How to Utilize Ethyl Acetate for Environmentally Safe Adhesives?

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate Adhesives: Background and Objectives

Ethyl acetate has emerged as a promising candidate in the development of environmentally safe adhesives, marking a significant shift in the adhesive industry's approach to sustainability. The evolution of adhesive technology has been driven by the growing demand for eco-friendly alternatives to traditional, petroleum-based adhesives that often contain volatile organic compounds (VOCs) and pose environmental risks.

The journey towards green adhesives began in the late 20th century, as awareness of environmental issues increased. Initially, water-based adhesives gained popularity as a more environmentally friendly option. However, these early alternatives often lacked the performance characteristics of their solvent-based counterparts. The search for a balance between environmental safety and adhesive efficacy led researchers to explore various bio-based materials, including ethyl acetate.

Ethyl acetate, a naturally occurring ester found in fruits and wines, has gained attention due to its low toxicity and biodegradability. Its potential as a key component in adhesive formulations aligns with the industry's goals of reducing environmental impact while maintaining or improving product performance. The use of ethyl acetate in adhesives represents a convergence of green chemistry principles and practical industrial applications.

The technical objectives for ethyl acetate-based adhesives are multifaceted. Primarily, researchers aim to develop formulations that offer strong bonding capabilities comparable to conventional adhesives. This includes achieving suitable viscosity, tack, and curing properties. Additionally, there is a focus on enhancing the stability and shelf life of these adhesives, ensuring they remain effective under various environmental conditions.

Another critical objective is to optimize the production process of ethyl acetate-based adhesives to make them economically viable on a large scale. This involves refining synthesis methods, exploring sustainable sources of raw materials, and developing efficient manufacturing techniques that minimize waste and energy consumption.

Furthermore, researchers are working towards expanding the application range of ethyl acetate adhesives. The goal is to create versatile formulations that can be used across various industries, from packaging and construction to electronics and automotive sectors. This requires tailoring the adhesive properties to meet specific industry standards and performance requirements.

As the adhesive industry continues to evolve, the development of ethyl acetate-based adhesives represents a significant step towards more sustainable practices. The technical challenges and objectives associated with this endeavor reflect the broader trend of integrating environmental considerations into product design and manufacturing processes, paving the way for a new generation of eco-friendly adhesive solutions.

The journey towards green adhesives began in the late 20th century, as awareness of environmental issues increased. Initially, water-based adhesives gained popularity as a more environmentally friendly option. However, these early alternatives often lacked the performance characteristics of their solvent-based counterparts. The search for a balance between environmental safety and adhesive efficacy led researchers to explore various bio-based materials, including ethyl acetate.

Ethyl acetate, a naturally occurring ester found in fruits and wines, has gained attention due to its low toxicity and biodegradability. Its potential as a key component in adhesive formulations aligns with the industry's goals of reducing environmental impact while maintaining or improving product performance. The use of ethyl acetate in adhesives represents a convergence of green chemistry principles and practical industrial applications.

The technical objectives for ethyl acetate-based adhesives are multifaceted. Primarily, researchers aim to develop formulations that offer strong bonding capabilities comparable to conventional adhesives. This includes achieving suitable viscosity, tack, and curing properties. Additionally, there is a focus on enhancing the stability and shelf life of these adhesives, ensuring they remain effective under various environmental conditions.

Another critical objective is to optimize the production process of ethyl acetate-based adhesives to make them economically viable on a large scale. This involves refining synthesis methods, exploring sustainable sources of raw materials, and developing efficient manufacturing techniques that minimize waste and energy consumption.

Furthermore, researchers are working towards expanding the application range of ethyl acetate adhesives. The goal is to create versatile formulations that can be used across various industries, from packaging and construction to electronics and automotive sectors. This requires tailoring the adhesive properties to meet specific industry standards and performance requirements.

As the adhesive industry continues to evolve, the development of ethyl acetate-based adhesives represents a significant step towards more sustainable practices. The technical challenges and objectives associated with this endeavor reflect the broader trend of integrating environmental considerations into product design and manufacturing processes, paving the way for a new generation of eco-friendly adhesive solutions.

Market Analysis for Eco-friendly Adhesive Solutions

The market for eco-friendly adhesive solutions has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations on volatile organic compounds (VOCs) emissions. The global green adhesives market is projected to reach $9.3 billion by 2026, with a compound annual growth rate of 5.8% from 2021 to 2026. This growth is primarily fueled by the rising demand for sustainable products across various industries, including packaging, construction, automotive, and consumer goods.

Ethyl acetate-based adhesives are gaining traction in this market due to their low toxicity and biodegradability. These adhesives offer a promising alternative to traditional solvent-based adhesives, which often contain harmful chemicals and contribute to air pollution. The packaging industry, in particular, has shown a strong interest in ethyl acetate-based adhesives, as they comply with food safety regulations and provide excellent bonding properties for flexible packaging materials.

The construction sector is another key driver for eco-friendly adhesives, with green building certifications like LEED (Leadership in Energy and Environmental Design) promoting the use of low-emission materials. Ethyl acetate-based adhesives align well with these standards, offering builders and contractors a sustainable option for various applications, including flooring, wall coverings, and insulation.

In the automotive industry, the shift towards electric vehicles and lightweight materials has created new opportunities for environmentally safe adhesives. Ethyl acetate-based solutions are being explored for their potential in bonding composite materials and reducing overall vehicle weight, contributing to improved fuel efficiency and reduced emissions.

Consumer preferences are also shaping the market landscape, with a growing segment of environmentally conscious consumers willing to pay a premium for sustainable products. This trend has led to increased demand for eco-friendly adhesives in consumer goods, particularly in the personal care and home improvement sectors.

Geographically, North America and Europe lead the market for eco-friendly adhesives, driven by strict environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by rapid industrialization, urbanization, and increasing adoption of green technologies in countries like China and India.

Despite the positive market outlook, challenges remain for ethyl acetate-based adhesives. These include the need for further research and development to improve performance characteristics, such as bond strength and durability, to match or exceed those of conventional adhesives. Additionally, the higher cost of production compared to traditional adhesives remains a barrier to widespread adoption, particularly in price-sensitive markets.

Ethyl acetate-based adhesives are gaining traction in this market due to their low toxicity and biodegradability. These adhesives offer a promising alternative to traditional solvent-based adhesives, which often contain harmful chemicals and contribute to air pollution. The packaging industry, in particular, has shown a strong interest in ethyl acetate-based adhesives, as they comply with food safety regulations and provide excellent bonding properties for flexible packaging materials.

The construction sector is another key driver for eco-friendly adhesives, with green building certifications like LEED (Leadership in Energy and Environmental Design) promoting the use of low-emission materials. Ethyl acetate-based adhesives align well with these standards, offering builders and contractors a sustainable option for various applications, including flooring, wall coverings, and insulation.

In the automotive industry, the shift towards electric vehicles and lightweight materials has created new opportunities for environmentally safe adhesives. Ethyl acetate-based solutions are being explored for their potential in bonding composite materials and reducing overall vehicle weight, contributing to improved fuel efficiency and reduced emissions.

Consumer preferences are also shaping the market landscape, with a growing segment of environmentally conscious consumers willing to pay a premium for sustainable products. This trend has led to increased demand for eco-friendly adhesives in consumer goods, particularly in the personal care and home improvement sectors.

Geographically, North America and Europe lead the market for eco-friendly adhesives, driven by strict environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by rapid industrialization, urbanization, and increasing adoption of green technologies in countries like China and India.

Despite the positive market outlook, challenges remain for ethyl acetate-based adhesives. These include the need for further research and development to improve performance characteristics, such as bond strength and durability, to match or exceed those of conventional adhesives. Additionally, the higher cost of production compared to traditional adhesives remains a barrier to widespread adoption, particularly in price-sensitive markets.

Current Challenges in Green Adhesive Technology

The development of green adhesives faces several significant challenges in the current technological landscape. One of the primary obstacles is achieving comparable performance to traditional petroleum-based adhesives while maintaining environmental sustainability. Many eco-friendly alternatives struggle to match the bonding strength, durability, and versatility of conventional adhesives, limiting their widespread adoption in various industries.

Another critical challenge is the cost-effectiveness of green adhesive production. The raw materials and manufacturing processes for environmentally safe adhesives often come with higher price tags, making them less competitive in the market. This economic barrier hinders the transition from conventional to green adhesive technologies, especially in price-sensitive sectors.

Stability and shelf life present additional hurdles for green adhesive technology. Many bio-based adhesives are prone to degradation over time, affecting their long-term performance and storage capabilities. This instability can lead to inconsistent product quality and reduced reliability, which are crucial factors in industrial applications.

The formulation of green adhesives also faces challenges in terms of compatibility with diverse substrates. Unlike traditional adhesives that have been optimized for a wide range of materials, eco-friendly alternatives often have limited versatility. Developing adhesives that can effectively bond different types of surfaces while maintaining their green credentials remains a significant technical challenge.

Regulatory compliance and standardization pose another set of challenges for green adhesive technology. The lack of unified global standards for eco-friendly adhesives creates confusion in the market and hinders their acceptance. Additionally, navigating the complex landscape of environmental regulations across different regions adds complexity to the development and commercialization of green adhesives.

The integration of green adhesives into existing manufacturing processes presents technical difficulties. Many industries have established production lines optimized for conventional adhesives, and the transition to eco-friendly alternatives often requires significant modifications to equipment and procedures. This adaptation process can be costly and time-consuming, deterring some manufacturers from making the switch.

Lastly, the challenge of scalability looms large in the green adhesive sector. While many promising eco-friendly adhesive technologies have been developed in laboratory settings, scaling up production to meet industrial demands without compromising environmental benefits or performance remains a significant hurdle. Overcoming these scaling issues is crucial for the widespread adoption of green adhesive technologies across various industries.

Another critical challenge is the cost-effectiveness of green adhesive production. The raw materials and manufacturing processes for environmentally safe adhesives often come with higher price tags, making them less competitive in the market. This economic barrier hinders the transition from conventional to green adhesive technologies, especially in price-sensitive sectors.

Stability and shelf life present additional hurdles for green adhesive technology. Many bio-based adhesives are prone to degradation over time, affecting their long-term performance and storage capabilities. This instability can lead to inconsistent product quality and reduced reliability, which are crucial factors in industrial applications.

The formulation of green adhesives also faces challenges in terms of compatibility with diverse substrates. Unlike traditional adhesives that have been optimized for a wide range of materials, eco-friendly alternatives often have limited versatility. Developing adhesives that can effectively bond different types of surfaces while maintaining their green credentials remains a significant technical challenge.

Regulatory compliance and standardization pose another set of challenges for green adhesive technology. The lack of unified global standards for eco-friendly adhesives creates confusion in the market and hinders their acceptance. Additionally, navigating the complex landscape of environmental regulations across different regions adds complexity to the development and commercialization of green adhesives.

The integration of green adhesives into existing manufacturing processes presents technical difficulties. Many industries have established production lines optimized for conventional adhesives, and the transition to eco-friendly alternatives often requires significant modifications to equipment and procedures. This adaptation process can be costly and time-consuming, deterring some manufacturers from making the switch.

Lastly, the challenge of scalability looms large in the green adhesive sector. While many promising eco-friendly adhesive technologies have been developed in laboratory settings, scaling up production to meet industrial demands without compromising environmental benefits or performance remains a significant hurdle. Overcoming these scaling issues is crucial for the widespread adoption of green adhesive technologies across various industries.

Existing Ethyl Acetate Adhesive Solutions

01 Biodegradable alternatives to ethyl acetate

Research focuses on developing environmentally friendly alternatives to ethyl acetate. These biodegradable substitutes aim to reduce environmental impact while maintaining similar functionality in various applications. Such alternatives may include bio-based solvents or compounds derived from renewable resources.- Biodegradable alternatives to ethyl acetate: Research focuses on developing environmentally friendly alternatives to ethyl acetate. These biodegradable substitutes aim to reduce environmental impact while maintaining similar solvent properties. Such alternatives may include bio-based solvents derived from renewable resources, which can be used in various industrial applications.

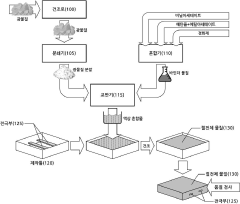

- Ethyl acetate recovery and recycling systems: Implementation of recovery and recycling systems for ethyl acetate in industrial processes. These systems aim to minimize environmental release and reduce waste by capturing and purifying used ethyl acetate for reuse. This approach helps to decrease the overall environmental footprint of processes involving ethyl acetate.

- Environmental monitoring and risk assessment: Development of methods and systems for monitoring ethyl acetate levels in the environment and assessing potential risks. This includes the use of sensors, data analysis techniques, and risk assessment models to evaluate the environmental impact of ethyl acetate use in various industries and guide safety measures.

- Green chemistry approaches for ethyl acetate production: Implementation of green chemistry principles in the production of ethyl acetate to enhance environmental safety. This involves using renewable feedstocks, optimizing reaction conditions to reduce energy consumption, and minimizing waste generation. These approaches aim to make ethyl acetate production more sustainable and environmentally friendly.

- Containment and disposal methods for ethyl acetate: Development of improved containment systems and disposal methods for ethyl acetate to prevent environmental contamination. This includes the design of specialized storage containers, spill prevention techniques, and environmentally safe disposal procedures. These methods aim to minimize the risk of accidental release and ensure proper handling of ethyl acetate throughout its lifecycle.

02 Ethyl acetate recovery and recycling systems

Implementation of recovery and recycling systems for ethyl acetate in industrial processes. These systems aim to minimize environmental release and promote sustainable use of the solvent. Methods may include distillation, adsorption, or membrane separation techniques to capture and reuse ethyl acetate.Expand Specific Solutions03 Emission control and waste management

Development of technologies and processes to control ethyl acetate emissions and manage waste containing the compound. This includes the use of scrubbers, catalytic oxidizers, or other air pollution control devices to reduce atmospheric release. Proper disposal and treatment methods for ethyl acetate-containing waste are also addressed.Expand Specific Solutions04 Safety measures in handling and storage

Implementation of safety protocols and equipment for the handling and storage of ethyl acetate to prevent environmental contamination. This includes the use of specialized containers, spill prevention systems, and proper ventilation to minimize accidental release and exposure risks.Expand Specific Solutions05 Environmental impact assessment and monitoring

Development of methods and tools for assessing and monitoring the environmental impact of ethyl acetate use. This includes the creation of sensors, analytical techniques, and modeling approaches to evaluate the compound's presence in air, water, and soil, as well as its effects on ecosystems and human health.Expand Specific Solutions

Key Players in Sustainable Adhesive Industry

The market for environmentally safe adhesives utilizing ethyl acetate is in a growth phase, driven by increasing environmental regulations and consumer demand for sustainable products. The global market size for eco-friendly adhesives is projected to reach several billion dollars by 2025. While the technology is advancing, it's not yet fully mature, with ongoing research to improve performance and cost-effectiveness. Key players like Dow Global Technologies, Wacker Chemie, and Henkel are investing heavily in R&D to develop innovative solutions. Smaller companies such as Forest Chemical Group and Alfa-Klebstoffe are also contributing to technological advancements. The competitive landscape is characterized by a mix of established chemical giants and specialized adhesive manufacturers, all vying for market share in this growing segment.

Dow Global Technologies LLC

Technical Solution: Dow has developed innovative technologies for utilizing ethyl acetate in environmentally safe adhesives. Their approach involves creating water-based adhesive formulations that incorporate ethyl acetate as a co-solvent, resulting in products with reduced VOC emissions and improved performance[1]. Dow's technology also includes the development of bio-based ethyl acetate derived from sustainable sources, which is used in their eco-friendly adhesive lines[2]. The company has introduced a series of pressure-sensitive adhesives that utilize ethyl acetate in combination with other green solvents, offering excellent adhesion properties while meeting strict environmental standards[3]. Additionally, Dow has implemented advanced manufacturing processes that optimize the use of ethyl acetate, minimizing waste and improving overall efficiency in adhesive production[4].

Strengths: Wide range of applications, use of bio-based materials, and optimized manufacturing processes. Weaknesses: Potential challenges in achieving the same level of performance as traditional solvent-based adhesives in some specialized applications.

Wacker Chemie AG

Technical Solution: Wacker Chemie has developed a unique approach to incorporating ethyl acetate into environmentally safe adhesives. Their technology focuses on creating silicone-based adhesives that utilize ethyl acetate as a key processing aid, resulting in products with excellent adhesion properties and low environmental impact[1]. The company has introduced a line of UV-curable silicone adhesives that incorporate ethyl acetate in their formulation, offering rapid curing and high performance while maintaining low VOC emissions[2]. Wacker's research has also led to the development of hybrid organic-silicone adhesives that use ethyl acetate as a solvent, combining the benefits of both chemical systems for improved durability and eco-friendliness[3]. Furthermore, the company has implemented a sophisticated solvent recovery system that allows for the efficient recycling of ethyl acetate used in the production process, significantly reducing waste and environmental impact[4].

Strengths: Unique silicone-based formulations, rapid curing technologies, and efficient solvent recovery. Weaknesses: Potentially higher costs compared to traditional adhesives and limited application in certain industries due to silicone content.

Innovations in Ethyl Acetate Adhesive Chemistry

Ethanol-soluble, electrically conductive adhesive

PatentInactiveEP2594619A1

Innovation

- An ethanol-soluble, electrically conductive adhesive composed of shellac, conductive metal particles (preferably silver flakes), and high-purity ethanol, which allows for strong bonding and easy removal without toxic chemicals by evaporating ethanol, enabling mechanical and electrical connection of flat materials to substrates and subsequent detachment.

Manufacturing Method and Compositions for Environment-Friendly Binder Material for Power Saver by using Ethanol and Ethyl Acetate

PatentInactiveKR1020200090328A

Innovation

- A binder material is formulated using vinyl acetate, ethanol, and ethyl acetate in specific ratios, mixed with mineral powders of 80-200 mesh, to create a power-saving material with enhanced compressive strength and dielectric properties, avoiding harmful substances.

Environmental Impact Assessment

The utilization of ethyl acetate in environmentally safe adhesives necessitates a comprehensive environmental impact assessment. This evaluation is crucial to understand the potential effects of ethyl acetate-based adhesives on ecosystems and human health throughout their lifecycle.

Ethyl acetate, when used in adhesive formulations, offers several environmental advantages over traditional solvent-based adhesives. Its low toxicity and biodegradability contribute to reduced ecological risks. However, the production and use of ethyl acetate still require careful consideration of potential environmental impacts.

During the manufacturing process, emissions of volatile organic compounds (VOCs) from ethyl acetate production must be monitored and controlled. While ethyl acetate is less harmful than many other solvents, it can still contribute to air pollution and smog formation if released in large quantities. Implementing proper emission control technologies and adhering to strict environmental regulations are essential to mitigate these risks.

Water pollution is another concern that needs to be addressed. Although ethyl acetate has low water solubility, any accidental releases during production or transportation could potentially contaminate water sources. Proper handling, storage, and disposal protocols must be established to prevent such incidents and protect aquatic ecosystems.

The use phase of ethyl acetate-based adhesives presents fewer environmental concerns compared to traditional adhesives. These formulations typically have lower VOC emissions during application and curing, reducing indoor air pollution and minimizing health risks for workers and end-users. Additionally, the improved biodegradability of ethyl acetate contributes to easier waste management and reduced environmental persistence.

End-of-life considerations for ethyl acetate-based adhesives are generally more favorable than those of conventional adhesives. The biodegradability of ethyl acetate facilitates natural breakdown in landfills or composting facilities, reducing long-term environmental impacts. However, proper disposal methods should still be encouraged to maximize these benefits and prevent any potential contamination.

Life cycle assessment (LCA) studies should be conducted to quantify the overall environmental impact of ethyl acetate-based adhesives compared to alternatives. These assessments should consider factors such as energy consumption, resource depletion, greenhouse gas emissions, and waste generation across all stages of the product lifecycle.

In conclusion, while ethyl acetate offers promising environmental benefits for adhesive applications, a thorough environmental impact assessment is crucial to ensure its sustainable use. By addressing potential risks and implementing appropriate mitigation measures, ethyl acetate-based adhesives can contribute to more environmentally friendly industrial practices.

Ethyl acetate, when used in adhesive formulations, offers several environmental advantages over traditional solvent-based adhesives. Its low toxicity and biodegradability contribute to reduced ecological risks. However, the production and use of ethyl acetate still require careful consideration of potential environmental impacts.

During the manufacturing process, emissions of volatile organic compounds (VOCs) from ethyl acetate production must be monitored and controlled. While ethyl acetate is less harmful than many other solvents, it can still contribute to air pollution and smog formation if released in large quantities. Implementing proper emission control technologies and adhering to strict environmental regulations are essential to mitigate these risks.

Water pollution is another concern that needs to be addressed. Although ethyl acetate has low water solubility, any accidental releases during production or transportation could potentially contaminate water sources. Proper handling, storage, and disposal protocols must be established to prevent such incidents and protect aquatic ecosystems.

The use phase of ethyl acetate-based adhesives presents fewer environmental concerns compared to traditional adhesives. These formulations typically have lower VOC emissions during application and curing, reducing indoor air pollution and minimizing health risks for workers and end-users. Additionally, the improved biodegradability of ethyl acetate contributes to easier waste management and reduced environmental persistence.

End-of-life considerations for ethyl acetate-based adhesives are generally more favorable than those of conventional adhesives. The biodegradability of ethyl acetate facilitates natural breakdown in landfills or composting facilities, reducing long-term environmental impacts. However, proper disposal methods should still be encouraged to maximize these benefits and prevent any potential contamination.

Life cycle assessment (LCA) studies should be conducted to quantify the overall environmental impact of ethyl acetate-based adhesives compared to alternatives. These assessments should consider factors such as energy consumption, resource depletion, greenhouse gas emissions, and waste generation across all stages of the product lifecycle.

In conclusion, while ethyl acetate offers promising environmental benefits for adhesive applications, a thorough environmental impact assessment is crucial to ensure its sustainable use. By addressing potential risks and implementing appropriate mitigation measures, ethyl acetate-based adhesives can contribute to more environmentally friendly industrial practices.

Regulatory Compliance for Green Adhesives

The regulatory landscape for green adhesives is becoming increasingly stringent, reflecting growing environmental concerns and the push towards sustainable manufacturing practices. In the context of utilizing ethyl acetate for environmentally safe adhesives, manufacturers must navigate a complex web of regulations that vary across regions and jurisdictions.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating adhesives through the Toxic Substances Control Act (TSCA) and the Clean Air Act. These regulations set limits on volatile organic compound (VOC) emissions and require manufacturers to report on the chemical composition of their products. The California Air Resources Board (CARB) has even stricter standards, which often set the benchmark for other states.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is another significant framework that adhesive manufacturers must comply with. REACH requires companies to register chemical substances and provide safety data, including information on environmental impact. The EU has also implemented the Classification, Labeling, and Packaging (CLP) Regulation, which harmonizes the criteria for classification of substances and mixtures.

In Asia, countries like Japan and South Korea have their own chemical control laws that mirror aspects of REACH. China has recently updated its Measures for Environmental Management of New Chemical Substances, which includes provisions for eco-friendly adhesives.

Compliance with these regulations often requires extensive testing and documentation. Manufacturers must conduct lifecycle assessments, toxicity studies, and environmental impact analyses. They need to demonstrate that their ethyl acetate-based adhesives meet or exceed the safety and environmental standards set by regulatory bodies.

Certification programs, such as Green Seal in the US or the EU Ecolabel, provide additional benchmarks for environmentally safe adhesives. These voluntary certifications can offer a competitive advantage in the market and help companies align with green procurement policies adopted by many governments and corporations.

To ensure ongoing compliance, companies must implement robust quality management systems and stay abreast of regulatory changes. This often involves dedicating resources to regulatory affairs, participating in industry associations, and engaging with regulatory bodies during the development of new standards.

As the regulatory landscape continues to evolve, manufacturers of ethyl acetate-based adhesives must remain agile and proactive. Investing in research and development to stay ahead of regulatory trends can help companies maintain compliance while driving innovation in environmentally safe adhesive technologies.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating adhesives through the Toxic Substances Control Act (TSCA) and the Clean Air Act. These regulations set limits on volatile organic compound (VOC) emissions and require manufacturers to report on the chemical composition of their products. The California Air Resources Board (CARB) has even stricter standards, which often set the benchmark for other states.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is another significant framework that adhesive manufacturers must comply with. REACH requires companies to register chemical substances and provide safety data, including information on environmental impact. The EU has also implemented the Classification, Labeling, and Packaging (CLP) Regulation, which harmonizes the criteria for classification of substances and mixtures.

In Asia, countries like Japan and South Korea have their own chemical control laws that mirror aspects of REACH. China has recently updated its Measures for Environmental Management of New Chemical Substances, which includes provisions for eco-friendly adhesives.

Compliance with these regulations often requires extensive testing and documentation. Manufacturers must conduct lifecycle assessments, toxicity studies, and environmental impact analyses. They need to demonstrate that their ethyl acetate-based adhesives meet or exceed the safety and environmental standards set by regulatory bodies.

Certification programs, such as Green Seal in the US or the EU Ecolabel, provide additional benchmarks for environmentally safe adhesives. These voluntary certifications can offer a competitive advantage in the market and help companies align with green procurement policies adopted by many governments and corporations.

To ensure ongoing compliance, companies must implement robust quality management systems and stay abreast of regulatory changes. This often involves dedicating resources to regulatory affairs, participating in industry associations, and engaging with regulatory bodies during the development of new standards.

As the regulatory landscape continues to evolve, manufacturers of ethyl acetate-based adhesives must remain agile and proactive. Investing in research and development to stay ahead of regulatory trends can help companies maintain compliance while driving innovation in environmentally safe adhesive technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!