How Muriatic Acid is Used in the Manufacture of Polybenzimidazole (PBI)

JUL 18, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PBI Manufacturing Background and Objectives

Polybenzimidazole (PBI) is a high-performance polymer known for its exceptional thermal and chemical stability. The development of PBI can be traced back to the 1960s when it was first synthesized for aerospace applications. Over the decades, PBI has evolved from a niche material to a versatile polymer used in various industries, including aerospace, automotive, and energy sectors.

The manufacturing process of PBI has undergone significant improvements since its inception. Initially, the production was limited and costly, restricting its use to specialized applications. However, advancements in polymer chemistry and manufacturing techniques have led to more efficient and scalable production methods, expanding PBI's potential applications.

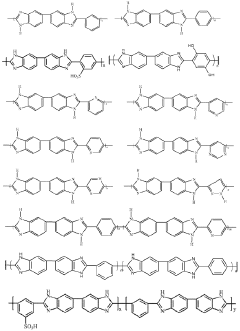

One of the key components in PBI manufacturing is muriatic acid, also known as hydrochloric acid. This strong mineral acid plays a crucial role in the synthesis and processing of PBI. The use of muriatic acid in PBI production is part of a complex chemical process that involves the condensation of aromatic tetraamines with aromatic dicarboxylic acids or their derivatives.

The primary objective of using muriatic acid in PBI manufacturing is to facilitate the polymerization process and control the molecular weight of the resulting polymer. Muriatic acid acts as a catalyst and a solvent, promoting the formation of the benzimidazole ring structure that gives PBI its unique properties.

As the demand for high-performance materials continues to grow, the PBI manufacturing industry faces several challenges and opportunities. These include improving production efficiency, reducing costs, and developing new grades of PBI with enhanced properties. The use of muriatic acid in this process is an area of ongoing research and development, with efforts focused on optimizing its role in the synthesis and potentially finding alternative, more environmentally friendly approaches.

The evolution of PBI manufacturing techniques, including the use of muriatic acid, is closely tied to technological advancements in polymer science and chemical engineering. Future developments in this field are expected to focus on sustainable production methods, improved material performance, and expanded applications in emerging technologies such as fuel cells, membranes for gas separation, and advanced composites for extreme environments.

The manufacturing process of PBI has undergone significant improvements since its inception. Initially, the production was limited and costly, restricting its use to specialized applications. However, advancements in polymer chemistry and manufacturing techniques have led to more efficient and scalable production methods, expanding PBI's potential applications.

One of the key components in PBI manufacturing is muriatic acid, also known as hydrochloric acid. This strong mineral acid plays a crucial role in the synthesis and processing of PBI. The use of muriatic acid in PBI production is part of a complex chemical process that involves the condensation of aromatic tetraamines with aromatic dicarboxylic acids or their derivatives.

The primary objective of using muriatic acid in PBI manufacturing is to facilitate the polymerization process and control the molecular weight of the resulting polymer. Muriatic acid acts as a catalyst and a solvent, promoting the formation of the benzimidazole ring structure that gives PBI its unique properties.

As the demand for high-performance materials continues to grow, the PBI manufacturing industry faces several challenges and opportunities. These include improving production efficiency, reducing costs, and developing new grades of PBI with enhanced properties. The use of muriatic acid in this process is an area of ongoing research and development, with efforts focused on optimizing its role in the synthesis and potentially finding alternative, more environmentally friendly approaches.

The evolution of PBI manufacturing techniques, including the use of muriatic acid, is closely tied to technological advancements in polymer science and chemical engineering. Future developments in this field are expected to focus on sustainable production methods, improved material performance, and expanded applications in emerging technologies such as fuel cells, membranes for gas separation, and advanced composites for extreme environments.

Market Analysis for PBI Products

The market for Polybenzimidazole (PBI) products has shown significant growth potential in recent years, driven by the material's exceptional thermal and chemical resistance properties. PBI finds applications across various industries, including aerospace, automotive, fire safety, and industrial manufacturing. The global PBI market size was valued at approximately $400 million in 2020 and is projected to grow at a compound annual growth rate (CAGR) of around 8% from 2021 to 2026.

The aerospace sector represents a key market for PBI products, particularly in high-temperature applications such as aircraft engine components and thermal insulation materials. The increasing demand for lightweight and heat-resistant materials in modern aircraft design is expected to drive the growth of PBI in this sector. Similarly, the automotive industry is adopting PBI for use in fuel cells, high-temperature seals, and other components that require exceptional thermal stability.

In the fire safety sector, PBI fibers are widely used in protective clothing for firefighters and industrial workers exposed to high-heat environments. The stringent safety regulations across various industries and the growing awareness of workplace safety are contributing to the increased adoption of PBI-based protective gear. This segment is anticipated to witness substantial growth in the coming years.

The industrial manufacturing sector utilizes PBI in various applications, including filtration systems, gaskets, and seals for high-temperature processes. The material's resistance to chemicals and extreme temperatures makes it ideal for use in harsh industrial environments. As industries continue to push the boundaries of operational conditions, the demand for PBI products in this sector is expected to rise.

Geographically, North America and Europe currently dominate the PBI market, owing to the presence of major aerospace and automotive manufacturers in these regions. However, the Asia-Pacific region is emerging as a lucrative market for PBI products, driven by rapid industrialization, increasing safety regulations, and growing investments in aerospace and defense sectors in countries like China and India.

Despite the positive market outlook, challenges such as high production costs and limited raw material availability may hinder the growth of the PBI market. Manufacturers are focusing on research and development to optimize production processes and explore alternative raw materials to address these challenges. Additionally, the development of new applications for PBI, such as in energy storage devices and membrane technologies, is expected to create new growth opportunities in the market.

The aerospace sector represents a key market for PBI products, particularly in high-temperature applications such as aircraft engine components and thermal insulation materials. The increasing demand for lightweight and heat-resistant materials in modern aircraft design is expected to drive the growth of PBI in this sector. Similarly, the automotive industry is adopting PBI for use in fuel cells, high-temperature seals, and other components that require exceptional thermal stability.

In the fire safety sector, PBI fibers are widely used in protective clothing for firefighters and industrial workers exposed to high-heat environments. The stringent safety regulations across various industries and the growing awareness of workplace safety are contributing to the increased adoption of PBI-based protective gear. This segment is anticipated to witness substantial growth in the coming years.

The industrial manufacturing sector utilizes PBI in various applications, including filtration systems, gaskets, and seals for high-temperature processes. The material's resistance to chemicals and extreme temperatures makes it ideal for use in harsh industrial environments. As industries continue to push the boundaries of operational conditions, the demand for PBI products in this sector is expected to rise.

Geographically, North America and Europe currently dominate the PBI market, owing to the presence of major aerospace and automotive manufacturers in these regions. However, the Asia-Pacific region is emerging as a lucrative market for PBI products, driven by rapid industrialization, increasing safety regulations, and growing investments in aerospace and defense sectors in countries like China and India.

Despite the positive market outlook, challenges such as high production costs and limited raw material availability may hinder the growth of the PBI market. Manufacturers are focusing on research and development to optimize production processes and explore alternative raw materials to address these challenges. Additionally, the development of new applications for PBI, such as in energy storage devices and membrane technologies, is expected to create new growth opportunities in the market.

Muriatic Acid in PBI Synthesis: Current Challenges

The synthesis of Polybenzimidazole (PBI) using muriatic acid, also known as hydrochloric acid, faces several significant challenges in current manufacturing processes. One of the primary issues is the corrosive nature of muriatic acid, which necessitates specialized equipment and safety measures. This corrosiveness not only poses risks to workers but also leads to increased maintenance costs and potential equipment failures.

Another challenge lies in the precise control of reaction conditions. The synthesis of PBI requires careful management of temperature, pressure, and acid concentration. Fluctuations in these parameters can result in inconsistent product quality, reduced yield, or even failed batches. Maintaining uniformity across large-scale production runs remains a persistent challenge for manufacturers.

The environmental impact of using muriatic acid in PBI synthesis is also a growing concern. The process generates acidic waste streams that require neutralization and proper disposal. This not only adds to production costs but also raises environmental compliance issues, particularly in regions with stringent regulations.

Furthermore, the high reactivity of muriatic acid can lead to side reactions and the formation of unwanted by-products. These impurities can affect the final properties of PBI, potentially compromising its performance in high-temperature and chemically resistant applications. Purification steps to remove these by-products add complexity and cost to the manufacturing process.

The storage and handling of muriatic acid present logistical challenges. Large quantities of the acid must be safely stored on-site, requiring specialized containment systems and rigorous safety protocols. Transportation of muriatic acid to manufacturing facilities also poses risks and regulatory hurdles.

Additionally, the energy-intensive nature of the PBI synthesis process using muriatic acid contributes to high production costs. The reaction typically requires elevated temperatures and extended processing times, leading to significant energy consumption. This not only impacts the economic viability of PBI production but also raises sustainability concerns in an increasingly environmentally conscious market.

Lastly, there is an ongoing challenge in optimizing the reaction kinetics to improve efficiency and reduce processing time. Current methods often involve lengthy reaction periods, which limit production capacity and increase operational costs. Developing catalysts or alternative reaction pathways to accelerate the synthesis while maintaining product quality remains an active area of research and development in the field.

Another challenge lies in the precise control of reaction conditions. The synthesis of PBI requires careful management of temperature, pressure, and acid concentration. Fluctuations in these parameters can result in inconsistent product quality, reduced yield, or even failed batches. Maintaining uniformity across large-scale production runs remains a persistent challenge for manufacturers.

The environmental impact of using muriatic acid in PBI synthesis is also a growing concern. The process generates acidic waste streams that require neutralization and proper disposal. This not only adds to production costs but also raises environmental compliance issues, particularly in regions with stringent regulations.

Furthermore, the high reactivity of muriatic acid can lead to side reactions and the formation of unwanted by-products. These impurities can affect the final properties of PBI, potentially compromising its performance in high-temperature and chemically resistant applications. Purification steps to remove these by-products add complexity and cost to the manufacturing process.

The storage and handling of muriatic acid present logistical challenges. Large quantities of the acid must be safely stored on-site, requiring specialized containment systems and rigorous safety protocols. Transportation of muriatic acid to manufacturing facilities also poses risks and regulatory hurdles.

Additionally, the energy-intensive nature of the PBI synthesis process using muriatic acid contributes to high production costs. The reaction typically requires elevated temperatures and extended processing times, leading to significant energy consumption. This not only impacts the economic viability of PBI production but also raises sustainability concerns in an increasingly environmentally conscious market.

Lastly, there is an ongoing challenge in optimizing the reaction kinetics to improve efficiency and reduce processing time. Current methods often involve lengthy reaction periods, which limit production capacity and increase operational costs. Developing catalysts or alternative reaction pathways to accelerate the synthesis while maintaining product quality remains an active area of research and development in the field.

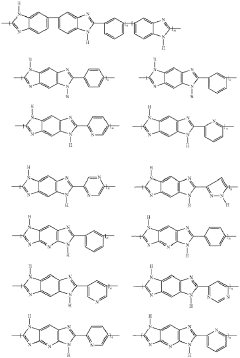

Current Muriatic Acid-Based PBI Synthesis Methods

01 Synthesis and production methods of PBI

Various methods for synthesizing and producing polybenzimidazole (PBI) are described. These include techniques for improving yield, purity, and efficiency of the production process. Some methods focus on optimizing reaction conditions, while others explore novel precursors or catalysts to enhance PBI synthesis.- Synthesis and production methods of PBI: Various methods for synthesizing and producing polybenzimidazole (PBI) are described. These include techniques for improving yield, purity, and efficiency of the production process. Some methods focus on optimizing reaction conditions, while others explore novel precursors or catalysts to enhance PBI synthesis.

- PBI-based membranes and films: PBI is used to create high-performance membranes and films for various applications. These materials exhibit excellent thermal stability, chemical resistance, and mechanical strength. Techniques for fabricating and modifying PBI membranes to enhance their properties, such as gas separation efficiency or proton conductivity, are discussed.

- PBI composites and blends: Research on developing PBI-based composites and polymer blends is presented. These materials combine the advantageous properties of PBI with other polymers or additives to create materials with enhanced characteristics. Applications include high-temperature resistant composites and flame-retardant materials.

- PBI fibers and textiles: Methods for producing PBI fibers and their application in textiles are explored. These fibers exhibit exceptional heat resistance and are used in protective clothing and high-performance textiles. Techniques for improving fiber properties, such as tensile strength and chemical resistance, are discussed.

- PBI in fuel cell applications: The use of PBI in fuel cell technology, particularly in high-temperature proton exchange membrane fuel cells, is investigated. Research focuses on improving proton conductivity, durability, and performance of PBI-based membranes under fuel cell operating conditions. Methods for doping PBI with acids to enhance its properties for fuel cell applications are also discussed.

02 PBI-based membranes and films

PBI is used to create high-performance membranes and films for various applications. These materials often exhibit excellent thermal stability, chemical resistance, and mechanical strength. Techniques for fabricating and modifying PBI membranes to enhance their properties, such as gas separation or proton conductivity, are discussed.Expand Specific Solutions03 PBI composites and blends

Research on developing PBI-based composites and polymer blends is presented. These materials combine the properties of PBI with other polymers or additives to create advanced materials with enhanced characteristics. Applications include high-temperature resistant composites and flame-retardant materials.Expand Specific Solutions04 PBI fibers and textiles

Methods for producing PBI fibers and their application in textiles are explored. These fibers are known for their exceptional heat and flame resistance, making them suitable for protective clothing and high-performance textiles. Techniques for spinning, processing, and modifying PBI fibers are discussed.Expand Specific Solutions05 PBI in fuel cells and energy applications

The use of PBI in fuel cell technology, particularly in high-temperature proton exchange membrane fuel cells, is investigated. Research focuses on improving proton conductivity, durability, and performance of PBI-based membranes in fuel cell systems. Other energy-related applications of PBI are also explored.Expand Specific Solutions

Key Industry Players in PBI Manufacturing

The development of polybenzimidazole (PBI) using muriatic acid is in a mature phase, with established manufacturing processes. The market for PBI is growing steadily, driven by its high-performance properties in extreme environments. Technologically, the process is well-understood, with key players like PBI Performance Products, DuPont, and Solvay leading commercial production. Research institutions such as the University of South Carolina and Beijing University of Chemical Technology continue to refine and optimize the synthesis methods. The involvement of major chemical companies and ongoing academic research indicates a competitive landscape with potential for further innovations in PBI manufacturing techniques and applications.

LG Chem Ltd.

Technical Solution: LG Chem utilizes muriatic acid in its PBI production process, focusing on membrane applications for fuel cells. The company's approach involves using muriatic acid in the post-polymerization treatment of PBI membranes to enhance their proton conductivity and mechanical strength. LG Chem has developed a controlled acid doping process that allows for precise manipulation of the membrane's properties, resulting in improved performance in high-temperature fuel cell applications. The company also employs advanced acid recovery systems to ensure efficient use of resources[5][6].

Strengths: Specialized in PBI membranes for fuel cells, advanced acid doping techniques. Weaknesses: Narrow focus may limit applications in other PBI markets.

DuPont de Nemours, Inc.

Technical Solution: DuPont employs muriatic acid in its PBI manufacturing process, particularly in the post-polymerization treatment of PBI fibers. The company has developed a proprietary method that involves controlled exposure of PBI fibers to muriatic acid, which helps in modifying the fiber surface properties and enhancing their overall performance. This treatment improves the fiber's resistance to chemicals and high temperatures, making them suitable for extreme environment applications. DuPont's process also incorporates advanced acid recycling techniques to minimize environmental impact[2][4].

Strengths: Advanced acid treatment techniques, focus on environmental sustainability. Weaknesses: Potentially higher production costs due to specialized processes.

Innovations in Muriatic Acid Usage for PBI Production

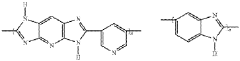

Low permeability polybenzimidazole (PBI) membranes for redox flow batteries

PatentWO2020056268A2

Innovation

- Development of low permeability polybenzimidazole (PBI) gel membranes formed through a process involving polyphosphoric acid (PPA) and aromatic or heteroaromatic compounds, allowing for high ionic conductivity and stability under high current loads, with a method that includes polymerization, hydrolysis, and densification to create a self-supporting structure.

Co-abpbi membranes and process for the preparation thereof

PatentWO2015029070A1

Innovation

- A sol-gel process for synthesizing co-ABPBI membranes using 3,4-diaminobenzoic acid, dicarboxylic acid, and tetramine in polyphosphoric acid as a solvent, allowing direct membrane casting from the reaction mixture without powder formation, achieving film form with enhanced mechanical strength and tunable acid content.

Environmental Impact of Muriatic Acid in PBI Manufacturing

The use of muriatic acid (hydrochloric acid) in the manufacture of Polybenzimidazole (PBI) raises significant environmental concerns that require careful consideration and management. The production process involves the use of this strong acid, which can have detrimental effects on the environment if not properly handled and disposed of.

One of the primary environmental impacts is the potential for acid runoff and soil contamination. If muriatic acid is accidentally released or improperly disposed of, it can seep into the ground, altering soil pH and potentially harming plant life and microorganisms. This can lead to long-term ecological damage in the surrounding areas of manufacturing facilities.

Water pollution is another critical concern. Muriatic acid, if discharged into water bodies, can dramatically lower the pH, creating inhospitable conditions for aquatic life. This can result in fish kills, disruption of aquatic ecosystems, and long-lasting damage to water resources. Proper wastewater treatment and neutralization processes are essential to mitigate these risks.

Air quality is also affected by the use of muriatic acid in PBI production. The volatile nature of the acid can lead to the release of hydrogen chloride gas, which contributes to air pollution and can cause respiratory issues in both humans and animals. Adequate ventilation systems and air scrubbers are necessary to minimize these emissions.

The transportation and storage of muriatic acid present additional environmental risks. Accidental spills during transport or leaks from storage tanks can result in localized environmental damage and pose health hazards to nearby communities. Strict safety protocols and containment measures are crucial to prevent such incidents.

From a broader perspective, the production and use of muriatic acid contribute to the overall carbon footprint of PBI manufacturing. The energy-intensive processes required for acid production and the subsequent treatment of waste products add to the industry's environmental impact, contributing to greenhouse gas emissions and climate change concerns.

To address these environmental challenges, manufacturers are increasingly adopting more sustainable practices. These include implementing closed-loop systems to recycle and reuse acid, investing in advanced wastewater treatment technologies, and exploring alternative, less harmful chemicals for PBI production. Additionally, stricter regulations and environmental monitoring are being put in place to ensure compliance with environmental standards and minimize the ecological footprint of PBI manufacturing processes.

One of the primary environmental impacts is the potential for acid runoff and soil contamination. If muriatic acid is accidentally released or improperly disposed of, it can seep into the ground, altering soil pH and potentially harming plant life and microorganisms. This can lead to long-term ecological damage in the surrounding areas of manufacturing facilities.

Water pollution is another critical concern. Muriatic acid, if discharged into water bodies, can dramatically lower the pH, creating inhospitable conditions for aquatic life. This can result in fish kills, disruption of aquatic ecosystems, and long-lasting damage to water resources. Proper wastewater treatment and neutralization processes are essential to mitigate these risks.

Air quality is also affected by the use of muriatic acid in PBI production. The volatile nature of the acid can lead to the release of hydrogen chloride gas, which contributes to air pollution and can cause respiratory issues in both humans and animals. Adequate ventilation systems and air scrubbers are necessary to minimize these emissions.

The transportation and storage of muriatic acid present additional environmental risks. Accidental spills during transport or leaks from storage tanks can result in localized environmental damage and pose health hazards to nearby communities. Strict safety protocols and containment measures are crucial to prevent such incidents.

From a broader perspective, the production and use of muriatic acid contribute to the overall carbon footprint of PBI manufacturing. The energy-intensive processes required for acid production and the subsequent treatment of waste products add to the industry's environmental impact, contributing to greenhouse gas emissions and climate change concerns.

To address these environmental challenges, manufacturers are increasingly adopting more sustainable practices. These include implementing closed-loop systems to recycle and reuse acid, investing in advanced wastewater treatment technologies, and exploring alternative, less harmful chemicals for PBI production. Additionally, stricter regulations and environmental monitoring are being put in place to ensure compliance with environmental standards and minimize the ecological footprint of PBI manufacturing processes.

Safety Protocols for Handling Muriatic Acid in PBI Production

The safe handling of muriatic acid (hydrochloric acid) in the production of Polybenzimidazole (PBI) is crucial to ensure worker safety and environmental protection. Strict safety protocols must be implemented throughout the manufacturing process to mitigate risks associated with this corrosive substance.

Personal protective equipment (PPE) is the first line of defense for workers handling muriatic acid. This includes chemical-resistant gloves, goggles, face shields, and acid-resistant aprons or suits. Respiratory protection may also be necessary, depending on the concentration and potential for vapor exposure. Regular inspection and replacement of PPE are essential to maintain its effectiveness.

Proper storage of muriatic acid is critical to prevent accidental spills or reactions. The acid should be stored in corrosion-resistant containers in a well-ventilated, cool, and dry area, away from incompatible materials. Storage areas must be equipped with secondary containment systems to capture potential leaks or spills.

Handling procedures for muriatic acid in PBI production should be clearly defined and communicated to all relevant personnel. This includes guidelines for transferring the acid, diluting it when necessary, and incorporating it into the PBI manufacturing process. Automated systems and closed transfer methods should be utilized whenever possible to minimize direct contact with the acid.

Emergency response plans must be in place to address potential acid spills or exposures. This includes the installation of emergency showers and eyewash stations in strategic locations throughout the production facility. Workers should be trained in proper spill containment and neutralization techniques, as well as first aid procedures for acid exposure.

Ventilation systems play a crucial role in maintaining a safe working environment. Adequate local exhaust ventilation should be installed in areas where muriatic acid is handled to remove any vapors or fumes. Regular monitoring of air quality and acid vapor levels is necessary to ensure that exposure limits are not exceeded.

Training and education are fundamental components of safety protocols. All personnel involved in handling muriatic acid or working in areas where it is used must receive comprehensive training on the hazards, proper handling techniques, and emergency procedures. Regular refresher courses and safety drills should be conducted to maintain awareness and preparedness.

Waste management and disposal procedures for muriatic acid and related materials must comply with local, state, and federal regulations. Proper neutralization and disposal methods should be established to prevent environmental contamination and ensure regulatory compliance.

Regular safety audits and inspections should be conducted to assess the effectiveness of safety protocols and identify areas for improvement. This includes reviewing incident reports, near-misses, and potential hazards to continuously enhance safety measures in the PBI production process.

Personal protective equipment (PPE) is the first line of defense for workers handling muriatic acid. This includes chemical-resistant gloves, goggles, face shields, and acid-resistant aprons or suits. Respiratory protection may also be necessary, depending on the concentration and potential for vapor exposure. Regular inspection and replacement of PPE are essential to maintain its effectiveness.

Proper storage of muriatic acid is critical to prevent accidental spills or reactions. The acid should be stored in corrosion-resistant containers in a well-ventilated, cool, and dry area, away from incompatible materials. Storage areas must be equipped with secondary containment systems to capture potential leaks or spills.

Handling procedures for muriatic acid in PBI production should be clearly defined and communicated to all relevant personnel. This includes guidelines for transferring the acid, diluting it when necessary, and incorporating it into the PBI manufacturing process. Automated systems and closed transfer methods should be utilized whenever possible to minimize direct contact with the acid.

Emergency response plans must be in place to address potential acid spills or exposures. This includes the installation of emergency showers and eyewash stations in strategic locations throughout the production facility. Workers should be trained in proper spill containment and neutralization techniques, as well as first aid procedures for acid exposure.

Ventilation systems play a crucial role in maintaining a safe working environment. Adequate local exhaust ventilation should be installed in areas where muriatic acid is handled to remove any vapors or fumes. Regular monitoring of air quality and acid vapor levels is necessary to ensure that exposure limits are not exceeded.

Training and education are fundamental components of safety protocols. All personnel involved in handling muriatic acid or working in areas where it is used must receive comprehensive training on the hazards, proper handling techniques, and emergency procedures. Regular refresher courses and safety drills should be conducted to maintain awareness and preparedness.

Waste management and disposal procedures for muriatic acid and related materials must comply with local, state, and federal regulations. Proper neutralization and disposal methods should be established to prevent environmental contamination and ensure regulatory compliance.

Regular safety audits and inspections should be conducted to assess the effectiveness of safety protocols and identify areas for improvement. This includes reviewing incident reports, near-misses, and potential hazards to continuously enhance safety measures in the PBI production process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!