How Ethyl Acetate Supports Sustainable Supply Chains?

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate Evolution

Ethyl acetate has undergone significant evolution in its production methods and applications, particularly in supporting sustainable supply chains. Initially synthesized in the early 19th century, ethyl acetate was primarily produced through the esterification of ethanol and acetic acid. This traditional method, while effective, had limitations in terms of efficiency and environmental impact.

The mid-20th century saw a shift towards more industrial-scale production techniques. The Tishchenko reaction, which uses acetaldehyde as a starting material, became a popular method for large-scale ethyl acetate synthesis. This process offered improved yields and reduced waste, marking a step towards more sustainable production.

In recent decades, the focus has shifted towards developing greener and more sustainable production methods. Biotechnological approaches have gained traction, with researchers exploring the use of enzymes and microorganisms for ethyl acetate synthesis. These bio-based methods offer the advantage of using renewable feedstocks and operating under milder conditions, significantly reducing energy consumption and environmental impact.

The advent of continuous flow chemistry has further revolutionized ethyl acetate production. This technique allows for more precise control over reaction conditions, leading to higher yields, improved product quality, and reduced waste. Continuous flow reactors also enable the integration of multiple reaction steps, streamlining the production process and reducing the overall environmental footprint.

Advancements in catalysis have played a crucial role in enhancing the sustainability of ethyl acetate production. Novel heterogeneous catalysts have been developed that improve reaction efficiency and selectivity while being easily recoverable and reusable. These catalysts have contributed to reducing the energy requirements and waste generation in ethyl acetate synthesis.

The evolution of ethyl acetate production has also been marked by efforts to utilize waste streams and byproducts from other industrial processes. For instance, researchers have explored the use of CO2 as a feedstock for ethyl acetate synthesis, offering a potential route for carbon capture and utilization. Similarly, the integration of ethyl acetate production with biorefinery concepts has opened up possibilities for more circular and sustainable supply chains.

Recent years have seen increased interest in developing bio-based alternatives to petrochemical-derived ethyl acetate. These efforts align with the broader trend towards bio-based chemicals and materials, driven by sustainability goals and the need to reduce dependence on fossil resources. The development of these bio-based routes not only enhances the sustainability of ethyl acetate production but also contributes to the creation of more resilient and environmentally friendly supply chains.

The mid-20th century saw a shift towards more industrial-scale production techniques. The Tishchenko reaction, which uses acetaldehyde as a starting material, became a popular method for large-scale ethyl acetate synthesis. This process offered improved yields and reduced waste, marking a step towards more sustainable production.

In recent decades, the focus has shifted towards developing greener and more sustainable production methods. Biotechnological approaches have gained traction, with researchers exploring the use of enzymes and microorganisms for ethyl acetate synthesis. These bio-based methods offer the advantage of using renewable feedstocks and operating under milder conditions, significantly reducing energy consumption and environmental impact.

The advent of continuous flow chemistry has further revolutionized ethyl acetate production. This technique allows for more precise control over reaction conditions, leading to higher yields, improved product quality, and reduced waste. Continuous flow reactors also enable the integration of multiple reaction steps, streamlining the production process and reducing the overall environmental footprint.

Advancements in catalysis have played a crucial role in enhancing the sustainability of ethyl acetate production. Novel heterogeneous catalysts have been developed that improve reaction efficiency and selectivity while being easily recoverable and reusable. These catalysts have contributed to reducing the energy requirements and waste generation in ethyl acetate synthesis.

The evolution of ethyl acetate production has also been marked by efforts to utilize waste streams and byproducts from other industrial processes. For instance, researchers have explored the use of CO2 as a feedstock for ethyl acetate synthesis, offering a potential route for carbon capture and utilization. Similarly, the integration of ethyl acetate production with biorefinery concepts has opened up possibilities for more circular and sustainable supply chains.

Recent years have seen increased interest in developing bio-based alternatives to petrochemical-derived ethyl acetate. These efforts align with the broader trend towards bio-based chemicals and materials, driven by sustainability goals and the need to reduce dependence on fossil resources. The development of these bio-based routes not only enhances the sustainability of ethyl acetate production but also contributes to the creation of more resilient and environmentally friendly supply chains.

Market Demand Analysis

The market demand for ethyl acetate in sustainable supply chains has been steadily increasing in recent years, driven by growing environmental concerns and stricter regulations on chemical usage. This versatile solvent, known for its low toxicity and biodegradability, has become a key component in various industries seeking to reduce their environmental footprint.

In the packaging industry, ethyl acetate has gained significant traction as a sustainable alternative to traditional petroleum-based solvents. The shift towards eco-friendly packaging materials has led to a surge in demand for ethyl acetate-based adhesives and coatings. This trend is particularly evident in the food and beverage sector, where consumers are increasingly demanding sustainable packaging solutions.

The pharmaceutical industry has also contributed to the rising demand for ethyl acetate in sustainable supply chains. As a less harmful solvent compared to many alternatives, ethyl acetate is being increasingly utilized in drug manufacturing processes. This shift is not only driven by environmental considerations but also by the industry's focus on worker safety and product quality.

In the cosmetics and personal care sector, ethyl acetate has found applications in nail polish removers and other beauty products. The market demand in this sector is fueled by consumer preferences for natural and eco-friendly ingredients, as well as regulatory pressures to reduce the use of harmful chemicals in personal care products.

The automotive industry has also recognized the potential of ethyl acetate in supporting sustainable supply chains. Its use in automotive paints and coatings has increased, as manufacturers seek to comply with stricter environmental regulations and reduce volatile organic compound (VOC) emissions.

The agricultural sector presents another growing market for ethyl acetate, particularly in the production of bio-based pesticides and herbicides. As the world moves towards more sustainable farming practices, the demand for environmentally friendly crop protection solutions continues to rise.

The electronics industry has also begun to incorporate ethyl acetate into its supply chains, particularly in the manufacturing of printed circuit boards and in cleaning processes. This shift is driven by the need to reduce the environmental impact of electronic waste and improve the sustainability of production processes.

As industries continue to prioritize sustainability and circular economy principles, the market demand for ethyl acetate is expected to grow further. Its versatility, coupled with its environmentally friendly properties, positions it as a key component in the transition towards more sustainable supply chains across multiple sectors.

In the packaging industry, ethyl acetate has gained significant traction as a sustainable alternative to traditional petroleum-based solvents. The shift towards eco-friendly packaging materials has led to a surge in demand for ethyl acetate-based adhesives and coatings. This trend is particularly evident in the food and beverage sector, where consumers are increasingly demanding sustainable packaging solutions.

The pharmaceutical industry has also contributed to the rising demand for ethyl acetate in sustainable supply chains. As a less harmful solvent compared to many alternatives, ethyl acetate is being increasingly utilized in drug manufacturing processes. This shift is not only driven by environmental considerations but also by the industry's focus on worker safety and product quality.

In the cosmetics and personal care sector, ethyl acetate has found applications in nail polish removers and other beauty products. The market demand in this sector is fueled by consumer preferences for natural and eco-friendly ingredients, as well as regulatory pressures to reduce the use of harmful chemicals in personal care products.

The automotive industry has also recognized the potential of ethyl acetate in supporting sustainable supply chains. Its use in automotive paints and coatings has increased, as manufacturers seek to comply with stricter environmental regulations and reduce volatile organic compound (VOC) emissions.

The agricultural sector presents another growing market for ethyl acetate, particularly in the production of bio-based pesticides and herbicides. As the world moves towards more sustainable farming practices, the demand for environmentally friendly crop protection solutions continues to rise.

The electronics industry has also begun to incorporate ethyl acetate into its supply chains, particularly in the manufacturing of printed circuit boards and in cleaning processes. This shift is driven by the need to reduce the environmental impact of electronic waste and improve the sustainability of production processes.

As industries continue to prioritize sustainability and circular economy principles, the market demand for ethyl acetate is expected to grow further. Its versatility, coupled with its environmentally friendly properties, positions it as a key component in the transition towards more sustainable supply chains across multiple sectors.

Technical Challenges

The adoption of ethyl acetate in sustainable supply chains faces several technical challenges that need to be addressed for its widespread implementation. One of the primary obstacles is the current production process, which heavily relies on fossil fuel-based feedstocks. This dependency not only contributes to environmental concerns but also raises questions about long-term sustainability and resource availability.

Another significant challenge lies in the energy-intensive nature of ethyl acetate production. The traditional manufacturing methods require substantial amounts of energy, often derived from non-renewable sources. This high energy consumption contradicts the sustainability goals that ethyl acetate aims to support in supply chains, creating a paradox that needs resolution.

The purification and separation processes in ethyl acetate production present additional technical hurdles. Current methods often involve multiple distillation steps, which are both energy-intensive and time-consuming. Developing more efficient separation techniques that maintain product quality while reducing energy consumption remains a critical area for improvement.

Storage and transportation of ethyl acetate also pose technical challenges. As a volatile organic compound, it requires specialized containment systems to prevent emissions and ensure safety. Developing advanced storage solutions and transportation methods that minimize losses and environmental impact is crucial for integrating ethyl acetate into sustainable supply chains effectively.

The recyclability and end-of-life management of ethyl acetate-based products represent another set of technical challenges. While ethyl acetate itself is biodegradable, its incorporation into complex products can complicate recycling processes. Developing innovative recycling technologies and designing products for easier disassembly and material recovery are essential for closing the loop in sustainable supply chains.

Furthermore, the scalability of green ethyl acetate production technologies presents a significant challenge. While laboratory-scale processes using renewable feedstocks have shown promise, translating these methods to industrial-scale production while maintaining economic viability remains a hurdle. This scaling issue is critical for meeting the growing demand for sustainable alternatives in global supply chains.

Lastly, the integration of ethyl acetate into existing supply chain infrastructures poses technical challenges. Many current systems are optimized for traditional, petroleum-based solvents and materials. Adapting these systems to accommodate the unique properties of ethyl acetate, such as its lower boiling point and different solvent characteristics, requires significant engineering and process modifications across various industries.

Another significant challenge lies in the energy-intensive nature of ethyl acetate production. The traditional manufacturing methods require substantial amounts of energy, often derived from non-renewable sources. This high energy consumption contradicts the sustainability goals that ethyl acetate aims to support in supply chains, creating a paradox that needs resolution.

The purification and separation processes in ethyl acetate production present additional technical hurdles. Current methods often involve multiple distillation steps, which are both energy-intensive and time-consuming. Developing more efficient separation techniques that maintain product quality while reducing energy consumption remains a critical area for improvement.

Storage and transportation of ethyl acetate also pose technical challenges. As a volatile organic compound, it requires specialized containment systems to prevent emissions and ensure safety. Developing advanced storage solutions and transportation methods that minimize losses and environmental impact is crucial for integrating ethyl acetate into sustainable supply chains effectively.

The recyclability and end-of-life management of ethyl acetate-based products represent another set of technical challenges. While ethyl acetate itself is biodegradable, its incorporation into complex products can complicate recycling processes. Developing innovative recycling technologies and designing products for easier disassembly and material recovery are essential for closing the loop in sustainable supply chains.

Furthermore, the scalability of green ethyl acetate production technologies presents a significant challenge. While laboratory-scale processes using renewable feedstocks have shown promise, translating these methods to industrial-scale production while maintaining economic viability remains a hurdle. This scaling issue is critical for meeting the growing demand for sustainable alternatives in global supply chains.

Lastly, the integration of ethyl acetate into existing supply chain infrastructures poses technical challenges. Many current systems are optimized for traditional, petroleum-based solvents and materials. Adapting these systems to accommodate the unique properties of ethyl acetate, such as its lower boiling point and different solvent characteristics, requires significant engineering and process modifications across various industries.

Current Green Solutions

01 Production and purification of ethyl acetate

Various methods for producing and purifying ethyl acetate are described, including esterification processes, distillation techniques, and separation methods. These processes aim to improve the yield and purity of ethyl acetate for industrial applications.- Production and purification of ethyl acetate: Various methods for producing and purifying ethyl acetate are described. These include distillation processes, reactive distillation, and the use of specific catalysts to improve yield and purity. Some techniques focus on energy-efficient production methods and the separation of ethyl acetate from other components in the reaction mixture.

- Applications of ethyl acetate in chemical processes: Ethyl acetate is utilized in various chemical processes and industries. It serves as a solvent in pharmaceutical manufacturing, as a component in coating formulations, and as a reactant in organic synthesis. Its use in extraction processes and as a cleaning agent in electronics manufacturing is also noted.

- Ethyl acetate in polymer and material science: The role of ethyl acetate in polymer and material science is explored. It is used as a solvent in polymer synthesis, as a component in adhesive formulations, and in the production of various composite materials. Its application in the modification of material properties and in the development of novel materials is also discussed.

- Environmental and safety considerations for ethyl acetate: Environmental and safety aspects related to ethyl acetate are addressed. This includes methods for reducing emissions during production and use, safe handling practices, and techniques for the recovery and recycling of ethyl acetate in industrial processes. Strategies for minimizing environmental impact and ensuring worker safety are also discussed.

- Novel synthesis routes and derivatives of ethyl acetate: Research into new synthesis routes for ethyl acetate and the development of its derivatives is presented. This includes the exploration of alternative feedstocks, novel catalytic systems, and the creation of functionalized ethyl acetate derivatives for specific applications. The potential for improving process efficiency and expanding the range of ethyl acetate-based products is also examined.

02 Applications of ethyl acetate in chemical processes

Ethyl acetate is utilized in diverse chemical processes, such as solvent extraction, as a reaction medium, and in the production of other chemicals. Its properties make it suitable for various industrial applications, including pharmaceuticals and polymer manufacturing.Expand Specific Solutions03 Ethyl acetate in coating and adhesive formulations

Ethyl acetate is employed in the formulation of coatings, adhesives, and related products. Its use as a solvent and carrier in these applications contributes to improved performance and application properties of the final products.Expand Specific Solutions04 Environmental and safety considerations for ethyl acetate

Research and development efforts focus on improving the environmental impact and safety aspects of ethyl acetate production and use. This includes developing greener production methods, reducing emissions, and enhancing handling procedures.Expand Specific Solutions05 Novel applications and derivatives of ethyl acetate

Innovative uses of ethyl acetate and the development of its derivatives are explored for various industries. These include applications in energy storage, advanced materials, and biotechnology, expanding the potential of ethyl acetate beyond its traditional uses.Expand Specific Solutions

Key Industry Players

The ethyl acetate market is in a growth phase, driven by increasing demand for sustainable and bio-based chemicals. The global market size is projected to expand significantly in the coming years, fueled by applications in various industries. While the technology is relatively mature, there is ongoing innovation in sustainable production methods. Key players like Celanese, Eastman Chemical, and BASF are established leaders, with emerging companies like LanzaTech and Viridis Chemical focusing on bio-based production. Universities and research institutions, such as the University of Campinas and Tianjin University, are contributing to advancements in green chemistry and sustainable manufacturing processes, indicating a collaborative ecosystem driving technological progress in this field.

Celanese International Corp.

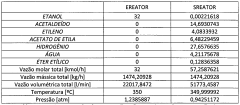

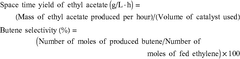

Technical Solution: Celanese has developed a sustainable production process for ethyl acetate using bioethanol as a feedstock. Their approach involves a two-step reaction: first, the dehydrogenation of ethanol to acetaldehyde, followed by the condensation of acetaldehyde with ethanol to form ethyl acetate[1]. This process significantly reduces carbon footprint compared to traditional petrochemical routes. Celanese has also implemented advanced catalysts and reactor designs to improve yield and energy efficiency[2]. The company has integrated this process into their existing manufacturing facilities, allowing for seamless adoption and scale-up[3].

Strengths: Reduced carbon footprint, utilization of renewable feedstock, improved energy efficiency. Weaknesses: Potential higher production costs compared to traditional methods, dependence on bioethanol availability.

Eastman Chemical Co.

Technical Solution: Eastman Chemical has developed a novel approach to ethyl acetate production using their proprietary Gasification Technology. This process converts biomass or waste materials into syngas, which is then used to synthesize ethyl acetate[4]. The technology allows for the use of a wide range of feedstocks, including agricultural residues and municipal solid waste. Eastman has also implemented advanced separation techniques to achieve high-purity ethyl acetate[5]. Their process incorporates heat integration and cogeneration systems to maximize energy efficiency and reduce overall environmental impact[6].

Strengths: Versatile feedstock options, potential for waste valorization, integrated energy efficiency measures. Weaknesses: Complex process requiring significant capital investment, potential challenges in scaling up.

Innovative Applications

Integrated system for producing ethyl acetate, acetaldehyde, hydrogen and ethylene, integrated process for producing ethyl acetate, acetaldehyde, hydrogen and ethylene, and products thereby produced

PatentWO2013029129A1

Innovation

- An integrated system utilizing a fixed-bed reactor with a calcined hydrotalcite catalyst for dehydrogenation and dehydration of ethanol, followed by a series of distillation columns for efficient separation and purification, employing ethylene glycol as a solvent to separate ethyl acetate from water, thereby reducing energy expenditure and minimizing azeotropy issues.

Method for producing ethyl acetate

PatentPendingUS20250002441A1

Innovation

- Controlling the palladium content in the catalyst within the range of 0.1 to 14 ppb by mass in a heteropolyacid or its salt supported on a carrier, such as silica, suppresses side reactions and ensures stable long-term operation.

Environmental Impact

Ethyl acetate plays a significant role in supporting sustainable supply chains through its environmental impact. As a widely used solvent in various industries, ethyl acetate offers several advantages that contribute to reducing the overall environmental footprint of production processes.

One of the key environmental benefits of ethyl acetate is its biodegradability. Unlike many synthetic solvents, ethyl acetate can be broken down naturally by microorganisms in the environment, reducing its long-term impact on ecosystems. This characteristic makes it a preferred choice for industries seeking to minimize their environmental impact and align with sustainability goals.

Furthermore, ethyl acetate has a relatively low toxicity profile compared to other solvents commonly used in industrial applications. This reduced toxicity translates to fewer harmful effects on aquatic life and terrestrial ecosystems in case of accidental spills or releases. The lower environmental risk associated with ethyl acetate contributes to the overall sustainability of supply chains by minimizing potential ecological damage.

In terms of air quality, ethyl acetate has a lower volatile organic compound (VOC) content compared to many alternative solvents. This property results in reduced emissions during production, transportation, and application processes, leading to improved air quality and decreased contribution to smog formation. The lower VOC emissions align with increasingly stringent environmental regulations and help companies meet their sustainability targets.

Ethyl acetate's production process also offers environmental advantages. It can be synthesized from renewable resources such as ethanol derived from biomass, providing a more sustainable alternative to petroleum-based solvents. This bio-based production route reduces dependence on fossil fuels and contributes to the circular economy by utilizing renewable feedstocks.

Additionally, ethyl acetate's high solvency power allows for efficient extraction and purification processes in various industries, including pharmaceuticals and food production. This efficiency translates to reduced energy consumption and waste generation, further enhancing the sustainability of supply chains.

The recyclability of ethyl acetate is another crucial factor in its environmental impact. Many industries have implemented solvent recovery systems that allow for the recapture and reuse of ethyl acetate, significantly reducing waste and the need for continuous production of new solvent. This closed-loop approach aligns with circular economy principles and helps minimize the overall environmental footprint of industrial processes.

In conclusion, ethyl acetate's environmental impact supports sustainable supply chains through its biodegradability, low toxicity, reduced VOC emissions, potential for bio-based production, process efficiency, and recyclability. These characteristics make it an attractive option for industries seeking to improve their environmental performance and meet sustainability goals throughout their supply chains.

One of the key environmental benefits of ethyl acetate is its biodegradability. Unlike many synthetic solvents, ethyl acetate can be broken down naturally by microorganisms in the environment, reducing its long-term impact on ecosystems. This characteristic makes it a preferred choice for industries seeking to minimize their environmental impact and align with sustainability goals.

Furthermore, ethyl acetate has a relatively low toxicity profile compared to other solvents commonly used in industrial applications. This reduced toxicity translates to fewer harmful effects on aquatic life and terrestrial ecosystems in case of accidental spills or releases. The lower environmental risk associated with ethyl acetate contributes to the overall sustainability of supply chains by minimizing potential ecological damage.

In terms of air quality, ethyl acetate has a lower volatile organic compound (VOC) content compared to many alternative solvents. This property results in reduced emissions during production, transportation, and application processes, leading to improved air quality and decreased contribution to smog formation. The lower VOC emissions align with increasingly stringent environmental regulations and help companies meet their sustainability targets.

Ethyl acetate's production process also offers environmental advantages. It can be synthesized from renewable resources such as ethanol derived from biomass, providing a more sustainable alternative to petroleum-based solvents. This bio-based production route reduces dependence on fossil fuels and contributes to the circular economy by utilizing renewable feedstocks.

Additionally, ethyl acetate's high solvency power allows for efficient extraction and purification processes in various industries, including pharmaceuticals and food production. This efficiency translates to reduced energy consumption and waste generation, further enhancing the sustainability of supply chains.

The recyclability of ethyl acetate is another crucial factor in its environmental impact. Many industries have implemented solvent recovery systems that allow for the recapture and reuse of ethyl acetate, significantly reducing waste and the need for continuous production of new solvent. This closed-loop approach aligns with circular economy principles and helps minimize the overall environmental footprint of industrial processes.

In conclusion, ethyl acetate's environmental impact supports sustainable supply chains through its biodegradability, low toxicity, reduced VOC emissions, potential for bio-based production, process efficiency, and recyclability. These characteristics make it an attractive option for industries seeking to improve their environmental performance and meet sustainability goals throughout their supply chains.

Regulatory Framework

The regulatory framework surrounding ethyl acetate plays a crucial role in shaping its use and impact on sustainable supply chains. As a solvent widely used in various industries, ethyl acetate is subject to a complex web of regulations at national and international levels.

In the United States, the Environmental Protection Agency (EPA) regulates ethyl acetate under the Toxic Substances Control Act (TSCA). The substance is listed on the TSCA inventory and is subject to reporting requirements for manufacturers and importers. Additionally, the Occupational Safety and Health Administration (OSHA) sets permissible exposure limits for workers handling ethyl acetate in industrial settings.

The European Union has implemented REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, which require manufacturers and importers to register ethyl acetate and provide safety data. The European Chemicals Agency (ECHA) oversees this process and ensures compliance with safety standards.

In Asia, countries like China and Japan have their own regulatory frameworks. China's Ministry of Ecology and Environment regulates ethyl acetate under the Measures for Environmental Management of New Chemical Substances. Japan's Chemical Substances Control Law (CSCL) governs the manufacture, import, and use of ethyl acetate.

Globally, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards, including those associated with ethyl acetate. This system facilitates international trade and enhances safety across borders.

Regulations also extend to the transportation of ethyl acetate. The International Maritime Dangerous Goods (IMDG) Code classifies it as a flammable liquid, imposing specific requirements for its shipping by sea. Similarly, air transport is governed by the International Air Transport Association's (IATA) Dangerous Goods Regulations.

As sustainability becomes increasingly important, regulations are evolving to promote greener practices. Some jurisdictions are implementing incentives for bio-based ethyl acetate production or mandating the use of recycled solvents in certain applications. These regulatory shifts are driving innovation in sustainable supply chains, encouraging manufacturers to explore eco-friendly alternatives and circular economy models.

The regulatory landscape for ethyl acetate is dynamic, with ongoing revisions and updates to existing frameworks. Companies operating in global supply chains must navigate this complex regulatory environment, ensuring compliance across multiple jurisdictions while striving for sustainability goals. This regulatory framework not only ensures safety and environmental protection but also shapes the future of ethyl acetate's role in sustainable supply chains.

In the United States, the Environmental Protection Agency (EPA) regulates ethyl acetate under the Toxic Substances Control Act (TSCA). The substance is listed on the TSCA inventory and is subject to reporting requirements for manufacturers and importers. Additionally, the Occupational Safety and Health Administration (OSHA) sets permissible exposure limits for workers handling ethyl acetate in industrial settings.

The European Union has implemented REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, which require manufacturers and importers to register ethyl acetate and provide safety data. The European Chemicals Agency (ECHA) oversees this process and ensures compliance with safety standards.

In Asia, countries like China and Japan have their own regulatory frameworks. China's Ministry of Ecology and Environment regulates ethyl acetate under the Measures for Environmental Management of New Chemical Substances. Japan's Chemical Substances Control Law (CSCL) governs the manufacture, import, and use of ethyl acetate.

Globally, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards, including those associated with ethyl acetate. This system facilitates international trade and enhances safety across borders.

Regulations also extend to the transportation of ethyl acetate. The International Maritime Dangerous Goods (IMDG) Code classifies it as a flammable liquid, imposing specific requirements for its shipping by sea. Similarly, air transport is governed by the International Air Transport Association's (IATA) Dangerous Goods Regulations.

As sustainability becomes increasingly important, regulations are evolving to promote greener practices. Some jurisdictions are implementing incentives for bio-based ethyl acetate production or mandating the use of recycled solvents in certain applications. These regulatory shifts are driving innovation in sustainable supply chains, encouraging manufacturers to explore eco-friendly alternatives and circular economy models.

The regulatory landscape for ethyl acetate is dynamic, with ongoing revisions and updates to existing frameworks. Companies operating in global supply chains must navigate this complex regulatory environment, ensuring compliance across multiple jurisdictions while striving for sustainability goals. This regulatory framework not only ensures safety and environmental protection but also shapes the future of ethyl acetate's role in sustainable supply chains.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!