How to Synchronize Ethyl Acetate with Emerging Technologies?

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate Synergy: Background and Objectives

Ethyl acetate, a versatile organic compound, has been a staple in various industries for decades. Its unique properties, including low toxicity, pleasant odor, and excellent solvency, have made it indispensable in sectors ranging from pharmaceuticals to food production. However, as we stand on the cusp of a technological revolution, the challenge lies in synchronizing this traditional chemical with emerging technologies to unlock new potentials and applications.

The evolution of ethyl acetate usage has been closely tied to industrial advancements. Initially utilized primarily as a solvent in paints and coatings, its application spectrum has expanded significantly over time. Today, it plays crucial roles in the production of flexible packaging, adhesives, and even in the extraction of caffeine from coffee beans. This historical trajectory sets the stage for exploring how ethyl acetate can be integrated with cutting-edge technologies to address contemporary challenges and create innovative solutions.

As we delve into the synergy between ethyl acetate and emerging technologies, our primary objective is to identify novel applications and processes that can revolutionize its use across various sectors. This exploration aims to enhance the efficiency of existing applications while uncovering entirely new domains where ethyl acetate's properties can be leveraged in conjunction with advanced technologies such as nanotechnology, artificial intelligence, and biotechnology.

One of the key areas of focus is the potential for ethyl acetate in green chemistry initiatives. With growing emphasis on sustainability and environmental responsibility, there is a pressing need to develop eco-friendly processes that utilize ethyl acetate's biodegradability and low toxicity. This aligns with the global trend towards circular economy models and zero-waste manufacturing processes.

Furthermore, the integration of ethyl acetate with smart materials and responsive systems presents an exciting frontier. By combining its chemical properties with emerging materials science, we can envision adaptive coatings, self-healing polymers, and intelligent drug delivery systems that respond to environmental stimuli. These innovations could have far-reaching implications in fields such as healthcare, aerospace, and consumer electronics.

Another critical objective is to explore how digital technologies can optimize the production, distribution, and application of ethyl acetate. The implementation of Internet of Things (IoT) sensors, blockchain for supply chain transparency, and AI-driven predictive maintenance in manufacturing facilities could significantly enhance the efficiency and sustainability of ethyl acetate usage across industries.

In essence, this technological synergy aims to transform ethyl acetate from a traditional chemical compound into a key component of future-oriented, high-tech solutions. By bridging the gap between established chemical processes and emerging technologies, we seek to unlock new value propositions and address complex challenges facing society and industry alike.

The evolution of ethyl acetate usage has been closely tied to industrial advancements. Initially utilized primarily as a solvent in paints and coatings, its application spectrum has expanded significantly over time. Today, it plays crucial roles in the production of flexible packaging, adhesives, and even in the extraction of caffeine from coffee beans. This historical trajectory sets the stage for exploring how ethyl acetate can be integrated with cutting-edge technologies to address contemporary challenges and create innovative solutions.

As we delve into the synergy between ethyl acetate and emerging technologies, our primary objective is to identify novel applications and processes that can revolutionize its use across various sectors. This exploration aims to enhance the efficiency of existing applications while uncovering entirely new domains where ethyl acetate's properties can be leveraged in conjunction with advanced technologies such as nanotechnology, artificial intelligence, and biotechnology.

One of the key areas of focus is the potential for ethyl acetate in green chemistry initiatives. With growing emphasis on sustainability and environmental responsibility, there is a pressing need to develop eco-friendly processes that utilize ethyl acetate's biodegradability and low toxicity. This aligns with the global trend towards circular economy models and zero-waste manufacturing processes.

Furthermore, the integration of ethyl acetate with smart materials and responsive systems presents an exciting frontier. By combining its chemical properties with emerging materials science, we can envision adaptive coatings, self-healing polymers, and intelligent drug delivery systems that respond to environmental stimuli. These innovations could have far-reaching implications in fields such as healthcare, aerospace, and consumer electronics.

Another critical objective is to explore how digital technologies can optimize the production, distribution, and application of ethyl acetate. The implementation of Internet of Things (IoT) sensors, blockchain for supply chain transparency, and AI-driven predictive maintenance in manufacturing facilities could significantly enhance the efficiency and sustainability of ethyl acetate usage across industries.

In essence, this technological synergy aims to transform ethyl acetate from a traditional chemical compound into a key component of future-oriented, high-tech solutions. By bridging the gap between established chemical processes and emerging technologies, we seek to unlock new value propositions and address complex challenges facing society and industry alike.

Market Analysis for Tech-Enhanced Ethyl Acetate

The market for ethyl acetate has been experiencing significant growth, driven by its versatile applications across various industries. As emerging technologies continue to reshape industrial processes, there is a growing demand for innovative solutions that can synchronize ethyl acetate production and utilization with these advancements. This market analysis aims to explore the potential of tech-enhanced ethyl acetate and its implications for the industry.

The global ethyl acetate market size was valued at approximately $3.3 billion in 2020 and is projected to reach $4.9 billion by 2028, growing at a CAGR of 5.1% during the forecast period. This growth is primarily attributed to the increasing demand from end-use industries such as paints and coatings, adhesives, pharmaceuticals, and food and beverages.

One of the key drivers for the tech-enhanced ethyl acetate market is the growing emphasis on sustainability and environmental regulations. As industries seek to reduce their carbon footprint, there is a rising interest in bio-based ethyl acetate production methods. This trend aligns with the broader shift towards green chemistry and circular economy principles, creating opportunities for innovative technologies that can improve the efficiency and sustainability of ethyl acetate production.

The integration of Industry 4.0 technologies in chemical manufacturing processes is another significant factor influencing the market. Smart manufacturing solutions, including IoT sensors, artificial intelligence, and advanced analytics, are being adopted to optimize production processes, reduce waste, and enhance quality control in ethyl acetate manufacturing. This digital transformation is expected to drive market growth by improving operational efficiency and product consistency.

Geographically, Asia Pacific dominates the ethyl acetate market, accounting for over 40% of the global market share. The region's rapid industrialization, particularly in countries like China and India, continues to fuel demand for ethyl acetate in various applications. However, emerging technologies are creating new opportunities for market expansion in developed regions such as North America and Europe, where there is a growing focus on high-value, specialty applications of ethyl acetate.

The pharmaceutical industry represents a particularly promising sector for tech-enhanced ethyl acetate. With the increasing complexity of drug formulations and the need for purer solvents, there is a growing demand for high-quality, pharmaceutical-grade ethyl acetate. Advanced purification technologies and process analytical tools are being developed to meet these stringent requirements, opening up new market segments for specialized ethyl acetate products.

In conclusion, the market for tech-enhanced ethyl acetate presents significant growth opportunities as industries seek more efficient, sustainable, and high-performance solutions. The convergence of emerging technologies with traditional chemical manufacturing processes is expected to drive innovation in the ethyl acetate market, creating value-added products and opening up new applications across various sectors.

The global ethyl acetate market size was valued at approximately $3.3 billion in 2020 and is projected to reach $4.9 billion by 2028, growing at a CAGR of 5.1% during the forecast period. This growth is primarily attributed to the increasing demand from end-use industries such as paints and coatings, adhesives, pharmaceuticals, and food and beverages.

One of the key drivers for the tech-enhanced ethyl acetate market is the growing emphasis on sustainability and environmental regulations. As industries seek to reduce their carbon footprint, there is a rising interest in bio-based ethyl acetate production methods. This trend aligns with the broader shift towards green chemistry and circular economy principles, creating opportunities for innovative technologies that can improve the efficiency and sustainability of ethyl acetate production.

The integration of Industry 4.0 technologies in chemical manufacturing processes is another significant factor influencing the market. Smart manufacturing solutions, including IoT sensors, artificial intelligence, and advanced analytics, are being adopted to optimize production processes, reduce waste, and enhance quality control in ethyl acetate manufacturing. This digital transformation is expected to drive market growth by improving operational efficiency and product consistency.

Geographically, Asia Pacific dominates the ethyl acetate market, accounting for over 40% of the global market share. The region's rapid industrialization, particularly in countries like China and India, continues to fuel demand for ethyl acetate in various applications. However, emerging technologies are creating new opportunities for market expansion in developed regions such as North America and Europe, where there is a growing focus on high-value, specialty applications of ethyl acetate.

The pharmaceutical industry represents a particularly promising sector for tech-enhanced ethyl acetate. With the increasing complexity of drug formulations and the need for purer solvents, there is a growing demand for high-quality, pharmaceutical-grade ethyl acetate. Advanced purification technologies and process analytical tools are being developed to meet these stringent requirements, opening up new market segments for specialized ethyl acetate products.

In conclusion, the market for tech-enhanced ethyl acetate presents significant growth opportunities as industries seek more efficient, sustainable, and high-performance solutions. The convergence of emerging technologies with traditional chemical manufacturing processes is expected to drive innovation in the ethyl acetate market, creating value-added products and opening up new applications across various sectors.

Current Challenges in Ethyl Acetate Integration

The integration of ethyl acetate with emerging technologies presents several significant challenges that require careful consideration and innovative solutions. One of the primary obstacles is the compatibility of ethyl acetate with advanced materials and processes used in cutting-edge industries. As new technologies emerge, the chemical properties of ethyl acetate may not always align seamlessly with novel manufacturing techniques or product requirements.

Another challenge lies in the environmental impact of ethyl acetate production and usage. With increasing global focus on sustainability, there is growing pressure to develop greener alternatives or more eco-friendly production methods for ethyl acetate. This necessitates substantial research and development efforts to reconcile the industrial demand for ethyl acetate with stringent environmental regulations.

The volatility of ethyl acetate poses challenges in its handling and storage, particularly when integrating it into sophisticated technological systems. Ensuring proper containment and preventing unwanted reactions or emissions becomes more complex as the applications of ethyl acetate expand into new technological domains.

Furthermore, the purity requirements for ethyl acetate in high-tech applications are becoming increasingly stringent. Achieving and maintaining the necessary level of purity while scaling up production to meet growing demand is a significant technical hurdle. This challenge is compounded by the need to develop more efficient purification processes that are both cost-effective and environmentally sustainable.

The integration of ethyl acetate into smart manufacturing systems and Industry 4.0 frameworks presents another set of challenges. Developing sensors and control systems capable of accurately monitoring and regulating ethyl acetate in real-time within complex production environments requires advanced engineering solutions and robust data analytics capabilities.

Additionally, the health and safety concerns associated with ethyl acetate usage in new technological applications necessitate the development of improved handling protocols and protective measures. As the substance finds its way into novel products and processes, ensuring worker safety and minimizing exposure risks become increasingly complex tasks.

Lastly, the economic viability of integrating ethyl acetate with emerging technologies remains a significant challenge. Balancing the cost of production, purification, and integration against the potential benefits and market demand requires careful analysis and strategic planning. This economic consideration is crucial in determining the feasibility and scalability of ethyl acetate applications in new technological frontiers.

Another challenge lies in the environmental impact of ethyl acetate production and usage. With increasing global focus on sustainability, there is growing pressure to develop greener alternatives or more eco-friendly production methods for ethyl acetate. This necessitates substantial research and development efforts to reconcile the industrial demand for ethyl acetate with stringent environmental regulations.

The volatility of ethyl acetate poses challenges in its handling and storage, particularly when integrating it into sophisticated technological systems. Ensuring proper containment and preventing unwanted reactions or emissions becomes more complex as the applications of ethyl acetate expand into new technological domains.

Furthermore, the purity requirements for ethyl acetate in high-tech applications are becoming increasingly stringent. Achieving and maintaining the necessary level of purity while scaling up production to meet growing demand is a significant technical hurdle. This challenge is compounded by the need to develop more efficient purification processes that are both cost-effective and environmentally sustainable.

The integration of ethyl acetate into smart manufacturing systems and Industry 4.0 frameworks presents another set of challenges. Developing sensors and control systems capable of accurately monitoring and regulating ethyl acetate in real-time within complex production environments requires advanced engineering solutions and robust data analytics capabilities.

Additionally, the health and safety concerns associated with ethyl acetate usage in new technological applications necessitate the development of improved handling protocols and protective measures. As the substance finds its way into novel products and processes, ensuring worker safety and minimizing exposure risks become increasingly complex tasks.

Lastly, the economic viability of integrating ethyl acetate with emerging technologies remains a significant challenge. Balancing the cost of production, purification, and integration against the potential benefits and market demand requires careful analysis and strategic planning. This economic consideration is crucial in determining the feasibility and scalability of ethyl acetate applications in new technological frontiers.

Existing Synchronization Solutions for Ethyl Acetate

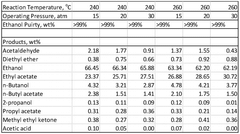

01 Production and purification of ethyl acetate

Various methods for producing and purifying ethyl acetate are described. These include esterification processes, distillation techniques, and the use of specific catalysts to improve yield and purity. The production methods aim to optimize the synthesis of ethyl acetate from ethanol and acetic acid or other precursors.- Production and purification of ethyl acetate: Various methods for producing and purifying ethyl acetate are described. These include distillation processes, reactive distillation, and the use of specific catalysts to improve yield and purity. Some techniques focus on energy-efficient production methods and the separation of ethyl acetate from other components in the reaction mixture.

- Applications of ethyl acetate in chemical processes: Ethyl acetate is utilized in various chemical processes as a solvent, reactant, or intermediate. It finds applications in the production of pharmaceuticals, polymers, and other organic compounds. Some patents describe its use in extraction processes, as a reaction medium, or as a component in formulations for specific industrial applications.

- Ethyl acetate in coating and adhesive formulations: Ethyl acetate is commonly used in coating and adhesive formulations due to its solvent properties and low toxicity. Patents describe its incorporation into various types of coatings, including those for packaging materials, and its use in adhesive compositions for different industrial applications.

- Recovery and recycling of ethyl acetate: Methods for recovering and recycling ethyl acetate from industrial processes are described. These include techniques for separating ethyl acetate from waste streams, purifying recovered ethyl acetate, and reusing it in various applications. Some patents focus on environmentally friendly and cost-effective recycling processes.

- Ethyl acetate as a green solvent alternative: Ethyl acetate is explored as a more environmentally friendly alternative to traditional solvents in various applications. Patents describe its use in place of more toxic or environmentally harmful solvents in processes such as extraction, cleaning, and chemical synthesis. Some innovations focus on optimizing ethyl acetate-based processes for improved sustainability.

02 Applications of ethyl acetate in chemical processes

Ethyl acetate is utilized in various chemical processes as a solvent, reactant, or intermediate. It finds applications in the production of pharmaceuticals, polymers, and other organic compounds. The versatility of ethyl acetate in different chemical reactions and its role in industrial processes are highlighted.Expand Specific Solutions03 Ethyl acetate in extraction and separation processes

The use of ethyl acetate as an extraction solvent and in separation processes is described. It is employed in liquid-liquid extraction, chromatography, and other purification techniques. The effectiveness of ethyl acetate in isolating specific compounds from complex mixtures is emphasized.Expand Specific Solutions04 Environmental and safety considerations for ethyl acetate

Methods for handling, storing, and disposing of ethyl acetate safely are discussed. This includes techniques for reducing emissions, recovering and recycling ethyl acetate, and minimizing its environmental impact. Safety measures for working with ethyl acetate in industrial settings are also addressed.Expand Specific Solutions05 Novel derivatives and modifications of ethyl acetate

Research on developing new derivatives or modified forms of ethyl acetate is presented. This includes the synthesis of novel compounds based on ethyl acetate, as well as modifications to improve its properties for specific applications. The potential of these new forms in various industries is explored.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The synchronization of ethyl acetate with emerging technologies is at a pivotal stage, with the market showing significant growth potential. The industry is transitioning from traditional production methods to more sustainable and efficient processes. Key players like Celanese International Corp., Kuraray Co., Ltd., and Eastman Chemical Co. are driving innovation in this field. The market is characterized by a mix of established chemical companies and emerging specialized firms like Viridis Chemical LLC, focusing on bio-based ethyl acetate production. Technological advancements are primarily aimed at improving production efficiency, reducing environmental impact, and exploring new applications in various industries. The involvement of research institutions such as the University of Campinas and Nanjing Tech University indicates ongoing efforts to further develop and refine ethyl acetate technologies.

Celanese International Corp.

Technical Solution: Celanese International Corp. has developed a cutting-edge approach to synchronize ethyl acetate production with emerging technologies. Their innovative process utilizes a proprietary VAntage™ technology platform, which combines advanced catalysis with optimized process design[11]. This integrated system allows for highly efficient production of ethyl acetate from various feedstocks, including both fossil-based and renewable sources. Celanese has also implemented Industry 4.0 technologies, such as AI-driven predictive maintenance and IoT-enabled process monitoring, to enhance overall plant reliability and performance[12]. Furthermore, they have developed a modular plant design that enables rapid capacity expansion and flexibility in production scale[13].

Strengths: Feedstock flexibility, scalable production, and advanced process control. Weaknesses: Dependence on proprietary technology and potential challenges in adapting to rapidly changing market demands.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to synchronize ethyl acetate production with emerging technologies. They have implemented a state-of-the-art integrated process that combines traditional esterification with advanced catalytic distillation technology[1]. This method allows for continuous production of high-purity ethyl acetate while significantly reducing energy consumption and improving overall efficiency. The process utilizes a novel heterogeneous catalyst that enhances reaction rates and selectivity[2]. Additionally, Sinopec has incorporated IoT sensors and AI-driven process control systems to optimize production parameters in real-time, ensuring consistent quality and maximizing yield[3].

Strengths: Improved energy efficiency, higher product purity, and increased production capacity. Weaknesses: High initial investment costs and potential complexity in system integration.

Innovative Approaches in Ethyl Acetate Syncing

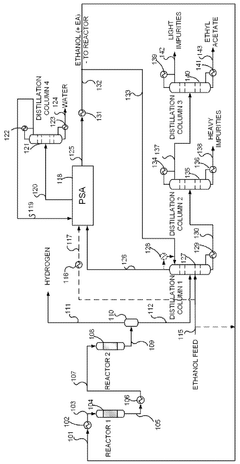

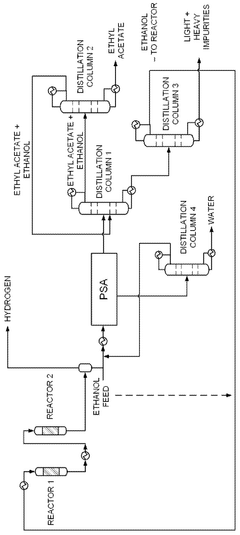

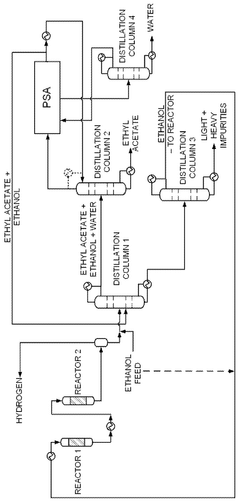

Process for production of ethyl acetate

PatentWO2025072073A1

Innovation

- A novel process that converts ethanol to ethyl acetate through dehydrogenation, followed by selective hydrogenation of byproducts to facilitate easier separation, and utilizes pressure swing adsorption to minimize water content and protect the catalyst.

Process of low energy consumption for preparing a carboxylic acid ester

PatentWO2012123279A1

Innovation

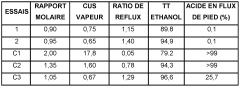

- A process involving the reaction of ethyl alcohol with acetic acid in the presence of a solid acid catalyst, using a reactive distillation system with a centrally placed reaction zone between upper and lower separation zones, optimizing the molar ratio of acetic acid to ethyl alcohol between 0.85 and 0.97, and controlling the reflux ratio between 1.0 and 1.5, significantly reduces energy costs and minimizes acetic acid at the column bottom.

Environmental Impact and Sustainability Considerations

The synchronization of ethyl acetate production with emerging technologies presents significant opportunities for enhancing environmental sustainability and reducing ecological impact. As a widely used solvent in various industries, ethyl acetate production has traditionally been associated with substantial energy consumption and greenhouse gas emissions. However, the integration of cutting-edge technologies offers promising avenues for mitigating these environmental concerns.

One of the primary areas of focus is the optimization of the production process through advanced process control systems and artificial intelligence. These technologies enable real-time monitoring and adjustment of reaction conditions, leading to improved efficiency and reduced energy consumption. By minimizing waste and maximizing yield, the overall environmental footprint of ethyl acetate production can be significantly reduced.

The incorporation of renewable energy sources into the manufacturing process represents another crucial aspect of environmental sustainability. Solar and wind power can be harnessed to power production facilities, decreasing reliance on fossil fuels and lowering carbon emissions. Additionally, the implementation of energy recovery systems can capture and repurpose waste heat, further enhancing overall energy efficiency.

Emerging biotechnology approaches offer potential for developing bio-based alternatives to traditional ethyl acetate production methods. Enzymatic processes and microbial fermentation techniques can utilize renewable feedstocks, reducing dependence on petrochemical resources. These bio-based routes often operate under milder conditions, consuming less energy and generating fewer harmful byproducts.

Water management is a critical consideration in ethyl acetate production. Advanced membrane technologies and water recycling systems can minimize water consumption and reduce wastewater generation. These innovations not only conserve water resources but also decrease the environmental impact associated with effluent treatment and disposal.

The adoption of green chemistry principles in ethyl acetate synthesis presents opportunities for developing more environmentally benign processes. This includes exploring alternative catalysts, solvents, and reaction pathways that minimize the use of hazardous substances and reduce waste generation. Such approaches align with the broader goals of sustainable chemistry and circular economy principles.

Life cycle assessment (LCA) tools, coupled with emerging data analytics capabilities, enable comprehensive evaluation of the environmental impact of ethyl acetate production across its entire lifecycle. This holistic approach allows for the identification of hotspots and optimization opportunities, guiding decision-making towards more sustainable practices throughout the value chain.

One of the primary areas of focus is the optimization of the production process through advanced process control systems and artificial intelligence. These technologies enable real-time monitoring and adjustment of reaction conditions, leading to improved efficiency and reduced energy consumption. By minimizing waste and maximizing yield, the overall environmental footprint of ethyl acetate production can be significantly reduced.

The incorporation of renewable energy sources into the manufacturing process represents another crucial aspect of environmental sustainability. Solar and wind power can be harnessed to power production facilities, decreasing reliance on fossil fuels and lowering carbon emissions. Additionally, the implementation of energy recovery systems can capture and repurpose waste heat, further enhancing overall energy efficiency.

Emerging biotechnology approaches offer potential for developing bio-based alternatives to traditional ethyl acetate production methods. Enzymatic processes and microbial fermentation techniques can utilize renewable feedstocks, reducing dependence on petrochemical resources. These bio-based routes often operate under milder conditions, consuming less energy and generating fewer harmful byproducts.

Water management is a critical consideration in ethyl acetate production. Advanced membrane technologies and water recycling systems can minimize water consumption and reduce wastewater generation. These innovations not only conserve water resources but also decrease the environmental impact associated with effluent treatment and disposal.

The adoption of green chemistry principles in ethyl acetate synthesis presents opportunities for developing more environmentally benign processes. This includes exploring alternative catalysts, solvents, and reaction pathways that minimize the use of hazardous substances and reduce waste generation. Such approaches align with the broader goals of sustainable chemistry and circular economy principles.

Life cycle assessment (LCA) tools, coupled with emerging data analytics capabilities, enable comprehensive evaluation of the environmental impact of ethyl acetate production across its entire lifecycle. This holistic approach allows for the identification of hotspots and optimization opportunities, guiding decision-making towards more sustainable practices throughout the value chain.

Regulatory Framework for Ethyl Acetate in Emerging Tech

The regulatory framework for ethyl acetate in emerging technologies is evolving rapidly to keep pace with technological advancements. As ethyl acetate finds new applications in cutting-edge fields, regulatory bodies are adapting their approaches to ensure safety, environmental protection, and ethical use of this versatile compound.

One of the primary focuses of the regulatory framework is the establishment of comprehensive safety standards for the use of ethyl acetate in emerging technologies. These standards address various aspects, including handling, storage, and disposal procedures. Regulatory agencies are working closely with industry experts to develop guidelines that balance innovation with risk mitigation.

Environmental considerations play a crucial role in shaping the regulatory landscape. As emerging technologies often involve novel production processes and applications, regulators are implementing stringent environmental impact assessments for ethyl acetate usage. This includes monitoring emissions, waste management protocols, and potential ecological effects.

The integration of ethyl acetate into emerging technologies has also prompted regulators to address issues of product quality and consistency. Quality control measures and standardization protocols are being developed to ensure that ethyl acetate-based products meet specific performance and safety criteria across different technological applications.

Regulatory bodies are increasingly adopting a collaborative approach, engaging with industry stakeholders, research institutions, and technology developers. This collaborative framework aims to foster innovation while maintaining regulatory oversight. It includes mechanisms for regular dialogue, knowledge sharing, and joint problem-solving initiatives.

As emerging technologies often transcend traditional industry boundaries, regulators are working on creating more flexible and adaptive regulatory frameworks. These frameworks are designed to accommodate the rapid pace of technological change while still providing adequate safeguards. This includes the development of regulatory sandboxes and pilot programs to test new applications of ethyl acetate in controlled environments.

International harmonization of regulations is another key aspect of the evolving framework. Given the global nature of technological development, regulatory bodies are striving to align standards and protocols across different jurisdictions. This harmonization effort aims to facilitate international trade and collaboration in ethyl acetate-based emerging technologies.

The regulatory framework also addresses the ethical implications of using ethyl acetate in certain emerging technologies, particularly in areas like biotechnology and nanotechnology. Ethical guidelines and review processes are being established to ensure responsible innovation and to address potential societal concerns.

One of the primary focuses of the regulatory framework is the establishment of comprehensive safety standards for the use of ethyl acetate in emerging technologies. These standards address various aspects, including handling, storage, and disposal procedures. Regulatory agencies are working closely with industry experts to develop guidelines that balance innovation with risk mitigation.

Environmental considerations play a crucial role in shaping the regulatory landscape. As emerging technologies often involve novel production processes and applications, regulators are implementing stringent environmental impact assessments for ethyl acetate usage. This includes monitoring emissions, waste management protocols, and potential ecological effects.

The integration of ethyl acetate into emerging technologies has also prompted regulators to address issues of product quality and consistency. Quality control measures and standardization protocols are being developed to ensure that ethyl acetate-based products meet specific performance and safety criteria across different technological applications.

Regulatory bodies are increasingly adopting a collaborative approach, engaging with industry stakeholders, research institutions, and technology developers. This collaborative framework aims to foster innovation while maintaining regulatory oversight. It includes mechanisms for regular dialogue, knowledge sharing, and joint problem-solving initiatives.

As emerging technologies often transcend traditional industry boundaries, regulators are working on creating more flexible and adaptive regulatory frameworks. These frameworks are designed to accommodate the rapid pace of technological change while still providing adequate safeguards. This includes the development of regulatory sandboxes and pilot programs to test new applications of ethyl acetate in controlled environments.

International harmonization of regulations is another key aspect of the evolving framework. Given the global nature of technological development, regulatory bodies are striving to align standards and protocols across different jurisdictions. This harmonization effort aims to facilitate international trade and collaboration in ethyl acetate-based emerging technologies.

The regulatory framework also addresses the ethical implications of using ethyl acetate in certain emerging technologies, particularly in areas like biotechnology and nanotechnology. Ethical guidelines and review processes are being established to ensure responsible innovation and to address potential societal concerns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!