How Ethyl Acetate Supports Sustainable International Practices?

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate Background and Sustainability Goals

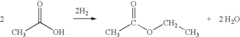

Ethyl acetate, a versatile organic compound, has gained significant attention in recent years due to its potential to support sustainable international practices. This ester, with its chemical formula CH3COOC2H5, has a rich history dating back to its first synthesis in the 19th century. Initially used primarily as a solvent in various industries, ethyl acetate's role has evolved significantly over time, aligning with the growing global emphasis on sustainability.

The development trajectory of ethyl acetate technology has been marked by continuous improvements in production methods and an expanding range of applications. From traditional uses in paints, coatings, and adhesives, it has found its way into more environmentally conscious applications, such as green solvents and biodegradable plastics. This evolution reflects the broader trend in chemical engineering towards more sustainable and eco-friendly processes.

As the world grapples with environmental challenges, the goals for ethyl acetate in supporting sustainable practices have become increasingly ambitious. One primary objective is to optimize its production process to minimize energy consumption and reduce carbon emissions. This involves exploring bio-based feedstocks and developing more efficient catalytic systems for its synthesis. Another key goal is to expand its use as a replacement for more harmful solvents in various industries, thereby reducing the overall environmental impact of industrial processes.

In the context of international sustainability practices, ethyl acetate plays a crucial role in fostering circular economy principles. Its biodegradability and potential for recycling make it an attractive option for countries striving to reduce waste and promote sustainable resource management. Furthermore, as a key component in the production of biodegradable plastics, ethyl acetate contributes to global efforts to address plastic pollution, a pressing environmental concern across nations.

The technology surrounding ethyl acetate is expected to continue evolving, with research focusing on enhancing its sustainability profile. This includes exploring new applications in green chemistry, improving its recovery and recycling processes, and developing novel formulations that maximize its environmental benefits. As international collaborations in sustainable technology increase, ethyl acetate stands at the forefront of compounds that can facilitate the transition to more sustainable industrial practices on a global scale.

The development trajectory of ethyl acetate technology has been marked by continuous improvements in production methods and an expanding range of applications. From traditional uses in paints, coatings, and adhesives, it has found its way into more environmentally conscious applications, such as green solvents and biodegradable plastics. This evolution reflects the broader trend in chemical engineering towards more sustainable and eco-friendly processes.

As the world grapples with environmental challenges, the goals for ethyl acetate in supporting sustainable practices have become increasingly ambitious. One primary objective is to optimize its production process to minimize energy consumption and reduce carbon emissions. This involves exploring bio-based feedstocks and developing more efficient catalytic systems for its synthesis. Another key goal is to expand its use as a replacement for more harmful solvents in various industries, thereby reducing the overall environmental impact of industrial processes.

In the context of international sustainability practices, ethyl acetate plays a crucial role in fostering circular economy principles. Its biodegradability and potential for recycling make it an attractive option for countries striving to reduce waste and promote sustainable resource management. Furthermore, as a key component in the production of biodegradable plastics, ethyl acetate contributes to global efforts to address plastic pollution, a pressing environmental concern across nations.

The technology surrounding ethyl acetate is expected to continue evolving, with research focusing on enhancing its sustainability profile. This includes exploring new applications in green chemistry, improving its recovery and recycling processes, and developing novel formulations that maximize its environmental benefits. As international collaborations in sustainable technology increase, ethyl acetate stands at the forefront of compounds that can facilitate the transition to more sustainable industrial practices on a global scale.

Global Market Demand for Sustainable Solvents

The global market for sustainable solvents has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations on volatile organic compounds (VOCs). Ethyl acetate, a biodegradable and low-toxicity solvent, has emerged as a key player in this expanding market. Its versatility and eco-friendly properties have positioned it as a preferred choice across various industries, including coatings, adhesives, pharmaceuticals, and food processing.

The demand for sustainable solvents is particularly strong in developed regions such as North America and Europe, where environmental regulations are more stringent. These markets have shown a consistent upward trend in the adoption of green solvents, with ethyl acetate gaining substantial market share. In emerging economies, the shift towards sustainable practices is gradually accelerating, presenting significant growth opportunities for ethyl acetate and other eco-friendly solvents.

The coatings and paints industry represents a major consumer of ethyl acetate, driven by the need for low-VOC formulations. As construction activities and automotive production continue to rise globally, the demand for sustainable coating solutions is expected to fuel further growth in the ethyl acetate market. Similarly, the adhesives sector has shown increasing preference for ethyl acetate-based formulations, particularly in packaging applications where food safety and environmental concerns are paramount.

In the pharmaceutical industry, ethyl acetate's role as a sustainable solvent has gained prominence in drug manufacturing processes. Its low toxicity and ease of recovery make it an attractive option for pharmaceutical companies striving to meet sustainability goals while maintaining product quality. The food and beverage industry has also contributed to the growing demand for ethyl acetate, particularly in the production of natural flavors and fragrances.

The market dynamics for sustainable solvents are further influenced by the circular economy concept, where ethyl acetate's recyclability offers a significant advantage. Companies are increasingly investing in technologies to recover and reuse ethyl acetate, aligning with global sustainability initiatives and reducing overall environmental impact. This trend is expected to drive innovation in solvent recovery systems and further enhance the appeal of ethyl acetate in international markets.

As industries worldwide continue to prioritize sustainability, the demand for ethyl acetate is projected to maintain a robust growth trajectory. Its ability to support sustainable international practices while offering performance comparable to traditional solvents positions ethyl acetate as a key contributor to the green chemistry movement. The market's expansion is likely to be accompanied by ongoing research and development efforts to optimize production processes and explore new applications, further solidifying ethyl acetate's role in the sustainable solvent landscape.

The demand for sustainable solvents is particularly strong in developed regions such as North America and Europe, where environmental regulations are more stringent. These markets have shown a consistent upward trend in the adoption of green solvents, with ethyl acetate gaining substantial market share. In emerging economies, the shift towards sustainable practices is gradually accelerating, presenting significant growth opportunities for ethyl acetate and other eco-friendly solvents.

The coatings and paints industry represents a major consumer of ethyl acetate, driven by the need for low-VOC formulations. As construction activities and automotive production continue to rise globally, the demand for sustainable coating solutions is expected to fuel further growth in the ethyl acetate market. Similarly, the adhesives sector has shown increasing preference for ethyl acetate-based formulations, particularly in packaging applications where food safety and environmental concerns are paramount.

In the pharmaceutical industry, ethyl acetate's role as a sustainable solvent has gained prominence in drug manufacturing processes. Its low toxicity and ease of recovery make it an attractive option for pharmaceutical companies striving to meet sustainability goals while maintaining product quality. The food and beverage industry has also contributed to the growing demand for ethyl acetate, particularly in the production of natural flavors and fragrances.

The market dynamics for sustainable solvents are further influenced by the circular economy concept, where ethyl acetate's recyclability offers a significant advantage. Companies are increasingly investing in technologies to recover and reuse ethyl acetate, aligning with global sustainability initiatives and reducing overall environmental impact. This trend is expected to drive innovation in solvent recovery systems and further enhance the appeal of ethyl acetate in international markets.

As industries worldwide continue to prioritize sustainability, the demand for ethyl acetate is projected to maintain a robust growth trajectory. Its ability to support sustainable international practices while offering performance comparable to traditional solvents positions ethyl acetate as a key contributor to the green chemistry movement. The market's expansion is likely to be accompanied by ongoing research and development efforts to optimize production processes and explore new applications, further solidifying ethyl acetate's role in the sustainable solvent landscape.

Current State and Challenges in Ethyl Acetate Production

The current state of ethyl acetate production is characterized by a growing demand driven by its versatile applications in various industries, including coatings, adhesives, pharmaceuticals, and food processing. Global production capacity has been steadily increasing, with major manufacturing hubs located in Asia, North America, and Europe. The production process predominantly relies on the esterification of ethanol and acetic acid, with some facilities utilizing alternative methods such as the Tishchenko process.

Despite its widespread use, the ethyl acetate industry faces several significant challenges in terms of sustainability and environmental impact. One of the primary concerns is the reliance on fossil fuel-derived feedstocks for traditional production methods. This dependency not only contributes to greenhouse gas emissions but also raises questions about long-term resource availability and price stability.

Energy consumption during the production process remains a critical issue, as the esterification reaction and subsequent purification steps require substantial thermal energy. Improving energy efficiency and exploring renewable energy sources for production facilities are ongoing challenges that the industry must address to enhance sustainability.

Water usage and wastewater management present another set of challenges. The production process generates significant amounts of wastewater containing organic compounds, which require proper treatment before discharge. Developing more efficient water recycling systems and minimizing water consumption are crucial areas for improvement.

The volatile organic compound (VOC) emissions associated with ethyl acetate production and use pose environmental and health concerns. Stricter regulations on VOC emissions are pushing manufacturers to invest in advanced emission control technologies and explore alternative production methods with lower environmental impact.

Another challenge lies in the purification and quality control of ethyl acetate. Achieving high purity levels while minimizing energy consumption and waste generation remains a balancing act for producers. Innovations in separation technologies and process optimization are needed to address this challenge effectively.

The industry is also grappling with the need for more sustainable packaging and transportation solutions. As a volatile compound, ethyl acetate requires careful handling and storage, which often involves energy-intensive processes and specialized packaging materials. Developing eco-friendly packaging options and optimizing logistics to reduce the carbon footprint of distribution are areas requiring further attention.

Lastly, the ethyl acetate industry faces the challenge of transitioning towards more sustainable feedstocks. Research into bio-based production methods, utilizing renewable resources such as agricultural waste or algae-derived feedstocks, is ongoing but faces hurdles in terms of scalability, cost-effectiveness, and product quality consistency. Overcoming these obstacles is crucial for the long-term sustainability of ethyl acetate production.

Despite its widespread use, the ethyl acetate industry faces several significant challenges in terms of sustainability and environmental impact. One of the primary concerns is the reliance on fossil fuel-derived feedstocks for traditional production methods. This dependency not only contributes to greenhouse gas emissions but also raises questions about long-term resource availability and price stability.

Energy consumption during the production process remains a critical issue, as the esterification reaction and subsequent purification steps require substantial thermal energy. Improving energy efficiency and exploring renewable energy sources for production facilities are ongoing challenges that the industry must address to enhance sustainability.

Water usage and wastewater management present another set of challenges. The production process generates significant amounts of wastewater containing organic compounds, which require proper treatment before discharge. Developing more efficient water recycling systems and minimizing water consumption are crucial areas for improvement.

The volatile organic compound (VOC) emissions associated with ethyl acetate production and use pose environmental and health concerns. Stricter regulations on VOC emissions are pushing manufacturers to invest in advanced emission control technologies and explore alternative production methods with lower environmental impact.

Another challenge lies in the purification and quality control of ethyl acetate. Achieving high purity levels while minimizing energy consumption and waste generation remains a balancing act for producers. Innovations in separation technologies and process optimization are needed to address this challenge effectively.

The industry is also grappling with the need for more sustainable packaging and transportation solutions. As a volatile compound, ethyl acetate requires careful handling and storage, which often involves energy-intensive processes and specialized packaging materials. Developing eco-friendly packaging options and optimizing logistics to reduce the carbon footprint of distribution are areas requiring further attention.

Lastly, the ethyl acetate industry faces the challenge of transitioning towards more sustainable feedstocks. Research into bio-based production methods, utilizing renewable resources such as agricultural waste or algae-derived feedstocks, is ongoing but faces hurdles in terms of scalability, cost-effectiveness, and product quality consistency. Overcoming these obstacles is crucial for the long-term sustainability of ethyl acetate production.

Existing Sustainable Practices in Ethyl Acetate Use

01 Production and purification of ethyl acetate

Various methods and processes for producing and purifying ethyl acetate are described. These include esterification reactions, distillation techniques, and the use of specific catalysts or reactants to improve yield and purity.- Production and purification of ethyl acetate: Various methods and processes for producing and purifying ethyl acetate are described. These include esterification reactions, distillation techniques, and the use of specific catalysts to improve yield and efficiency. The purification processes often involve multiple stages to remove impurities and achieve high-quality ethyl acetate.

- Applications of ethyl acetate in industrial processes: Ethyl acetate finds diverse applications in industrial processes, including its use as a solvent in various chemical reactions, as a component in coatings and adhesives, and in the production of pharmaceuticals and fragrances. Its versatility stems from its solvent properties and relatively low toxicity.

- Ethyl acetate in green chemistry and sustainable processes: Research focuses on developing environmentally friendly methods for producing and using ethyl acetate. This includes the use of renewable resources as feedstock, the development of more energy-efficient processes, and the exploration of ethyl acetate as a green solvent alternative in various applications.

- Recovery and recycling of ethyl acetate: Methods for recovering and recycling ethyl acetate from industrial processes are described. These techniques aim to reduce waste, improve process efficiency, and minimize environmental impact. They often involve separation processes such as distillation, membrane separation, or adsorption.

- Novel catalysts and reaction systems for ethyl acetate synthesis: Research on new catalysts and reaction systems for the synthesis of ethyl acetate is ongoing. These innovations aim to improve reaction rates, selectivity, and yield while reducing energy consumption and waste production. Some approaches involve heterogeneous catalysts, continuous flow reactors, or novel reaction media.

02 Applications of ethyl acetate in industrial processes

Ethyl acetate is utilized in diverse industrial applications, including as a solvent in chemical reactions, as a component in coatings and adhesives, and in the production of various materials such as plastics and textiles.Expand Specific Solutions03 Ethyl acetate in pharmaceutical and cosmetic formulations

The use of ethyl acetate in pharmaceutical and cosmetic products is explored, including its role as a solvent for active ingredients, as an excipient in drug formulations, and as a component in personal care products.Expand Specific Solutions04 Environmental and safety considerations for ethyl acetate

Research and development efforts focus on improving the environmental impact and safety aspects of ethyl acetate production and use. This includes developing greener production methods, reducing emissions, and enhancing handling procedures.Expand Specific Solutions05 Novel derivatives and modifications of ethyl acetate

Innovations in creating new derivatives or modified forms of ethyl acetate are presented. These modifications aim to enhance its properties or create new compounds with improved characteristics for specific applications.Expand Specific Solutions

Key Players in Ethyl Acetate and Green Chemistry

The ethyl acetate market is in a mature growth stage, with a global market size expected to reach $4.3 billion by 2026. The technology for producing ethyl acetate is well-established, with major players like Celanese, Eastman Chemical, and China Petroleum & Chemical Corp dominating the market. However, there is increasing focus on sustainable production methods, with companies like LanzaTech developing bio-based alternatives. The competitive landscape is characterized by a mix of large chemical conglomerates and specialized producers, with ongoing research at institutions like MIT and Nanjing Normal University driving innovation in greener production processes and applications.

Celanese International Corp.

Technical Solution: Celanese has developed a sustainable ethyl acetate production process using bioethanol as a feedstock. Their innovative approach involves fermenting renewable biomass to produce bioethanol, which is then esterified with acetic acid to create bio-based ethyl acetate. This method significantly reduces carbon footprint compared to traditional petrochemical routes [1]. The company has also implemented energy-efficient distillation techniques and waste heat recovery systems in their production facilities, further enhancing the sustainability of their ethyl acetate manufacturing process [3].

Strengths: Renewable feedstock, reduced carbon emissions, energy-efficient production. Weaknesses: Potential higher production costs, dependence on bioethanol availability.

LanzaTech NZ Ltd.

Technical Solution: LanzaTech has pioneered a gas fermentation technology that converts waste carbon monoxide and carbon dioxide into ethanol, which can be further processed into ethyl acetate. Their process utilizes proprietary microorganisms to ferment these waste gases, effectively recycling carbon emissions from industrial sources [2]. The company has successfully scaled up this technology, partnering with major steel manufacturers to capture and convert their emissions. LanzaTech's approach not only produces sustainable ethyl acetate but also contributes to circular economy principles by utilizing waste streams as valuable resources [4].

Strengths: Innovative carbon recycling, industrial waste utilization, scalable technology. Weaknesses: Reliance on specific industrial waste gases, potential process complexity.

Innovations in Eco-friendly Ethyl Acetate Synthesis

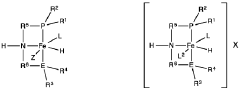

Homogeneous iron catalysts for the conversion of ethanol to ethyl acetate and hydrogen

PatentWO2019027965A1

Innovation

- A process utilizing a homogeneous iron catalyst with a tridentate pincer ligand for dehydrogenative coupling of ethanol at moderate temperatures, producing ethyl acetate efficiently and selectively, with iron loadings as low as 0.001 mol%, allowing for continuous operation and easy separation of ethyl acetate from the catalyst.

Processes for making ethyl acetate from acetic acid

PatentInactiveUS20100197959A1

Innovation

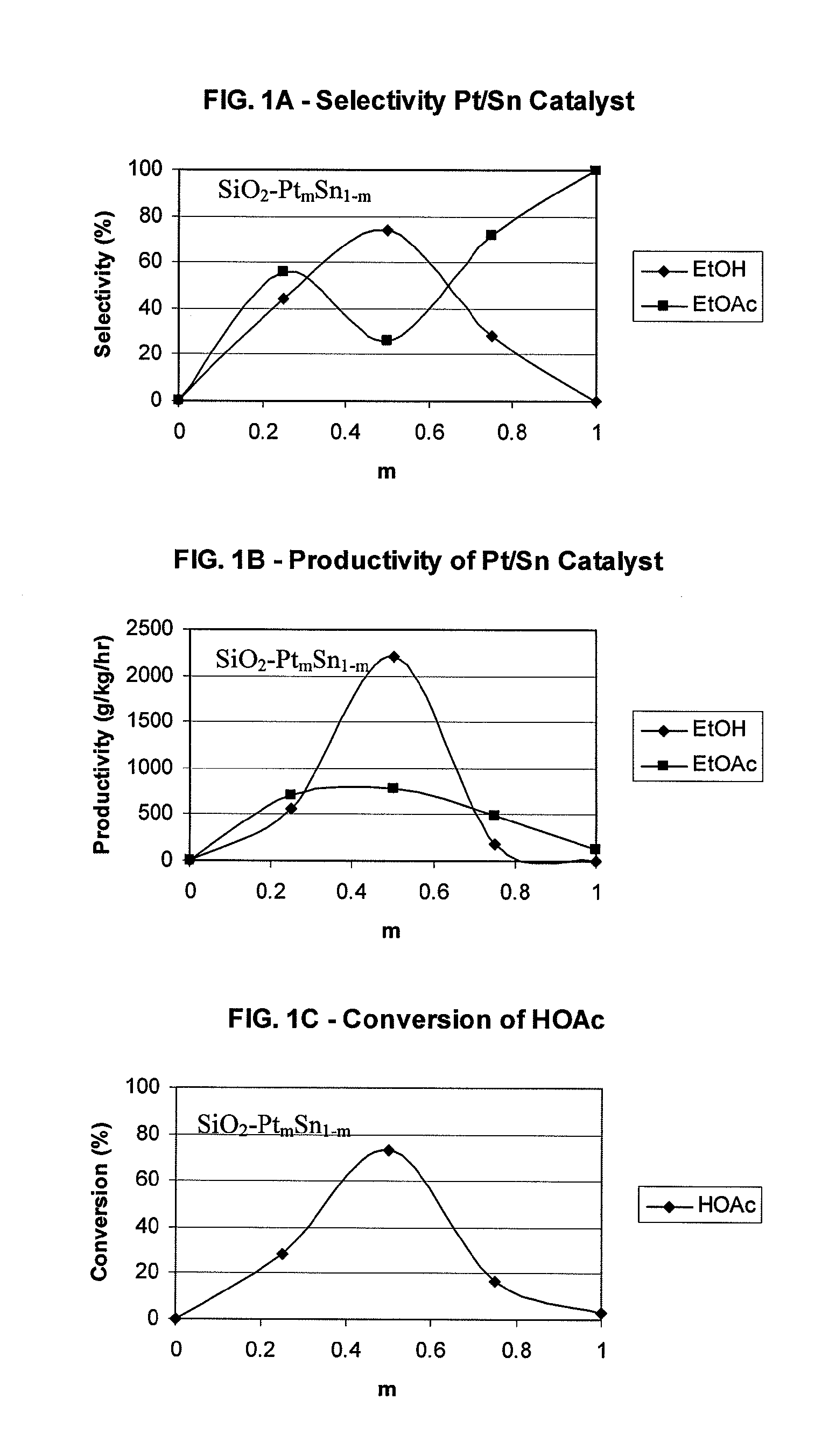

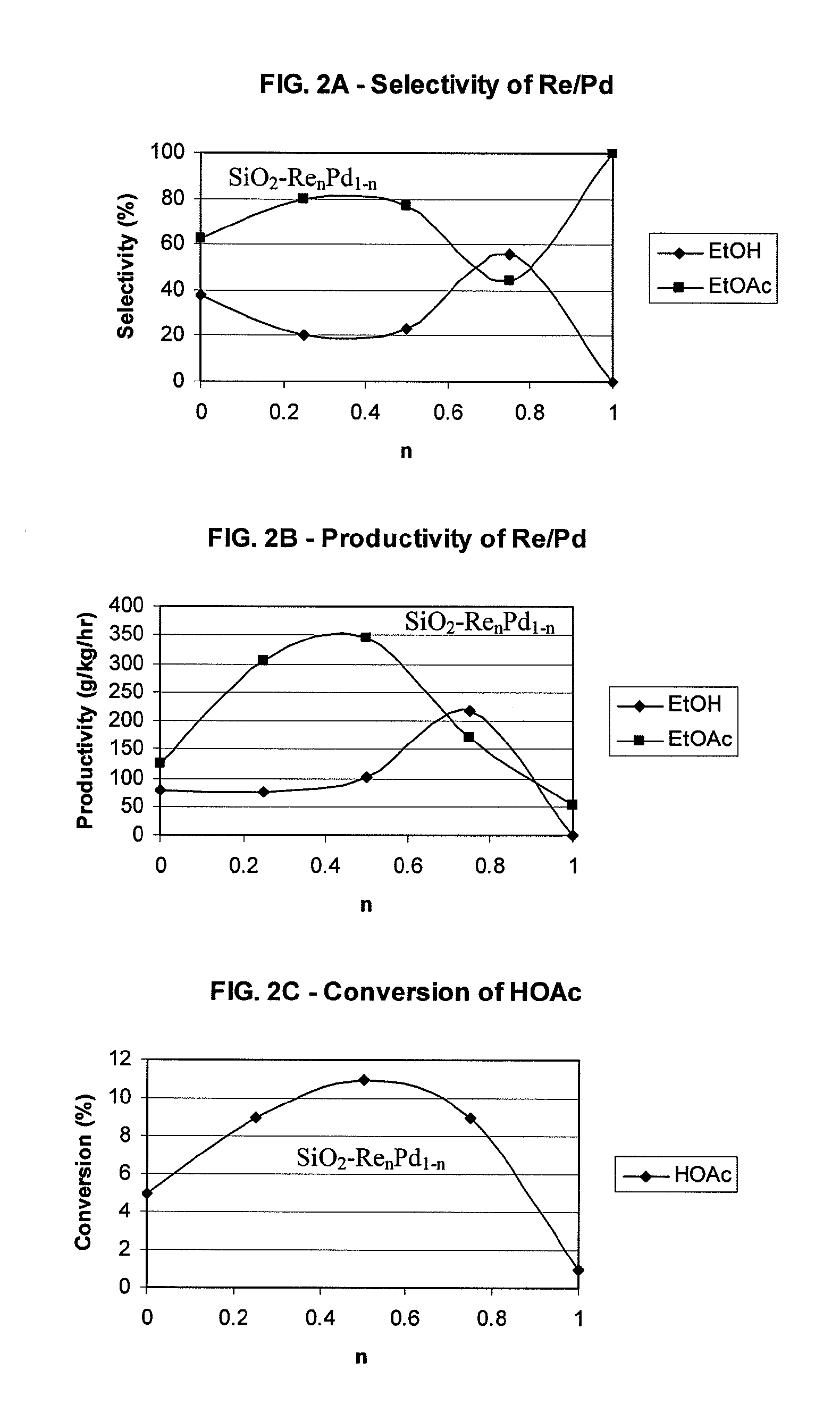

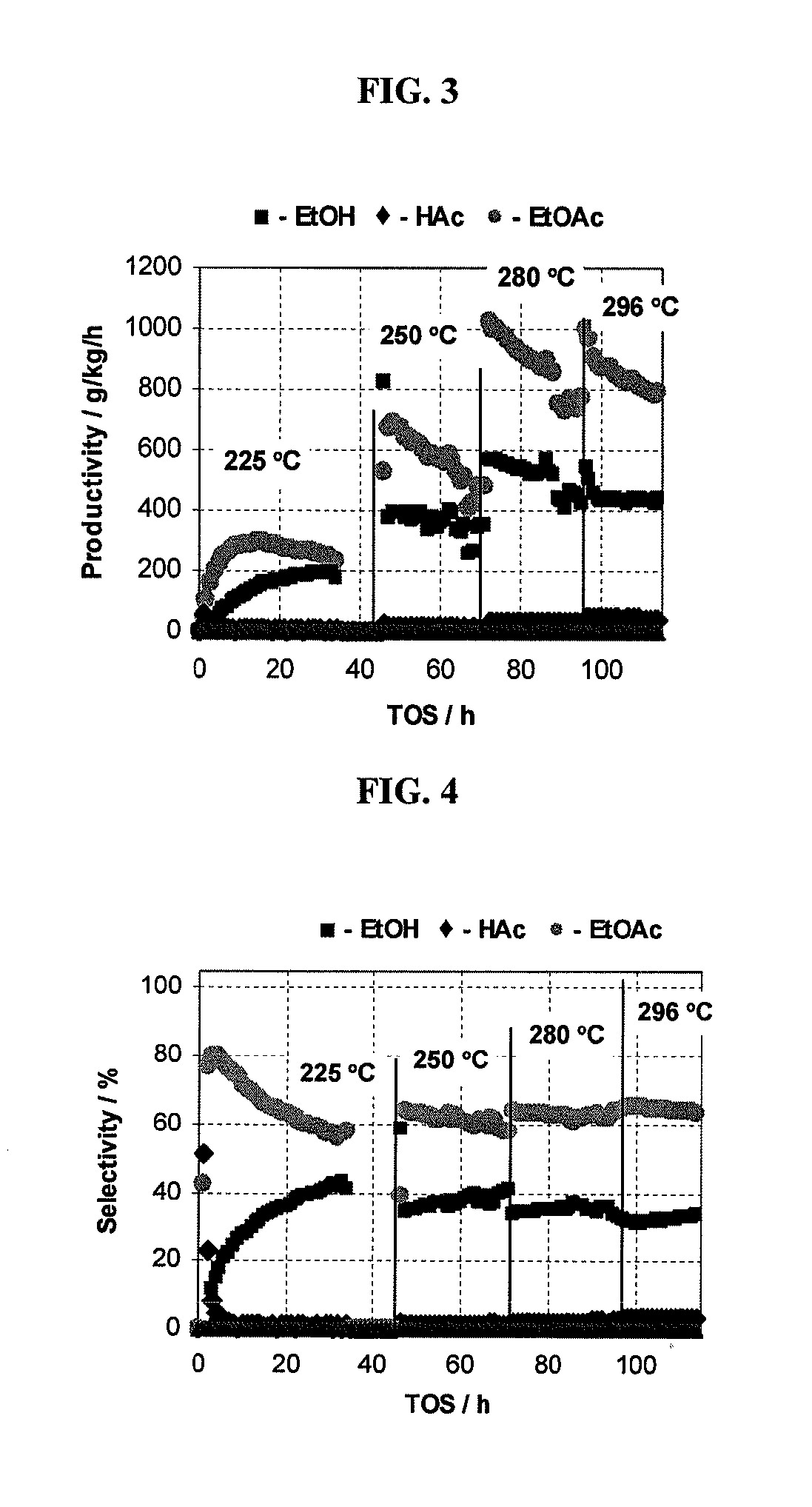

- A process utilizing catalysts comprising metals like nickel, palladium, or platinum, combined with support materials like silica or titania, and modified with oxides of Group IVB, VB, or VIB metals, which are effective in hydrogenating acetic acid to produce ethyl acetate with high selectivity and minimizing by-product formation.

Environmental Impact Assessment of Ethyl Acetate

The environmental impact assessment of ethyl acetate is crucial for understanding its role in supporting sustainable international practices. Ethyl acetate, a widely used organic solvent, has both positive and negative effects on the environment throughout its lifecycle.

In terms of production, ethyl acetate can be synthesized through various methods, including the esterification of ethanol and acetic acid. This process is relatively energy-efficient compared to the production of some other solvents. Additionally, ethyl acetate can be derived from renewable resources, such as bioethanol, which contributes to its potential as a more sustainable alternative to petroleum-based solvents.

During its use phase, ethyl acetate demonstrates several environmentally favorable characteristics. It has a low toxicity profile and is biodegradable, breaking down into ethanol and acetic acid in the environment. This property reduces its long-term environmental persistence and potential for bioaccumulation. Furthermore, ethyl acetate has a relatively low vapor pressure, which helps minimize volatile organic compound (VOC) emissions during application processes.

However, the release of ethyl acetate into the environment can still have some negative impacts. In the atmosphere, it can contribute to the formation of ground-level ozone and photochemical smog when it reacts with nitrogen oxides in the presence of sunlight. While these effects are less severe compared to many other solvents, they still warrant consideration in air quality management strategies.

In aquatic environments, ethyl acetate can pose risks to aquatic organisms if released in large quantities. Although it is biodegradable, high concentrations can lead to oxygen depletion in water bodies during the breakdown process. This underscores the importance of proper handling and disposal practices in industrial settings.

From a lifecycle perspective, the production and use of ethyl acetate generally have a lower carbon footprint compared to many traditional petroleum-based solvents. Its potential for bio-based production further enhances its sustainability profile. However, the overall environmental impact depends heavily on factors such as production methods, transportation, and end-of-life management.

To maximize the environmental benefits of ethyl acetate, several strategies can be employed. These include optimizing production processes to reduce energy consumption and waste, implementing closed-loop systems to minimize emissions and promote recycling, and exploring bio-based feedstocks for production. Additionally, developing improved recovery and recycling technologies can help reduce the need for virgin material production and minimize environmental releases.

In terms of production, ethyl acetate can be synthesized through various methods, including the esterification of ethanol and acetic acid. This process is relatively energy-efficient compared to the production of some other solvents. Additionally, ethyl acetate can be derived from renewable resources, such as bioethanol, which contributes to its potential as a more sustainable alternative to petroleum-based solvents.

During its use phase, ethyl acetate demonstrates several environmentally favorable characteristics. It has a low toxicity profile and is biodegradable, breaking down into ethanol and acetic acid in the environment. This property reduces its long-term environmental persistence and potential for bioaccumulation. Furthermore, ethyl acetate has a relatively low vapor pressure, which helps minimize volatile organic compound (VOC) emissions during application processes.

However, the release of ethyl acetate into the environment can still have some negative impacts. In the atmosphere, it can contribute to the formation of ground-level ozone and photochemical smog when it reacts with nitrogen oxides in the presence of sunlight. While these effects are less severe compared to many other solvents, they still warrant consideration in air quality management strategies.

In aquatic environments, ethyl acetate can pose risks to aquatic organisms if released in large quantities. Although it is biodegradable, high concentrations can lead to oxygen depletion in water bodies during the breakdown process. This underscores the importance of proper handling and disposal practices in industrial settings.

From a lifecycle perspective, the production and use of ethyl acetate generally have a lower carbon footprint compared to many traditional petroleum-based solvents. Its potential for bio-based production further enhances its sustainability profile. However, the overall environmental impact depends heavily on factors such as production methods, transportation, and end-of-life management.

To maximize the environmental benefits of ethyl acetate, several strategies can be employed. These include optimizing production processes to reduce energy consumption and waste, implementing closed-loop systems to minimize emissions and promote recycling, and exploring bio-based feedstocks for production. Additionally, developing improved recovery and recycling technologies can help reduce the need for virgin material production and minimize environmental releases.

Regulatory Framework for Sustainable Chemicals

The regulatory framework for sustainable chemicals plays a crucial role in promoting the use of ethyl acetate as a sustainable solvent in international practices. Governments and international organizations have established comprehensive guidelines and standards to ensure the responsible production, use, and disposal of chemicals, including ethyl acetate.

At the global level, the United Nations Environment Programme (UNEP) has implemented the Strategic Approach to International Chemicals Management (SAICM), which provides a policy framework to foster the sound management of chemicals throughout their lifecycle. This initiative encourages the adoption of green chemistry principles and the use of environmentally friendly solvents like ethyl acetate.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is a cornerstone of chemical management in Europe. Under REACH, ethyl acetate has been registered and evaluated for its safety and environmental impact. Its favorable profile has contributed to its increased use as a sustainable alternative to more hazardous solvents.

In the United States, the Environmental Protection Agency (EPA) regulates chemicals under the Toxic Substances Control Act (TSCA). The EPA has recognized ethyl acetate as a safer alternative in its Safer Chemical Ingredients List, promoting its use in various applications. This designation has encouraged industries to adopt ethyl acetate in their processes to meet sustainability goals.

Many countries have implemented Green Public Procurement (GPP) policies, which prioritize the purchase of environmentally friendly products and services by government agencies. These policies often favor the use of sustainable solvents like ethyl acetate in cleaning products, paints, and other applications, driving market demand for eco-friendly alternatives.

The International Organization for Standardization (ISO) has developed several standards related to environmental management and sustainable practices. ISO 14001, for instance, provides a framework for organizations to implement effective environmental management systems. Companies using ethyl acetate can leverage these standards to demonstrate their commitment to sustainability and gain a competitive edge in the global market.

Industry-specific regulations also play a role in promoting sustainable chemicals. For example, in the pharmaceutical industry, the International Conference on Harmonisation (ICH) guidelines address the use of solvents in drug manufacturing. Ethyl acetate's classification as a less toxic solvent in these guidelines has led to its increased adoption in pharmaceutical processes worldwide.

As sustainability becomes an increasingly important factor in international trade, many countries have introduced eco-labeling schemes and certification programs. These initiatives often consider the environmental impact of chemicals used in product manufacturing. Ethyl acetate's favorable environmental profile makes it an attractive choice for companies seeking to obtain these certifications and access environmentally conscious markets.

At the global level, the United Nations Environment Programme (UNEP) has implemented the Strategic Approach to International Chemicals Management (SAICM), which provides a policy framework to foster the sound management of chemicals throughout their lifecycle. This initiative encourages the adoption of green chemistry principles and the use of environmentally friendly solvents like ethyl acetate.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is a cornerstone of chemical management in Europe. Under REACH, ethyl acetate has been registered and evaluated for its safety and environmental impact. Its favorable profile has contributed to its increased use as a sustainable alternative to more hazardous solvents.

In the United States, the Environmental Protection Agency (EPA) regulates chemicals under the Toxic Substances Control Act (TSCA). The EPA has recognized ethyl acetate as a safer alternative in its Safer Chemical Ingredients List, promoting its use in various applications. This designation has encouraged industries to adopt ethyl acetate in their processes to meet sustainability goals.

Many countries have implemented Green Public Procurement (GPP) policies, which prioritize the purchase of environmentally friendly products and services by government agencies. These policies often favor the use of sustainable solvents like ethyl acetate in cleaning products, paints, and other applications, driving market demand for eco-friendly alternatives.

The International Organization for Standardization (ISO) has developed several standards related to environmental management and sustainable practices. ISO 14001, for instance, provides a framework for organizations to implement effective environmental management systems. Companies using ethyl acetate can leverage these standards to demonstrate their commitment to sustainability and gain a competitive edge in the global market.

Industry-specific regulations also play a role in promoting sustainable chemicals. For example, in the pharmaceutical industry, the International Conference on Harmonisation (ICH) guidelines address the use of solvents in drug manufacturing. Ethyl acetate's classification as a less toxic solvent in these guidelines has led to its increased adoption in pharmaceutical processes worldwide.

As sustainability becomes an increasingly important factor in international trade, many countries have introduced eco-labeling schemes and certification programs. These initiatives often consider the environmental impact of chemicals used in product manufacturing. Ethyl acetate's favorable environmental profile makes it an attractive choice for companies seeking to obtain these certifications and access environmentally conscious markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!