How Muriatic Acid is Used in the Manufacture of Insecticides

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Muriatic Acid in Insecticides: Background and Objectives

Muriatic acid, also known as hydrochloric acid, has played a significant role in the development and production of insecticides since the early 20th century. This strong mineral acid has been instrumental in various stages of insecticide manufacturing, from synthesis to formulation. The evolution of its use in this field mirrors the broader advancements in agricultural chemistry and pest control strategies.

The primary objective of utilizing muriatic acid in insecticide production is to enhance the effectiveness and stability of the final product. Its versatile chemical properties make it an invaluable component in creating a wide range of insecticidal compounds, particularly organochlorine and organophosphate insecticides. These classes of insecticides have been crucial in controlling pest populations and protecting crops worldwide.

Historically, the use of muriatic acid in insecticide manufacturing gained prominence during the 1940s and 1950s, coinciding with the rapid expansion of synthetic pesticide production. This period saw the introduction of numerous chlorinated hydrocarbon insecticides, where muriatic acid served as a key reagent in their synthesis. The acid's ability to facilitate chlorination reactions made it indispensable in producing compounds such as DDT, aldrin, and dieldrin.

As environmental concerns grew and regulations tightened in the latter half of the 20th century, the focus shifted towards developing more targeted and less persistent insecticides. This transition led to new applications of muriatic acid in the production of organophosphates and carbamates, which offered improved selectivity and reduced environmental impact compared to their predecessors.

In recent years, the trend towards biopesticides and integrated pest management strategies has influenced the role of muriatic acid in insecticide manufacturing. While its use in traditional synthetic insecticide production continues, researchers are exploring novel applications in the development of more sustainable and eco-friendly pest control solutions. These include its potential in modifying natural compounds to enhance their insecticidal properties or in creating delivery systems for biological control agents.

The ongoing technological advancements in chemical synthesis and formulation techniques are expected to further refine the use of muriatic acid in insecticide production. Emerging areas of focus include the development of nanoformulations and controlled-release systems, where muriatic acid may play a role in modifying the physical and chemical properties of the active ingredients.

As the global demand for food security intensifies and environmental regulations become more stringent, the insecticide industry faces the challenge of developing more efficient and sustainable products. The versatility of muriatic acid positions it as a valuable tool in meeting these evolving needs, potentially contributing to the next generation of pest control solutions that balance efficacy with environmental stewardship.

The primary objective of utilizing muriatic acid in insecticide production is to enhance the effectiveness and stability of the final product. Its versatile chemical properties make it an invaluable component in creating a wide range of insecticidal compounds, particularly organochlorine and organophosphate insecticides. These classes of insecticides have been crucial in controlling pest populations and protecting crops worldwide.

Historically, the use of muriatic acid in insecticide manufacturing gained prominence during the 1940s and 1950s, coinciding with the rapid expansion of synthetic pesticide production. This period saw the introduction of numerous chlorinated hydrocarbon insecticides, where muriatic acid served as a key reagent in their synthesis. The acid's ability to facilitate chlorination reactions made it indispensable in producing compounds such as DDT, aldrin, and dieldrin.

As environmental concerns grew and regulations tightened in the latter half of the 20th century, the focus shifted towards developing more targeted and less persistent insecticides. This transition led to new applications of muriatic acid in the production of organophosphates and carbamates, which offered improved selectivity and reduced environmental impact compared to their predecessors.

In recent years, the trend towards biopesticides and integrated pest management strategies has influenced the role of muriatic acid in insecticide manufacturing. While its use in traditional synthetic insecticide production continues, researchers are exploring novel applications in the development of more sustainable and eco-friendly pest control solutions. These include its potential in modifying natural compounds to enhance their insecticidal properties or in creating delivery systems for biological control agents.

The ongoing technological advancements in chemical synthesis and formulation techniques are expected to further refine the use of muriatic acid in insecticide production. Emerging areas of focus include the development of nanoformulations and controlled-release systems, where muriatic acid may play a role in modifying the physical and chemical properties of the active ingredients.

As the global demand for food security intensifies and environmental regulations become more stringent, the insecticide industry faces the challenge of developing more efficient and sustainable products. The versatility of muriatic acid positions it as a valuable tool in meeting these evolving needs, potentially contributing to the next generation of pest control solutions that balance efficacy with environmental stewardship.

Market Analysis for Muriatic Acid-Based Insecticides

The market for muriatic acid-based insecticides has shown significant growth in recent years, driven by increasing demand for effective pest control solutions in agriculture and urban environments. The global insecticide market, valued at approximately $16 billion in 2020, is projected to reach $23 billion by 2026, with muriatic acid-based products playing a crucial role in this expansion.

Agricultural applications dominate the market for muriatic acid-based insecticides, accounting for over 60% of total consumption. The rising need for crop protection against a wide range of pests, coupled with the growing adoption of intensive farming practices, has fueled the demand for these products. Developing countries in Asia-Pacific and Latin America are experiencing the fastest growth in this sector due to rapid agricultural modernization and increasing awareness about crop yield optimization.

The urban pest control segment is another key driver of market growth for muriatic acid-based insecticides. Urbanization and the associated rise in pest-related health concerns have led to increased demand for effective insecticide solutions in residential and commercial settings. This segment is expected to grow at a CAGR of 5.5% from 2021 to 2026, with North America and Europe being the primary markets.

Environmental concerns and regulatory pressures are shaping the market landscape for muriatic acid-based insecticides. There is a growing trend towards eco-friendly and less toxic formulations, which has prompted manufacturers to invest in research and development of safer alternatives. This shift is particularly evident in developed markets, where stringent regulations on chemical pesticides are driving innovation in product formulations.

The competitive landscape of the muriatic acid-based insecticide market is characterized by the presence of both large multinational corporations and regional players. Key market players are focusing on product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position. The top five companies in this sector collectively hold a market share of approximately 40%, indicating a moderately consolidated industry structure.

Looking ahead, the market for muriatic acid-based insecticides is expected to continue its growth trajectory, albeit with some challenges. The increasing adoption of integrated pest management practices and the rise of biopesticides may pose a threat to traditional chemical insecticides. However, the superior efficacy and cost-effectiveness of muriatic acid-based products are likely to maintain their relevance in the global insecticide market for the foreseeable future.

Agricultural applications dominate the market for muriatic acid-based insecticides, accounting for over 60% of total consumption. The rising need for crop protection against a wide range of pests, coupled with the growing adoption of intensive farming practices, has fueled the demand for these products. Developing countries in Asia-Pacific and Latin America are experiencing the fastest growth in this sector due to rapid agricultural modernization and increasing awareness about crop yield optimization.

The urban pest control segment is another key driver of market growth for muriatic acid-based insecticides. Urbanization and the associated rise in pest-related health concerns have led to increased demand for effective insecticide solutions in residential and commercial settings. This segment is expected to grow at a CAGR of 5.5% from 2021 to 2026, with North America and Europe being the primary markets.

Environmental concerns and regulatory pressures are shaping the market landscape for muriatic acid-based insecticides. There is a growing trend towards eco-friendly and less toxic formulations, which has prompted manufacturers to invest in research and development of safer alternatives. This shift is particularly evident in developed markets, where stringent regulations on chemical pesticides are driving innovation in product formulations.

The competitive landscape of the muriatic acid-based insecticide market is characterized by the presence of both large multinational corporations and regional players. Key market players are focusing on product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position. The top five companies in this sector collectively hold a market share of approximately 40%, indicating a moderately consolidated industry structure.

Looking ahead, the market for muriatic acid-based insecticides is expected to continue its growth trajectory, albeit with some challenges. The increasing adoption of integrated pest management practices and the rise of biopesticides may pose a threat to traditional chemical insecticides. However, the superior efficacy and cost-effectiveness of muriatic acid-based products are likely to maintain their relevance in the global insecticide market for the foreseeable future.

Current Applications and Challenges in Insecticide Production

Muriatic acid, also known as hydrochloric acid, plays a crucial role in the production of various insecticides. Its primary application lies in the synthesis of organochlorine compounds, which have been widely used as effective pesticides. These compounds, such as DDT and lindane, were once popular due to their broad-spectrum activity against insects. However, their use has been significantly restricted or banned in many countries due to environmental and health concerns.

In current insecticide manufacturing, muriatic acid is utilized in several key processes. It serves as a catalyst in the chlorination of organic compounds, a critical step in producing chlorinated hydrocarbon insecticides. The acid's strong proton-donating properties facilitate these reactions, allowing for efficient synthesis of active ingredients. Additionally, muriatic acid is employed in pH adjustment during formulation processes, ensuring optimal stability and efficacy of the final insecticide products.

Another important application is in the production of organophosphate insecticides. Muriatic acid is used in the hydrolysis of phosphorus oxychloride, a key intermediate in the synthesis of many organophosphate compounds. This process is fundamental in creating insecticides like malathion and chlorpyrifos, which are still widely used in agriculture and pest control.

Despite its utility, the use of muriatic acid in insecticide production faces several challenges. Environmental concerns are paramount, as the acid can contribute to soil and water pollution if not properly managed. Strict regulations govern its handling and disposal, necessitating sophisticated waste treatment systems in manufacturing facilities. Worker safety is another critical issue, requiring robust safety protocols and protective equipment to prevent exposure to this corrosive substance.

The evolving regulatory landscape poses additional challenges. As governments worldwide tighten restrictions on certain insecticides, manufacturers must adapt their production processes. This often involves developing new synthesis routes that minimize or eliminate the use of muriatic acid, driving research into greener alternatives and more environmentally friendly production methods.

Furthermore, there is growing consumer demand for organic and biopesticides, which typically do not involve muriatic acid in their production. This shift in market preferences is pushing the industry to innovate and explore novel insecticide formulations that rely less on traditional chemical synthesis methods.

In response to these challenges, the industry is investing in research and development to optimize the use of muriatic acid and explore alternatives. Advanced reactor designs and process control systems are being implemented to improve efficiency and reduce environmental impact. Simultaneously, efforts are underway to develop new catalysts and reaction pathways that could potentially replace muriatic acid in certain applications, aligning with the principles of green chemistry.

In current insecticide manufacturing, muriatic acid is utilized in several key processes. It serves as a catalyst in the chlorination of organic compounds, a critical step in producing chlorinated hydrocarbon insecticides. The acid's strong proton-donating properties facilitate these reactions, allowing for efficient synthesis of active ingredients. Additionally, muriatic acid is employed in pH adjustment during formulation processes, ensuring optimal stability and efficacy of the final insecticide products.

Another important application is in the production of organophosphate insecticides. Muriatic acid is used in the hydrolysis of phosphorus oxychloride, a key intermediate in the synthesis of many organophosphate compounds. This process is fundamental in creating insecticides like malathion and chlorpyrifos, which are still widely used in agriculture and pest control.

Despite its utility, the use of muriatic acid in insecticide production faces several challenges. Environmental concerns are paramount, as the acid can contribute to soil and water pollution if not properly managed. Strict regulations govern its handling and disposal, necessitating sophisticated waste treatment systems in manufacturing facilities. Worker safety is another critical issue, requiring robust safety protocols and protective equipment to prevent exposure to this corrosive substance.

The evolving regulatory landscape poses additional challenges. As governments worldwide tighten restrictions on certain insecticides, manufacturers must adapt their production processes. This often involves developing new synthesis routes that minimize or eliminate the use of muriatic acid, driving research into greener alternatives and more environmentally friendly production methods.

Furthermore, there is growing consumer demand for organic and biopesticides, which typically do not involve muriatic acid in their production. This shift in market preferences is pushing the industry to innovate and explore novel insecticide formulations that rely less on traditional chemical synthesis methods.

In response to these challenges, the industry is investing in research and development to optimize the use of muriatic acid and explore alternatives. Advanced reactor designs and process control systems are being implemented to improve efficiency and reduce environmental impact. Simultaneously, efforts are underway to develop new catalysts and reaction pathways that could potentially replace muriatic acid in certain applications, aligning with the principles of green chemistry.

Muriatic Acid Integration in Insecticide Formulations

01 Chemical properties and applications

Muriatic acid, also known as hydrochloric acid, is a strong mineral acid with various industrial and household applications. It is commonly used for cleaning, pH adjustment, and as a reagent in chemical processes. Its corrosive nature makes it effective for removing rust, scale, and other deposits.- Chemical properties and applications: Muriatic acid, also known as hydrochloric acid, is a strong mineral acid with various industrial and commercial applications. It is used in metal cleaning, pH adjustment, and as a reagent in chemical processes. Its corrosive nature and ability to dissolve certain metals make it useful in surface preparation and etching.

- Production and manufacturing methods: Various methods are employed to produce muriatic acid, including the reaction of sodium chloride with sulfuric acid, and as a byproduct in chlorine production. Innovations in manufacturing processes focus on improving efficiency, purity, and reducing environmental impact.

- Safety and handling considerations: Due to its corrosive nature, special precautions are necessary when handling muriatic acid. This includes proper storage, transportation, and disposal methods. Safety equipment and neutralization techniques are essential to prevent accidents and environmental contamination.

- Environmental impact and waste treatment: The use and disposal of muriatic acid can have significant environmental implications. Research focuses on developing eco-friendly alternatives, waste treatment methods, and recycling processes to minimize its environmental footprint and comply with regulations.

- Specialized applications in industry: Muriatic acid finds specialized applications in various industries, including water treatment, oil and gas, pharmaceuticals, and food processing. Innovations in these areas focus on optimizing acid concentration, developing acid-resistant materials, and improving application techniques for specific industrial processes.

02 Production and manufacturing processes

Various methods are employed to produce muriatic acid, including the reaction of sodium chloride with sulfuric acid and the direct synthesis from hydrogen and chlorine. Industrial processes often involve the recovery of hydrochloric acid as a byproduct from other chemical reactions.Expand Specific Solutions03 Safety and handling precautions

Due to its corrosive nature, proper safety measures are crucial when handling muriatic acid. This includes using appropriate personal protective equipment, proper storage containers, and ventilation systems. Neutralization and disposal procedures are also important considerations in its use and management.Expand Specific Solutions04 Environmental impact and regulations

The use and disposal of muriatic acid are subject to environmental regulations due to its potential impact on ecosystems and water sources. Treatment and neutralization processes are often required before discharge. Some applications focus on developing more environmentally friendly alternatives or reducing its usage in industrial processes.Expand Specific Solutions05 Specialized applications in industry

Muriatic acid finds specialized applications in various industries, including metal processing, water treatment, and oil well acidizing. It is used in the production of chlorides, in the food industry for processing certain products, and in the pharmaceutical sector for the synthesis of various compounds.Expand Specific Solutions

Key Manufacturers and Industry Landscape

The market for muriatic acid in insecticide manufacturing is in a mature stage, with established players and stable demand. The global insecticide market size is projected to reach $23 billion by 2027, driven by increasing agricultural activities and pest control needs. Technologically, the use of muriatic acid in insecticides is well-established, with companies like Bayer CropScience, FMC Corporation, and Sumitomo Chemical leading innovation. These firms, along with others like Nihon Nohyaku and Nippon Soda, have developed advanced formulations and application methods to enhance efficacy and safety. Research institutions such as East China University of Science & Technology and the University of Florida continue to explore new applications and improvements in this field.

Sumitomo Chemical Co., Ltd.

Technical Solution: Sumitomo Chemical Co., Ltd. employs muriatic acid in the production of various insecticides, particularly in the synthesis of neonicotinoid compounds. The company has developed a proprietary process that uses muriatic acid as a key reagent in the chlorination of pyridine derivatives, which are precursors to neonicotinoid insecticides[13]. Sumitomo's approach involves a highly controlled reaction environment that maximizes yield and minimizes side products. The corporation also utilizes muriatic acid in the purification of active ingredients, where it aids in the removal of impurities through selective precipitation[14]. Additionally, Sumitomo has implemented an innovative acid recovery system that allows for the regeneration and reuse of muriatic acid, significantly reducing waste and improving process sustainability[15].

Strengths: Expertise in neonicotinoid synthesis, efficient chlorination processes, and advanced acid recovery technology. Weaknesses: Potential regulatory challenges associated with neonicotinoids and the need for continuous innovation to address environmental concerns.

FMC Corp.

Technical Solution: FMC Corp. utilizes muriatic acid in various stages of insecticide production, including synthesis, purification, and formulation. The company has developed a novel approach that employs muriatic acid as both a reactant and a catalyst in the production of certain pyrethroid insecticides[7]. FMC's process involves a controlled acid-mediated rearrangement step that enhances the potency of the final product. The corporation also uses muriatic acid in the extraction of natural pyrethrins from chrysanthemum flowers, where the acid helps in isolating the active compounds[8]. Additionally, FMC has implemented an innovative acid neutralization system that converts excess muriatic acid into valuable by-products, which are then used in other industrial applications[9].

Strengths: Innovative use of acid in pyrethroid synthesis, efficient natural product extraction, and value-added acid neutralization. Weaknesses: Reliance on chrysanthemum supply for natural pyrethrins and potential acid-related environmental concerns.

Innovative Techniques in Muriatic Acid Utilization

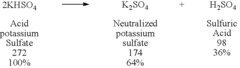

Process for the production of hydrochloric acid and neutralized sulfates

PatentInactiveUS6676917B2

Innovation

- A process that reacts sulfuric acid with alkaline metal chlorides to produce hydrochloric acid and acid sulfates, followed by neutralization and crystallization of neutralized sulfates without the need for dilution, using sodium chloride and sodium carbonate as sodium sources and ammonia as a nitrogen source, reducing energy consumption and equipment requirements.

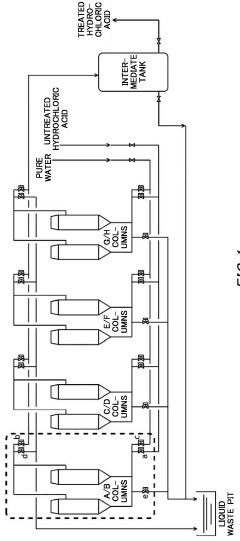

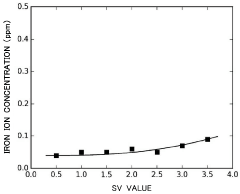

Method and apparatus for producing hydrochloric acid

PatentInactiveIN201614002500A

Innovation

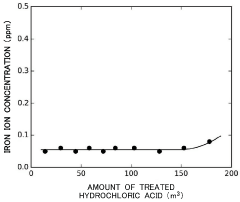

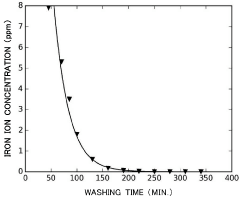

- A method and apparatus utilizing a series of parallel refinery columns filled with strongly basic anion-exchange resins to capture and regenerate iron ions, allowing continuous iron ion removal and acid production by switching treatment between columns as ion-exchange resin capabilities deteriorate, ensuring high-purity hydrochloric acid production.

Environmental Impact and Regulatory Compliance

The use of muriatic acid in insecticide manufacturing raises significant environmental and regulatory concerns. The production process and the resulting products can have substantial impacts on ecosystems, human health, and natural resources. Consequently, stringent regulations and compliance measures have been implemented to mitigate these risks.

Environmental impacts of muriatic acid in insecticide production are multifaceted. The acid's corrosive nature poses risks to soil and water quality if not properly handled or disposed of. Accidental spills or leaks can lead to soil acidification, affecting plant growth and microbial communities. Water bodies near manufacturing facilities are particularly vulnerable, as acid runoff can alter pH levels, harming aquatic life and disrupting entire ecosystems.

Air pollution is another critical concern. The production process may release harmful vapors and particulates, contributing to air quality degradation and potentially affecting local communities. These emissions can lead to respiratory issues and other health problems in both humans and wildlife.

To address these environmental challenges, regulatory bodies worldwide have established comprehensive frameworks. In the United States, the Environmental Protection Agency (EPA) oversees the regulation of insecticide production under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). This act mandates strict controls on the manufacture, distribution, and use of pesticides, including those produced using muriatic acid.

Compliance requirements typically include rigorous waste management protocols, emission control measures, and safety standards for handling and storing muriatic acid. Manufacturers must implement advanced treatment systems to neutralize acid waste before disposal and install air scrubbers to minimize atmospheric emissions.

Water quality regulations are particularly stringent, with limits on effluent discharge and mandatory monitoring of nearby water bodies. Companies are often required to conduct regular environmental impact assessments and maintain detailed records of their chemical usage and disposal practices.

Worker safety is another crucial aspect of regulatory compliance. Occupational Safety and Health Administration (OSHA) standards in the U.S. dictate strict protocols for personal protective equipment, handling procedures, and emergency response plans when working with muriatic acid in insecticide production.

Internationally, the Stockholm Convention on Persistent Organic Pollutants and the Rotterdam Convention on the Prior Informed Consent Procedure for Certain Hazardous Chemicals and Pesticides in International Trade provide global frameworks for regulating the production and trade of hazardous chemicals, including certain insecticides.

As environmental awareness grows, regulations continue to evolve, becoming increasingly stringent. Manufacturers are under pressure to adopt cleaner production methods, explore alternative chemicals, and invest in more sustainable practices. This regulatory landscape not only protects the environment but also drives innovation in the insecticide industry, pushing for the development of safer, more eco-friendly production processes and products.

Environmental impacts of muriatic acid in insecticide production are multifaceted. The acid's corrosive nature poses risks to soil and water quality if not properly handled or disposed of. Accidental spills or leaks can lead to soil acidification, affecting plant growth and microbial communities. Water bodies near manufacturing facilities are particularly vulnerable, as acid runoff can alter pH levels, harming aquatic life and disrupting entire ecosystems.

Air pollution is another critical concern. The production process may release harmful vapors and particulates, contributing to air quality degradation and potentially affecting local communities. These emissions can lead to respiratory issues and other health problems in both humans and wildlife.

To address these environmental challenges, regulatory bodies worldwide have established comprehensive frameworks. In the United States, the Environmental Protection Agency (EPA) oversees the regulation of insecticide production under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). This act mandates strict controls on the manufacture, distribution, and use of pesticides, including those produced using muriatic acid.

Compliance requirements typically include rigorous waste management protocols, emission control measures, and safety standards for handling and storing muriatic acid. Manufacturers must implement advanced treatment systems to neutralize acid waste before disposal and install air scrubbers to minimize atmospheric emissions.

Water quality regulations are particularly stringent, with limits on effluent discharge and mandatory monitoring of nearby water bodies. Companies are often required to conduct regular environmental impact assessments and maintain detailed records of their chemical usage and disposal practices.

Worker safety is another crucial aspect of regulatory compliance. Occupational Safety and Health Administration (OSHA) standards in the U.S. dictate strict protocols for personal protective equipment, handling procedures, and emergency response plans when working with muriatic acid in insecticide production.

Internationally, the Stockholm Convention on Persistent Organic Pollutants and the Rotterdam Convention on the Prior Informed Consent Procedure for Certain Hazardous Chemicals and Pesticides in International Trade provide global frameworks for regulating the production and trade of hazardous chemicals, including certain insecticides.

As environmental awareness grows, regulations continue to evolve, becoming increasingly stringent. Manufacturers are under pressure to adopt cleaner production methods, explore alternative chemicals, and invest in more sustainable practices. This regulatory landscape not only protects the environment but also drives innovation in the insecticide industry, pushing for the development of safer, more eco-friendly production processes and products.

Safety Protocols in Muriatic Acid Handling

The handling of muriatic acid, also known as hydrochloric acid, in the manufacture of insecticides requires strict adherence to safety protocols to protect workers and the environment. These protocols are essential due to the corrosive and hazardous nature of the acid.

Personal protective equipment (PPE) is paramount when working with muriatic acid. Workers must wear chemical-resistant gloves, goggles, face shields, and protective clothing. Respiratory protection may also be necessary, depending on the concentration and potential for vapor exposure. All PPE should be regularly inspected and replaced as needed to ensure its effectiveness.

Proper storage of muriatic acid is crucial to prevent accidents and spills. The acid should be stored in corrosion-resistant containers in a cool, dry, and well-ventilated area. Containers must be clearly labeled and kept away from incompatible materials, such as bases, metals, and oxidizing agents. Secondary containment systems should be in place to contain potential leaks or spills.

Handling procedures for muriatic acid should be clearly defined and communicated to all workers. This includes guidelines for safe transfer of the acid between containers, proper dilution techniques, and procedures for cleaning up spills. Workers should be trained in these procedures and regularly updated on any changes or improvements to safety protocols.

Emergency response plans are a critical component of safety protocols. These plans should outline procedures for dealing with spills, chemical exposure, and other potential emergencies. Eyewash stations and safety showers must be readily accessible in areas where muriatic acid is used or stored. First aid kits specifically designed for chemical exposures should also be available.

Ventilation is another key consideration in facilities using muriatic acid. Adequate ventilation systems should be in place to remove acid vapors and maintain safe air quality. Regular monitoring of air quality and exposure levels is essential to ensure that workers are not exposed to harmful concentrations of acid fumes.

Training and education form the foundation of effective safety protocols. All workers involved in handling muriatic acid should receive comprehensive training on its properties, hazards, and safe handling procedures. This training should be regularly updated and reinforced through safety meetings and refresher courses.

Proper disposal of muriatic acid and any waste products is also a critical aspect of safety protocols. Facilities must comply with local, state, and federal regulations regarding the disposal of hazardous materials. This may involve neutralization processes or specialized waste management services.

By implementing and strictly adhering to these safety protocols, manufacturers can significantly reduce the risks associated with using muriatic acid in the production of insecticides, ensuring the safety of workers and the protection of the environment.

Personal protective equipment (PPE) is paramount when working with muriatic acid. Workers must wear chemical-resistant gloves, goggles, face shields, and protective clothing. Respiratory protection may also be necessary, depending on the concentration and potential for vapor exposure. All PPE should be regularly inspected and replaced as needed to ensure its effectiveness.

Proper storage of muriatic acid is crucial to prevent accidents and spills. The acid should be stored in corrosion-resistant containers in a cool, dry, and well-ventilated area. Containers must be clearly labeled and kept away from incompatible materials, such as bases, metals, and oxidizing agents. Secondary containment systems should be in place to contain potential leaks or spills.

Handling procedures for muriatic acid should be clearly defined and communicated to all workers. This includes guidelines for safe transfer of the acid between containers, proper dilution techniques, and procedures for cleaning up spills. Workers should be trained in these procedures and regularly updated on any changes or improvements to safety protocols.

Emergency response plans are a critical component of safety protocols. These plans should outline procedures for dealing with spills, chemical exposure, and other potential emergencies. Eyewash stations and safety showers must be readily accessible in areas where muriatic acid is used or stored. First aid kits specifically designed for chemical exposures should also be available.

Ventilation is another key consideration in facilities using muriatic acid. Adequate ventilation systems should be in place to remove acid vapors and maintain safe air quality. Regular monitoring of air quality and exposure levels is essential to ensure that workers are not exposed to harmful concentrations of acid fumes.

Training and education form the foundation of effective safety protocols. All workers involved in handling muriatic acid should receive comprehensive training on its properties, hazards, and safe handling procedures. This training should be regularly updated and reinforced through safety meetings and refresher courses.

Proper disposal of muriatic acid and any waste products is also a critical aspect of safety protocols. Facilities must comply with local, state, and federal regulations regarding the disposal of hazardous materials. This may involve neutralization processes or specialized waste management services.

By implementing and strictly adhering to these safety protocols, manufacturers can significantly reduce the risks associated with using muriatic acid in the production of insecticides, ensuring the safety of workers and the protection of the environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!