Ethyl Acetate Use in Agrochemical Applications

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate in Agrochemicals: Background and Objectives

Ethyl acetate has emerged as a significant compound in the agrochemical industry, playing a crucial role in the formulation and application of various agricultural products. This versatile organic solvent, with its unique chemical properties, has been increasingly utilized in the development of pesticides, herbicides, and other crop protection agents. The evolution of ethyl acetate's use in agrochemicals can be traced back to the mid-20th century, coinciding with the rapid advancement of agricultural technologies and the growing demand for more effective and environmentally friendly farming solutions.

The primary objective of researching ethyl acetate in agrochemical applications is to enhance the efficacy and safety of agricultural products while minimizing environmental impact. As global agricultural practices continue to evolve, there is a pressing need for innovative solutions that can address the challenges of pest control, crop yield improvement, and sustainable farming. Ethyl acetate, with its low toxicity and high solvency power, presents a promising avenue for achieving these goals.

One of the key trends driving the increased adoption of ethyl acetate in agrochemicals is the shift towards more sustainable and eco-friendly farming practices. As regulatory bodies worldwide impose stricter guidelines on the use of chemical agents in agriculture, ethyl acetate's relatively benign environmental profile makes it an attractive alternative to more harmful solvents. This trend is expected to continue, with researchers and agrochemical companies focusing on developing formulations that maximize the benefits of ethyl acetate while minimizing potential drawbacks.

The technical evolution of ethyl acetate in agrochemicals has seen significant advancements in recent years. Researchers have been exploring novel ways to leverage its solvent properties to improve the stability, efficacy, and delivery mechanisms of various agrochemical formulations. This includes the development of microemulsions, controlled-release systems, and enhanced penetration formulations that utilize ethyl acetate as a key component.

Looking ahead, the future of ethyl acetate in agrochemical applications appears promising, with several key areas of focus for ongoing research and development. These include optimizing formulation techniques to enhance the performance of active ingredients, investigating synergistic effects with other compounds, and exploring new applications in precision agriculture and biopesticides. As the global agricultural sector continues to face challenges such as climate change, population growth, and resource scarcity, the role of ethyl acetate in developing innovative agrochemical solutions is likely to become increasingly important.

The primary objective of researching ethyl acetate in agrochemical applications is to enhance the efficacy and safety of agricultural products while minimizing environmental impact. As global agricultural practices continue to evolve, there is a pressing need for innovative solutions that can address the challenges of pest control, crop yield improvement, and sustainable farming. Ethyl acetate, with its low toxicity and high solvency power, presents a promising avenue for achieving these goals.

One of the key trends driving the increased adoption of ethyl acetate in agrochemicals is the shift towards more sustainable and eco-friendly farming practices. As regulatory bodies worldwide impose stricter guidelines on the use of chemical agents in agriculture, ethyl acetate's relatively benign environmental profile makes it an attractive alternative to more harmful solvents. This trend is expected to continue, with researchers and agrochemical companies focusing on developing formulations that maximize the benefits of ethyl acetate while minimizing potential drawbacks.

The technical evolution of ethyl acetate in agrochemicals has seen significant advancements in recent years. Researchers have been exploring novel ways to leverage its solvent properties to improve the stability, efficacy, and delivery mechanisms of various agrochemical formulations. This includes the development of microemulsions, controlled-release systems, and enhanced penetration formulations that utilize ethyl acetate as a key component.

Looking ahead, the future of ethyl acetate in agrochemical applications appears promising, with several key areas of focus for ongoing research and development. These include optimizing formulation techniques to enhance the performance of active ingredients, investigating synergistic effects with other compounds, and exploring new applications in precision agriculture and biopesticides. As the global agricultural sector continues to face challenges such as climate change, population growth, and resource scarcity, the role of ethyl acetate in developing innovative agrochemical solutions is likely to become increasingly important.

Market Analysis for Ethyl Acetate-based Agrochemicals

The global market for ethyl acetate-based agrochemicals has been experiencing steady growth in recent years, driven by increasing demand for effective and environmentally friendly crop protection solutions. This segment of the agrochemical industry is expected to continue its upward trajectory due to several key factors influencing market dynamics.

One of the primary drivers of market growth is the rising global population and the consequent need for increased food production. As arable land becomes scarcer, farmers are turning to more efficient and targeted agrochemical solutions to maximize crop yields. Ethyl acetate-based formulations have gained popularity due to their effectiveness in delivering active ingredients to crops while minimizing environmental impact.

The market for ethyl acetate-based agrochemicals is also benefiting from the growing trend towards sustainable agriculture. These formulations often offer improved biodegradability and reduced toxicity compared to traditional petrochemical-based alternatives. This aligns well with increasingly stringent environmental regulations and consumer preferences for eco-friendly agricultural practices.

Regionally, Asia-Pacific is emerging as a key market for ethyl acetate-based agrochemicals, with China and India leading the growth. The large agricultural sectors in these countries, coupled with government initiatives to promote modern farming techniques, are driving demand. North America and Europe, while mature markets, continue to show steady growth due to the adoption of precision agriculture and the push for more sustainable farming practices.

The market is characterized by a mix of established agrochemical companies and innovative startups. Major players are investing heavily in research and development to create novel ethyl acetate-based formulations that offer improved efficacy and environmental profiles. This has led to a surge in patent applications and collaborations between agrochemical firms and research institutions.

Despite the positive outlook, the market faces challenges such as price volatility of raw materials and regulatory hurdles in some regions. The cost of ethyl acetate, which is derived from ethanol or acetic acid, can fluctuate based on feedstock prices and production capacities. Additionally, the registration process for new agrochemical formulations can be lengthy and costly, potentially slowing market growth.

Looking ahead, the market for ethyl acetate-based agrochemicals is poised for further expansion. Technological advancements in formulation techniques and the development of new active ingredients compatible with ethyl acetate are expected to drive innovation in the sector. The increasing adoption of integrated pest management strategies and precision agriculture is likely to create new opportunities for targeted, ethyl acetate-based agrochemical applications.

One of the primary drivers of market growth is the rising global population and the consequent need for increased food production. As arable land becomes scarcer, farmers are turning to more efficient and targeted agrochemical solutions to maximize crop yields. Ethyl acetate-based formulations have gained popularity due to their effectiveness in delivering active ingredients to crops while minimizing environmental impact.

The market for ethyl acetate-based agrochemicals is also benefiting from the growing trend towards sustainable agriculture. These formulations often offer improved biodegradability and reduced toxicity compared to traditional petrochemical-based alternatives. This aligns well with increasingly stringent environmental regulations and consumer preferences for eco-friendly agricultural practices.

Regionally, Asia-Pacific is emerging as a key market for ethyl acetate-based agrochemicals, with China and India leading the growth. The large agricultural sectors in these countries, coupled with government initiatives to promote modern farming techniques, are driving demand. North America and Europe, while mature markets, continue to show steady growth due to the adoption of precision agriculture and the push for more sustainable farming practices.

The market is characterized by a mix of established agrochemical companies and innovative startups. Major players are investing heavily in research and development to create novel ethyl acetate-based formulations that offer improved efficacy and environmental profiles. This has led to a surge in patent applications and collaborations between agrochemical firms and research institutions.

Despite the positive outlook, the market faces challenges such as price volatility of raw materials and regulatory hurdles in some regions. The cost of ethyl acetate, which is derived from ethanol or acetic acid, can fluctuate based on feedstock prices and production capacities. Additionally, the registration process for new agrochemical formulations can be lengthy and costly, potentially slowing market growth.

Looking ahead, the market for ethyl acetate-based agrochemicals is poised for further expansion. Technological advancements in formulation techniques and the development of new active ingredients compatible with ethyl acetate are expected to drive innovation in the sector. The increasing adoption of integrated pest management strategies and precision agriculture is likely to create new opportunities for targeted, ethyl acetate-based agrochemical applications.

Current Challenges in Ethyl Acetate Agrochemical Applications

The use of ethyl acetate in agrochemical applications faces several significant challenges that hinder its widespread adoption and optimal utilization. One of the primary concerns is the volatility of ethyl acetate, which can lead to rapid evaporation during application. This characteristic not only reduces the effectiveness of the agrochemical formulations but also raises environmental concerns due to the release of volatile organic compounds (VOCs) into the atmosphere.

Another challenge lies in the compatibility of ethyl acetate with various active ingredients used in agrochemicals. While ethyl acetate is an excellent solvent for many organic compounds, it may not be suitable for all types of pesticides, herbicides, or plant growth regulators. This limitation restricts its universal application across different agrochemical products and necessitates careful formulation design to ensure stability and efficacy.

The potential for phytotoxicity is also a significant concern when using ethyl acetate in agrochemical applications. Some crops may be sensitive to ethyl acetate, especially when used in high concentrations or under certain environmental conditions. This sensitivity can lead to crop damage, yield reduction, or quality issues, which are unacceptable outcomes in agricultural production.

Furthermore, the regulatory landscape poses challenges for the use of ethyl acetate in agrochemicals. Different countries and regions have varying regulations regarding the use of solvents in agricultural products. Compliance with these diverse regulatory requirements can be complex and costly for manufacturers, potentially limiting the global market for ethyl acetate-based agrochemical formulations.

The cost-effectiveness of ethyl acetate compared to alternative solvents or formulation technologies is another challenge. While ethyl acetate offers certain advantages, its production costs and the need for specialized handling and application equipment may make it less economically viable for some agrochemical applications, particularly in developing countries or for low-value crops.

Lastly, there are technical challenges related to the formulation stability of ethyl acetate-based agrochemicals. The solvent's properties can affect the long-term stability of the formulation, potentially leading to issues such as phase separation, crystallization of active ingredients, or changes in viscosity during storage. Overcoming these stability challenges requires advanced formulation techniques and may necessitate the use of additional additives, further complicating the product development process.

Addressing these challenges requires a multifaceted approach, involving research in formulation chemistry, application technology, and regulatory science. Innovations in controlled-release technologies, microencapsulation, and the development of ethyl acetate-based co-solvent systems may offer potential solutions to some of these issues, paving the way for more effective and sustainable use of ethyl acetate in agrochemical applications.

Another challenge lies in the compatibility of ethyl acetate with various active ingredients used in agrochemicals. While ethyl acetate is an excellent solvent for many organic compounds, it may not be suitable for all types of pesticides, herbicides, or plant growth regulators. This limitation restricts its universal application across different agrochemical products and necessitates careful formulation design to ensure stability and efficacy.

The potential for phytotoxicity is also a significant concern when using ethyl acetate in agrochemical applications. Some crops may be sensitive to ethyl acetate, especially when used in high concentrations or under certain environmental conditions. This sensitivity can lead to crop damage, yield reduction, or quality issues, which are unacceptable outcomes in agricultural production.

Furthermore, the regulatory landscape poses challenges for the use of ethyl acetate in agrochemicals. Different countries and regions have varying regulations regarding the use of solvents in agricultural products. Compliance with these diverse regulatory requirements can be complex and costly for manufacturers, potentially limiting the global market for ethyl acetate-based agrochemical formulations.

The cost-effectiveness of ethyl acetate compared to alternative solvents or formulation technologies is another challenge. While ethyl acetate offers certain advantages, its production costs and the need for specialized handling and application equipment may make it less economically viable for some agrochemical applications, particularly in developing countries or for low-value crops.

Lastly, there are technical challenges related to the formulation stability of ethyl acetate-based agrochemicals. The solvent's properties can affect the long-term stability of the formulation, potentially leading to issues such as phase separation, crystallization of active ingredients, or changes in viscosity during storage. Overcoming these stability challenges requires advanced formulation techniques and may necessitate the use of additional additives, further complicating the product development process.

Addressing these challenges requires a multifaceted approach, involving research in formulation chemistry, application technology, and regulatory science. Innovations in controlled-release technologies, microencapsulation, and the development of ethyl acetate-based co-solvent systems may offer potential solutions to some of these issues, paving the way for more effective and sustainable use of ethyl acetate in agrochemical applications.

Existing Ethyl Acetate Formulations for Crop Protection

01 Production and purification of ethyl acetate

Various methods are employed for the production and purification of ethyl acetate, including distillation, extraction, and reactive distillation processes. These techniques aim to improve the yield and purity of ethyl acetate while reducing energy consumption and production costs.- Production and purification of ethyl acetate: Ethyl acetate is produced through various methods, including esterification of ethanol and acetic acid. Purification techniques involve distillation, extraction, and membrane separation to obtain high-quality ethyl acetate for industrial applications.

- Applications in chemical processes and solvents: Ethyl acetate is widely used as a solvent in various industries, including pharmaceuticals, paints, and coatings. It is also employed in chemical processes as a reaction medium and extractant due to its favorable properties and low toxicity.

- Ethyl acetate in polymer and material science: Ethyl acetate plays a crucial role in polymer synthesis and processing. It is used as a solvent for various polymers, in the production of adhesives, and in the development of advanced materials with specific properties.

- Environmental and safety considerations: Research focuses on developing environmentally friendly production methods for ethyl acetate, as well as improving safety measures in its handling and storage. This includes the use of green chemistry principles and the implementation of advanced process control systems.

- Novel applications and derivatives of ethyl acetate: Ongoing research explores new applications of ethyl acetate and its derivatives in fields such as energy storage, drug delivery systems, and advanced materials. This includes the development of functionalized ethyl acetate compounds for specific industrial and technological applications.

02 Applications of ethyl acetate in chemical processes

Ethyl acetate is widely used as a solvent and reagent in various chemical processes. It finds applications in the production of pharmaceuticals, polymers, and other organic compounds. Its properties make it suitable for extraction, crystallization, and as a reaction medium in different industrial processes.Expand Specific Solutions03 Ethyl acetate in coating and adhesive formulations

Ethyl acetate is a key component in many coating and adhesive formulations. It is used as a solvent in paints, varnishes, and lacquers, providing good solvency and fast evaporation properties. In adhesives, it helps to improve the application and drying characteristics of the formulations.Expand Specific Solutions04 Ethyl acetate in the food and flavor industry

In the food and flavor industry, ethyl acetate is used as a flavoring agent and solvent for the extraction of natural flavors and fragrances. It is also employed in the production of artificial fruit essences and as a component in some food packaging materials.Expand Specific Solutions05 Environmental and safety considerations for ethyl acetate

As ethyl acetate is a volatile organic compound, there are environmental and safety considerations associated with its use and production. Research focuses on developing more environmentally friendly production methods, improving handling and storage practices, and exploring potential alternatives in certain applications to reduce its environmental impact.Expand Specific Solutions

Key Players in Ethyl Acetate Agrochemical Industry

The research on ethyl acetate use in agrochemical applications is in a growth phase, with increasing market size due to rising demand for eco-friendly pesticides and solvents. The global market for ethyl acetate in agrochemicals is expanding, driven by its versatility and lower toxicity compared to alternatives. Technologically, the field is moderately mature, with ongoing innovations focused on improving efficiency and sustainability. Key players like BASF Corp., Eastman Chemical Co., and Celanese International Corp. are at the forefront, investing in R&D to enhance product performance and reduce environmental impact. Emerging companies such as Nantong Acetic Acid Chemical Co., Ltd. and LanzaTech NZ, Inc. are also contributing to technological advancements, particularly in bio-based ethyl acetate production.

Eastman Chemical Co.

Technical Solution: Eastman Chemical Co. has conducted research on the use of ethyl acetate in agrochemical applications, focusing on its role as a solvent and co-formulant. Their approach involves utilizing ethyl acetate's favorable properties, such as low toxicity and high solvency, in the development of eco-friendly pesticide formulations[10]. Eastman has explored the use of ethyl acetate in emulsifiable concentrate (EC) formulations, where it serves as a primary solvent for active ingredients, improving their stability and ease of application[11]. They have also investigated the potential of ethyl acetate-based co-solvents to enhance the penetration of systemic pesticides through plant tissues, potentially leading to reduced application rates[12].

Strengths: Expertise in specialty chemicals and sustainable solutions. Weaknesses: Limited direct presence in the agrochemical market compared to dedicated agrochemical companies.

BASF Corp.

Technical Solution: BASF has developed innovative formulations incorporating ethyl acetate for agrochemical applications. Their research focuses on enhancing the efficacy and sustainability of crop protection products. BASF's approach involves using ethyl acetate as a solvent in microemulsion concentrates, which improves the stability and bioavailability of active ingredients[1]. They have also explored the use of ethyl acetate in seed treatment formulations, where it acts as a carrier for fungicides and insecticides, ensuring better coverage and adhesion to seeds[2]. Additionally, BASF has investigated the potential of ethyl acetate-based adjuvants to improve the spreading and penetration of foliar-applied agrochemicals, potentially reducing the required application rates[3].

Strengths: Extensive R&D capabilities, global market presence, and a diverse product portfolio. Weaknesses: Potential environmental concerns associated with solvent use and regulatory challenges in different regions.

Innovations in Ethyl Acetate-based Agrochemical Solutions

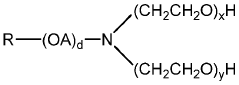

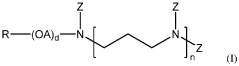

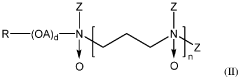

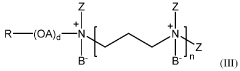

Alkyl etheramine polyglycerol surfactants

PatentWO2021219681A1

Innovation

- Development of alkyl etheramine polyglycerol surfactants using glycidol, which is less hazardous than ethylene oxide, and reacting it with etheramines to create surfactants with structures that include glyceryl residues and hydrocarbon groups, allowing for easier handling and manufacturing, and providing compatibility in high load pesticide compositions.

Processes for making ethyl acetate from acetic acid

PatentInactiveEP2493607A1

Innovation

- A process involving hydrogenation of acetic acid using catalysts composed of metals like nickel, palladium, or platinum, combined with support materials like silica or titania, and modified with oxides of Group IVB, VB, or VIB metals, which achieve high selectivity to ethyl acetate while minimizing by-product formation.

Environmental Impact of Ethyl Acetate in Agrochemicals

The use of ethyl acetate in agrochemical applications has raised concerns about its potential environmental impact. As a widely used solvent in pesticide formulations, ethyl acetate's presence in agricultural ecosystems warrants careful examination. When applied to crops, a significant portion of ethyl acetate can volatilize into the atmosphere, contributing to air pollution and potentially affecting air quality in surrounding areas.

In soil environments, ethyl acetate exhibits moderate mobility and can leach into groundwater systems. However, its rapid biodegradation in both aerobic and anaerobic conditions mitigates long-term soil contamination risks. Microbial communities in soil readily metabolize ethyl acetate, typically resulting in a half-life of less than two weeks under favorable conditions. This rapid breakdown limits its persistence in terrestrial ecosystems.

Aquatic ecosystems face potential risks from ethyl acetate runoff. While the compound is moderately toxic to aquatic organisms, its high volatility and quick biodegradation in water bodies reduce the likelihood of prolonged exposure. Studies have shown that ethyl acetate concentrations in surface waters typically decrease rapidly due to evaporation and microbial degradation, minimizing chronic effects on aquatic life.

The impact of ethyl acetate on non-target organisms, including beneficial insects and pollinators, remains a subject of ongoing research. While acute toxicity is generally low, sublethal effects on behavior and reproduction require further investigation. Some studies suggest that ethyl acetate may act as an attractant for certain insect species, potentially disrupting natural ecological balances.

From a broader environmental perspective, the production and use of ethyl acetate in agrochemicals contribute to overall carbon emissions and energy consumption. Life cycle assessments indicate that the manufacturing process and transportation of ethyl acetate-based agrochemicals have a notable carbon footprint. However, when compared to some alternative solvents, ethyl acetate often presents a more favorable environmental profile due to its biodegradability and lower toxicity.

Regulatory bodies worldwide have established guidelines for the use and disposal of ethyl acetate in agricultural settings. These regulations aim to minimize environmental contamination and protect ecosystem health. Best practices for handling and applying ethyl acetate-based agrochemicals include proper storage, controlled application techniques, and appropriate disposal methods for unused products and containers.

As the agricultural sector continues to prioritize sustainability, ongoing research focuses on developing greener alternatives to ethyl acetate and optimizing its use in agrochemical formulations. Innovations in precision agriculture and smart delivery systems show promise in reducing the overall environmental footprint of ethyl acetate and other solvents in agricultural applications.

In soil environments, ethyl acetate exhibits moderate mobility and can leach into groundwater systems. However, its rapid biodegradation in both aerobic and anaerobic conditions mitigates long-term soil contamination risks. Microbial communities in soil readily metabolize ethyl acetate, typically resulting in a half-life of less than two weeks under favorable conditions. This rapid breakdown limits its persistence in terrestrial ecosystems.

Aquatic ecosystems face potential risks from ethyl acetate runoff. While the compound is moderately toxic to aquatic organisms, its high volatility and quick biodegradation in water bodies reduce the likelihood of prolonged exposure. Studies have shown that ethyl acetate concentrations in surface waters typically decrease rapidly due to evaporation and microbial degradation, minimizing chronic effects on aquatic life.

The impact of ethyl acetate on non-target organisms, including beneficial insects and pollinators, remains a subject of ongoing research. While acute toxicity is generally low, sublethal effects on behavior and reproduction require further investigation. Some studies suggest that ethyl acetate may act as an attractant for certain insect species, potentially disrupting natural ecological balances.

From a broader environmental perspective, the production and use of ethyl acetate in agrochemicals contribute to overall carbon emissions and energy consumption. Life cycle assessments indicate that the manufacturing process and transportation of ethyl acetate-based agrochemicals have a notable carbon footprint. However, when compared to some alternative solvents, ethyl acetate often presents a more favorable environmental profile due to its biodegradability and lower toxicity.

Regulatory bodies worldwide have established guidelines for the use and disposal of ethyl acetate in agricultural settings. These regulations aim to minimize environmental contamination and protect ecosystem health. Best practices for handling and applying ethyl acetate-based agrochemicals include proper storage, controlled application techniques, and appropriate disposal methods for unused products and containers.

As the agricultural sector continues to prioritize sustainability, ongoing research focuses on developing greener alternatives to ethyl acetate and optimizing its use in agrochemical formulations. Innovations in precision agriculture and smart delivery systems show promise in reducing the overall environmental footprint of ethyl acetate and other solvents in agricultural applications.

Regulatory Framework for Agrochemical Solvents

The regulatory framework for agrochemical solvents plays a crucial role in ensuring the safe and responsible use of ethyl acetate in agricultural applications. Governments and international organizations have established comprehensive guidelines and regulations to govern the production, distribution, and application of agrochemical solvents, including ethyl acetate.

At the global level, the Food and Agriculture Organization (FAO) and the World Health Organization (WHO) have jointly developed the International Code of Conduct on Pesticide Management. This code provides a framework for best practices in pesticide management, including the use of solvents like ethyl acetate. It emphasizes the importance of risk assessment, proper labeling, and responsible handling of agrochemical products.

In the United States, the Environmental Protection Agency (EPA) regulates agrochemical solvents under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). This act requires manufacturers to register their products and provide detailed information on their composition, including solvents used. The EPA also sets tolerance levels for residues of agrochemical solvents in food products.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to all chemical substances, including those used in agrochemical formulations. Under REACH, manufacturers and importers must register their substances and provide safety data to the European Chemicals Agency (ECHA).

Many countries have established their own regulatory bodies to oversee the use of agrochemical solvents. For instance, in China, the Institute for the Control of Agrochemicals, Ministry of Agriculture (ICAMA) is responsible for pesticide registration and management, including the regulation of solvents used in agrochemical formulations.

Regulatory frameworks often include specific requirements for the labeling of agrochemical products containing solvents like ethyl acetate. These labels must provide information on proper handling, storage, and disposal, as well as potential environmental and health risks associated with the product.

Environmental protection is a key focus of regulatory frameworks for agrochemical solvents. Many jurisdictions require manufacturers to conduct environmental impact assessments and implement measures to minimize the ecological footprint of their products. This includes guidelines for proper disposal of unused solvents and contaminated packaging.

Occupational health and safety regulations also play a significant role in the regulatory framework for agrochemical solvents. These regulations set standards for worker protection, including requirements for personal protective equipment, exposure limits, and safety training programs.

As research on ethyl acetate use in agrochemical applications continues to evolve, regulatory frameworks are regularly updated to reflect new scientific findings and emerging best practices. This ongoing process ensures that the use of ethyl acetate and other solvents in agriculture remains safe, effective, and environmentally responsible.

At the global level, the Food and Agriculture Organization (FAO) and the World Health Organization (WHO) have jointly developed the International Code of Conduct on Pesticide Management. This code provides a framework for best practices in pesticide management, including the use of solvents like ethyl acetate. It emphasizes the importance of risk assessment, proper labeling, and responsible handling of agrochemical products.

In the United States, the Environmental Protection Agency (EPA) regulates agrochemical solvents under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). This act requires manufacturers to register their products and provide detailed information on their composition, including solvents used. The EPA also sets tolerance levels for residues of agrochemical solvents in food products.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to all chemical substances, including those used in agrochemical formulations. Under REACH, manufacturers and importers must register their substances and provide safety data to the European Chemicals Agency (ECHA).

Many countries have established their own regulatory bodies to oversee the use of agrochemical solvents. For instance, in China, the Institute for the Control of Agrochemicals, Ministry of Agriculture (ICAMA) is responsible for pesticide registration and management, including the regulation of solvents used in agrochemical formulations.

Regulatory frameworks often include specific requirements for the labeling of agrochemical products containing solvents like ethyl acetate. These labels must provide information on proper handling, storage, and disposal, as well as potential environmental and health risks associated with the product.

Environmental protection is a key focus of regulatory frameworks for agrochemical solvents. Many jurisdictions require manufacturers to conduct environmental impact assessments and implement measures to minimize the ecological footprint of their products. This includes guidelines for proper disposal of unused solvents and contaminated packaging.

Occupational health and safety regulations also play a significant role in the regulatory framework for agrochemical solvents. These regulations set standards for worker protection, including requirements for personal protective equipment, exposure limits, and safety training programs.

As research on ethyl acetate use in agrochemical applications continues to evolve, regulatory frameworks are regularly updated to reflect new scientific findings and emerging best practices. This ongoing process ensures that the use of ethyl acetate and other solvents in agriculture remains safe, effective, and environmentally responsible.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!