Maximizing Efficiency in Ethyl Acetate Solvent Systems

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate Solvent Evolution and Objectives

Ethyl acetate has been a cornerstone solvent in various industries for decades, with its evolution closely tied to advancements in chemical engineering and process optimization. The journey of ethyl acetate as a solvent system began in the early 20th century, primarily in the production of lacquers and paints. As industrial processes became more sophisticated, the demand for efficient and versatile solvents grew, propelling ethyl acetate to the forefront of solvent technology.

The evolution of ethyl acetate solvent systems has been marked by continuous improvements in production methods, purification techniques, and application-specific formulations. Initially, ethyl acetate was produced through the esterification of ethanol and acetic acid, a process that has since been refined to achieve higher yields and purity levels. The introduction of catalytic processes in the mid-20th century significantly enhanced production efficiency, making ethyl acetate more economically viable for large-scale industrial use.

In recent years, the focus has shifted towards developing more sustainable and environmentally friendly ethyl acetate production methods. This includes exploring bio-based feedstocks and implementing green chemistry principles to reduce the carbon footprint of ethyl acetate manufacturing. The advent of advanced separation technologies has also played a crucial role in improving the recovery and recycling of ethyl acetate in various applications, contributing to its increased efficiency and reduced environmental impact.

The current technological landscape presents both challenges and opportunities for maximizing efficiency in ethyl acetate solvent systems. Key objectives in this field include optimizing reaction kinetics to improve yield and selectivity, developing novel catalysts for enhanced performance, and implementing advanced process control systems for real-time optimization of production parameters. Additionally, there is a growing emphasis on integrating ethyl acetate solvent systems with other unit operations to create more streamlined and energy-efficient industrial processes.

Looking ahead, the future of ethyl acetate solvent systems is likely to be shaped by emerging technologies such as artificial intelligence and machine learning for process optimization, as well as the development of hybrid solvent systems that combine the benefits of ethyl acetate with other complementary solvents. The overarching goal is to create more efficient, sustainable, and versatile solvent systems that can meet the evolving needs of various industries while minimizing environmental impact and maximizing resource utilization.

The evolution of ethyl acetate solvent systems has been marked by continuous improvements in production methods, purification techniques, and application-specific formulations. Initially, ethyl acetate was produced through the esterification of ethanol and acetic acid, a process that has since been refined to achieve higher yields and purity levels. The introduction of catalytic processes in the mid-20th century significantly enhanced production efficiency, making ethyl acetate more economically viable for large-scale industrial use.

In recent years, the focus has shifted towards developing more sustainable and environmentally friendly ethyl acetate production methods. This includes exploring bio-based feedstocks and implementing green chemistry principles to reduce the carbon footprint of ethyl acetate manufacturing. The advent of advanced separation technologies has also played a crucial role in improving the recovery and recycling of ethyl acetate in various applications, contributing to its increased efficiency and reduced environmental impact.

The current technological landscape presents both challenges and opportunities for maximizing efficiency in ethyl acetate solvent systems. Key objectives in this field include optimizing reaction kinetics to improve yield and selectivity, developing novel catalysts for enhanced performance, and implementing advanced process control systems for real-time optimization of production parameters. Additionally, there is a growing emphasis on integrating ethyl acetate solvent systems with other unit operations to create more streamlined and energy-efficient industrial processes.

Looking ahead, the future of ethyl acetate solvent systems is likely to be shaped by emerging technologies such as artificial intelligence and machine learning for process optimization, as well as the development of hybrid solvent systems that combine the benefits of ethyl acetate with other complementary solvents. The overarching goal is to create more efficient, sustainable, and versatile solvent systems that can meet the evolving needs of various industries while minimizing environmental impact and maximizing resource utilization.

Industrial Demand Analysis for Ethyl Acetate Systems

The demand for ethyl acetate solvent systems in industrial applications has been steadily increasing due to its versatile properties and wide range of uses. Ethyl acetate is a colorless, flammable liquid with a characteristic sweet odor, making it an attractive choice for various industries. Its low toxicity, high solvency power, and rapid evaporation rate have contributed to its growing popularity in sectors such as paints and coatings, pharmaceuticals, adhesives, and food processing.

In the paints and coatings industry, ethyl acetate is extensively used as a solvent for lacquers, varnishes, and inks. The increasing demand for eco-friendly and low-VOC (volatile organic compound) products has further boosted the use of ethyl acetate in this sector. As construction activities and automotive production continue to rise globally, the demand for paints and coatings is expected to grow, consequently driving the need for efficient ethyl acetate solvent systems.

The pharmaceutical industry represents another significant market for ethyl acetate systems. It is commonly used in the production of various drugs and as an extraction solvent in the manufacture of antibiotics. With the ongoing expansion of the pharmaceutical sector, particularly in emerging economies, the demand for high-purity ethyl acetate is projected to increase substantially.

In the adhesives industry, ethyl acetate serves as a crucial component in the formulation of adhesives and sealants. The growth of the packaging industry, coupled with the rising demand for consumer goods, has led to an increased need for efficient adhesive solutions. This trend is expected to drive the demand for ethyl acetate solvent systems in the coming years.

The food processing industry also contributes to the demand for ethyl acetate systems. It is used as a flavoring agent and in the decaffeination of coffee and tea. As consumer preferences shift towards natural and organic products, the use of ethyl acetate as a more environmentally friendly solvent in food processing is likely to grow.

The Asia-Pacific region, particularly China and India, is expected to be the fastest-growing market for ethyl acetate solvent systems. Rapid industrialization, urbanization, and increasing disposable incomes in these countries are driving the demand across various end-use industries. North America and Europe, while mature markets, continue to show steady growth due to ongoing technological advancements and the shift towards sustainable solutions.

As industries strive for greater efficiency and sustainability, the focus on maximizing the efficiency of ethyl acetate solvent systems has become paramount. This includes developing improved recovery and recycling methods, optimizing solvent formulations, and exploring novel applications. The growing emphasis on circular economy principles is likely to further drive innovation in ethyl acetate solvent systems, creating new opportunities for market growth and technological advancements.

In the paints and coatings industry, ethyl acetate is extensively used as a solvent for lacquers, varnishes, and inks. The increasing demand for eco-friendly and low-VOC (volatile organic compound) products has further boosted the use of ethyl acetate in this sector. As construction activities and automotive production continue to rise globally, the demand for paints and coatings is expected to grow, consequently driving the need for efficient ethyl acetate solvent systems.

The pharmaceutical industry represents another significant market for ethyl acetate systems. It is commonly used in the production of various drugs and as an extraction solvent in the manufacture of antibiotics. With the ongoing expansion of the pharmaceutical sector, particularly in emerging economies, the demand for high-purity ethyl acetate is projected to increase substantially.

In the adhesives industry, ethyl acetate serves as a crucial component in the formulation of adhesives and sealants. The growth of the packaging industry, coupled with the rising demand for consumer goods, has led to an increased need for efficient adhesive solutions. This trend is expected to drive the demand for ethyl acetate solvent systems in the coming years.

The food processing industry also contributes to the demand for ethyl acetate systems. It is used as a flavoring agent and in the decaffeination of coffee and tea. As consumer preferences shift towards natural and organic products, the use of ethyl acetate as a more environmentally friendly solvent in food processing is likely to grow.

The Asia-Pacific region, particularly China and India, is expected to be the fastest-growing market for ethyl acetate solvent systems. Rapid industrialization, urbanization, and increasing disposable incomes in these countries are driving the demand across various end-use industries. North America and Europe, while mature markets, continue to show steady growth due to ongoing technological advancements and the shift towards sustainable solutions.

As industries strive for greater efficiency and sustainability, the focus on maximizing the efficiency of ethyl acetate solvent systems has become paramount. This includes developing improved recovery and recycling methods, optimizing solvent formulations, and exploring novel applications. The growing emphasis on circular economy principles is likely to further drive innovation in ethyl acetate solvent systems, creating new opportunities for market growth and technological advancements.

Current Challenges in Ethyl Acetate Efficiency

Despite the widespread use of ethyl acetate as a solvent in various industries, several challenges persist in maximizing its efficiency. One of the primary issues is the high energy consumption associated with the production and purification of ethyl acetate. The traditional manufacturing process, which involves the esterification of ethanol and acetic acid, requires significant heat input and multiple distillation steps, leading to substantial energy costs and environmental concerns.

Another challenge lies in the recovery and recycling of ethyl acetate from industrial processes. The solvent's relatively low boiling point (77.1°C) makes it prone to evaporation, resulting in losses during use and storage. This not only increases operational costs but also raises environmental and safety concerns due to volatile organic compound (VOC) emissions. Developing more efficient recovery systems and minimizing solvent losses remain critical challenges for many industries.

The purity of ethyl acetate is another area of concern, particularly in high-precision applications such as electronics manufacturing and pharmaceutical production. Trace impurities can significantly impact product quality and process efficiency. Achieving and maintaining high purity levels without excessive energy expenditure or complex purification processes continues to be a technical hurdle.

Furthermore, the stability of ethyl acetate under various operating conditions poses challenges in certain applications. The solvent can undergo hydrolysis in the presence of water, especially at elevated temperatures or in acidic environments. This degradation not only reduces solvent efficiency but can also introduce unwanted byproducts into the process, affecting product quality and requiring more frequent solvent replacement.

The optimization of ethyl acetate-based solvent systems for specific applications presents another set of challenges. Different industries and processes require tailored solvent properties, such as specific dissolution capabilities, evaporation rates, or compatibility with other materials. Developing customized ethyl acetate formulations that meet these diverse requirements while maintaining overall efficiency and cost-effectiveness is an ongoing challenge for researchers and formulators.

Lastly, regulatory pressures and sustainability concerns are driving the need for more environmentally friendly solvent systems. While ethyl acetate is generally considered less harmful than many other organic solvents, there is still a push to reduce its environmental footprint. This includes developing bio-based production methods, improving energy efficiency throughout the lifecycle, and exploring potential alternatives or hybrid solvent systems that can match or exceed the performance of ethyl acetate while offering enhanced sustainability profiles.

Another challenge lies in the recovery and recycling of ethyl acetate from industrial processes. The solvent's relatively low boiling point (77.1°C) makes it prone to evaporation, resulting in losses during use and storage. This not only increases operational costs but also raises environmental and safety concerns due to volatile organic compound (VOC) emissions. Developing more efficient recovery systems and minimizing solvent losses remain critical challenges for many industries.

The purity of ethyl acetate is another area of concern, particularly in high-precision applications such as electronics manufacturing and pharmaceutical production. Trace impurities can significantly impact product quality and process efficiency. Achieving and maintaining high purity levels without excessive energy expenditure or complex purification processes continues to be a technical hurdle.

Furthermore, the stability of ethyl acetate under various operating conditions poses challenges in certain applications. The solvent can undergo hydrolysis in the presence of water, especially at elevated temperatures or in acidic environments. This degradation not only reduces solvent efficiency but can also introduce unwanted byproducts into the process, affecting product quality and requiring more frequent solvent replacement.

The optimization of ethyl acetate-based solvent systems for specific applications presents another set of challenges. Different industries and processes require tailored solvent properties, such as specific dissolution capabilities, evaporation rates, or compatibility with other materials. Developing customized ethyl acetate formulations that meet these diverse requirements while maintaining overall efficiency and cost-effectiveness is an ongoing challenge for researchers and formulators.

Lastly, regulatory pressures and sustainability concerns are driving the need for more environmentally friendly solvent systems. While ethyl acetate is generally considered less harmful than many other organic solvents, there is still a push to reduce its environmental footprint. This includes developing bio-based production methods, improving energy efficiency throughout the lifecycle, and exploring potential alternatives or hybrid solvent systems that can match or exceed the performance of ethyl acetate while offering enhanced sustainability profiles.

Existing Efficiency Enhancement Techniques

01 Ethyl acetate as an efficient solvent in extraction processes

Ethyl acetate demonstrates high efficiency as a solvent in various extraction processes. It is particularly effective in extracting organic compounds from aqueous solutions due to its moderate polarity and low boiling point. This solvent system is widely used in industries such as pharmaceuticals, food processing, and chemical manufacturing for its ability to selectively extract target compounds while minimizing impurities.- Efficiency in extraction and separation processes: Ethyl acetate solvent systems demonstrate high efficiency in various extraction and separation processes. They are particularly effective in liquid-liquid extraction, showing good selectivity and separation capabilities for different compounds. The solvent's properties allow for efficient mass transfer and phase separation, making it suitable for industrial-scale applications.

- Use in chromatography and analytical techniques: Ethyl acetate solvent systems are widely used in chromatographic techniques, including thin-layer chromatography (TLC) and high-performance liquid chromatography (HPLC). The solvent's polarity and elution strength make it effective for separating and analyzing various organic compounds, enhancing the efficiency and resolution of analytical processes.

- Application in polymer and resin processing: Ethyl acetate solvent systems show high efficiency in polymer and resin processing. They are effective in dissolving various polymers and resins, facilitating processes such as coating, adhesive formulation, and polymer synthesis. The solvent's volatility and solvency properties contribute to improved processing efficiency and product quality.

- Efficiency in pharmaceutical and fine chemical synthesis: In pharmaceutical and fine chemical synthesis, ethyl acetate solvent systems demonstrate high efficiency. They are effective in reaction media, product isolation, and purification processes. The solvent's properties allow for efficient synthesis of various compounds, including active pharmaceutical ingredients and specialty chemicals.

- Environmental and safety considerations: While ethyl acetate solvent systems are efficient, their use also involves environmental and safety considerations. Research focuses on optimizing solvent recovery and recycling processes to enhance overall efficiency and reduce environmental impact. Additionally, studies explore safer alternatives and improved handling methods to address flammability and exposure risks associated with ethyl acetate use.

02 Ethyl acetate in polymer and resin applications

Ethyl acetate serves as an efficient solvent system in polymer and resin applications. It is used in the production of various polymers, coatings, and adhesives due to its ability to dissolve a wide range of organic compounds. The solvent's low boiling point facilitates easy removal after processing, making it ideal for applications where residual solvent content must be minimized.Expand Specific Solutions03 Ethyl acetate in chromatographic separations

Ethyl acetate is utilized as an efficient component in solvent systems for chromatographic separations. Its moderate polarity makes it suitable for separating a wide range of compounds, particularly in thin-layer chromatography (TLC) and column chromatography. When combined with other solvents, ethyl acetate can be used to create mobile phases with tailored polarities for optimal separation efficiency.Expand Specific Solutions04 Ethyl acetate in ink and coating formulations

Ethyl acetate demonstrates high efficiency as a solvent in ink and coating formulations. Its rapid evaporation rate and ability to dissolve various resins and pigments make it ideal for fast-drying inks and coatings. The solvent's compatibility with many polymers and its low toxicity contribute to its widespread use in printing and coating industries.Expand Specific Solutions05 Ethyl acetate in green chemistry applications

Ethyl acetate is increasingly recognized as an efficient and environmentally friendly solvent in green chemistry applications. Its relatively low toxicity, biodegradability, and potential for bio-based production make it a preferred choice over more hazardous solvents. The solvent's efficiency in various chemical processes, combined with its favorable environmental profile, positions it as a key component in sustainable chemical manufacturing and processing.Expand Specific Solutions

Key Industry Players in Solvent Systems

The ethyl acetate solvent systems market is in a mature stage, characterized by established technologies and a stable competitive landscape. The global market size is estimated to be in the billions of dollars, driven by widespread industrial applications. Technologically, the field is well-developed, with ongoing incremental improvements in efficiency and sustainability. Key players like Kuraray Co., Ltd., China Petroleum & Chemical Corp., and Air Liquide SA dominate the market, leveraging their extensive R&D capabilities and global presence. Emerging companies such as Viridis Chemical LLC are introducing innovative bio-based solutions, indicating a shift towards more environmentally friendly processes. Universities and research institutions, including the University of Campinas and National Taiwan University, contribute to advancing the technology through collaborative research efforts with industry partners.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to maximize efficiency in ethyl acetate solvent systems. Their method involves a novel catalytic distillation process that integrates reaction and separation in a single unit. This process utilizes a heterogeneous acid catalyst fixed in the distillation column, allowing for continuous production of high-purity ethyl acetate. The system operates at lower temperatures and pressures compared to conventional methods, resulting in reduced energy consumption[1]. Additionally, Sinopec has implemented advanced process control systems and heat integration techniques to further optimize the production process, achieving a reported yield of over 99% and energy savings of up to 30%[3].

Strengths: High yield, energy efficiency, and product purity. Integrated process reduces equipment footprint. Weaknesses: Potential catalyst deactivation over time, may require specialized equipment for implementation.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has developed a reactive distillation technology for ethyl acetate production that significantly enhances efficiency. Their approach utilizes a specially designed structured packing with catalytic properties, allowing simultaneous reaction and separation. This system achieves higher conversion rates and reduces the number of unit operations required. Dow's process incorporates advanced process modeling and simulation tools to optimize operating conditions, resulting in a reported 25% reduction in energy consumption compared to conventional methods[2]. Furthermore, they have implemented a proprietary solvent recovery system that recycles unreacted components, minimizing waste and improving overall process economics[4].

Strengths: Reduced energy consumption, improved process integration, and enhanced product quality. Weaknesses: Higher initial capital investment, potential complexity in process control.

Innovative Approaches in Ethyl Acetate Optimization

Process of low energy consumption for preparing a carboxylic acid ester

PatentWO2012123279A1

Innovation

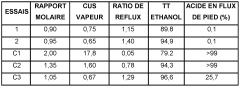

- A process involving the reaction of ethyl alcohol with acetic acid in the presence of a solid acid catalyst, using a reactive distillation system with a centrally placed reaction zone between upper and lower separation zones, optimizing the molar ratio of acetic acid to ethyl alcohol between 0.85 and 0.97, and controlling the reflux ratio between 1.0 and 1.5, significantly reduces energy costs and minimizes acetic acid at the column bottom.

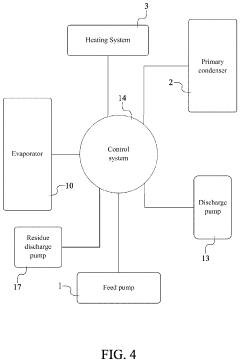

Solvent Recovery System

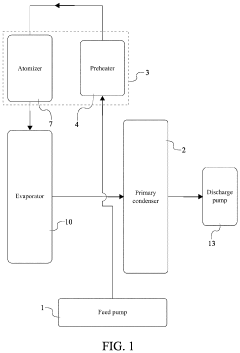

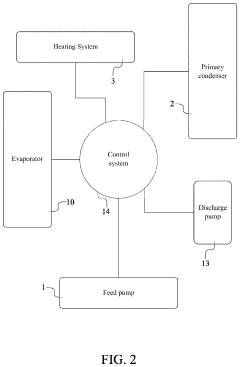

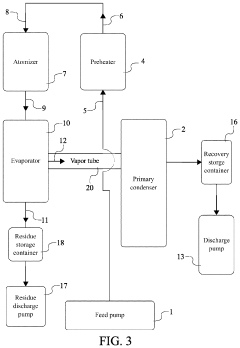

PatentInactiveUS20200070061A1

Innovation

- A solvent recovery system with an improved feed and distribution system using a gear pump and vacuum to continuously feed material to the top of the heat exchanger column, atomizing and evaporating it as it falls, combined with a control system for efficient processing and solvent discharge.

Environmental Impact and Sustainability Considerations

The environmental impact and sustainability considerations of ethyl acetate solvent systems are crucial aspects in maximizing their efficiency. Ethyl acetate, while widely used in various industries, poses several environmental challenges that need to be addressed for sustainable practices.

One of the primary concerns is the volatile organic compound (VOC) emissions associated with ethyl acetate. These emissions contribute to air pollution and can have adverse effects on human health and the environment. To mitigate this issue, industries are increasingly adopting advanced emission control technologies, such as regenerative thermal oxidizers and carbon adsorption systems. These technologies help capture and treat VOC emissions, significantly reducing their environmental impact.

Water pollution is another critical consideration in ethyl acetate solvent systems. Improper disposal or accidental spills can lead to contamination of water bodies, affecting aquatic ecosystems. Implementing robust waste management protocols and investing in efficient wastewater treatment facilities are essential steps in minimizing water pollution risks.

The production and use of ethyl acetate also have implications for energy consumption and carbon footprint. Manufacturers are exploring more energy-efficient production processes and considering renewable energy sources to power their operations. Additionally, the development of bio-based ethyl acetate from renewable resources, such as sugarcane or corn, is gaining traction as a more sustainable alternative to petroleum-derived ethyl acetate.

Recycling and recovery of ethyl acetate play a vital role in enhancing the sustainability of solvent systems. Advanced distillation and membrane separation techniques are being employed to recover and purify used ethyl acetate, reducing waste generation and raw material consumption. This circular approach not only minimizes environmental impact but also offers economic benefits to industries.

The lifecycle assessment of ethyl acetate solvent systems is becoming increasingly important in evaluating their overall environmental impact. This comprehensive approach considers all stages, from raw material extraction to end-of-life disposal, helping industries make informed decisions about process improvements and alternative solutions.

Regulatory compliance and industry standards are driving forces behind the adoption of more sustainable practices in ethyl acetate usage. Stringent environmental regulations, such as those imposed by the Environmental Protection Agency (EPA) in the United States and the European Chemicals Agency (ECHA) in Europe, are pushing industries to innovate and implement cleaner technologies.

As the focus on sustainability intensifies, research and development efforts are being directed towards finding greener alternatives to ethyl acetate. These include the exploration of bio-based solvents, supercritical fluids, and ionic liquids that offer similar functionality with reduced environmental impact. While these alternatives show promise, their scalability and cost-effectiveness remain challenges that need to be addressed for widespread adoption.

One of the primary concerns is the volatile organic compound (VOC) emissions associated with ethyl acetate. These emissions contribute to air pollution and can have adverse effects on human health and the environment. To mitigate this issue, industries are increasingly adopting advanced emission control technologies, such as regenerative thermal oxidizers and carbon adsorption systems. These technologies help capture and treat VOC emissions, significantly reducing their environmental impact.

Water pollution is another critical consideration in ethyl acetate solvent systems. Improper disposal or accidental spills can lead to contamination of water bodies, affecting aquatic ecosystems. Implementing robust waste management protocols and investing in efficient wastewater treatment facilities are essential steps in minimizing water pollution risks.

The production and use of ethyl acetate also have implications for energy consumption and carbon footprint. Manufacturers are exploring more energy-efficient production processes and considering renewable energy sources to power their operations. Additionally, the development of bio-based ethyl acetate from renewable resources, such as sugarcane or corn, is gaining traction as a more sustainable alternative to petroleum-derived ethyl acetate.

Recycling and recovery of ethyl acetate play a vital role in enhancing the sustainability of solvent systems. Advanced distillation and membrane separation techniques are being employed to recover and purify used ethyl acetate, reducing waste generation and raw material consumption. This circular approach not only minimizes environmental impact but also offers economic benefits to industries.

The lifecycle assessment of ethyl acetate solvent systems is becoming increasingly important in evaluating their overall environmental impact. This comprehensive approach considers all stages, from raw material extraction to end-of-life disposal, helping industries make informed decisions about process improvements and alternative solutions.

Regulatory compliance and industry standards are driving forces behind the adoption of more sustainable practices in ethyl acetate usage. Stringent environmental regulations, such as those imposed by the Environmental Protection Agency (EPA) in the United States and the European Chemicals Agency (ECHA) in Europe, are pushing industries to innovate and implement cleaner technologies.

As the focus on sustainability intensifies, research and development efforts are being directed towards finding greener alternatives to ethyl acetate. These include the exploration of bio-based solvents, supercritical fluids, and ionic liquids that offer similar functionality with reduced environmental impact. While these alternatives show promise, their scalability and cost-effectiveness remain challenges that need to be addressed for widespread adoption.

Economic Feasibility of Efficiency Improvements

The economic feasibility of efficiency improvements in ethyl acetate solvent systems is a critical consideration for industries seeking to optimize their processes. The primary drivers for such improvements are cost reduction, increased productivity, and environmental sustainability. When evaluating the economic viability of efficiency enhancements, several factors must be taken into account.

Capital investment is a significant aspect of implementing efficiency improvements. This may include upgrading existing equipment, installing new technologies, or redesigning process flows. The initial outlay can be substantial, but it is essential to consider the long-term benefits and return on investment. Companies must carefully assess whether the projected savings and increased output justify the upfront costs.

Operating costs are another crucial element in the economic equation. Efficiency improvements often lead to reduced energy consumption, lower raw material usage, and decreased waste generation. These factors contribute to ongoing cost savings, which can significantly impact the overall profitability of the operation. It is important to quantify these potential savings accurately to determine the payback period for the initial investment.

Labor costs may also be affected by efficiency improvements. While some enhancements might reduce the need for manual intervention, others may require additional skilled personnel to operate and maintain advanced systems. The net impact on labor expenses should be carefully evaluated as part of the economic feasibility study.

Market dynamics play a role in determining the economic viability of efficiency improvements. If the enhanced production capacity leads to increased market share or enables entry into new markets, the economic benefits could be substantial. However, it is crucial to consider market demand and competition to ensure that the increased output can be absorbed profitably.

Regulatory compliance is an increasingly important factor in the economic feasibility of efficiency improvements. Stricter environmental regulations may necessitate investments in cleaner technologies, which can be costly but may also provide long-term economic benefits through reduced environmental liabilities and improved corporate image.

The time frame for realizing economic benefits is a critical consideration. Some efficiency improvements may yield immediate results, while others may require a longer period to show significant returns. Companies must balance short-term financial pressures with long-term strategic goals when evaluating the economic feasibility of such investments.

In conclusion, the economic feasibility of efficiency improvements in ethyl acetate solvent systems depends on a complex interplay of factors. A comprehensive analysis that considers capital costs, operational savings, market opportunities, regulatory requirements, and time horizons is essential for making informed decisions about implementing efficiency enhancements in this critical area of industrial chemistry.

Capital investment is a significant aspect of implementing efficiency improvements. This may include upgrading existing equipment, installing new technologies, or redesigning process flows. The initial outlay can be substantial, but it is essential to consider the long-term benefits and return on investment. Companies must carefully assess whether the projected savings and increased output justify the upfront costs.

Operating costs are another crucial element in the economic equation. Efficiency improvements often lead to reduced energy consumption, lower raw material usage, and decreased waste generation. These factors contribute to ongoing cost savings, which can significantly impact the overall profitability of the operation. It is important to quantify these potential savings accurately to determine the payback period for the initial investment.

Labor costs may also be affected by efficiency improvements. While some enhancements might reduce the need for manual intervention, others may require additional skilled personnel to operate and maintain advanced systems. The net impact on labor expenses should be carefully evaluated as part of the economic feasibility study.

Market dynamics play a role in determining the economic viability of efficiency improvements. If the enhanced production capacity leads to increased market share or enables entry into new markets, the economic benefits could be substantial. However, it is crucial to consider market demand and competition to ensure that the increased output can be absorbed profitably.

Regulatory compliance is an increasingly important factor in the economic feasibility of efficiency improvements. Stricter environmental regulations may necessitate investments in cleaner technologies, which can be costly but may also provide long-term economic benefits through reduced environmental liabilities and improved corporate image.

The time frame for realizing economic benefits is a critical consideration. Some efficiency improvements may yield immediate results, while others may require a longer period to show significant returns. Companies must balance short-term financial pressures with long-term strategic goals when evaluating the economic feasibility of such investments.

In conclusion, the economic feasibility of efficiency improvements in ethyl acetate solvent systems depends on a complex interplay of factors. A comprehensive analysis that considers capital costs, operational savings, market opportunities, regulatory requirements, and time horizons is essential for making informed decisions about implementing efficiency enhancements in this critical area of industrial chemistry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!