusion, the market analysis for biodegradable polymer applications, with a focus on ethyl acetate, reveals a promising outlook. The growing demand for sustainable materials, coupled with supportive government policies and increasing consumer awareness, is expected to drive continued expansion in this sector. As technology advances and production scales up, the biodegradable polymer market is poised for sustained growth, offering significant opportunities for innovation and market penetration across various industries.

Within the biodegradable polymer market, ethyl acetate plays a crucial role as a solvent and processing aid in the production of various biodegradable polymer systems. The demand for ethyl acetate in this sector is expected to grow in tandem with the overall market expansion. Key applications of biodegradable polymers incorporating ethyl acetate include packaging films, disposable cutlery, and agricultural mulch films.

The packaging industry represents the largest end-use segment for biodegradable polymers, accounting for approximately 60% of the total market share. This is due to the increasing adoption of eco-friendly packaging materials by major brands and retailers in response to consumer preferences for sustainable products. The food and beverage sector, in particular, has shown strong interest in biodegradable polymer packaging solutions, with a focus on reducing single-use plastic waste.

Geographically, Europe leads the biodegradable polymer market, followed by North America and Asia-Pacific. Europe's dominance is attributed to stringent regulations on single-use plastics and a well-established infrastructure for composting and recycling. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing environmental awareness in countries like China and India.

The market for biodegradable polymers faces certain challenges, including higher production costs compared to conventional plastics and limited waste management infrastructure in some regions. However, ongoing research and development efforts are focused on improving the performance and cost-effectiveness of biodegradable polymer systems, which is expected to drive further market growth.

In conclusion, the market analysis for biodegradable polymer applications, with a focus on ethyl acetate, reveals a promising outlook. The growing demand for sustainable materials, coupled with supportive government policies and increasing consumer awareness, is expected to drive continued expansion in this sector. As technology advances and production scales up, the biodegradable polymer market is poised for sustained growth, offering significant opportunities for innovation and market penetration across various industries.

Current Challenges in Ethyl Acetate Integration

The integration of ethyl acetate into biodegradable polymer systems presents several significant challenges that researchers and manufacturers are currently grappling with. One of the primary obstacles is achieving optimal compatibility between ethyl acetate and various biodegradable polymers. The solvent properties of ethyl acetate can sometimes lead to undesired interactions with polymer chains, potentially affecting the structural integrity and mechanical properties of the final product.

Another major challenge lies in controlling the release rate of ethyl acetate from the polymer matrix. This is particularly crucial in applications where sustained or controlled release of the solvent is desired. The volatility of ethyl acetate adds complexity to this issue, as it can lead to rapid evaporation during processing or storage, potentially altering the intended composition and performance of the polymer system.

The impact of ethyl acetate on the biodegradation rate of the polymer system is also a significant concern. While ethyl acetate itself is biodegradable, its presence may alter the degradation kinetics of the host polymer. This can result in unpredictable or non-uniform degradation patterns, which could be problematic in applications where precise control over the material's lifespan is required.

Processing challenges also emerge when incorporating ethyl acetate into biodegradable polymers. The solvent's low boiling point can cause difficulties during melt processing or solution casting, potentially leading to defects in the final product or necessitating specialized equipment and techniques. Additionally, ensuring homogeneous distribution of ethyl acetate throughout the polymer matrix remains a technical hurdle, particularly in large-scale production scenarios.

Environmental and safety considerations pose another set of challenges. Despite being less toxic than many other solvents, ethyl acetate still requires careful handling and disposal. Manufacturers must implement robust systems to minimize environmental impact and ensure worker safety, which can add complexity and cost to production processes.

Regulatory compliance presents an ongoing challenge, particularly as standards for biodegradable materials continue to evolve. Ensuring that ethyl acetate-containing polymer systems meet various regional and international regulations regarding biodegradability, toxicity, and environmental impact requires continuous monitoring and potentially frequent reformulation efforts.

Lastly, the economic viability of integrating ethyl acetate into biodegradable polymer systems remains a significant challenge. Balancing the cost of ethyl acetate, any necessary specialized equipment or processes, and potential changes in material properties against the benefits of its inclusion requires careful consideration and may limit widespread adoption in certain applications or markets.

Another major challenge lies in controlling the release rate of ethyl acetate from the polymer matrix. This is particularly crucial in applications where sustained or controlled release of the solvent is desired. The volatility of ethyl acetate adds complexity to this issue, as it can lead to rapid evaporation during processing or storage, potentially altering the intended composition and performance of the polymer system.

The impact of ethyl acetate on the biodegradation rate of the polymer system is also a significant concern. While ethyl acetate itself is biodegradable, its presence may alter the degradation kinetics of the host polymer. This can result in unpredictable or non-uniform degradation patterns, which could be problematic in applications where precise control over the material's lifespan is required.

Processing challenges also emerge when incorporating ethyl acetate into biodegradable polymers. The solvent's low boiling point can cause difficulties during melt processing or solution casting, potentially leading to defects in the final product or necessitating specialized equipment and techniques. Additionally, ensuring homogeneous distribution of ethyl acetate throughout the polymer matrix remains a technical hurdle, particularly in large-scale production scenarios.

Environmental and safety considerations pose another set of challenges. Despite being less toxic than many other solvents, ethyl acetate still requires careful handling and disposal. Manufacturers must implement robust systems to minimize environmental impact and ensure worker safety, which can add complexity and cost to production processes.

Regulatory compliance presents an ongoing challenge, particularly as standards for biodegradable materials continue to evolve. Ensuring that ethyl acetate-containing polymer systems meet various regional and international regulations regarding biodegradability, toxicity, and environmental impact requires continuous monitoring and potentially frequent reformulation efforts.

Lastly, the economic viability of integrating ethyl acetate into biodegradable polymer systems remains a significant challenge. Balancing the cost of ethyl acetate, any necessary specialized equipment or processes, and potential changes in material properties against the benefits of its inclusion requires careful consideration and may limit widespread adoption in certain applications or markets.

Existing Solutions for Ethyl Acetate Incorporation

01 Production and purification of ethyl acetate

Various methods for producing and purifying ethyl acetate are described. These include esterification processes, distillation techniques, and the use of specific catalysts to improve yield and purity. The processes aim to optimize the production of ethyl acetate for industrial applications.- Production and purification of ethyl acetate: Various methods for producing and purifying ethyl acetate are described. These include esterification processes, distillation techniques, and the use of specific catalysts to improve yield and purity. The processes aim to optimize the production of ethyl acetate for industrial applications.

- Applications of ethyl acetate in chemical processes: Ethyl acetate is utilized in diverse chemical processes, including as a solvent in reactions, extractions, and separations. It plays a role in the synthesis of various compounds and is employed in the production of coatings, adhesives, and other industrial products.

- Ethyl acetate in pharmaceutical and cosmetic formulations: The use of ethyl acetate in pharmaceutical and cosmetic formulations is explored. It serves as a solvent and excipient in drug formulations and is used in the production of various personal care products. Its properties make it suitable for these applications while meeting regulatory requirements.

- Environmental and safety considerations for ethyl acetate: Research focuses on improving the environmental impact and safety of ethyl acetate production and use. This includes developing greener production methods, implementing recycling processes, and enhancing handling and storage practices to minimize risks associated with its flammability and volatility.

- Novel applications and modifications of ethyl acetate: Innovative uses and modifications of ethyl acetate are being explored. These include its application in advanced materials, nanotechnology, and as a precursor for novel compounds. Research also focuses on modifying its properties to enhance its performance in specific applications.

02 Applications of ethyl acetate in chemical processes

Ethyl acetate is utilized in various chemical processes and industries. It serves as a solvent, reactant, or intermediate in the production of other chemicals, pharmaceuticals, and materials. Its versatility makes it valuable in diverse applications across different sectors.Expand Specific Solutions03 Ethyl acetate in extraction and separation processes

Ethyl acetate is employed in extraction and separation processes for various compounds. Its properties make it suitable for liquid-liquid extraction, chromatography, and other separation techniques. These processes are used in the purification of natural products, pharmaceuticals, and other chemicals.Expand Specific Solutions04 Environmental and safety considerations for ethyl acetate

The use and handling of ethyl acetate involve environmental and safety considerations. This includes methods for reducing emissions, improving workplace safety, and developing more environmentally friendly processes for its production and use. Proper storage, handling, and disposal techniques are also addressed.Expand Specific Solutions05 Novel applications and formulations of ethyl acetate

Innovative applications and formulations of ethyl acetate are explored. These include its use in new materials, coatings, adhesives, and specialty chemicals. The development of novel formulations aims to enhance the performance and expand the utility of ethyl acetate in various industries.Expand Specific Solutions

Key Players in Biopolymer and Ethyl Acetate Industries

The focus on Ethyl Acetate in Biodegradable Polymer Systems is currently in a growth phase, with increasing market size and technological advancements. The competitive landscape is characterized by a mix of established chemical companies and innovative startups. Key players like BASF, Bayer, and Nitto Denko are leveraging their extensive R&D capabilities to develop novel biodegradable polymer solutions. Emerging companies such as Novamont and SK Geo Centric are also making significant contributions, particularly in bio-based materials. The technology's maturity is progressing, with companies like Abbott Laboratories and Allergan exploring applications in medical devices and pharmaceuticals, indicating a broadening range of potential uses across industries.

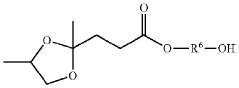

CJ CheilJedang Corp.

Technical Solution: CJ CheilJedang Corp. has developed an innovative approach to incorporating ethyl acetate in biodegradable polymer systems, focusing on its PHA (polyhydroxyalkanoate) production. The company utilizes ethyl acetate as a non-toxic extractant in the downstream processing of PHA from microbial fermentation[1]. This method significantly reduces the environmental impact of PHA production compared to traditional chloroform-based extraction. Additionally, CJ CheilJedang has patented a process for producing PHA-ethyl acetate blends with improved processability and flexibility[3]. The company has also explored the use of ethyl acetate as a solvent in the production of PHA-based nanocomposites, resulting in materials with enhanced mechanical and barrier properties[5].

Strengths: Environmentally friendly PHA extraction process; improved processability of PHA materials. Weaknesses: Potential challenges in scaling up the ethyl acetate-based extraction process; may require additional purification steps.

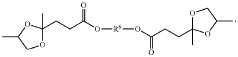

BASF Corp.

Technical Solution: BASF Corp. has developed a novel biodegradable polymer system incorporating ethyl acetate as a key component. Their approach involves using ethyl acetate as a solvent and plasticizer in the production of poly(lactic acid) (PLA) based materials. This method enhances the processability and flexibility of PLA while maintaining its biodegradability[1]. The company has also introduced a proprietary blend of PLA and ethyl acetate-modified cellulose acetate, which exhibits improved thermal stability and mechanical properties compared to pure PLA[3]. Additionally, BASF has patented a process for producing biodegradable polyester films using ethyl acetate as a cosolvent, resulting in films with enhanced barrier properties and reduced moisture sensitivity[5].

Strengths: Improved processability and flexibility of biodegradable polymers, enhanced thermal stability, and better barrier properties. Weaknesses: Potential volatility of ethyl acetate during processing, which may require additional safety measures.

Innovations in Ethyl Acetate-Biopolymer Interactions

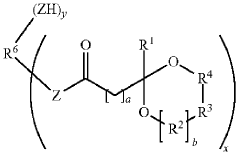

Impact-modified biodegradable polymer compositions

PatentWO2021119253A1

Innovation

- A polymer composition combining cellulose acetate with bio-based impact modifiers, such as acrylic core/shell particles and polybutylene adipate terephthalate, and plasticizers to enhance impact resistance and melt strength, while maintaining biodegradability.

Low emission cellulose ester composition and articles made therefrom

PatentWO2021119259A1

Innovation

- A cellulose acetate polymer composition is developed, combined with plasticizers and bio-based polymers, and incorporating acid scavengers to improve melt processing and reduce acidic emissions, resulting in a biodegradable material with enhanced physical properties similar to petroleum-based polymers.

Environmental Impact Assessment

The environmental impact assessment of ethyl acetate in biodegradable polymer systems reveals both positive and negative aspects that warrant careful consideration. On the positive side, the use of ethyl acetate as a solvent in the production of biodegradable polymers contributes to the overall sustainability of these materials. Biodegradable polymers offer significant advantages over traditional petroleum-based plastics in terms of end-of-life disposal and reduced environmental persistence.

Ethyl acetate is considered a relatively low-toxicity solvent compared to many alternatives used in polymer processing. It has a lower environmental impact due to its biodegradability and lower persistence in the environment. When released, ethyl acetate tends to break down relatively quickly in both air and water, reducing long-term ecological risks. Additionally, it can be produced from renewable resources, further enhancing its environmental credentials.

However, the production and use of ethyl acetate are not without environmental concerns. The manufacturing process of ethyl acetate can result in emissions of volatile organic compounds (VOCs), which contribute to air pollution and the formation of ground-level ozone. These emissions may have localized impacts on air quality and human health in areas surrounding production facilities.

Water pollution is another potential issue, as improper handling or disposal of ethyl acetate can lead to contamination of water bodies. While biodegradable, high concentrations of ethyl acetate in aquatic environments can have short-term toxic effects on aquatic life. Proper waste management and treatment protocols are essential to mitigate these risks.

Energy consumption and greenhouse gas emissions associated with the production and transportation of ethyl acetate also contribute to its overall environmental footprint. Life cycle assessments indicate that while the use phase of biodegradable polymers may have reduced impacts, the production phase, including solvent use, can still have significant energy and carbon implications.

In the context of biodegradable polymer systems, the environmental impact of ethyl acetate must be weighed against the benefits of the final product. The improved end-of-life characteristics of biodegradable polymers, such as reduced plastic pollution and lower persistence in the environment, may offset some of the impacts associated with their production processes, including solvent use.

To minimize environmental impacts, industry best practices should focus on optimizing production processes to reduce ethyl acetate emissions, implementing closed-loop systems for solvent recovery and reuse, and exploring alternative, even more environmentally friendly solvents. Continuous improvement in these areas will be crucial for enhancing the overall sustainability profile of biodegradable polymer systems that utilize ethyl acetate.

Ethyl acetate is considered a relatively low-toxicity solvent compared to many alternatives used in polymer processing. It has a lower environmental impact due to its biodegradability and lower persistence in the environment. When released, ethyl acetate tends to break down relatively quickly in both air and water, reducing long-term ecological risks. Additionally, it can be produced from renewable resources, further enhancing its environmental credentials.

However, the production and use of ethyl acetate are not without environmental concerns. The manufacturing process of ethyl acetate can result in emissions of volatile organic compounds (VOCs), which contribute to air pollution and the formation of ground-level ozone. These emissions may have localized impacts on air quality and human health in areas surrounding production facilities.

Water pollution is another potential issue, as improper handling or disposal of ethyl acetate can lead to contamination of water bodies. While biodegradable, high concentrations of ethyl acetate in aquatic environments can have short-term toxic effects on aquatic life. Proper waste management and treatment protocols are essential to mitigate these risks.

Energy consumption and greenhouse gas emissions associated with the production and transportation of ethyl acetate also contribute to its overall environmental footprint. Life cycle assessments indicate that while the use phase of biodegradable polymers may have reduced impacts, the production phase, including solvent use, can still have significant energy and carbon implications.

In the context of biodegradable polymer systems, the environmental impact of ethyl acetate must be weighed against the benefits of the final product. The improved end-of-life characteristics of biodegradable polymers, such as reduced plastic pollution and lower persistence in the environment, may offset some of the impacts associated with their production processes, including solvent use.

To minimize environmental impacts, industry best practices should focus on optimizing production processes to reduce ethyl acetate emissions, implementing closed-loop systems for solvent recovery and reuse, and exploring alternative, even more environmentally friendly solvents. Continuous improvement in these areas will be crucial for enhancing the overall sustainability profile of biodegradable polymer systems that utilize ethyl acetate.

Regulatory Framework for Biopolymer Materials

The regulatory framework for biopolymer materials, particularly those involving ethyl acetate in biodegradable polymer systems, is a complex and evolving landscape. Governments and international organizations have been developing and refining regulations to ensure the safety, efficacy, and environmental sustainability of these materials.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating biopolymers used in food packaging and medical applications. The FDA's guidance on biodegradable polymers focuses on their safety for human contact and potential migration of substances into food or medical products. Ethyl acetate, when used in biodegradable polymer systems, falls under scrutiny for its potential to leach into consumables.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the use of ethyl acetate and other substances in biopolymer production. REACH requires manufacturers to register chemicals and provide safety data, ensuring that potentially harmful substances are properly managed throughout their lifecycle.

Environmental regulations also play a significant role in shaping the biopolymer industry. The EU's Waste Framework Directive and Packaging and Packaging Waste Directive set targets for recycling and biodegradability, influencing the development and adoption of biodegradable polymer systems. These regulations encourage the use of materials that can decompose naturally, reducing environmental impact.

In Asia, countries like Japan and China have been developing their own regulatory frameworks for biopolymers. Japan's Biomass Plastics Mark certification system promotes the use of plant-based materials in plastic production, while China has introduced standards for biodegradable plastics to address pollution concerns.

International standards organizations, such as the International Organization for Standardization (ISO) and ASTM International, have developed guidelines and testing methods for biodegradable polymers. These standards help ensure consistency in product quality and environmental performance across different jurisdictions.

As the field of biodegradable polymers continues to advance, regulatory bodies are adapting their frameworks to keep pace with technological developments. This includes addressing the use of novel additives like ethyl acetate and their potential environmental and health impacts. The ongoing challenge for regulators is to balance innovation in biopolymer technology with the need to protect public health and the environment.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating biopolymers used in food packaging and medical applications. The FDA's guidance on biodegradable polymers focuses on their safety for human contact and potential migration of substances into food or medical products. Ethyl acetate, when used in biodegradable polymer systems, falls under scrutiny for its potential to leach into consumables.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the use of ethyl acetate and other substances in biopolymer production. REACH requires manufacturers to register chemicals and provide safety data, ensuring that potentially harmful substances are properly managed throughout their lifecycle.

Environmental regulations also play a significant role in shaping the biopolymer industry. The EU's Waste Framework Directive and Packaging and Packaging Waste Directive set targets for recycling and biodegradability, influencing the development and adoption of biodegradable polymer systems. These regulations encourage the use of materials that can decompose naturally, reducing environmental impact.

In Asia, countries like Japan and China have been developing their own regulatory frameworks for biopolymers. Japan's Biomass Plastics Mark certification system promotes the use of plant-based materials in plastic production, while China has introduced standards for biodegradable plastics to address pollution concerns.

International standards organizations, such as the International Organization for Standardization (ISO) and ASTM International, have developed guidelines and testing methods for biodegradable polymers. These standards help ensure consistency in product quality and environmental performance across different jurisdictions.

As the field of biodegradable polymers continues to advance, regulatory bodies are adapting their frameworks to keep pace with technological developments. This includes addressing the use of novel additives like ethyl acetate and their potential environmental and health impacts. The ongoing challenge for regulators is to balance innovation in biopolymer technology with the need to protect public health and the environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!