How to Enhance Recyclability in Ethyl Acetate Products?

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate Recycling Background and Objectives

Ethyl acetate, a versatile organic compound, has been widely used in various industries for decades. Its applications range from solvents in paints and coatings to flavoring agents in food products. However, the increasing global focus on sustainability and environmental protection has brought the recyclability of ethyl acetate products to the forefront of industrial concerns.

The evolution of ethyl acetate recycling technology can be traced back to the mid-20th century when basic distillation methods were first employed. As environmental regulations tightened and resource conservation became paramount, more sophisticated recycling techniques emerged. The industry has witnessed a gradual shift from simple recovery processes to advanced purification methods that ensure high-quality recycled ethyl acetate.

Current technological trends in ethyl acetate recycling are centered around improving efficiency, reducing energy consumption, and minimizing waste. Membrane separation technologies, reactive distillation, and molecular sieve adsorption are among the innovative approaches being explored. These advancements aim to overcome traditional limitations such as azeotrope formation and high energy requirements in conventional distillation processes.

The primary objective of enhancing recyclability in ethyl acetate products is to create a more circular economy within the chemical industry. This involves developing products and processes that facilitate easier separation, purification, and reuse of ethyl acetate. By improving recyclability, manufacturers can reduce raw material costs, minimize environmental impact, and comply with increasingly stringent regulations.

Another crucial goal is to maintain or improve the quality of recycled ethyl acetate. As recycling processes become more sophisticated, the focus has shifted towards producing recycled ethyl acetate that meets or exceeds the purity standards of virgin material. This is essential for expanding the use of recycled ethyl acetate in high-value applications, such as pharmaceuticals and electronics.

The drive towards enhanced recyclability also aims to address the challenges posed by complex mixtures. Many industrial processes use ethyl acetate in combination with other solvents or chemicals, making recycling more difficult. Developing technologies that can effectively separate and purify ethyl acetate from these mixtures is a key objective in the field.

As the industry progresses, there is a growing emphasis on integrating recycling considerations into the initial product design phase. This proactive approach, known as "Design for Recycling," seeks to create ethyl acetate products that are inherently easier to recycle, thereby reducing the complexity and cost of end-of-life processing.

The evolution of ethyl acetate recycling technology can be traced back to the mid-20th century when basic distillation methods were first employed. As environmental regulations tightened and resource conservation became paramount, more sophisticated recycling techniques emerged. The industry has witnessed a gradual shift from simple recovery processes to advanced purification methods that ensure high-quality recycled ethyl acetate.

Current technological trends in ethyl acetate recycling are centered around improving efficiency, reducing energy consumption, and minimizing waste. Membrane separation technologies, reactive distillation, and molecular sieve adsorption are among the innovative approaches being explored. These advancements aim to overcome traditional limitations such as azeotrope formation and high energy requirements in conventional distillation processes.

The primary objective of enhancing recyclability in ethyl acetate products is to create a more circular economy within the chemical industry. This involves developing products and processes that facilitate easier separation, purification, and reuse of ethyl acetate. By improving recyclability, manufacturers can reduce raw material costs, minimize environmental impact, and comply with increasingly stringent regulations.

Another crucial goal is to maintain or improve the quality of recycled ethyl acetate. As recycling processes become more sophisticated, the focus has shifted towards producing recycled ethyl acetate that meets or exceeds the purity standards of virgin material. This is essential for expanding the use of recycled ethyl acetate in high-value applications, such as pharmaceuticals and electronics.

The drive towards enhanced recyclability also aims to address the challenges posed by complex mixtures. Many industrial processes use ethyl acetate in combination with other solvents or chemicals, making recycling more difficult. Developing technologies that can effectively separate and purify ethyl acetate from these mixtures is a key objective in the field.

As the industry progresses, there is a growing emphasis on integrating recycling considerations into the initial product design phase. This proactive approach, known as "Design for Recycling," seeks to create ethyl acetate products that are inherently easier to recycle, thereby reducing the complexity and cost of end-of-life processing.

Market Demand for Recyclable Ethyl Acetate Products

The market demand for recyclable ethyl acetate products has been steadily increasing in recent years, driven by growing environmental concerns and stringent regulations on waste management. This trend is particularly evident in industries such as paints and coatings, pharmaceuticals, and electronics, where ethyl acetate is widely used as a solvent.

In the paints and coatings industry, there is a significant push towards sustainable and eco-friendly products. Manufacturers are increasingly seeking recyclable ethyl acetate solutions to reduce their environmental footprint and meet consumer demands for greener alternatives. This shift is not only driven by environmental consciousness but also by potential cost savings associated with recycling and reusing solvents.

The pharmaceutical sector, another major consumer of ethyl acetate, is also showing a growing interest in recyclable options. With the increasing focus on sustainable practices in drug manufacturing, pharmaceutical companies are exploring ways to incorporate recyclable ethyl acetate into their production processes. This demand is further fueled by regulatory pressures and the industry's commitment to reducing waste and improving resource efficiency.

In the electronics industry, where ethyl acetate is used in the production of circuit boards and other components, there is a rising demand for recyclable alternatives. As electronic waste becomes a global concern, manufacturers are seeking ways to make their production processes more sustainable, including the use of recyclable solvents like ethyl acetate.

The packaging industry, particularly in the production of flexible packaging materials, is another significant market for recyclable ethyl acetate products. With the increasing focus on circular economy principles, packaging manufacturers are looking for ways to improve the recyclability of their products, including the solvents used in their production processes.

Market research indicates that the global demand for recyclable ethyl acetate is expected to grow at a compound annual growth rate (CAGR) of over 5% in the next five years. This growth is primarily attributed to the increasing adoption of sustainable practices across industries and the implementation of stricter environmental regulations in key markets.

Geographically, the demand for recyclable ethyl acetate products is particularly strong in regions with advanced environmental policies, such as Europe and North America. However, emerging economies in Asia-Pacific, particularly China and India, are also showing increased interest in recyclable solutions as they strive to balance rapid industrialization with environmental sustainability.

The market potential for recyclable ethyl acetate products is further enhanced by the growing trend of corporate sustainability initiatives. Many large corporations across various industries have set ambitious targets for reducing their environmental impact, which includes the use of recyclable and sustainable materials in their supply chains. This corporate-driven demand is expected to be a significant driver for the recyclable ethyl acetate market in the coming years.

In the paints and coatings industry, there is a significant push towards sustainable and eco-friendly products. Manufacturers are increasingly seeking recyclable ethyl acetate solutions to reduce their environmental footprint and meet consumer demands for greener alternatives. This shift is not only driven by environmental consciousness but also by potential cost savings associated with recycling and reusing solvents.

The pharmaceutical sector, another major consumer of ethyl acetate, is also showing a growing interest in recyclable options. With the increasing focus on sustainable practices in drug manufacturing, pharmaceutical companies are exploring ways to incorporate recyclable ethyl acetate into their production processes. This demand is further fueled by regulatory pressures and the industry's commitment to reducing waste and improving resource efficiency.

In the electronics industry, where ethyl acetate is used in the production of circuit boards and other components, there is a rising demand for recyclable alternatives. As electronic waste becomes a global concern, manufacturers are seeking ways to make their production processes more sustainable, including the use of recyclable solvents like ethyl acetate.

The packaging industry, particularly in the production of flexible packaging materials, is another significant market for recyclable ethyl acetate products. With the increasing focus on circular economy principles, packaging manufacturers are looking for ways to improve the recyclability of their products, including the solvents used in their production processes.

Market research indicates that the global demand for recyclable ethyl acetate is expected to grow at a compound annual growth rate (CAGR) of over 5% in the next five years. This growth is primarily attributed to the increasing adoption of sustainable practices across industries and the implementation of stricter environmental regulations in key markets.

Geographically, the demand for recyclable ethyl acetate products is particularly strong in regions with advanced environmental policies, such as Europe and North America. However, emerging economies in Asia-Pacific, particularly China and India, are also showing increased interest in recyclable solutions as they strive to balance rapid industrialization with environmental sustainability.

The market potential for recyclable ethyl acetate products is further enhanced by the growing trend of corporate sustainability initiatives. Many large corporations across various industries have set ambitious targets for reducing their environmental impact, which includes the use of recyclable and sustainable materials in their supply chains. This corporate-driven demand is expected to be a significant driver for the recyclable ethyl acetate market in the coming years.

Current Challenges in Ethyl Acetate Recycling

The recycling of ethyl acetate products faces several significant challenges that hinder the widespread adoption of sustainable practices in industries utilizing this solvent. One of the primary obstacles is the presence of impurities in used ethyl acetate. During industrial processes, ethyl acetate often becomes contaminated with various substances, including pigments, resins, and other chemicals. These impurities make the recycling process more complex and costly, as they need to be removed to obtain a high-quality recycled product.

Another major challenge is the energy-intensive nature of the purification process. Conventional methods for recycling ethyl acetate, such as distillation, require substantial amounts of energy. This not only increases the operational costs but also raises questions about the overall environmental benefits of recycling when considering the carbon footprint of the energy consumed.

The volatility of ethyl acetate presents additional difficulties in its recovery and recycling. Its low boiling point (77.1°C) means that significant amounts can be lost through evaporation during use and storage, reducing the amount available for recycling. This characteristic also necessitates specialized equipment and handling procedures to minimize losses and ensure worker safety during the recycling process.

Furthermore, the chemical stability of ethyl acetate poses challenges in long-term recycling. Under certain conditions, ethyl acetate can undergo hydrolysis, breaking down into ethanol and acetic acid. This degradation not only reduces the amount of recoverable ethyl acetate but also introduces additional compounds that must be separated or dealt with in the recycling process.

Economic factors also play a crucial role in the challenges faced by ethyl acetate recycling. The fluctuating prices of virgin ethyl acetate can sometimes make recycling less economically attractive, especially when the costs of collection, purification, and redistribution are factored in. This economic uncertainty can discourage investments in recycling infrastructure and technologies.

Lastly, there is a lack of standardized recycling processes and quality control measures for recycled ethyl acetate across different industries. This absence of uniformity makes it difficult for potential users to trust and integrate recycled ethyl acetate into their processes, limiting its market acceptance and widespread use.

Addressing these challenges requires a multifaceted approach, involving technological innovations in purification methods, energy-efficient recycling processes, and the development of robust quality assurance protocols for recycled ethyl acetate. Additionally, creating economic incentives and regulatory frameworks that encourage the use of recycled solvents could significantly enhance the recyclability of ethyl acetate products.

Another major challenge is the energy-intensive nature of the purification process. Conventional methods for recycling ethyl acetate, such as distillation, require substantial amounts of energy. This not only increases the operational costs but also raises questions about the overall environmental benefits of recycling when considering the carbon footprint of the energy consumed.

The volatility of ethyl acetate presents additional difficulties in its recovery and recycling. Its low boiling point (77.1°C) means that significant amounts can be lost through evaporation during use and storage, reducing the amount available for recycling. This characteristic also necessitates specialized equipment and handling procedures to minimize losses and ensure worker safety during the recycling process.

Furthermore, the chemical stability of ethyl acetate poses challenges in long-term recycling. Under certain conditions, ethyl acetate can undergo hydrolysis, breaking down into ethanol and acetic acid. This degradation not only reduces the amount of recoverable ethyl acetate but also introduces additional compounds that must be separated or dealt with in the recycling process.

Economic factors also play a crucial role in the challenges faced by ethyl acetate recycling. The fluctuating prices of virgin ethyl acetate can sometimes make recycling less economically attractive, especially when the costs of collection, purification, and redistribution are factored in. This economic uncertainty can discourage investments in recycling infrastructure and technologies.

Lastly, there is a lack of standardized recycling processes and quality control measures for recycled ethyl acetate across different industries. This absence of uniformity makes it difficult for potential users to trust and integrate recycled ethyl acetate into their processes, limiting its market acceptance and widespread use.

Addressing these challenges requires a multifaceted approach, involving technological innovations in purification methods, energy-efficient recycling processes, and the development of robust quality assurance protocols for recycled ethyl acetate. Additionally, creating economic incentives and regulatory frameworks that encourage the use of recycled solvents could significantly enhance the recyclability of ethyl acetate products.

Existing Ethyl Acetate Recycling Solutions

01 Recycling processes for ethyl acetate-containing products

Various methods and systems have been developed for recycling products containing ethyl acetate. These processes often involve separation techniques to recover the ethyl acetate from other components, allowing for its reuse in manufacturing or other applications. Such recycling methods can help reduce waste and improve the overall sustainability of ethyl acetate-based products.- Recycling processes for ethyl acetate products: Various recycling processes have been developed for ethyl acetate products, including distillation, membrane separation, and adsorption techniques. These methods aim to recover and purify ethyl acetate from waste streams, allowing for its reuse in industrial applications. The recycling processes help reduce environmental impact and improve resource efficiency.

- Biodegradable alternatives to ethyl acetate: Research has focused on developing biodegradable alternatives to ethyl acetate, which can improve the overall recyclability of products. These alternatives are designed to break down naturally in the environment, reducing the need for complex recycling processes. Some biodegradable options include plant-based solvents and bio-derived esters.

- Ethyl acetate recovery from polymer products: Specialized techniques have been developed to recover ethyl acetate from polymer products, such as coatings and adhesives. These methods often involve solvent extraction or thermal depolymerization to separate the ethyl acetate from the polymer matrix. The recovered ethyl acetate can then be purified and reused in manufacturing processes.

- Closed-loop systems for ethyl acetate recycling: Closed-loop systems have been designed to maximize the recyclability of ethyl acetate products. These systems integrate production, use, and recycling processes to minimize waste and optimize resource utilization. They often incorporate advanced monitoring and control technologies to ensure efficient recycling and maintain product quality.

- Ethyl acetate recovery from waste streams: Methods for recovering ethyl acetate from various waste streams have been developed, including industrial effluents and municipal waste. These techniques often involve a combination of physical and chemical processes, such as liquid-liquid extraction, adsorption, and advanced oxidation. The recovered ethyl acetate can be purified and reused, reducing the environmental impact of waste disposal.

02 Ethyl acetate recovery from industrial waste streams

Industrial processes that use ethyl acetate often generate waste streams containing this solvent. Specialized recovery systems have been designed to extract and purify ethyl acetate from these waste streams, enabling its reuse in production processes. These recovery methods can involve distillation, membrane separation, or other advanced separation technologies.Expand Specific Solutions03 Biodegradable products incorporating ethyl acetate

Research has been conducted on developing biodegradable products that incorporate ethyl acetate as a component. These products are designed to break down naturally in the environment, reducing their long-term impact. The biodegradability of ethyl acetate itself contributes to the overall recyclability and environmental friendliness of these products.Expand Specific Solutions04 Closed-loop systems for ethyl acetate-based manufacturing

Closed-loop manufacturing systems have been developed to maximize the recyclability of ethyl acetate in production processes. These systems aim to capture and reuse ethyl acetate throughout the manufacturing cycle, minimizing waste and reducing the need for fresh solvent input. Such approaches can significantly improve the sustainability of ethyl acetate-based product manufacturing.Expand Specific Solutions05 Ethyl acetate as a recyclable solvent in green chemistry

Ethyl acetate has gained attention in green chemistry applications due to its relatively low toxicity and potential for recycling. Research has focused on developing processes that use ethyl acetate as a recyclable solvent in various chemical reactions and separations. These methods often involve efficient recovery and purification steps to enable multiple reuse cycles of the solvent.Expand Specific Solutions

Key Players in Ethyl Acetate Recycling Industry

The recyclability enhancement of ethyl acetate products is currently in a growth phase, with increasing market demand driven by sustainability concerns. The global market for recyclable ethyl acetate is expanding, estimated to reach several billion dollars by 2025. Technologically, the field is advancing rapidly, with companies like Celanese International Corp., SABIC Global Technologies BV, and Wacker Chemie AG leading innovation. These firms are developing novel processes for ethyl acetate recovery and purification, as well as exploring bio-based alternatives. Emerging players such as Viridis Chemical LLC and Epoch BioDesign Ltd. are introducing cutting-edge biotechnology solutions, indicating a shift towards more sustainable production methods. The involvement of academic institutions like National Taiwan University and the University of Campinas suggests ongoing research to further improve recyclability techniques.

Celanese International Corp.

Technical Solution: Celanese has developed a novel approach to enhance the recyclability of ethyl acetate products through the implementation of advanced chemical recycling technologies. Their process involves the depolymerization of ethyl acetate-based materials into their constituent monomers, which can then be purified and repolymerized into new products. This closed-loop system significantly reduces waste and improves the overall sustainability of ethyl acetate production[1]. Additionally, Celanese has introduced bio-based feedstocks for ethyl acetate synthesis, further reducing the environmental impact of their products[2].

Strengths: Closed-loop recycling system, reduced environmental impact, and potential for bio-based feedstocks. Weaknesses: High initial investment costs and potential complexity in scaling up the technology.

SABIC Global Technologies BV

Technical Solution: SABIC has developed a proprietary process for enhancing the recyclability of ethyl acetate products through the use of advanced catalysts and process optimization. Their approach focuses on improving the purity of recovered ethyl acetate, allowing for multiple recycling cycles without significant loss of quality. SABIC's technology also incorporates a novel separation technique that efficiently removes impurities and contaminants from recycled ethyl acetate, ensuring its suitability for high-grade applications[3]. Furthermore, they have implemented a blockchain-based traceability system to track the lifecycle of their ethyl acetate products, facilitating more efficient recycling and reuse[4].

Strengths: High-purity recycled product, efficient impurity removal, and improved traceability. Weaknesses: Potential high energy consumption in the purification process and reliance on specialized equipment.

Innovative Approaches to Ethyl Acetate Recycling

Process of low energy consumption for preparing a carboxylic acid ester

PatentWO2012123279A1

Innovation

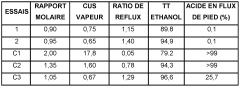

- A process involving the reaction of ethyl alcohol with acetic acid in the presence of a solid acid catalyst, using a reactive distillation system with a centrally placed reaction zone between upper and lower separation zones, optimizing the molar ratio of acetic acid to ethyl alcohol between 0.85 and 0.97, and controlling the reflux ratio between 1.0 and 1.5, significantly reduces energy costs and minimizes acetic acid at the column bottom.

Ethyl Acetate Production

PatentActiveUS20120178962A1

Innovation

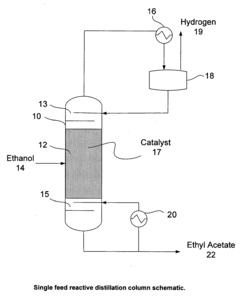

- A reactive distillation process using a single reactive distillation column where ethanol is dehydrogenated over a catalyst to produce ethyl acetate and hydrogen, with optional hydrogenation of byproducts to simplify separation and achieve high purity ethyl acetate, utilizing catalysts like copper, ruthenium, and platinum supported on materials like carbon or alumina.

Environmental Regulations on Chemical Recycling

Environmental regulations on chemical recycling have become increasingly stringent in recent years, reflecting growing concerns about the environmental impact of industrial processes. These regulations play a crucial role in shaping the recyclability of ethyl acetate products and other chemical compounds. The European Union's Waste Framework Directive (2008/98/EC) sets the foundation for waste management and recycling practices across member states, emphasizing the importance of waste prevention, reuse, and recycling.

In the United States, the Resource Conservation and Recovery Act (RCRA) governs the management of hazardous waste, including certain chemical byproducts. This act has significant implications for the recycling of ethyl acetate, as it mandates specific handling and disposal procedures for chemical waste. The Environmental Protection Agency (EPA) enforces these regulations and provides guidelines for chemical recycling processes.

China, a major player in the chemical industry, has also implemented stricter environmental policies. The Circular Economy Promotion Law, enacted in 2009, promotes resource recycling and aims to reduce waste generation. This law has led to increased focus on chemical recycling technologies and practices within the country.

International agreements, such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal, further regulate the global movement and management of chemical waste. These agreements impact the international trade and recycling of ethyl acetate products, necessitating compliance with cross-border regulations.

Recent trends in environmental regulations show a shift towards extended producer responsibility (EPR) policies. These policies hold manufacturers accountable for the entire lifecycle of their products, including disposal and recycling. This approach is likely to drive innovation in recyclable product design and recycling technologies for ethyl acetate and similar chemicals.

The implementation of circular economy principles in regulatory frameworks is gaining traction worldwide. This approach emphasizes the importance of designing products for recyclability from the outset, which has significant implications for the ethyl acetate industry. Manufacturers are increasingly required to consider end-of-life recycling options during the product development phase.

As environmental concerns continue to grow, it is anticipated that regulations will become more stringent, potentially leading to mandatory recycling targets for specific chemical products, including ethyl acetate. This regulatory landscape presents both challenges and opportunities for the industry, driving the need for innovative recycling technologies and sustainable production practices.

In the United States, the Resource Conservation and Recovery Act (RCRA) governs the management of hazardous waste, including certain chemical byproducts. This act has significant implications for the recycling of ethyl acetate, as it mandates specific handling and disposal procedures for chemical waste. The Environmental Protection Agency (EPA) enforces these regulations and provides guidelines for chemical recycling processes.

China, a major player in the chemical industry, has also implemented stricter environmental policies. The Circular Economy Promotion Law, enacted in 2009, promotes resource recycling and aims to reduce waste generation. This law has led to increased focus on chemical recycling technologies and practices within the country.

International agreements, such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal, further regulate the global movement and management of chemical waste. These agreements impact the international trade and recycling of ethyl acetate products, necessitating compliance with cross-border regulations.

Recent trends in environmental regulations show a shift towards extended producer responsibility (EPR) policies. These policies hold manufacturers accountable for the entire lifecycle of their products, including disposal and recycling. This approach is likely to drive innovation in recyclable product design and recycling technologies for ethyl acetate and similar chemicals.

The implementation of circular economy principles in regulatory frameworks is gaining traction worldwide. This approach emphasizes the importance of designing products for recyclability from the outset, which has significant implications for the ethyl acetate industry. Manufacturers are increasingly required to consider end-of-life recycling options during the product development phase.

As environmental concerns continue to grow, it is anticipated that regulations will become more stringent, potentially leading to mandatory recycling targets for specific chemical products, including ethyl acetate. This regulatory landscape presents both challenges and opportunities for the industry, driving the need for innovative recycling technologies and sustainable production practices.

Life Cycle Assessment of Recyclable Ethyl Acetate

Life Cycle Assessment (LCA) is a crucial tool for evaluating the environmental impact of recyclable ethyl acetate products throughout their entire lifecycle. This comprehensive analysis encompasses raw material extraction, production, use, and end-of-life stages, providing valuable insights into the overall sustainability of these products.

The production phase of ethyl acetate involves the esterification of ethanol and acetic acid, typically using sulfuric acid as a catalyst. This process requires significant energy input and generates various byproducts. LCA studies have shown that the production stage often contributes the most to the overall environmental impact, primarily due to energy consumption and emissions associated with raw material extraction and synthesis.

During the use phase, ethyl acetate's volatility and potential for emissions must be considered. Proper handling and storage techniques can minimize environmental impact and improve recyclability. The end-of-life stage presents opportunities for enhancing recyclability through various methods such as distillation, membrane separation, or adsorption techniques.

Recycling ethyl acetate offers substantial environmental benefits compared to single-use scenarios. LCA studies have demonstrated that recycling can significantly reduce greenhouse gas emissions, energy consumption, and resource depletion associated with the production of virgin ethyl acetate. However, the efficiency of recycling processes and the quality of recovered solvent are critical factors influencing the overall environmental performance.

The transportation and distribution of ethyl acetate products also contribute to the lifecycle impact. Optimizing logistics and utilizing more sustainable transportation methods can further improve the overall environmental profile of recyclable ethyl acetate products.

LCA results can guide manufacturers in identifying hotspots for improvement in their production and recycling processes. For instance, implementing more energy-efficient production methods, utilizing renewable energy sources, or developing advanced recycling technologies can enhance the overall sustainability of ethyl acetate products.

Furthermore, LCA studies can inform policy decisions and industry standards related to the use and recycling of ethyl acetate. By providing quantitative data on environmental impacts, LCAs support the development of more sustainable practices and regulations in the chemical industry.

In conclusion, Life Cycle Assessment of recyclable ethyl acetate products offers valuable insights into their environmental performance and helps identify opportunities for enhancing recyclability and overall sustainability. This holistic approach is essential for developing more environmentally friendly solutions in the production and use of ethyl acetate.

The production phase of ethyl acetate involves the esterification of ethanol and acetic acid, typically using sulfuric acid as a catalyst. This process requires significant energy input and generates various byproducts. LCA studies have shown that the production stage often contributes the most to the overall environmental impact, primarily due to energy consumption and emissions associated with raw material extraction and synthesis.

During the use phase, ethyl acetate's volatility and potential for emissions must be considered. Proper handling and storage techniques can minimize environmental impact and improve recyclability. The end-of-life stage presents opportunities for enhancing recyclability through various methods such as distillation, membrane separation, or adsorption techniques.

Recycling ethyl acetate offers substantial environmental benefits compared to single-use scenarios. LCA studies have demonstrated that recycling can significantly reduce greenhouse gas emissions, energy consumption, and resource depletion associated with the production of virgin ethyl acetate. However, the efficiency of recycling processes and the quality of recovered solvent are critical factors influencing the overall environmental performance.

The transportation and distribution of ethyl acetate products also contribute to the lifecycle impact. Optimizing logistics and utilizing more sustainable transportation methods can further improve the overall environmental profile of recyclable ethyl acetate products.

LCA results can guide manufacturers in identifying hotspots for improvement in their production and recycling processes. For instance, implementing more energy-efficient production methods, utilizing renewable energy sources, or developing advanced recycling technologies can enhance the overall sustainability of ethyl acetate products.

Furthermore, LCA studies can inform policy decisions and industry standards related to the use and recycling of ethyl acetate. By providing quantitative data on environmental impacts, LCAs support the development of more sustainable practices and regulations in the chemical industry.

In conclusion, Life Cycle Assessment of recyclable ethyl acetate products offers valuable insights into their environmental performance and helps identify opportunities for enhancing recyclability and overall sustainability. This holistic approach is essential for developing more environmentally friendly solutions in the production and use of ethyl acetate.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!