How Muriatic Acid is Used in the Manufacture of Polyimide (PI)

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PI Manufacturing Background and Objectives

Polyimide (PI) is a high-performance polymer known for its exceptional thermal stability, mechanical strength, and chemical resistance. The development of PI can be traced back to the 1950s when DuPont researchers first synthesized these remarkable materials. Since then, PI has become an indispensable component in various industries, including aerospace, electronics, and automotive.

The evolution of PI technology has been driven by the increasing demand for materials capable of withstanding extreme conditions. As electronic devices became more compact and powerful, the need for heat-resistant insulating materials grew exponentially. PI's ability to maintain its properties at high temperatures made it an ideal candidate for such applications.

In recent years, the focus of PI development has shifted towards enhancing its processability and expanding its application range. Researchers are exploring new synthesis methods and modifications to improve PI's solubility, reduce its curing temperature, and increase its flexibility without compromising its core properties.

The primary objective of using muriatic acid (hydrochloric acid) in PI manufacturing is to facilitate the synthesis process and improve the final product's characteristics. Muriatic acid plays a crucial role in the polymerization reaction, acting as a catalyst and helping to control the molecular weight of the resulting polymer.

One of the key goals in PI manufacturing is to achieve a balance between high-performance properties and ease of processing. Muriatic acid aids in this by promoting the formation of polyamic acid, an intermediate in PI synthesis. The controlled use of muriatic acid can lead to more consistent polymer chain lengths and improved molecular weight distribution, which directly impacts the final PI product's mechanical and thermal properties.

Another objective is to enhance the purity of the PI product. Muriatic acid assists in removing impurities and unwanted byproducts during the synthesis process, resulting in a higher-quality end product. This is particularly important for applications in the electronics industry, where even minute impurities can significantly affect performance.

Furthermore, the use of muriatic acid in PI manufacturing aims to optimize production efficiency and reduce costs. By carefully controlling the acid concentration and reaction conditions, manufacturers can achieve faster reaction rates and higher yields, leading to more economical production processes.

As environmental concerns gain prominence, there is also a growing emphasis on developing greener synthesis methods for PI. Research is underway to explore alternatives to traditional acid catalysts or to minimize the use of harsh chemicals like muriatic acid while maintaining the desired product quality and performance characteristics.

The evolution of PI technology has been driven by the increasing demand for materials capable of withstanding extreme conditions. As electronic devices became more compact and powerful, the need for heat-resistant insulating materials grew exponentially. PI's ability to maintain its properties at high temperatures made it an ideal candidate for such applications.

In recent years, the focus of PI development has shifted towards enhancing its processability and expanding its application range. Researchers are exploring new synthesis methods and modifications to improve PI's solubility, reduce its curing temperature, and increase its flexibility without compromising its core properties.

The primary objective of using muriatic acid (hydrochloric acid) in PI manufacturing is to facilitate the synthesis process and improve the final product's characteristics. Muriatic acid plays a crucial role in the polymerization reaction, acting as a catalyst and helping to control the molecular weight of the resulting polymer.

One of the key goals in PI manufacturing is to achieve a balance between high-performance properties and ease of processing. Muriatic acid aids in this by promoting the formation of polyamic acid, an intermediate in PI synthesis. The controlled use of muriatic acid can lead to more consistent polymer chain lengths and improved molecular weight distribution, which directly impacts the final PI product's mechanical and thermal properties.

Another objective is to enhance the purity of the PI product. Muriatic acid assists in removing impurities and unwanted byproducts during the synthesis process, resulting in a higher-quality end product. This is particularly important for applications in the electronics industry, where even minute impurities can significantly affect performance.

Furthermore, the use of muriatic acid in PI manufacturing aims to optimize production efficiency and reduce costs. By carefully controlling the acid concentration and reaction conditions, manufacturers can achieve faster reaction rates and higher yields, leading to more economical production processes.

As environmental concerns gain prominence, there is also a growing emphasis on developing greener synthesis methods for PI. Research is underway to explore alternatives to traditional acid catalysts or to minimize the use of harsh chemicals like muriatic acid while maintaining the desired product quality and performance characteristics.

Market Analysis for PI Products

The global market for polyimide (PI) products has been experiencing steady growth, driven by increasing demand across various industries. The aerospace and electronics sectors are the primary consumers of PI products, owing to the material's exceptional thermal stability, mechanical strength, and electrical insulation properties. In recent years, the automotive industry has also emerged as a significant market for PI, particularly in electric vehicle applications.

The Asia-Pacific region, led by China and Japan, dominates the PI market, accounting for a substantial share of global production and consumption. This is largely due to the concentration of electronics manufacturing in these countries. North America and Europe follow, with a focus on high-performance applications in aerospace and defense industries.

The PI market is segmented into several product types, including films, fibers, resins, and coatings. PI films hold the largest market share, finding extensive use in flexible printed circuits, wire and cable insulation, and display technologies. The demand for PI fibers is growing rapidly, particularly in aerospace and automotive applications, where their high strength-to-weight ratio is highly valued.

In terms of end-use industries, electronics and electrical applications continue to be the largest consumers of PI products. The increasing complexity of electronic devices and the trend towards miniaturization are driving the demand for high-performance insulating materials like PI. The aerospace industry remains a crucial market, with PI components used in aircraft engines, interiors, and structural parts.

The automotive sector is showing the fastest growth rate in PI consumption, primarily due to the expansion of the electric vehicle market. PI materials are used in battery components, motor insulation, and lightweight structural parts, contributing to improved vehicle efficiency and performance.

The global PI market is characterized by intense competition among a few major players and numerous smaller regional manufacturers. Key market participants are focusing on research and development to introduce innovative PI products with enhanced properties, such as improved heat resistance or lower dielectric constants. There is also a growing trend towards developing bio-based and sustainable PI materials to address environmental concerns.

Looking ahead, the PI market is expected to continue its growth trajectory, driven by technological advancements in end-use industries and the expansion of applications in emerging sectors such as 5G infrastructure and renewable energy. The increasing focus on lightweight materials in transportation and the growing demand for flexible electronics are likely to create new opportunities for PI products in the coming years.

The Asia-Pacific region, led by China and Japan, dominates the PI market, accounting for a substantial share of global production and consumption. This is largely due to the concentration of electronics manufacturing in these countries. North America and Europe follow, with a focus on high-performance applications in aerospace and defense industries.

The PI market is segmented into several product types, including films, fibers, resins, and coatings. PI films hold the largest market share, finding extensive use in flexible printed circuits, wire and cable insulation, and display technologies. The demand for PI fibers is growing rapidly, particularly in aerospace and automotive applications, where their high strength-to-weight ratio is highly valued.

In terms of end-use industries, electronics and electrical applications continue to be the largest consumers of PI products. The increasing complexity of electronic devices and the trend towards miniaturization are driving the demand for high-performance insulating materials like PI. The aerospace industry remains a crucial market, with PI components used in aircraft engines, interiors, and structural parts.

The automotive sector is showing the fastest growth rate in PI consumption, primarily due to the expansion of the electric vehicle market. PI materials are used in battery components, motor insulation, and lightweight structural parts, contributing to improved vehicle efficiency and performance.

The global PI market is characterized by intense competition among a few major players and numerous smaller regional manufacturers. Key market participants are focusing on research and development to introduce innovative PI products with enhanced properties, such as improved heat resistance or lower dielectric constants. There is also a growing trend towards developing bio-based and sustainable PI materials to address environmental concerns.

Looking ahead, the PI market is expected to continue its growth trajectory, driven by technological advancements in end-use industries and the expansion of applications in emerging sectors such as 5G infrastructure and renewable energy. The increasing focus on lightweight materials in transportation and the growing demand for flexible electronics are likely to create new opportunities for PI products in the coming years.

Muriatic Acid in PI Synthesis: Current Status and Challenges

The current status of muriatic acid usage in polyimide (PI) synthesis presents both significant advancements and notable challenges. Muriatic acid, also known as hydrochloric acid, plays a crucial role in the production of polyimide precursors, particularly in the synthesis of aromatic dianhydrides and diamines. Its strong acidic properties make it an effective catalyst and reagent in various stages of PI manufacturing.

In recent years, the industry has witnessed improvements in the efficiency of muriatic acid utilization during PI synthesis. Advanced reaction systems have been developed to optimize acid consumption and minimize waste generation. These systems often incorporate precise dosing mechanisms and closed-loop recycling processes, allowing for better control over acid concentration and reducing environmental impact.

However, several challenges persist in the use of muriatic acid for PI production. One major concern is the corrosive nature of the acid, which necessitates specialized equipment and handling procedures. This requirement increases production costs and poses potential safety risks to workers. Additionally, the disposal of acid waste remains a significant environmental challenge, requiring sophisticated treatment processes to neutralize and safely dispose of the byproducts.

Another ongoing issue is the variability in acid quality and concentration, which can affect the consistency and properties of the final PI product. Manufacturers must implement rigorous quality control measures to ensure the acid meets the required specifications for each production batch. This often involves additional testing and purification steps, adding complexity to the manufacturing process.

The industry is also grappling with the need to reduce the overall environmental footprint of PI production. While muriatic acid is an effective reagent, its production and use contribute to greenhouse gas emissions and potential water pollution. This has led to increased research into alternative catalysts and synthesis routes that could potentially reduce or eliminate the need for strong mineral acids like muriatic acid.

Furthermore, regulatory pressures are mounting, with stricter environmental and safety standards being implemented globally. Manufacturers are thus compelled to invest in advanced emission control systems and waste treatment facilities, which can significantly impact production costs and competitiveness.

Despite these challenges, muriatic acid remains a key component in PI synthesis due to its effectiveness and relatively low cost. The industry continues to explore innovative solutions to address the associated issues, including the development of less corrosive acid formulations, improved reactor designs for better acid management, and novel recycling technologies to minimize waste generation.

In recent years, the industry has witnessed improvements in the efficiency of muriatic acid utilization during PI synthesis. Advanced reaction systems have been developed to optimize acid consumption and minimize waste generation. These systems often incorporate precise dosing mechanisms and closed-loop recycling processes, allowing for better control over acid concentration and reducing environmental impact.

However, several challenges persist in the use of muriatic acid for PI production. One major concern is the corrosive nature of the acid, which necessitates specialized equipment and handling procedures. This requirement increases production costs and poses potential safety risks to workers. Additionally, the disposal of acid waste remains a significant environmental challenge, requiring sophisticated treatment processes to neutralize and safely dispose of the byproducts.

Another ongoing issue is the variability in acid quality and concentration, which can affect the consistency and properties of the final PI product. Manufacturers must implement rigorous quality control measures to ensure the acid meets the required specifications for each production batch. This often involves additional testing and purification steps, adding complexity to the manufacturing process.

The industry is also grappling with the need to reduce the overall environmental footprint of PI production. While muriatic acid is an effective reagent, its production and use contribute to greenhouse gas emissions and potential water pollution. This has led to increased research into alternative catalysts and synthesis routes that could potentially reduce or eliminate the need for strong mineral acids like muriatic acid.

Furthermore, regulatory pressures are mounting, with stricter environmental and safety standards being implemented globally. Manufacturers are thus compelled to invest in advanced emission control systems and waste treatment facilities, which can significantly impact production costs and competitiveness.

Despite these challenges, muriatic acid remains a key component in PI synthesis due to its effectiveness and relatively low cost. The industry continues to explore innovative solutions to address the associated issues, including the development of less corrosive acid formulations, improved reactor designs for better acid management, and novel recycling technologies to minimize waste generation.

Current Muriatic Acid-based PI Synthesis Methods

01 Chemical properties and applications of muriatic acid

Muriatic acid, also known as hydrochloric acid, is a strong mineral acid with various industrial and household applications. It is commonly used for cleaning, pH adjustment, and as a reagent in chemical processes. Its corrosive nature makes it effective for removing rust, scale, and other deposits.- Chemical properties and applications: Muriatic acid, also known as hydrochloric acid, is a strong mineral acid with various industrial and commercial applications. It is commonly used in metal cleaning, pH adjustment, and as a chemical intermediate in manufacturing processes. Its corrosive nature and ability to dissolve certain metals make it useful in surface preparation and etching.

- Use in construction and building materials: Muriatic acid is utilized in the construction industry for cleaning masonry, concrete, and other building materials. It can remove efflorescence, stains, and mineral deposits from surfaces. Additionally, it is used in the production of certain construction materials and in the treatment of swimming pools for pH control.

- Environmental and safety considerations: Due to its corrosive nature, proper handling and disposal of muriatic acid are crucial. Safety measures include using appropriate personal protective equipment and following specific storage and transportation guidelines. Environmental concerns related to its use and disposal are addressed through various regulations and treatment processes.

- Industrial processes and manufacturing: Muriatic acid plays a significant role in various industrial processes, including metal processing, oil well acidizing, and food production. It is used in the manufacture of chemicals, pharmaceuticals, and in the treatment of water and wastewater. The acid's ability to control pH and remove impurities makes it valuable in many manufacturing applications.

- Innovations in production and purification: Advancements in the production and purification of muriatic acid have led to improved quality and efficiency. These innovations include novel synthesis methods, enhanced purification techniques, and the development of specialized equipment for handling and processing the acid. Such improvements have expanded its applications and increased its effectiveness in various industries.

02 Use in metal treatment and surface preparation

Muriatic acid is widely used in metal treatment processes, including pickling, etching, and surface preparation. It helps remove oxides, scale, and other impurities from metal surfaces, improving their quality and appearance. This acid is particularly useful in the steel industry and for preparing surfaces before coating or painting.Expand Specific Solutions03 Environmental and safety considerations

Handling and disposal of muriatic acid require careful attention to environmental and safety regulations. Proper containment, neutralization, and treatment methods are essential to prevent environmental contamination and ensure worker safety. Specialized equipment and procedures are often necessary when working with this corrosive substance.Expand Specific Solutions04 Production and purification methods

Various methods exist for producing and purifying muriatic acid. These include the reaction of sodium chloride with sulfuric acid, as well as the direct synthesis from hydrogen and chlorine. Purification techniques may involve distillation, adsorption, or membrane separation to remove impurities and achieve the desired concentration.Expand Specific Solutions05 Specialized applications in construction and manufacturing

Muriatic acid finds specialized applications in construction and manufacturing industries. It is used for cleaning masonry, concrete, and tiles, as well as in the production of certain chemicals and pharmaceuticals. In the semiconductor industry, high-purity muriatic acid is utilized for cleaning and etching silicon wafers.Expand Specific Solutions

Key Players in PI and Chemical Industry

The competitive landscape for the use of muriatic acid in polyimide (PI) manufacturing is characterized by a mature industry with established players and ongoing research efforts. The market size is substantial, driven by the growing demand for PI in various high-tech applications. Technologically, the process is well-developed, with companies like PI Advanced Materials, Solvay Specialty Polymers, and Kolon Industries leading the field. However, continuous innovation is evident, with research institutions such as Sichuan University and Southeast University contributing to advancements. The industry is in a phase of incremental improvements rather than disruptive changes, focusing on enhancing PI properties and production efficiency. Companies are competing on product quality, cost-effectiveness, and specialized applications to maintain their market positions.

PI Advanced Materials Co., Ltd.

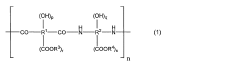

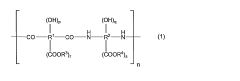

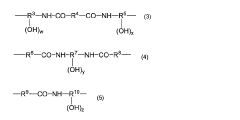

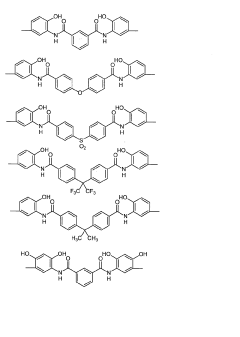

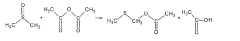

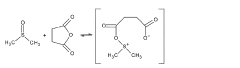

Technical Solution: PI Advanced Materials Co., Ltd. utilizes muriatic acid (HCl) in their innovative polyimide (PI) manufacturing process, focusing on producing high-performance PI films for various industrial applications. Their method involves a controlled two-step process: first, synthesizing polyamic acid through the reaction of aromatic dianhydride and aromatic diamine, then using HCl as a chemical imidization catalyst to convert polyamic acid to polyimide[10]. The company has developed a proprietary technique that employs HCl to fine-tune the imidization kinetics, resulting in PI films with enhanced thermal stability and mechanical properties[11]. This process allows PI Advanced Materials to produce PI films with a wide range of thicknesses (from 7.5 to 125 microns) and tailor-made properties for specific applications, such as flexible printed circuits and aerospace components[12].

Strengths: Ability to produce PI films with customized properties for diverse applications. Weaknesses: The use of HCl may require specialized handling and waste treatment procedures.

Solvay SA

Technical Solution: Solvay SA employs a two-step polymerization process for polyimide (PI) production using muriatic acid (HCl). In the first step, aromatic dianhydride reacts with aromatic diamine in a polar aprotic solvent to form polyamic acid. HCl is then used as a dehydrating agent in the second step, facilitating the cyclization of polyamic acid to polyimide[1][3]. This process, known as chemical imidization, allows for better control over the molecular weight and properties of the final PI product. Solvay has optimized this method to achieve high-temperature resistance (up to 400°C) and excellent mechanical properties in their PI materials[2].

Strengths: Precise control over PI properties, high-temperature resistance, and excellent mechanical characteristics. Weaknesses: The use of corrosive HCl requires specialized equipment and safety measures, potentially increasing production costs.

Innovations in Muriatic Acid Usage for PI Production

Production method of polyimide precursor

PatentInactiveJP2019183007A

Innovation

- Controlling water content in the resin solution to 10-10,000 ppm after polymerization to improve stability of film thickness.

- Using a dehydrating agent (molecular sieve, silica gel, or activated alumina) to remove excess water from the reaction solvent.

- Producing a polyimide precursor with a hydroxy group-containing structural unit in the side chain as the main component.

Manufacturing method of polyamide acid

PatentInactiveJP2017008276A

Innovation

- A method involving the synthesis of polyamic acid using a mixed solvent of dimethyl sulfoxide and a cyclic ester compound, such as propylene carbonate or γ-butyrolactone, to produce a polyamic acid solution with a narrow molecular weight distribution without requiring special conditions and using a solvent that poses no safety concerns.

Environmental Impact of Muriatic Acid in PI Manufacturing

The use of muriatic acid (hydrochloric acid) in the manufacture of polyimide (PI) has significant environmental implications that require careful consideration and management. The production process involves the use of this strong acid, which can pose risks to both the environment and human health if not properly handled and disposed of.

One of the primary environmental concerns is the potential for acid runoff and contamination of water sources. Muriatic acid, if released into aquatic ecosystems, can dramatically alter pH levels, leading to detrimental effects on aquatic life and biodiversity. This acidification can disrupt the delicate balance of freshwater and marine environments, potentially causing long-term ecological damage.

Air pollution is another critical issue associated with the use of muriatic acid in PI manufacturing. The volatile nature of the acid can result in the release of acidic fumes and vapors into the atmosphere. These emissions can contribute to the formation of acid rain, which has far-reaching consequences for both natural ecosystems and man-made structures.

The production process also generates hazardous waste that requires specialized disposal methods. Improper disposal of acid-containing waste can lead to soil contamination, affecting plant life and potentially entering the food chain. This highlights the importance of implementing robust waste management protocols in PI manufacturing facilities.

Worker safety is an additional concern, as exposure to muriatic acid can cause severe health issues. While not directly an environmental impact, the need for protective equipment and safety measures can indirectly affect resource consumption and waste generation.

To mitigate these environmental risks, many PI manufacturers are adopting cleaner production techniques. These include closed-loop systems that minimize acid waste, advanced air filtration systems to reduce emissions, and the implementation of strict handling and storage protocols to prevent spills and leaks.

Some companies are exploring alternative production methods that reduce or eliminate the use of muriatic acid. This includes the development of less hazardous precursors and the adoption of greener chemistry principles in PI synthesis. These innovations aim to maintain the high performance of PI materials while significantly reducing the environmental footprint of their production.

Regulatory bodies worldwide are increasingly focusing on the environmental impact of chemical manufacturing processes. This has led to stricter regulations governing the use and disposal of acids like muriatic acid in industrial applications, including PI production. Manufacturers are now required to implement comprehensive environmental management systems and regularly report on their emissions and waste handling practices.

One of the primary environmental concerns is the potential for acid runoff and contamination of water sources. Muriatic acid, if released into aquatic ecosystems, can dramatically alter pH levels, leading to detrimental effects on aquatic life and biodiversity. This acidification can disrupt the delicate balance of freshwater and marine environments, potentially causing long-term ecological damage.

Air pollution is another critical issue associated with the use of muriatic acid in PI manufacturing. The volatile nature of the acid can result in the release of acidic fumes and vapors into the atmosphere. These emissions can contribute to the formation of acid rain, which has far-reaching consequences for both natural ecosystems and man-made structures.

The production process also generates hazardous waste that requires specialized disposal methods. Improper disposal of acid-containing waste can lead to soil contamination, affecting plant life and potentially entering the food chain. This highlights the importance of implementing robust waste management protocols in PI manufacturing facilities.

Worker safety is an additional concern, as exposure to muriatic acid can cause severe health issues. While not directly an environmental impact, the need for protective equipment and safety measures can indirectly affect resource consumption and waste generation.

To mitigate these environmental risks, many PI manufacturers are adopting cleaner production techniques. These include closed-loop systems that minimize acid waste, advanced air filtration systems to reduce emissions, and the implementation of strict handling and storage protocols to prevent spills and leaks.

Some companies are exploring alternative production methods that reduce or eliminate the use of muriatic acid. This includes the development of less hazardous precursors and the adoption of greener chemistry principles in PI synthesis. These innovations aim to maintain the high performance of PI materials while significantly reducing the environmental footprint of their production.

Regulatory bodies worldwide are increasingly focusing on the environmental impact of chemical manufacturing processes. This has led to stricter regulations governing the use and disposal of acids like muriatic acid in industrial applications, including PI production. Manufacturers are now required to implement comprehensive environmental management systems and regularly report on their emissions and waste handling practices.

Safety Protocols in PI Chemical Processes

Safety protocols in the manufacture of polyimide (PI) using muriatic acid are of paramount importance due to the hazardous nature of the chemicals involved. The production process requires stringent safety measures to protect workers, equipment, and the environment. These protocols encompass a wide range of practices, from personal protective equipment (PPE) to emergency response procedures.

Proper handling of muriatic acid, also known as hydrochloric acid, is crucial. Workers must wear appropriate PPE, including chemical-resistant gloves, goggles, face shields, and protective clothing. Respiratory protection may be necessary depending on the concentration and exposure levels. Regular training on the proper use and maintenance of PPE is essential to ensure its effectiveness.

Ventilation systems play a critical role in maintaining a safe working environment. Adequate local exhaust ventilation must be installed to remove acid vapors and other potentially harmful fumes generated during the PI manufacturing process. Regular monitoring of air quality and ventilation system performance is necessary to maintain a safe atmosphere.

Storage and transportation of muriatic acid require specialized containers and handling procedures. Acid-resistant storage tanks, pipelines, and transfer equipment must be used to prevent leaks and spills. Secondary containment systems should be in place to capture any accidental releases. Clear labeling and proper segregation of chemicals are essential to prevent inadvertent mixing of incompatible substances.

Emergency response protocols must be well-established and regularly practiced. This includes procedures for spill containment, neutralization, and disposal. Eyewash stations and safety showers should be readily accessible in all areas where acid handling occurs. A comprehensive emergency communication system must be in place to alert workers and initiate evacuation procedures if necessary.

Regular safety audits and inspections are crucial to maintain compliance with safety protocols. These should include checks on equipment integrity, PPE condition, and adherence to handling procedures. Any identified issues must be promptly addressed and corrective actions implemented.

Employee training is a cornerstone of safety in PI manufacturing. Workers must receive comprehensive instruction on chemical hazards, proper handling techniques, emergency procedures, and the use of safety equipment. Refresher courses should be conducted periodically to reinforce safety practices and introduce any updates to protocols.

Environmental considerations are also an integral part of safety protocols. Proper waste management procedures must be in place to handle and dispose of acid waste and other chemical byproducts. This may include neutralization processes, wastewater treatment, and compliance with local environmental regulations.

Proper handling of muriatic acid, also known as hydrochloric acid, is crucial. Workers must wear appropriate PPE, including chemical-resistant gloves, goggles, face shields, and protective clothing. Respiratory protection may be necessary depending on the concentration and exposure levels. Regular training on the proper use and maintenance of PPE is essential to ensure its effectiveness.

Ventilation systems play a critical role in maintaining a safe working environment. Adequate local exhaust ventilation must be installed to remove acid vapors and other potentially harmful fumes generated during the PI manufacturing process. Regular monitoring of air quality and ventilation system performance is necessary to maintain a safe atmosphere.

Storage and transportation of muriatic acid require specialized containers and handling procedures. Acid-resistant storage tanks, pipelines, and transfer equipment must be used to prevent leaks and spills. Secondary containment systems should be in place to capture any accidental releases. Clear labeling and proper segregation of chemicals are essential to prevent inadvertent mixing of incompatible substances.

Emergency response protocols must be well-established and regularly practiced. This includes procedures for spill containment, neutralization, and disposal. Eyewash stations and safety showers should be readily accessible in all areas where acid handling occurs. A comprehensive emergency communication system must be in place to alert workers and initiate evacuation procedures if necessary.

Regular safety audits and inspections are crucial to maintain compliance with safety protocols. These should include checks on equipment integrity, PPE condition, and adherence to handling procedures. Any identified issues must be promptly addressed and corrective actions implemented.

Employee training is a cornerstone of safety in PI manufacturing. Workers must receive comprehensive instruction on chemical hazards, proper handling techniques, emergency procedures, and the use of safety equipment. Refresher courses should be conducted periodically to reinforce safety practices and introduce any updates to protocols.

Environmental considerations are also an integral part of safety protocols. Proper waste management procedures must be in place to handle and dispose of acid waste and other chemical byproducts. This may include neutralization processes, wastewater treatment, and compliance with local environmental regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!