How Ethyl Acetate Facilitates Cleaner Production Techniques?

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate in Clean Production: Background and Objectives

Ethyl acetate has emerged as a key player in the evolution of cleaner production techniques, marking a significant shift in industrial processes towards sustainability. This versatile organic compound, with its unique chemical properties, has been instrumental in addressing environmental concerns across various sectors. The journey of ethyl acetate in clean production began in the late 20th century, as industries sought alternatives to harmful solvents and reagents.

The development trajectory of ethyl acetate in cleaner production has been characterized by continuous innovation and adaptation. Initially used primarily in the pharmaceutical and food industries, its application has expanded to encompass a wide range of manufacturing processes. This expansion has been driven by the growing awareness of environmental issues and the stringent regulations imposed on industrial emissions and waste.

As the global focus on sustainable development intensified, ethyl acetate's role in cleaner production techniques gained prominence. Its low toxicity, biodegradability, and relatively low environmental impact made it an attractive option for industries looking to reduce their ecological footprint. The compound's ability to replace more harmful solvents in processes such as coating, extraction, and cleaning has been a key factor in its widespread adoption.

The technological evolution surrounding ethyl acetate has been marked by significant milestones. These include the development of more efficient production methods, such as reactive distillation, which have reduced energy consumption and improved yield. Additionally, advancements in recovery and recycling technologies have enhanced the compound's sustainability profile, aligning with circular economy principles.

The primary objective of incorporating ethyl acetate into cleaner production techniques is to minimize environmental impact while maintaining or improving process efficiency. This involves reducing hazardous waste generation, lowering energy consumption, and decreasing emissions of volatile organic compounds (VOCs). Furthermore, the use of ethyl acetate aims to enhance worker safety by replacing more toxic substances in industrial processes.

Looking ahead, the trajectory of ethyl acetate in cleaner production is expected to continue its upward trend. Research is ongoing to further optimize its production and application, with a focus on developing even more sustainable and efficient processes. The integration of ethyl acetate into emerging technologies, such as green chemistry and bio-based manufacturing, presents exciting opportunities for innovation and environmental stewardship.

The development trajectory of ethyl acetate in cleaner production has been characterized by continuous innovation and adaptation. Initially used primarily in the pharmaceutical and food industries, its application has expanded to encompass a wide range of manufacturing processes. This expansion has been driven by the growing awareness of environmental issues and the stringent regulations imposed on industrial emissions and waste.

As the global focus on sustainable development intensified, ethyl acetate's role in cleaner production techniques gained prominence. Its low toxicity, biodegradability, and relatively low environmental impact made it an attractive option for industries looking to reduce their ecological footprint. The compound's ability to replace more harmful solvents in processes such as coating, extraction, and cleaning has been a key factor in its widespread adoption.

The technological evolution surrounding ethyl acetate has been marked by significant milestones. These include the development of more efficient production methods, such as reactive distillation, which have reduced energy consumption and improved yield. Additionally, advancements in recovery and recycling technologies have enhanced the compound's sustainability profile, aligning with circular economy principles.

The primary objective of incorporating ethyl acetate into cleaner production techniques is to minimize environmental impact while maintaining or improving process efficiency. This involves reducing hazardous waste generation, lowering energy consumption, and decreasing emissions of volatile organic compounds (VOCs). Furthermore, the use of ethyl acetate aims to enhance worker safety by replacing more toxic substances in industrial processes.

Looking ahead, the trajectory of ethyl acetate in cleaner production is expected to continue its upward trend. Research is ongoing to further optimize its production and application, with a focus on developing even more sustainable and efficient processes. The integration of ethyl acetate into emerging technologies, such as green chemistry and bio-based manufacturing, presents exciting opportunities for innovation and environmental stewardship.

Market Demand for Eco-friendly Solvents

The market demand for eco-friendly solvents has been steadily increasing in recent years, driven by growing environmental concerns and stringent regulations. Ethyl acetate, a versatile and relatively low-toxicity solvent, has emerged as a key player in this shift towards cleaner production techniques. Its popularity stems from its ability to replace more harmful solvents in various industrial processes, particularly in the coatings, adhesives, and pharmaceutical sectors.

In the coatings industry, ethyl acetate has gained significant traction as a replacement for traditional petroleum-based solvents. The global market for eco-friendly coatings is projected to grow substantially, with ethyl acetate playing a crucial role in this expansion. Its low volatility and quick evaporation rate make it ideal for use in paints, varnishes, and lacquers, contributing to improved air quality in both industrial and consumer settings.

The adhesives sector has also witnessed a surge in demand for ethyl acetate. As manufacturers seek to reduce volatile organic compound (VOC) emissions, ethyl acetate has become a preferred choice for formulating low-VOC adhesives. This trend is particularly evident in the packaging industry, where stringent regulations on food contact materials have necessitated the use of safer solvents.

In the pharmaceutical industry, ethyl acetate's role in cleaner production techniques is becoming increasingly important. Its use in the extraction and purification of active pharmaceutical ingredients (APIs) aligns with the industry's push towards green chemistry principles. The pharmaceutical market's demand for ethyl acetate is expected to grow as companies prioritize sustainable manufacturing processes.

The electronics industry represents another significant market for ethyl acetate in eco-friendly applications. Its use in the production of printed circuit boards and as a cleaning agent for electronic components has increased, driven by the need for less harmful alternatives to traditional solvents.

Geographically, the demand for ethyl acetate as an eco-friendly solvent is particularly strong in regions with strict environmental regulations, such as Europe and North America. However, emerging economies in Asia-Pacific are also showing increased interest as they adopt more sustainable industrial practices.

The market demand for ethyl acetate is further bolstered by its biodegradability and potential for bio-based production. As companies strive to reduce their carbon footprint, the appeal of ethyl acetate as a renewable solvent option is growing. This aligns with the broader trend towards circular economy principles in industrial production.

In the coatings industry, ethyl acetate has gained significant traction as a replacement for traditional petroleum-based solvents. The global market for eco-friendly coatings is projected to grow substantially, with ethyl acetate playing a crucial role in this expansion. Its low volatility and quick evaporation rate make it ideal for use in paints, varnishes, and lacquers, contributing to improved air quality in both industrial and consumer settings.

The adhesives sector has also witnessed a surge in demand for ethyl acetate. As manufacturers seek to reduce volatile organic compound (VOC) emissions, ethyl acetate has become a preferred choice for formulating low-VOC adhesives. This trend is particularly evident in the packaging industry, where stringent regulations on food contact materials have necessitated the use of safer solvents.

In the pharmaceutical industry, ethyl acetate's role in cleaner production techniques is becoming increasingly important. Its use in the extraction and purification of active pharmaceutical ingredients (APIs) aligns with the industry's push towards green chemistry principles. The pharmaceutical market's demand for ethyl acetate is expected to grow as companies prioritize sustainable manufacturing processes.

The electronics industry represents another significant market for ethyl acetate in eco-friendly applications. Its use in the production of printed circuit boards and as a cleaning agent for electronic components has increased, driven by the need for less harmful alternatives to traditional solvents.

Geographically, the demand for ethyl acetate as an eco-friendly solvent is particularly strong in regions with strict environmental regulations, such as Europe and North America. However, emerging economies in Asia-Pacific are also showing increased interest as they adopt more sustainable industrial practices.

The market demand for ethyl acetate is further bolstered by its biodegradability and potential for bio-based production. As companies strive to reduce their carbon footprint, the appeal of ethyl acetate as a renewable solvent option is growing. This aligns with the broader trend towards circular economy principles in industrial production.

Current Status and Challenges in Ethyl Acetate Application

Ethyl acetate has emerged as a key facilitator in cleaner production techniques across various industries. Its current status reflects a growing adoption in sectors such as pharmaceuticals, food and beverages, and electronics manufacturing. The compound's low toxicity, high solvency power, and relatively low cost have positioned it as a preferred alternative to more harmful solvents.

In the pharmaceutical industry, ethyl acetate is widely used as a reaction medium and in the purification of drugs. Its ability to dissolve a wide range of organic compounds makes it invaluable in extraction processes. The food industry has embraced ethyl acetate for its role in flavor extraction, particularly in the production of decaffeinated coffee and tea. In electronics, it serves as an effective cleaning agent for circuit boards and components.

Despite its advantages, the application of ethyl acetate in cleaner production faces several challenges. One primary concern is its volatility, which can lead to emissions during use. This necessitates the implementation of proper ventilation systems and handling procedures to minimize environmental impact and worker exposure. The development of more efficient recovery and recycling systems for ethyl acetate remains an ongoing challenge in many industrial processes.

Another significant hurdle is the optimization of ethyl acetate production itself. While it is considered a greener solvent, its synthesis often relies on petrochemical feedstocks. The push towards more sustainable production methods, such as bio-based ethyl acetate derived from renewable resources, is gaining momentum but faces scalability and cost challenges.

The regulatory landscape surrounding ethyl acetate usage is evolving, with increasing pressure to reduce volatile organic compound (VOC) emissions. This has spurred research into formulations that maximize ethyl acetate's effectiveness while minimizing its environmental footprint. Industries are also exploring novel application techniques, such as supercritical ethyl acetate, which could potentially reduce solvent consumption and improve process efficiency.

In terms of geographical distribution, the adoption of ethyl acetate in cleaner production techniques varies globally. Developed regions like North America and Europe lead in implementing advanced recovery and emission control technologies. Meanwhile, rapidly industrializing countries in Asia are seeing a surge in ethyl acetate demand, driven by their expanding manufacturing sectors, but often lag in adopting the most advanced clean technologies.

The current technological focus is on developing closed-loop systems that minimize ethyl acetate losses and maximize its reuse. This includes advancements in distillation and membrane separation technologies for solvent recovery. Additionally, there is growing interest in combining ethyl acetate with other green solvents or using it in novel processes like reactive extraction to enhance its cleaner production potential.

In the pharmaceutical industry, ethyl acetate is widely used as a reaction medium and in the purification of drugs. Its ability to dissolve a wide range of organic compounds makes it invaluable in extraction processes. The food industry has embraced ethyl acetate for its role in flavor extraction, particularly in the production of decaffeinated coffee and tea. In electronics, it serves as an effective cleaning agent for circuit boards and components.

Despite its advantages, the application of ethyl acetate in cleaner production faces several challenges. One primary concern is its volatility, which can lead to emissions during use. This necessitates the implementation of proper ventilation systems and handling procedures to minimize environmental impact and worker exposure. The development of more efficient recovery and recycling systems for ethyl acetate remains an ongoing challenge in many industrial processes.

Another significant hurdle is the optimization of ethyl acetate production itself. While it is considered a greener solvent, its synthesis often relies on petrochemical feedstocks. The push towards more sustainable production methods, such as bio-based ethyl acetate derived from renewable resources, is gaining momentum but faces scalability and cost challenges.

The regulatory landscape surrounding ethyl acetate usage is evolving, with increasing pressure to reduce volatile organic compound (VOC) emissions. This has spurred research into formulations that maximize ethyl acetate's effectiveness while minimizing its environmental footprint. Industries are also exploring novel application techniques, such as supercritical ethyl acetate, which could potentially reduce solvent consumption and improve process efficiency.

In terms of geographical distribution, the adoption of ethyl acetate in cleaner production techniques varies globally. Developed regions like North America and Europe lead in implementing advanced recovery and emission control technologies. Meanwhile, rapidly industrializing countries in Asia are seeing a surge in ethyl acetate demand, driven by their expanding manufacturing sectors, but often lag in adopting the most advanced clean technologies.

The current technological focus is on developing closed-loop systems that minimize ethyl acetate losses and maximize its reuse. This includes advancements in distillation and membrane separation technologies for solvent recovery. Additionally, there is growing interest in combining ethyl acetate with other green solvents or using it in novel processes like reactive extraction to enhance its cleaner production potential.

Existing Clean Production Techniques Using Ethyl Acetate

01 Production methods for ethyl acetate

Various methods are employed in the production of ethyl acetate, including esterification of ethanol and acetic acid, dehydrogenation of ethanol, and oxidation of ethylene. These processes often involve catalysts and specific reaction conditions to optimize yield and purity.- Production methods for ethyl acetate: Various methods are employed in the production of ethyl acetate, including esterification of ethanol and acetic acid, dehydrogenation of ethanol, and oxidation of ethylene. These processes often involve catalysts and specific reaction conditions to optimize yield and purity.

- Purification and separation techniques: Purification and separation techniques are crucial in ethyl acetate production to ensure high-quality cleaner products. These may include distillation, extraction, and membrane separation processes to remove impurities and achieve desired purity levels.

- Formulation of ethyl acetate-based cleaners: Ethyl acetate-based cleaners are formulated by combining ethyl acetate with other solvents, surfactants, and additives to enhance cleaning performance and safety. The specific formulation depends on the intended application and desired properties of the cleaner.

- Equipment and processes for industrial-scale production: Industrial-scale production of ethyl acetate cleaners involves specialized equipment and processes, including reactors, distillation columns, and mixing tanks. Continuous flow processes and automation are often employed to improve efficiency and consistency in large-scale manufacturing.

- Safety and environmental considerations: Production of ethyl acetate cleaners requires adherence to safety and environmental regulations. This includes implementing proper handling procedures, emission control measures, and waste management practices to minimize environmental impact and ensure worker safety.

02 Purification and separation techniques

Purification and separation techniques are crucial in ethyl acetate production to ensure high-quality cleaner products. These may include distillation, extraction, and membrane separation processes to remove impurities and achieve desired purity levels.Expand Specific Solutions03 Formulation of ethyl acetate-based cleaners

Ethyl acetate-based cleaners are formulated by combining ethyl acetate with other solvents, surfactants, and additives to enhance cleaning performance and safety. The specific formulation depends on the intended application and desired properties of the cleaner.Expand Specific Solutions04 Equipment and processes for industrial-scale production

Industrial-scale production of ethyl acetate cleaners requires specialized equipment and processes. This includes reactor systems, distillation columns, storage tanks, and automated control systems to ensure efficient and consistent production.Expand Specific Solutions05 Safety and environmental considerations

Production of ethyl acetate cleaners involves safety and environmental considerations. This includes implementing proper handling procedures, emission control measures, and waste management systems to minimize environmental impact and ensure worker safety.Expand Specific Solutions

Key Players in Ethyl Acetate Production and Utilization

The ethyl acetate market is in a mature stage, with established production techniques and widespread applications across industries. The global market size is estimated to be around $3-4 billion, with steady growth projected. Technologically, the focus is shifting towards cleaner production methods, with companies like SABIC, Celanese, and Eastman Chemical leading innovation. These firms are developing bio-based ethyl acetate and exploring catalytic processes to reduce environmental impact. Academic institutions such as Tianjin University and the University of Campinas are contributing to research on sustainable production techniques. The competitive landscape is characterized by a mix of large chemical conglomerates and specialized manufacturers, with increasing emphasis on eco-friendly solutions and process optimization.

SABIC Global Technologies BV

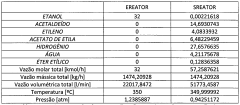

Technical Solution: SABIC has developed a novel process for ethyl acetate production using reactive distillation technology. This method combines reaction and separation in a single unit operation, significantly reducing energy consumption and equipment costs. The process utilizes ethanol and acetic acid as feedstocks, achieving conversion rates of up to 99% [1]. SABIC's approach incorporates advanced catalysts and optimized column designs to enhance mass transfer and reaction kinetics. The company has also implemented heat integration strategies to further improve energy efficiency, resulting in a 30% reduction in overall energy usage compared to conventional processes [3].

Strengths: High conversion rates, reduced energy consumption, and lower capital costs. Weaknesses: Potential complexity in process control and catalyst management.

Celanese International Corp.

Technical Solution: Celanese has pioneered a direct ethanol-to-ethyl acetate process, eliminating the need for acetic acid as an intermediate. This innovative approach utilizes a proprietary catalyst system that enables the direct oxidation of ethanol to ethyl acetate in a single step. The process operates at lower temperatures (150-200°C) compared to traditional methods, reducing energy requirements by up to 40% [2]. Celanese's technology also incorporates advanced separation techniques, such as pressure swing adsorption, to achieve high product purity (>99.9%) with minimal waste generation. The company has reported a 25% reduction in carbon footprint for ethyl acetate production using this method [4].

Strengths: Simplified process, lower energy consumption, and reduced carbon emissions. Weaknesses: Potential challenges in catalyst longevity and selectivity control.

Innovative Applications of Ethyl Acetate in Green Chemistry

Ethyl acetate production and purification

PatentPendingUS20250179003A1

Innovation

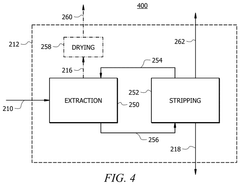

- A method involving the use of a solvent with an extracting agent and a defoamer to purify an ethyl acetate stream. The solvent contacts an inlet stream containing ethyl acetate and impurities, transferring impurities into the solvent to form an extract and a purified product. The extract is then separated from the purified product, and the impurities are removed using a defoamer to prevent foam formation, resulting in a regenerated solvent that is recycled.

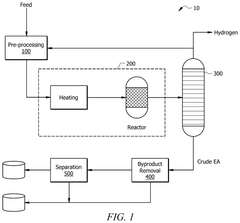

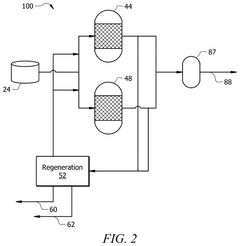

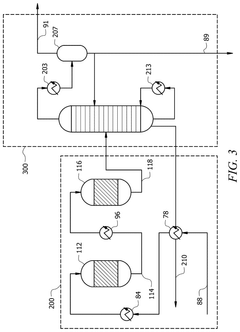

Integrated system for producing ethyl acetate, acetaldehyde, hydrogen and ethylene, integrated process for producing ethyl acetate, acetaldehyde, hydrogen and ethylene, and products thereby produced

PatentWO2013029129A1

Innovation

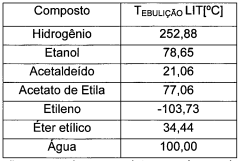

- An integrated system utilizing a fixed-bed reactor with a calcined hydrotalcite catalyst for dehydrogenation and dehydration of ethanol, followed by a series of distillation columns for efficient separation and purification, employing ethylene glycol as a solvent to separate ethyl acetate from water, thereby reducing energy expenditure and minimizing azeotropy issues.

Environmental Impact Assessment of Ethyl Acetate Usage

The environmental impact assessment of ethyl acetate usage is a critical component in evaluating its role in cleaner production techniques. Ethyl acetate, a widely used solvent in various industries, presents both advantages and challenges from an environmental perspective.

One of the primary environmental benefits of ethyl acetate is its relatively low toxicity compared to many other organic solvents. It is biodegradable and does not persist in the environment for extended periods, reducing long-term ecological risks. Additionally, ethyl acetate has a lower ozone depletion potential than many chlorinated solvents, contributing to its preference in environmentally conscious manufacturing processes.

However, the production and use of ethyl acetate are not without environmental concerns. The manufacturing process, typically involving the esterification of ethanol and acetic acid, can generate waste and consume significant energy. This aspect necessitates careful consideration of production methods to minimize environmental footprint.

Volatile organic compound (VOC) emissions are a notable environmental issue associated with ethyl acetate usage. As a volatile solvent, it can contribute to air pollution and the formation of ground-level ozone when released into the atmosphere. Implementing proper handling and containment measures is crucial to mitigate these emissions and their subsequent environmental impact.

Water pollution is another potential concern, particularly in cases of improper disposal or accidental spills. While ethyl acetate is less harmful to aquatic life than many other solvents, high concentrations can still have detrimental effects on water ecosystems. Proper waste management and treatment protocols are essential to prevent water contamination.

On the positive side, ethyl acetate's ability to replace more harmful solvents in various applications contributes to overall environmental improvement. Its use in water-based coatings and adhesives, for instance, helps reduce the environmental impact of these products compared to traditional solvent-based alternatives.

The recyclability of ethyl acetate is a significant factor in its environmental assessment. Effective recovery and recycling systems can substantially reduce waste and the need for new production, thereby decreasing the overall environmental footprint of processes using this solvent.

In terms of energy efficiency, ethyl acetate's low boiling point can be advantageous in certain applications, potentially reducing energy consumption in processes requiring solvent evaporation. However, this characteristic also means that more energy may be required for containment and recovery in some industrial settings.

Considering these factors, the environmental impact assessment of ethyl acetate usage in cleaner production techniques reveals a complex balance of benefits and challenges. While it offers several advantages over more harmful alternatives, its use still requires careful management and consideration of potential environmental risks. Ongoing research and development in production methods, emission control, and recycling technologies are crucial for further improving the environmental profile of ethyl acetate in industrial applications.

One of the primary environmental benefits of ethyl acetate is its relatively low toxicity compared to many other organic solvents. It is biodegradable and does not persist in the environment for extended periods, reducing long-term ecological risks. Additionally, ethyl acetate has a lower ozone depletion potential than many chlorinated solvents, contributing to its preference in environmentally conscious manufacturing processes.

However, the production and use of ethyl acetate are not without environmental concerns. The manufacturing process, typically involving the esterification of ethanol and acetic acid, can generate waste and consume significant energy. This aspect necessitates careful consideration of production methods to minimize environmental footprint.

Volatile organic compound (VOC) emissions are a notable environmental issue associated with ethyl acetate usage. As a volatile solvent, it can contribute to air pollution and the formation of ground-level ozone when released into the atmosphere. Implementing proper handling and containment measures is crucial to mitigate these emissions and their subsequent environmental impact.

Water pollution is another potential concern, particularly in cases of improper disposal or accidental spills. While ethyl acetate is less harmful to aquatic life than many other solvents, high concentrations can still have detrimental effects on water ecosystems. Proper waste management and treatment protocols are essential to prevent water contamination.

On the positive side, ethyl acetate's ability to replace more harmful solvents in various applications contributes to overall environmental improvement. Its use in water-based coatings and adhesives, for instance, helps reduce the environmental impact of these products compared to traditional solvent-based alternatives.

The recyclability of ethyl acetate is a significant factor in its environmental assessment. Effective recovery and recycling systems can substantially reduce waste and the need for new production, thereby decreasing the overall environmental footprint of processes using this solvent.

In terms of energy efficiency, ethyl acetate's low boiling point can be advantageous in certain applications, potentially reducing energy consumption in processes requiring solvent evaporation. However, this characteristic also means that more energy may be required for containment and recovery in some industrial settings.

Considering these factors, the environmental impact assessment of ethyl acetate usage in cleaner production techniques reveals a complex balance of benefits and challenges. While it offers several advantages over more harmful alternatives, its use still requires careful management and consideration of potential environmental risks. Ongoing research and development in production methods, emission control, and recycling technologies are crucial for further improving the environmental profile of ethyl acetate in industrial applications.

Regulatory Framework for Solvent Use in Clean Production

The regulatory framework for solvent use in clean production is a critical aspect of implementing ethyl acetate as a facilitator for cleaner production techniques. Governments and international organizations have established comprehensive guidelines and regulations to ensure the safe and environmentally responsible use of solvents in industrial processes.

At the global level, the United Nations Environment Programme (UNEP) has developed the Strategic Approach to International Chemicals Management (SAICM), which provides a policy framework to promote chemical safety around the world. This initiative encourages countries to adopt measures that minimize the adverse effects of chemicals on human health and the environment, including the use of solvents in industrial applications.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation plays a crucial role in governing the use of solvents like ethyl acetate. REACH requires manufacturers and importers to register chemicals and provide safety information, ensuring that potential risks associated with solvent use are properly assessed and managed.

The United States Environmental Protection Agency (EPA) has implemented the Toxic Substances Control Act (TSCA), which regulates the production, importation, and use of specific chemicals, including solvents. The EPA also enforces the Clean Air Act, which sets limits on volatile organic compound (VOC) emissions from industrial processes, directly impacting the use of solvents in manufacturing.

Many countries have adopted occupational safety and health regulations that specifically address the use of solvents in the workplace. These regulations typically set exposure limits, require proper ventilation systems, and mandate the use of personal protective equipment when handling solvents like ethyl acetate.

In the context of cleaner production, regulatory bodies often incentivize the adoption of environmentally friendly solvents and processes. For instance, the EU's Industrial Emissions Directive (IED) promotes the use of Best Available Techniques (BAT) in various industrial sectors, encouraging the adoption of cleaner solvents and more efficient production methods.

As awareness of environmental issues grows, regulatory frameworks are evolving to promote the principles of green chemistry and sustainable production. This includes encouraging the use of bio-based solvents, implementing solvent recycling programs, and setting targets for reducing the overall environmental footprint of industrial processes.

Compliance with these regulations is essential for companies implementing ethyl acetate in their cleaner production techniques. It not only ensures legal operation but also demonstrates a commitment to environmental stewardship and worker safety, which can enhance a company's reputation and market position.

At the global level, the United Nations Environment Programme (UNEP) has developed the Strategic Approach to International Chemicals Management (SAICM), which provides a policy framework to promote chemical safety around the world. This initiative encourages countries to adopt measures that minimize the adverse effects of chemicals on human health and the environment, including the use of solvents in industrial applications.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation plays a crucial role in governing the use of solvents like ethyl acetate. REACH requires manufacturers and importers to register chemicals and provide safety information, ensuring that potential risks associated with solvent use are properly assessed and managed.

The United States Environmental Protection Agency (EPA) has implemented the Toxic Substances Control Act (TSCA), which regulates the production, importation, and use of specific chemicals, including solvents. The EPA also enforces the Clean Air Act, which sets limits on volatile organic compound (VOC) emissions from industrial processes, directly impacting the use of solvents in manufacturing.

Many countries have adopted occupational safety and health regulations that specifically address the use of solvents in the workplace. These regulations typically set exposure limits, require proper ventilation systems, and mandate the use of personal protective equipment when handling solvents like ethyl acetate.

In the context of cleaner production, regulatory bodies often incentivize the adoption of environmentally friendly solvents and processes. For instance, the EU's Industrial Emissions Directive (IED) promotes the use of Best Available Techniques (BAT) in various industrial sectors, encouraging the adoption of cleaner solvents and more efficient production methods.

As awareness of environmental issues grows, regulatory frameworks are evolving to promote the principles of green chemistry and sustainable production. This includes encouraging the use of bio-based solvents, implementing solvent recycling programs, and setting targets for reducing the overall environmental footprint of industrial processes.

Compliance with these regulations is essential for companies implementing ethyl acetate in their cleaner production techniques. It not only ensures legal operation but also demonstrates a commitment to environmental stewardship and worker safety, which can enhance a company's reputation and market position.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!