How Muriatic Acid is Used in the Manufacture of Polyether Block Amides (PEBAX)

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEBAX Manufacturing Overview

Polyether Block Amides (PEBAX) are a family of high-performance thermoplastic elastomers that combine the properties of polyamides and polyethers. The manufacturing process of PEBAX involves several key steps, with muriatic acid playing a crucial role in the production of these versatile materials.

The synthesis of PEBAX begins with the preparation of polyether blocks, typically derived from polytetramethylene glycol (PTMG) or polyethylene glycol (PEG). These polyether segments contribute to the flexibility and elasticity of the final product. Concurrently, polyamide blocks are synthesized, often using nylon-6 or nylon-12 as the base material. The polyamide segments impart strength and rigidity to the copolymer.

Muriatic acid, also known as hydrochloric acid, is utilized in the manufacturing process primarily as a catalyst and pH regulator. During the polymerization reaction, muriatic acid helps to control the rate of reaction and ensures the proper formation of chemical bonds between the polyether and polyamide blocks. The acid's ability to donate protons facilitates the condensation reactions necessary for polymer chain growth.

The production of PEBAX involves a two-step polymerization process. In the first step, the polyether and polyamide precursors are combined in the presence of muriatic acid. The acid catalyzes the formation of amide linkages between the two components, initiating the block copolymer structure. The second step involves the extension of these initial blocks to form longer polymer chains, resulting in the desired molecular weight and properties of the final PEBAX material.

Temperature control is critical during the manufacturing process, with reactions typically carried out at elevated temperatures ranging from 200°C to 250°C. Muriatic acid's role in maintaining the appropriate pH is essential for achieving optimal reaction conditions and preventing unwanted side reactions that could compromise the quality of the final product.

The use of muriatic acid in PEBAX production also extends to the purification and post-processing stages. After polymerization, the acid helps in neutralizing any remaining reactive groups and assists in the removal of unreacted monomers or oligomers. This purification step is crucial for ensuring the consistency and performance characteristics of the PEBAX material.

Precise control of muriatic acid concentration and exposure time is essential throughout the manufacturing process. Excess acid can lead to degradation of the polymer chains, while insufficient acid may result in incomplete polymerization. Advanced process control systems and analytical techniques are employed to monitor and adjust acid levels, ensuring the production of high-quality PEBAX with consistent properties.

The synthesis of PEBAX begins with the preparation of polyether blocks, typically derived from polytetramethylene glycol (PTMG) or polyethylene glycol (PEG). These polyether segments contribute to the flexibility and elasticity of the final product. Concurrently, polyamide blocks are synthesized, often using nylon-6 or nylon-12 as the base material. The polyamide segments impart strength and rigidity to the copolymer.

Muriatic acid, also known as hydrochloric acid, is utilized in the manufacturing process primarily as a catalyst and pH regulator. During the polymerization reaction, muriatic acid helps to control the rate of reaction and ensures the proper formation of chemical bonds between the polyether and polyamide blocks. The acid's ability to donate protons facilitates the condensation reactions necessary for polymer chain growth.

The production of PEBAX involves a two-step polymerization process. In the first step, the polyether and polyamide precursors are combined in the presence of muriatic acid. The acid catalyzes the formation of amide linkages between the two components, initiating the block copolymer structure. The second step involves the extension of these initial blocks to form longer polymer chains, resulting in the desired molecular weight and properties of the final PEBAX material.

Temperature control is critical during the manufacturing process, with reactions typically carried out at elevated temperatures ranging from 200°C to 250°C. Muriatic acid's role in maintaining the appropriate pH is essential for achieving optimal reaction conditions and preventing unwanted side reactions that could compromise the quality of the final product.

The use of muriatic acid in PEBAX production also extends to the purification and post-processing stages. After polymerization, the acid helps in neutralizing any remaining reactive groups and assists in the removal of unreacted monomers or oligomers. This purification step is crucial for ensuring the consistency and performance characteristics of the PEBAX material.

Precise control of muriatic acid concentration and exposure time is essential throughout the manufacturing process. Excess acid can lead to degradation of the polymer chains, while insufficient acid may result in incomplete polymerization. Advanced process control systems and analytical techniques are employed to monitor and adjust acid levels, ensuring the production of high-quality PEBAX with consistent properties.

Market Analysis for PEBAX

The global market for Polyether Block Amides (PEBAX) has been experiencing steady growth, driven by increasing demand across various industries. PEBAX, a versatile thermoplastic elastomer, offers a unique combination of properties that make it attractive for applications in sports equipment, medical devices, automotive components, and electronics.

In the sports and leisure sector, PEBAX has gained significant traction, particularly in the footwear industry. Major athletic shoe manufacturers have incorporated PEBAX into their high-performance running shoes and soccer cleats due to its excellent energy return and lightweight characteristics. This trend has contributed to a substantial market share in the sports equipment segment.

The medical device industry represents another key market for PEBAX. Its biocompatibility, flexibility, and resistance to sterilization processes make it an ideal material for catheters, tubing, and other medical components. As healthcare expenditures continue to rise globally, the demand for advanced medical devices is expected to drive further growth in this sector.

Automotive applications for PEBAX are also expanding, with the material being used in fuel line systems, air brake tubing, and interior components. The automotive industry's shift towards lightweight materials to improve fuel efficiency has created new opportunities for PEBAX in this market segment.

Geographically, North America and Europe have been the largest markets for PEBAX, owing to the presence of major end-user industries and advanced manufacturing capabilities. However, the Asia-Pacific region is emerging as a significant growth market, fueled by rapid industrialization, increasing disposable incomes, and growing demand for high-performance materials in countries like China and India.

The competitive landscape of the PEBAX market is characterized by a few key players dominating the production and distribution. Arkema, the original developer of PEBAX, remains the primary manufacturer and holds a significant market share. Other companies have entered the market with similar thermoplastic elastomers, but PEBAX maintains a strong brand recognition and loyalty among end-users.

Market analysts project continued growth for PEBAX in the coming years, with some estimates suggesting a compound annual growth rate (CAGR) in the mid-single digits. This growth is expected to be driven by innovations in material science, expanding applications in existing industries, and penetration into new market segments.

In the sports and leisure sector, PEBAX has gained significant traction, particularly in the footwear industry. Major athletic shoe manufacturers have incorporated PEBAX into their high-performance running shoes and soccer cleats due to its excellent energy return and lightweight characteristics. This trend has contributed to a substantial market share in the sports equipment segment.

The medical device industry represents another key market for PEBAX. Its biocompatibility, flexibility, and resistance to sterilization processes make it an ideal material for catheters, tubing, and other medical components. As healthcare expenditures continue to rise globally, the demand for advanced medical devices is expected to drive further growth in this sector.

Automotive applications for PEBAX are also expanding, with the material being used in fuel line systems, air brake tubing, and interior components. The automotive industry's shift towards lightweight materials to improve fuel efficiency has created new opportunities for PEBAX in this market segment.

Geographically, North America and Europe have been the largest markets for PEBAX, owing to the presence of major end-user industries and advanced manufacturing capabilities. However, the Asia-Pacific region is emerging as a significant growth market, fueled by rapid industrialization, increasing disposable incomes, and growing demand for high-performance materials in countries like China and India.

The competitive landscape of the PEBAX market is characterized by a few key players dominating the production and distribution. Arkema, the original developer of PEBAX, remains the primary manufacturer and holds a significant market share. Other companies have entered the market with similar thermoplastic elastomers, but PEBAX maintains a strong brand recognition and loyalty among end-users.

Market analysts project continued growth for PEBAX in the coming years, with some estimates suggesting a compound annual growth rate (CAGR) in the mid-single digits. This growth is expected to be driven by innovations in material science, expanding applications in existing industries, and penetration into new market segments.

Muriatic Acid in PEBAX Production

Muriatic acid, also known as hydrochloric acid, plays a crucial role in the production of Polyether Block Amides (PEBAX). This versatile acid is utilized in various stages of the manufacturing process, contributing to the formation of high-quality PEBAX materials with desired properties.

In the initial phase of PEBAX production, muriatic acid is employed as a catalyst to facilitate the polymerization reaction between polyether and polyamide segments. The acid's strong proton-donating ability helps initiate and control the rate of polymerization, ensuring the formation of well-defined block copolymer structures.

During the synthesis of polyether segments, muriatic acid acts as a ring-opening agent for epoxide monomers. This step is critical in creating the flexible, soft segments of PEBAX. The acid's controlled addition allows for precise manipulation of the polyether chain length, which directly influences the final material's elasticity and flexibility.

Muriatic acid also serves as a pH regulator throughout the manufacturing process. By carefully adjusting the acidity of the reaction mixture, manufacturers can optimize the polymerization kinetics and prevent unwanted side reactions. This pH control is essential for achieving consistent product quality and desired molecular weight distributions.

In the purification stage, muriatic acid is used to neutralize any residual basic compounds and remove metal impurities. This step is crucial for enhancing the thermal and chemical stability of the final PEBAX product. The acid treatment helps in eliminating potential catalytic sites that could lead to degradation during the material's service life.

Furthermore, muriatic acid plays a role in the surface modification of PEBAX materials. Controlled acid etching can be employed to alter the surface properties, improving adhesion characteristics or creating micro-textures for specific applications. This surface treatment enhances the material's compatibility with other substances in composite structures or coatings.

The acid's use extends to the recycling and recovery processes of PEBAX materials. In chemical recycling methods, muriatic acid can be used to break down the polymer chains, facilitating the separation and recovery of valuable monomers or oligomers for reuse in new PEBAX production cycles.

Proper handling and dosage of muriatic acid are critical aspects of PEBAX manufacturing. Advanced process control systems and safety protocols are implemented to ensure precise acid addition and maintain a safe working environment. The use of corrosion-resistant equipment and specialized acid-handling systems is essential to prevent equipment damage and ensure worker safety.

In the initial phase of PEBAX production, muriatic acid is employed as a catalyst to facilitate the polymerization reaction between polyether and polyamide segments. The acid's strong proton-donating ability helps initiate and control the rate of polymerization, ensuring the formation of well-defined block copolymer structures.

During the synthesis of polyether segments, muriatic acid acts as a ring-opening agent for epoxide monomers. This step is critical in creating the flexible, soft segments of PEBAX. The acid's controlled addition allows for precise manipulation of the polyether chain length, which directly influences the final material's elasticity and flexibility.

Muriatic acid also serves as a pH regulator throughout the manufacturing process. By carefully adjusting the acidity of the reaction mixture, manufacturers can optimize the polymerization kinetics and prevent unwanted side reactions. This pH control is essential for achieving consistent product quality and desired molecular weight distributions.

In the purification stage, muriatic acid is used to neutralize any residual basic compounds and remove metal impurities. This step is crucial for enhancing the thermal and chemical stability of the final PEBAX product. The acid treatment helps in eliminating potential catalytic sites that could lead to degradation during the material's service life.

Furthermore, muriatic acid plays a role in the surface modification of PEBAX materials. Controlled acid etching can be employed to alter the surface properties, improving adhesion characteristics or creating micro-textures for specific applications. This surface treatment enhances the material's compatibility with other substances in composite structures or coatings.

The acid's use extends to the recycling and recovery processes of PEBAX materials. In chemical recycling methods, muriatic acid can be used to break down the polymer chains, facilitating the separation and recovery of valuable monomers or oligomers for reuse in new PEBAX production cycles.

Proper handling and dosage of muriatic acid are critical aspects of PEBAX manufacturing. Advanced process control systems and safety protocols are implemented to ensure precise acid addition and maintain a safe working environment. The use of corrosion-resistant equipment and specialized acid-handling systems is essential to prevent equipment damage and ensure worker safety.

Current PEBAX Production Methods

01 Production and purification of muriatic acid

Muriatic acid, also known as hydrochloric acid, can be produced and purified through various industrial processes. These methods often involve the reaction of chlorine with hydrogen or the treatment of salt (sodium chloride) with sulfuric acid. Purification techniques may include distillation or membrane separation to remove impurities and achieve the desired concentration.- Production and purification of muriatic acid: Muriatic acid, also known as hydrochloric acid, can be produced and purified through various industrial processes. These methods involve the reaction of chlorine with hydrogen or the treatment of chloride salts with sulfuric acid. Purification techniques may include distillation or membrane separation to remove impurities and achieve desired concentrations.

- Applications in metal treatment and surface cleaning: Muriatic acid is widely used in metal treatment processes, including pickling, etching, and surface cleaning. It effectively removes rust, scale, and other contaminants from metal surfaces, preparing them for further processing or coating. The acid's strong reactivity makes it suitable for various industrial cleaning applications.

- Use in construction and building materials: Muriatic acid finds applications in the construction industry, particularly in the treatment of concrete and masonry surfaces. It can be used for cleaning, etching, or preparing surfaces for further treatment. The acid is also employed in the production of certain building materials and in the maintenance of swimming pools.

- Environmental and safety considerations: Handling and disposal of muriatic acid require careful attention to environmental and safety regulations. Proper storage, transportation, and waste management practices are essential to prevent environmental contamination and ensure worker safety. Neutralization and treatment processes may be necessary before disposal or release into the environment.

- Specialized applications in chemical processes: Muriatic acid serves as a key reagent in various chemical processes and industries. It is used in the production of pharmaceuticals, food additives, and other chemicals. The acid's properties make it valuable for pH adjustment, catalysis, and as a reactant in organic synthesis and inorganic compound production.

02 Applications in metal treatment and surface cleaning

Muriatic acid is widely used in metal treatment processes, such as pickling, etching, and surface cleaning. It effectively removes rust, scale, and other contaminants from metal surfaces, preparing them for further processing or coating. The acid's strong reactivity makes it suitable for various industrial cleaning applications.Expand Specific Solutions03 Use in construction and building materials

In the construction industry, muriatic acid is utilized for cleaning masonry, concrete, and other building materials. It can remove efflorescence, mortar residues, and stains from surfaces. Additionally, it is used in the production of certain construction materials and in the treatment of swimming pool water to maintain proper pH levels.Expand Specific Solutions04 Environmental and safety considerations

Handling and disposal of muriatic acid require careful attention to environmental and safety regulations. Proper storage, transportation, and use of protective equipment are essential to prevent accidents and minimize environmental impact. Neutralization techniques and specialized disposal methods are often employed to manage waste acid safely.Expand Specific Solutions05 Alternative applications and formulations

Beyond its traditional uses, muriatic acid finds applications in various industries. It can be used in the production of pharmaceuticals, food processing, and water treatment. Modified formulations or combinations with other chemicals may enhance its effectiveness for specific applications or reduce its corrosive properties while maintaining its desired functions.Expand Specific Solutions

Key PEBAX Manufacturers

The competitive landscape for the use of muriatic acid in the manufacture of Polyether Block Amides (PEBAX) is characterized by a mature market with established players. The industry is in a growth phase, driven by increasing demand for high-performance polymers in various applications. Key players like Arkema France SA, Evonik Operations GmbH, and China Petroleum & Chemical Corp. dominate the market, leveraging their extensive R&D capabilities and global presence. The technology is well-developed, with companies focusing on process optimization and product customization to maintain their competitive edge. Emerging players and research institutions are also contributing to technological advancements, indicating a dynamic and innovation-driven competitive environment.

Arkema France SA

Technical Solution: Arkema, as the inventor and leading manufacturer of PEBAX, utilizes muriatic acid (hydrochloric acid) in the production process of polyether block amides. The acid is used in the polycondensation reaction between dicarboxylic acid-terminated polyamide blocks and hydroxyl-terminated polyether blocks[1]. Arkema's process involves carefully controlled pH levels, where muriatic acid plays a crucial role in maintaining the optimal acidity for the reaction. The company has developed proprietary techniques to manage the acid's concentration and reaction conditions, ensuring high-quality PEBAX production with consistent properties[2]. Arkema's advanced manufacturing facilities incorporate state-of-the-art acid handling and neutralization systems to maximize efficiency and minimize environmental impact[3].

Strengths: Extensive experience as the original developer of PEBAX, proprietary acid management techniques, and optimized production processes. Weaknesses: Potential environmental concerns related to acid handling and disposal, and the need for specialized equipment and safety measures.

Evonik Operations GmbH

Technical Solution: Evonik, a major player in specialty chemicals, has developed its own approach to using muriatic acid in the production of polyether block amides. The company's process focuses on precise control of acid concentration and reaction kinetics to achieve desired polymer properties. Evonik's method involves a two-step reaction where muriatic acid is used to activate the amine end groups of the polyamide blocks before coupling with polyether segments[4]. This approach allows for better control over block length and distribution, resulting in PEBAX-like materials with tailored characteristics. Evonik has also implemented advanced acid recycling systems in their production facilities, reducing waste and improving overall process efficiency[5].

Strengths: Innovative acid activation technique, efficient acid recycling, and ability to produce customized polyether block amides. Weaknesses: May require more complex process control and potentially higher production costs compared to traditional methods.

Muriatic Acid Innovations

Process to make copolymers having polyamide blocks and polyether blocks

PatentInactiveEP1783157A1

Innovation

- Incorporating a trifunctional polyol as a coupling agent during the synthesis process, which provides additional hydroxyl groups, enhances catalyst compatibility, and allows for medium vacuum conditions, thereby improving molecular weight and reducing cycle time and degradation.

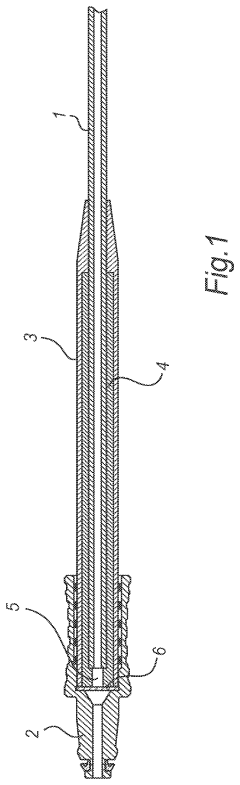

Gas sampling line

PatentPendingUS20230346257A1

Innovation

- A gas sampling line using a polyether block amide material with polyethyleneoxide segments for the gas sampling tube, which allows moisture to permeate while preventing component absorption, combined with a hydrophilic drying assembly for efficient water removal and a hydrophobic filter to protect the gas monitor from contaminants.

Environmental Impact Assessment

The use of muriatic acid in the manufacture of Polyether Block Amides (PEBAX) raises several environmental concerns that require careful assessment and mitigation strategies. The production process involves the handling and disposal of hazardous chemicals, which can potentially impact air quality, water resources, and soil composition if not managed properly.

One of the primary environmental risks associated with muriatic acid usage is the potential for acid vapor emissions. These emissions can contribute to air pollution and pose health risks to workers and nearby communities. To address this issue, manufacturers must implement robust air filtration systems and ensure proper ventilation in production facilities. Regular monitoring of air quality and the use of personal protective equipment for workers are essential measures to minimize exposure risks.

Water pollution is another significant concern in the PEBAX manufacturing process. The discharge of acidic wastewater can adversely affect aquatic ecosystems and water quality if not adequately treated. Implementing advanced wastewater treatment systems is crucial to neutralize the acidic effluents and remove any harmful contaminants before release into the environment. Additionally, closed-loop water recycling systems can help reduce overall water consumption and minimize the volume of wastewater generated.

Soil contamination is a potential risk if proper containment and handling procedures are not followed. Accidental spills or leaks of muriatic acid can lead to soil acidification, affecting plant growth and soil microorganisms. Manufacturers must establish comprehensive spill prevention and response protocols, including the use of containment barriers and neutralization agents to mitigate the impact of any accidental releases.

The transportation and storage of muriatic acid also present environmental risks. Strict adherence to safety regulations and the use of appropriate containment vessels are essential to prevent accidental releases during transport or storage. Implementing regular inspections and maintenance programs for storage facilities and transportation equipment can help minimize the likelihood of environmental incidents.

To reduce the overall environmental footprint of PEBAX production, manufacturers should explore alternative production methods that minimize or eliminate the use of muriatic acid. This may include investigating greener chemical processes or developing novel catalysts that can achieve similar results with less environmental impact. Additionally, implementing energy-efficient technologies and optimizing production processes can help reduce greenhouse gas emissions associated with PEBAX manufacturing.

Lifecycle assessment studies should be conducted to evaluate the environmental impact of PEBAX products from raw material extraction to end-of-life disposal. This holistic approach can identify opportunities for improvement throughout the product lifecycle and guide the development of more sustainable manufacturing practices.

One of the primary environmental risks associated with muriatic acid usage is the potential for acid vapor emissions. These emissions can contribute to air pollution and pose health risks to workers and nearby communities. To address this issue, manufacturers must implement robust air filtration systems and ensure proper ventilation in production facilities. Regular monitoring of air quality and the use of personal protective equipment for workers are essential measures to minimize exposure risks.

Water pollution is another significant concern in the PEBAX manufacturing process. The discharge of acidic wastewater can adversely affect aquatic ecosystems and water quality if not adequately treated. Implementing advanced wastewater treatment systems is crucial to neutralize the acidic effluents and remove any harmful contaminants before release into the environment. Additionally, closed-loop water recycling systems can help reduce overall water consumption and minimize the volume of wastewater generated.

Soil contamination is a potential risk if proper containment and handling procedures are not followed. Accidental spills or leaks of muriatic acid can lead to soil acidification, affecting plant growth and soil microorganisms. Manufacturers must establish comprehensive spill prevention and response protocols, including the use of containment barriers and neutralization agents to mitigate the impact of any accidental releases.

The transportation and storage of muriatic acid also present environmental risks. Strict adherence to safety regulations and the use of appropriate containment vessels are essential to prevent accidental releases during transport or storage. Implementing regular inspections and maintenance programs for storage facilities and transportation equipment can help minimize the likelihood of environmental incidents.

To reduce the overall environmental footprint of PEBAX production, manufacturers should explore alternative production methods that minimize or eliminate the use of muriatic acid. This may include investigating greener chemical processes or developing novel catalysts that can achieve similar results with less environmental impact. Additionally, implementing energy-efficient technologies and optimizing production processes can help reduce greenhouse gas emissions associated with PEBAX manufacturing.

Lifecycle assessment studies should be conducted to evaluate the environmental impact of PEBAX products from raw material extraction to end-of-life disposal. This holistic approach can identify opportunities for improvement throughout the product lifecycle and guide the development of more sustainable manufacturing practices.

Safety Protocols in Production

Safety protocols in the production of Polyether Block Amides (PEBAX) using muriatic acid are of paramount importance due to the hazardous nature of the chemicals involved. The manufacturing process requires strict adherence to safety guidelines to protect workers, equipment, and the environment.

Personal protective equipment (PPE) is a crucial component of safety protocols. Workers must wear appropriate chemical-resistant gloves, goggles, face shields, and protective clothing when handling muriatic acid. Respiratory protection may also be necessary, depending on the concentration and exposure levels. Regular training on proper PPE usage and maintenance is essential to ensure its effectiveness.

Proper ventilation systems are critical in areas where muriatic acid is used or stored. These systems should be designed to effectively remove acid vapors and maintain safe air quality levels. Regular monitoring of air quality and ventilation system performance is necessary to prevent the accumulation of harmful fumes.

Storage and handling procedures for muriatic acid must be carefully implemented. Acid-resistant containers should be used, and storage areas should be equipped with secondary containment systems to prevent spills from spreading. Clear labeling and segregation of incompatible chemicals are essential to prevent accidental mixing and potential reactions.

Emergency response plans must be in place and regularly updated. This includes the installation of emergency showers and eyewash stations in easily accessible locations throughout the production area. Workers should be trained in emergency procedures, including spill containment and neutralization techniques.

Regular safety audits and inspections are necessary to identify potential hazards and ensure compliance with safety protocols. This includes checking the integrity of equipment, verifying the proper functioning of safety systems, and reviewing documentation of safety procedures and incident reports.

Proper waste management and disposal procedures for muriatic acid and related chemicals must be established and followed. This may involve neutralization processes, proper containment, and adherence to local and national regulations regarding hazardous waste disposal.

Continuous education and training programs should be implemented to keep workers informed about the latest safety practices and potential hazards associated with muriatic acid use in PEBAX production. This includes regular safety meetings, updates on regulatory changes, and hands-on training sessions.

By implementing and strictly adhering to these comprehensive safety protocols, manufacturers can significantly reduce the risks associated with using muriatic acid in the production of Polyether Block Amides, ensuring a safer work environment and more sustainable production process.

Personal protective equipment (PPE) is a crucial component of safety protocols. Workers must wear appropriate chemical-resistant gloves, goggles, face shields, and protective clothing when handling muriatic acid. Respiratory protection may also be necessary, depending on the concentration and exposure levels. Regular training on proper PPE usage and maintenance is essential to ensure its effectiveness.

Proper ventilation systems are critical in areas where muriatic acid is used or stored. These systems should be designed to effectively remove acid vapors and maintain safe air quality levels. Regular monitoring of air quality and ventilation system performance is necessary to prevent the accumulation of harmful fumes.

Storage and handling procedures for muriatic acid must be carefully implemented. Acid-resistant containers should be used, and storage areas should be equipped with secondary containment systems to prevent spills from spreading. Clear labeling and segregation of incompatible chemicals are essential to prevent accidental mixing and potential reactions.

Emergency response plans must be in place and regularly updated. This includes the installation of emergency showers and eyewash stations in easily accessible locations throughout the production area. Workers should be trained in emergency procedures, including spill containment and neutralization techniques.

Regular safety audits and inspections are necessary to identify potential hazards and ensure compliance with safety protocols. This includes checking the integrity of equipment, verifying the proper functioning of safety systems, and reviewing documentation of safety procedures and incident reports.

Proper waste management and disposal procedures for muriatic acid and related chemicals must be established and followed. This may involve neutralization processes, proper containment, and adherence to local and national regulations regarding hazardous waste disposal.

Continuous education and training programs should be implemented to keep workers informed about the latest safety practices and potential hazards associated with muriatic acid use in PEBAX production. This includes regular safety meetings, updates on regulatory changes, and hands-on training sessions.

By implementing and strictly adhering to these comprehensive safety protocols, manufacturers can significantly reduce the risks associated with using muriatic acid in the production of Polyether Block Amides, ensuring a safer work environment and more sustainable production process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!