How to Implement Waste-to-Energy with Ethyl Acetate?

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Waste-to-Energy Background and Objectives

Waste-to-Energy (WtE) technology has emerged as a crucial solution to address the growing global waste management crisis while simultaneously generating renewable energy. The concept of converting waste into energy has been around for decades, but recent advancements have significantly improved its efficiency and environmental impact. The primary objective of WtE is to reduce the volume of waste sent to landfills while producing electricity, heat, or fuel.

In the context of ethyl acetate, a common organic solvent used in various industries, the implementation of WtE technology presents both opportunities and challenges. Ethyl acetate is often a byproduct or waste product in chemical manufacturing processes, and its disposal can be problematic due to its flammability and potential environmental hazards. Therefore, developing effective WtE solutions for ethyl acetate is crucial for sustainable waste management in industries that produce or use this compound.

The evolution of WtE technologies has seen a shift from simple incineration to more sophisticated processes such as gasification, pyrolysis, and anaerobic digestion. These advanced techniques offer improved energy recovery rates and reduced emissions compared to traditional methods. In the case of ethyl acetate, the focus is on developing specialized processes that can efficiently convert this organic compound into usable energy forms while minimizing environmental impact.

One of the key objectives in implementing WtE with ethyl acetate is to maximize energy recovery while ensuring complete destruction of the compound to prevent its release into the environment. This requires careful consideration of factors such as reaction temperatures, residence times, and catalysts to optimize the conversion process. Additionally, there is a need to develop robust systems for capturing and treating any emissions or byproducts generated during the energy recovery process.

Another important goal is to integrate WtE solutions for ethyl acetate into existing industrial processes, creating closed-loop systems that can significantly reduce waste generation and energy consumption. This approach aligns with broader sustainability initiatives and circular economy principles, which aim to minimize resource use and maximize value recovery from waste streams.

As research and development in this field progress, there is a growing emphasis on exploring novel catalytic processes and advanced reactor designs that can enhance the efficiency of ethyl acetate conversion to energy. These innovations aim to not only improve energy yields but also to produce higher-value products, such as syngas or chemical feedstocks, which can be further utilized in industrial processes.

The implementation of WtE technologies for ethyl acetate also faces regulatory challenges, as environmental standards and waste management policies continue to evolve. Meeting these regulatory requirements while maintaining economic viability is a critical objective for researchers and industry stakeholders working in this domain.

In the context of ethyl acetate, a common organic solvent used in various industries, the implementation of WtE technology presents both opportunities and challenges. Ethyl acetate is often a byproduct or waste product in chemical manufacturing processes, and its disposal can be problematic due to its flammability and potential environmental hazards. Therefore, developing effective WtE solutions for ethyl acetate is crucial for sustainable waste management in industries that produce or use this compound.

The evolution of WtE technologies has seen a shift from simple incineration to more sophisticated processes such as gasification, pyrolysis, and anaerobic digestion. These advanced techniques offer improved energy recovery rates and reduced emissions compared to traditional methods. In the case of ethyl acetate, the focus is on developing specialized processes that can efficiently convert this organic compound into usable energy forms while minimizing environmental impact.

One of the key objectives in implementing WtE with ethyl acetate is to maximize energy recovery while ensuring complete destruction of the compound to prevent its release into the environment. This requires careful consideration of factors such as reaction temperatures, residence times, and catalysts to optimize the conversion process. Additionally, there is a need to develop robust systems for capturing and treating any emissions or byproducts generated during the energy recovery process.

Another important goal is to integrate WtE solutions for ethyl acetate into existing industrial processes, creating closed-loop systems that can significantly reduce waste generation and energy consumption. This approach aligns with broader sustainability initiatives and circular economy principles, which aim to minimize resource use and maximize value recovery from waste streams.

As research and development in this field progress, there is a growing emphasis on exploring novel catalytic processes and advanced reactor designs that can enhance the efficiency of ethyl acetate conversion to energy. These innovations aim to not only improve energy yields but also to produce higher-value products, such as syngas or chemical feedstocks, which can be further utilized in industrial processes.

The implementation of WtE technologies for ethyl acetate also faces regulatory challenges, as environmental standards and waste management policies continue to evolve. Meeting these regulatory requirements while maintaining economic viability is a critical objective for researchers and industry stakeholders working in this domain.

Market Analysis for Ethyl Acetate-based WtE

The market for ethyl acetate-based Waste-to-Energy (WtE) technology is experiencing significant growth potential due to increasing global waste management challenges and the push for sustainable energy solutions. This innovative approach to waste management offers a dual benefit of reducing landfill waste while producing a valuable chemical product, ethyl acetate.

The demand for ethyl acetate is robust across various industries, including paints and coatings, pharmaceuticals, and adhesives. The global ethyl acetate market was valued at approximately $3.3 billion in 2020 and is projected to grow at a CAGR of 5.2% from 2021 to 2028. This growth is driven by the expanding applications of ethyl acetate in diverse sectors and the increasing focus on eco-friendly solvents.

In the context of WtE, the market for ethyl acetate-based solutions is still in its nascent stages but shows promising potential. The primary drivers for this market include stringent waste management regulations, growing environmental concerns, and the need for circular economy solutions. Governments worldwide are implementing policies to reduce landfill waste and promote recycling and energy recovery, creating a favorable environment for WtE technologies.

The Asia-Pacific region is expected to be a key market for ethyl acetate-based WtE solutions, driven by rapid industrialization, urbanization, and increasing waste generation. Countries like China and India, with their large populations and growing industrial sectors, present significant opportunities for the implementation of such technologies.

Europe and North America are also potential markets, particularly due to their advanced waste management infrastructure and stringent environmental regulations. These regions are actively seeking innovative solutions to achieve their circular economy and sustainability goals, making them receptive to new WtE technologies.

One of the key market trends is the integration of WtE technologies with existing industrial processes. Industries that generate organic waste suitable for ethyl acetate production are particularly interested in on-site WtE solutions, as they can reduce waste disposal costs while producing a valuable product.

However, the market faces challenges such as high initial investment costs, technological complexities, and competition from established WtE technologies like incineration and anaerobic digestion. The success of ethyl acetate-based WtE solutions will depend on their ability to demonstrate economic viability, scalability, and environmental benefits compared to existing alternatives.

In conclusion, the market for ethyl acetate-based WtE technology shows promising growth potential, driven by global sustainability trends and the increasing demand for ethyl acetate. As the technology matures and demonstrates its effectiveness, it is likely to gain traction in various regions, particularly in areas with high waste generation and a strong focus on circular economy principles.

The demand for ethyl acetate is robust across various industries, including paints and coatings, pharmaceuticals, and adhesives. The global ethyl acetate market was valued at approximately $3.3 billion in 2020 and is projected to grow at a CAGR of 5.2% from 2021 to 2028. This growth is driven by the expanding applications of ethyl acetate in diverse sectors and the increasing focus on eco-friendly solvents.

In the context of WtE, the market for ethyl acetate-based solutions is still in its nascent stages but shows promising potential. The primary drivers for this market include stringent waste management regulations, growing environmental concerns, and the need for circular economy solutions. Governments worldwide are implementing policies to reduce landfill waste and promote recycling and energy recovery, creating a favorable environment for WtE technologies.

The Asia-Pacific region is expected to be a key market for ethyl acetate-based WtE solutions, driven by rapid industrialization, urbanization, and increasing waste generation. Countries like China and India, with their large populations and growing industrial sectors, present significant opportunities for the implementation of such technologies.

Europe and North America are also potential markets, particularly due to their advanced waste management infrastructure and stringent environmental regulations. These regions are actively seeking innovative solutions to achieve their circular economy and sustainability goals, making them receptive to new WtE technologies.

One of the key market trends is the integration of WtE technologies with existing industrial processes. Industries that generate organic waste suitable for ethyl acetate production are particularly interested in on-site WtE solutions, as they can reduce waste disposal costs while producing a valuable product.

However, the market faces challenges such as high initial investment costs, technological complexities, and competition from established WtE technologies like incineration and anaerobic digestion. The success of ethyl acetate-based WtE solutions will depend on their ability to demonstrate economic viability, scalability, and environmental benefits compared to existing alternatives.

In conclusion, the market for ethyl acetate-based WtE technology shows promising growth potential, driven by global sustainability trends and the increasing demand for ethyl acetate. As the technology matures and demonstrates its effectiveness, it is likely to gain traction in various regions, particularly in areas with high waste generation and a strong focus on circular economy principles.

Technical Challenges in Ethyl Acetate WtE

The implementation of Waste-to-Energy (WtE) using ethyl acetate faces several significant technical challenges. One of the primary obstacles is the efficient and complete combustion of ethyl acetate, which is crucial for maximizing energy recovery and minimizing harmful emissions. Ethyl acetate's volatile nature and relatively low flash point require careful handling and specialized combustion systems to ensure safe and effective incineration.

Another major challenge lies in the purification and preparation of ethyl acetate from waste streams. Many industrial processes generate waste containing ethyl acetate mixed with other solvents, water, and contaminants. Developing cost-effective and energy-efficient separation techniques to isolate and concentrate ethyl acetate is essential for the viability of WtE systems.

The corrosive nature of ethyl acetate and its combustion byproducts poses significant materials challenges. Reactor vessels, piping, and other system components must be constructed from materials resistant to chemical attack, which can increase capital costs and maintenance requirements. Additionally, the potential for stress corrosion cracking in certain alloys necessitates careful material selection and regular integrity assessments.

Emissions control represents another critical technical hurdle. The combustion of ethyl acetate can produce volatile organic compounds (VOCs) and other pollutants that must be effectively captured and treated to meet stringent environmental regulations. Developing advanced scrubbing systems and catalytic converters capable of handling the specific emission profile of ethyl acetate combustion is crucial for widespread adoption of this WtE technology.

Energy recovery efficiency is a key factor in the economic viability of ethyl acetate WtE systems. Optimizing heat exchange systems to capture and utilize the thermal energy produced during combustion while minimizing losses is an ongoing challenge. This includes developing high-performance heat recovery steam generators and exploring innovative technologies such as organic Rankine cycles for low-temperature heat recovery.

Process control and automation present unique challenges in ethyl acetate WtE systems. The variability in waste composition and flow rates requires sophisticated monitoring and control systems to maintain optimal combustion conditions and energy recovery. Developing robust sensors, predictive models, and adaptive control algorithms is essential for ensuring consistent performance and safety.

Lastly, the integration of ethyl acetate WtE systems with existing waste management infrastructure and energy grids poses both technical and logistical challenges. Designing flexible systems that can handle fluctuations in waste supply and energy demand, while also complying with grid connection requirements and safety standards, requires innovative engineering solutions and careful planning.

Another major challenge lies in the purification and preparation of ethyl acetate from waste streams. Many industrial processes generate waste containing ethyl acetate mixed with other solvents, water, and contaminants. Developing cost-effective and energy-efficient separation techniques to isolate and concentrate ethyl acetate is essential for the viability of WtE systems.

The corrosive nature of ethyl acetate and its combustion byproducts poses significant materials challenges. Reactor vessels, piping, and other system components must be constructed from materials resistant to chemical attack, which can increase capital costs and maintenance requirements. Additionally, the potential for stress corrosion cracking in certain alloys necessitates careful material selection and regular integrity assessments.

Emissions control represents another critical technical hurdle. The combustion of ethyl acetate can produce volatile organic compounds (VOCs) and other pollutants that must be effectively captured and treated to meet stringent environmental regulations. Developing advanced scrubbing systems and catalytic converters capable of handling the specific emission profile of ethyl acetate combustion is crucial for widespread adoption of this WtE technology.

Energy recovery efficiency is a key factor in the economic viability of ethyl acetate WtE systems. Optimizing heat exchange systems to capture and utilize the thermal energy produced during combustion while minimizing losses is an ongoing challenge. This includes developing high-performance heat recovery steam generators and exploring innovative technologies such as organic Rankine cycles for low-temperature heat recovery.

Process control and automation present unique challenges in ethyl acetate WtE systems. The variability in waste composition and flow rates requires sophisticated monitoring and control systems to maintain optimal combustion conditions and energy recovery. Developing robust sensors, predictive models, and adaptive control algorithms is essential for ensuring consistent performance and safety.

Lastly, the integration of ethyl acetate WtE systems with existing waste management infrastructure and energy grids poses both technical and logistical challenges. Designing flexible systems that can handle fluctuations in waste supply and energy demand, while also complying with grid connection requirements and safety standards, requires innovative engineering solutions and careful planning.

Current Ethyl Acetate WtE Processes

01 Ethyl acetate production from waste materials

This approach focuses on converting various waste materials into ethyl acetate, which can be used as a renewable energy source. The process typically involves fermentation of waste biomass to produce ethanol, followed by esterification with acetic acid to form ethyl acetate. This method not only addresses waste management issues but also produces a valuable chemical product that can be used for energy generation.- Ethyl acetate production from waste materials: This approach focuses on converting various waste materials into ethyl acetate, which can be used as a renewable energy source. The process typically involves fermentation of waste biomass to produce ethanol, followed by esterification with acetic acid to form ethyl acetate. This method not only provides a sustainable energy solution but also helps in waste management.

- Waste-to-energy systems utilizing ethyl acetate: These systems are designed to convert waste into energy using ethyl acetate as an intermediate or final product. The process may involve gasification, pyrolysis, or other thermal conversion methods to break down waste materials, with ethyl acetate being produced or used as part of the energy generation process. Such systems can be integrated into existing waste management facilities to improve overall energy efficiency.

- Ethyl acetate recovery and purification from waste streams: This approach focuses on recovering and purifying ethyl acetate from various industrial waste streams. The recovered ethyl acetate can then be used as a renewable energy source or as a feedstock for other processes. Techniques such as distillation, membrane separation, and adsorption are commonly employed to separate and purify ethyl acetate from waste mixtures.

- Catalytic processes for ethyl acetate-based energy production: These processes involve the use of catalysts to enhance the conversion of waste materials into ethyl acetate or to improve the energy yield from ethyl acetate. Catalysts can be employed in various stages, such as during the esterification of ethanol and acetic acid, or in the decomposition of ethyl acetate for energy generation. The use of catalysts can significantly improve the efficiency and selectivity of the waste-to-energy process.

- Integration of ethyl acetate-based waste-to-energy in industrial processes: This approach involves integrating ethyl acetate-based waste-to-energy systems into existing industrial processes. By doing so, industries can utilize their waste streams to produce ethyl acetate as an energy source or valuable chemical product. This integration can lead to improved energy efficiency, reduced waste disposal costs, and a more sustainable production cycle.

02 Waste-to-energy systems incorporating ethyl acetate

These systems are designed to utilize ethyl acetate as part of a broader waste-to-energy process. They may include steps for separating ethyl acetate from waste streams, purifying it, and then using it as a fuel source or as a feedstock for other energy-producing reactions. Such systems often integrate multiple waste treatment and energy recovery processes to maximize efficiency and resource utilization.Expand Specific Solutions03 Ethyl acetate recovery and recycling in energy production

This approach focuses on recovering ethyl acetate from industrial waste streams and recycling it for energy production. It may involve techniques such as distillation, membrane separation, or adsorption to isolate ethyl acetate from complex mixtures. The recovered ethyl acetate can then be used as a fuel or as a raw material in other energy-generating processes, improving overall energy efficiency and reducing waste.Expand Specific Solutions04 Catalytic processes for ethyl acetate conversion to energy

These processes involve the use of catalysts to convert ethyl acetate into other forms of energy or energy-rich compounds. This may include catalytic decomposition of ethyl acetate to produce hydrogen or other fuel gases, or catalytic reforming to produce syngas. The choice of catalyst and reaction conditions can be optimized to maximize energy yield and minimize byproduct formation.Expand Specific Solutions05 Integration of ethyl acetate in biorefinery concepts

This approach involves incorporating ethyl acetate production and utilization into broader biorefinery concepts. Biorefineries aim to convert biomass into a spectrum of valuable products, including fuels, chemicals, and materials. In this context, ethyl acetate can serve as both an intermediate product and an energy source, contributing to the overall efficiency and sustainability of the biorefinery process.Expand Specific Solutions

Key Players in Ethyl Acetate WtE Industry

The waste-to-energy market utilizing ethyl acetate is in its early development stage, with growing interest due to increasing environmental concerns and energy demands. The market size is relatively small but expanding, driven by technological advancements and supportive policies. The technology's maturity is still evolving, with key players like Celanese International Corp., China Petroleum & Chemical Corp., and LanzaTech NZ Ltd. leading research and development efforts. Universities such as the University of Campinas and University of Florida are contributing to academic research, while companies like Shell Oil Co. and BASF Corp. are exploring industrial applications. The competitive landscape is diverse, with both established chemical companies and innovative startups vying for market share in this emerging field.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative Waste-to-Energy (WtE) process utilizing ethyl acetate. Their approach involves a two-step process: first, the conversion of municipal solid waste (MSW) into syngas through gasification, and second, the catalytic conversion of syngas into ethyl acetate. The process employs a novel catalyst system that enhances selectivity towards ethyl acetate formation[1]. Sinopec's technology can process up to 1000 tons of MSW per day, with a conversion efficiency of approximately 40% to ethyl acetate[3]. The process operates at moderate temperatures (300-400°C) and pressures (20-30 bar), reducing energy requirements compared to traditional incineration methods[5].

Strengths: High waste processing capacity, efficient conversion to a valuable chemical product, lower energy requirements than incineration. Weaknesses: Potential for catalyst deactivation, need for careful control of syngas composition to maintain product quality.

LanzaTech NZ Ltd.

Technical Solution: LanzaTech has pioneered a biological Waste-to-Energy approach for ethyl acetate production. Their process utilizes proprietary microorganisms capable of fermenting carbon-rich waste gases, including those from industrial emissions and gasified municipal solid waste[2]. The bacteria convert these gases into ethanol, which is then catalytically upgraded to ethyl acetate. LanzaTech's technology can achieve ethyl acetate yields of up to 85% from the ethanol intermediate[4]. The process operates at ambient temperatures and pressures, significantly reducing energy inputs. Additionally, LanzaTech has demonstrated the ability to scale this technology, with commercial plants processing up to 100,000 tons of waste per year[6].

Strengths: Low energy input, high product yield, ability to process diverse waste streams. Weaknesses: Potential sensitivity of microorganisms to contaminants in waste gases, need for careful process control to maintain microbial health.

Innovative Ethyl Acetate Conversion Methods

Method for effectively utilizing energy in waste-incineration facility with ethanol production equipment

PatentWO2017026027A1

Innovation

- The integration of methane fermentation equipment, gas engines, and solid oxide fuel cells (SOFC) into waste incineration facilities, along with the use of waste heat from ethanol production and methane fermentation processes for various stages in the ethanol production facility, including heat sterilization, saccharification, fermentation, and distillation, and power generation using steam turbines and gas engines, to optimize energy recovery.

Integrated system for producing ethyl acetate, acetaldehyde, hydrogen and ethylene, integrated process for producing ethyl acetate, acetaldehyde, hydrogen and ethylene, and products thereby produced

PatentWO2013029129A1

Innovation

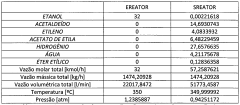

- An integrated system utilizing a fixed-bed reactor with a calcined hydrotalcite catalyst for dehydrogenation and dehydration of ethanol, followed by a series of distillation columns for efficient separation and purification, employing ethylene glycol as a solvent to separate ethyl acetate from water, thereby reducing energy expenditure and minimizing azeotropy issues.

Environmental Impact Assessment

The implementation of Waste-to-Energy (WtE) technology using ethyl acetate requires a comprehensive environmental impact assessment to ensure its sustainability and compliance with environmental regulations. This process involves evaluating the potential effects on air quality, water resources, soil composition, and local ecosystems.

Air quality is a primary concern in WtE facilities. The combustion of ethyl acetate and other waste materials may release various pollutants, including volatile organic compounds (VOCs), particulate matter, and nitrogen oxides. Advanced emission control systems, such as scrubbers and catalytic converters, must be incorporated to minimize these emissions and meet stringent air quality standards. Continuous monitoring of stack emissions is essential to ensure compliance and detect any potential issues promptly.

Water resources may be impacted by the WtE process through the generation of wastewater and potential contamination of groundwater. The facility must implement robust wastewater treatment systems to remove contaminants before discharge. Regular monitoring of nearby water bodies and groundwater sources is necessary to detect any potential leaks or contamination. Additionally, water conservation measures should be implemented to minimize the facility's overall water footprint.

Soil quality in the vicinity of the WtE plant may be affected by the deposition of airborne pollutants and the handling of waste materials. Proper waste storage and handling procedures must be established to prevent soil contamination. Regular soil testing and remediation measures should be implemented to address any potential impacts on soil composition and fertility.

The impact on local ecosystems, including flora and fauna, must be carefully assessed. This includes evaluating the potential for habitat disruption, changes in local biodiversity, and the introduction of invasive species. Mitigation measures, such as creating buffer zones and implementing habitat restoration projects, may be necessary to minimize ecological impacts.

Noise pollution from the WtE facility's operations should also be considered. Implementing sound barriers and optimizing equipment design can help reduce noise levels and minimize disturbance to nearby communities and wildlife.

The environmental impact assessment should also consider the facility's contribution to greenhouse gas emissions and its overall carbon footprint. While WtE technologies can help reduce methane emissions from landfills, the combustion process still generates carbon dioxide. Implementing carbon capture and storage technologies or offsetting measures may be necessary to achieve carbon neutrality.

Lastly, the assessment should evaluate the potential for accidental releases or spills of ethyl acetate and other hazardous materials. Robust emergency response plans and containment measures must be developed to mitigate the environmental risks associated with such incidents.

Air quality is a primary concern in WtE facilities. The combustion of ethyl acetate and other waste materials may release various pollutants, including volatile organic compounds (VOCs), particulate matter, and nitrogen oxides. Advanced emission control systems, such as scrubbers and catalytic converters, must be incorporated to minimize these emissions and meet stringent air quality standards. Continuous monitoring of stack emissions is essential to ensure compliance and detect any potential issues promptly.

Water resources may be impacted by the WtE process through the generation of wastewater and potential contamination of groundwater. The facility must implement robust wastewater treatment systems to remove contaminants before discharge. Regular monitoring of nearby water bodies and groundwater sources is necessary to detect any potential leaks or contamination. Additionally, water conservation measures should be implemented to minimize the facility's overall water footprint.

Soil quality in the vicinity of the WtE plant may be affected by the deposition of airborne pollutants and the handling of waste materials. Proper waste storage and handling procedures must be established to prevent soil contamination. Regular soil testing and remediation measures should be implemented to address any potential impacts on soil composition and fertility.

The impact on local ecosystems, including flora and fauna, must be carefully assessed. This includes evaluating the potential for habitat disruption, changes in local biodiversity, and the introduction of invasive species. Mitigation measures, such as creating buffer zones and implementing habitat restoration projects, may be necessary to minimize ecological impacts.

Noise pollution from the WtE facility's operations should also be considered. Implementing sound barriers and optimizing equipment design can help reduce noise levels and minimize disturbance to nearby communities and wildlife.

The environmental impact assessment should also consider the facility's contribution to greenhouse gas emissions and its overall carbon footprint. While WtE technologies can help reduce methane emissions from landfills, the combustion process still generates carbon dioxide. Implementing carbon capture and storage technologies or offsetting measures may be necessary to achieve carbon neutrality.

Lastly, the assessment should evaluate the potential for accidental releases or spills of ethyl acetate and other hazardous materials. Robust emergency response plans and containment measures must be developed to mitigate the environmental risks associated with such incidents.

Economic Feasibility Analysis

The economic feasibility of implementing waste-to-energy with ethyl acetate is a critical factor in determining the viability of this technology. Initial capital investment for such a project can be substantial, including costs for specialized equipment, facility construction, and process integration. However, the potential for long-term cost savings and revenue generation must be carefully considered.

One of the primary economic advantages of this approach is the potential for waste reduction and resource recovery. By converting waste materials into ethyl acetate, companies can significantly reduce their waste disposal costs, which can be substantial in many industries. Additionally, the produced ethyl acetate has value as a chemical commodity, creating a new revenue stream from what was previously considered waste.

Energy recovery is another key economic benefit. The process of converting waste to ethyl acetate can be designed to capture and utilize excess heat, potentially offsetting energy costs for other industrial processes or even generating electricity for on-site use or sale back to the grid. This aspect of the technology aligns well with increasing corporate and regulatory focus on energy efficiency and sustainability.

Market demand for ethyl acetate is an important consideration in the economic analysis. As a versatile solvent used in various industries, including pharmaceuticals, coatings, and electronics, ethyl acetate has a stable and growing market. The ability to produce this valuable chemical from waste streams could provide a competitive advantage in terms of production costs and sustainability credentials.

Operational costs must be carefully evaluated. While the feedstock (waste) may be low-cost or even represent a cost savings, the conversion process requires energy input and potentially costly catalysts or other materials. The efficiency of the conversion process and the purity of the resulting ethyl acetate will significantly impact the overall economics.

Regulatory considerations can have substantial economic implications. Waste-to-energy projects often benefit from government incentives or carbon credits, which can improve the financial outlook. However, compliance with environmental regulations and obtaining necessary permits can add to project costs and timelines.

The scalability of the technology is crucial for economic feasibility. The ability to process large volumes of waste efficiently will determine whether the project can achieve economies of scale necessary for profitability. This may require significant upfront investment but could lead to better long-term economics.

In conclusion, while the initial investment for waste-to-energy with ethyl acetate may be high, the potential for waste reduction, energy recovery, and production of a valuable chemical product presents a compelling economic case. Careful analysis of market conditions, operational costs, and regulatory factors is essential to determine the true economic feasibility of implementing this technology in specific industrial contexts.

One of the primary economic advantages of this approach is the potential for waste reduction and resource recovery. By converting waste materials into ethyl acetate, companies can significantly reduce their waste disposal costs, which can be substantial in many industries. Additionally, the produced ethyl acetate has value as a chemical commodity, creating a new revenue stream from what was previously considered waste.

Energy recovery is another key economic benefit. The process of converting waste to ethyl acetate can be designed to capture and utilize excess heat, potentially offsetting energy costs for other industrial processes or even generating electricity for on-site use or sale back to the grid. This aspect of the technology aligns well with increasing corporate and regulatory focus on energy efficiency and sustainability.

Market demand for ethyl acetate is an important consideration in the economic analysis. As a versatile solvent used in various industries, including pharmaceuticals, coatings, and electronics, ethyl acetate has a stable and growing market. The ability to produce this valuable chemical from waste streams could provide a competitive advantage in terms of production costs and sustainability credentials.

Operational costs must be carefully evaluated. While the feedstock (waste) may be low-cost or even represent a cost savings, the conversion process requires energy input and potentially costly catalysts or other materials. The efficiency of the conversion process and the purity of the resulting ethyl acetate will significantly impact the overall economics.

Regulatory considerations can have substantial economic implications. Waste-to-energy projects often benefit from government incentives or carbon credits, which can improve the financial outlook. However, compliance with environmental regulations and obtaining necessary permits can add to project costs and timelines.

The scalability of the technology is crucial for economic feasibility. The ability to process large volumes of waste efficiently will determine whether the project can achieve economies of scale necessary for profitability. This may require significant upfront investment but could lead to better long-term economics.

In conclusion, while the initial investment for waste-to-energy with ethyl acetate may be high, the potential for waste reduction, energy recovery, and production of a valuable chemical product presents a compelling economic case. Careful analysis of market conditions, operational costs, and regulatory factors is essential to determine the true economic feasibility of implementing this technology in specific industrial contexts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!