How Muriatic Acid is Used in the Manufacture of Polysulfone

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysulfone Manufacturing Background and Objectives

Polysulfone, a high-performance thermoplastic, has gained significant attention in various industries due to its exceptional properties. The development of polysulfone can be traced back to the 1960s when it was first synthesized by Union Carbide Corporation. Since then, the material has undergone continuous improvements and refinements to meet the evolving demands of modern applications.

The primary objective in polysulfone manufacturing is to produce a polymer with superior mechanical strength, thermal stability, and chemical resistance. These properties make polysulfone an ideal candidate for use in demanding environments, such as medical devices, automotive components, and aerospace applications. The manufacturing process aims to achieve consistent quality while optimizing production efficiency and minimizing environmental impact.

One of the key components in polysulfone production is muriatic acid, also known as hydrochloric acid. This strong mineral acid plays a crucial role in the synthesis and purification stages of polysulfone manufacturing. The use of muriatic acid contributes to the formation of the polymer's unique molecular structure, which is responsible for its exceptional properties.

The evolution of polysulfone manufacturing techniques has been driven by advancements in polymer science and chemical engineering. Early production methods faced challenges in achieving uniform molecular weight distribution and eliminating impurities. However, ongoing research and development efforts have led to improved synthesis routes and purification techniques, resulting in higher-quality polysulfone materials.

In recent years, there has been a growing focus on sustainable manufacturing practices in the polymer industry. This trend has influenced polysulfone production, with manufacturers exploring ways to reduce energy consumption, minimize waste generation, and incorporate renewable resources into the manufacturing process. The use of muriatic acid in polysulfone production is also being optimized to enhance efficiency and reduce environmental impact.

The global demand for high-performance polymers like polysulfone is expected to continue growing, driven by increasing applications in sectors such as healthcare, water treatment, and electronics. This market trend has spurred further research into advanced manufacturing techniques and novel formulations to expand the material's capabilities and address emerging technological needs.

As the polysulfone industry moves forward, the primary goals are to enhance production efficiency, improve material properties, and develop more sustainable manufacturing processes. The role of muriatic acid in polysulfone production remains critical, and ongoing research aims to optimize its usage while exploring alternative synthesis routes that may offer additional benefits in terms of performance and environmental sustainability.

The primary objective in polysulfone manufacturing is to produce a polymer with superior mechanical strength, thermal stability, and chemical resistance. These properties make polysulfone an ideal candidate for use in demanding environments, such as medical devices, automotive components, and aerospace applications. The manufacturing process aims to achieve consistent quality while optimizing production efficiency and minimizing environmental impact.

One of the key components in polysulfone production is muriatic acid, also known as hydrochloric acid. This strong mineral acid plays a crucial role in the synthesis and purification stages of polysulfone manufacturing. The use of muriatic acid contributes to the formation of the polymer's unique molecular structure, which is responsible for its exceptional properties.

The evolution of polysulfone manufacturing techniques has been driven by advancements in polymer science and chemical engineering. Early production methods faced challenges in achieving uniform molecular weight distribution and eliminating impurities. However, ongoing research and development efforts have led to improved synthesis routes and purification techniques, resulting in higher-quality polysulfone materials.

In recent years, there has been a growing focus on sustainable manufacturing practices in the polymer industry. This trend has influenced polysulfone production, with manufacturers exploring ways to reduce energy consumption, minimize waste generation, and incorporate renewable resources into the manufacturing process. The use of muriatic acid in polysulfone production is also being optimized to enhance efficiency and reduce environmental impact.

The global demand for high-performance polymers like polysulfone is expected to continue growing, driven by increasing applications in sectors such as healthcare, water treatment, and electronics. This market trend has spurred further research into advanced manufacturing techniques and novel formulations to expand the material's capabilities and address emerging technological needs.

As the polysulfone industry moves forward, the primary goals are to enhance production efficiency, improve material properties, and develop more sustainable manufacturing processes. The role of muriatic acid in polysulfone production remains critical, and ongoing research aims to optimize its usage while exploring alternative synthesis routes that may offer additional benefits in terms of performance and environmental sustainability.

Market Analysis for Polysulfone Products

The polysulfone market has shown significant growth in recent years, driven by increasing demand across various industries. Polysulfone, a high-performance thermoplastic, offers exceptional thermal stability, chemical resistance, and mechanical strength, making it an attractive material for numerous applications.

In the healthcare sector, polysulfone has gained traction due to its biocompatibility and ability to withstand sterilization processes. The material is widely used in medical devices, surgical instruments, and dialysis membranes. With the global healthcare industry expanding, particularly in emerging economies, the demand for polysulfone in this sector is expected to continue its upward trajectory.

The aerospace and automotive industries have also contributed to the growth of the polysulfone market. The material's lightweight properties, combined with its high strength-to-weight ratio, make it ideal for replacing metal components in aircraft and vehicles. As manufacturers strive to improve fuel efficiency and reduce emissions, the adoption of polysulfone in these industries is likely to increase.

In the electronics sector, polysulfone's excellent electrical insulation properties and dimensional stability have led to its use in various components, including connectors, circuit boards, and housings for electronic devices. The rapid growth of the electronics industry, particularly in Asia-Pacific regions, has further boosted the demand for polysulfone.

The water treatment industry represents another significant market for polysulfone products. The material's resistance to chlorine and other chemicals makes it suitable for use in filtration membranes and water purification systems. As global water scarcity concerns grow and regulations on water quality become more stringent, the demand for polysulfone in this sector is expected to rise.

Geographically, North America and Europe have been the traditional strongholds for polysulfone consumption, primarily due to their well-established healthcare and aerospace industries. However, the Asia-Pacific region is emerging as a key growth market, driven by rapid industrialization, increasing healthcare expenditure, and growing automotive production in countries like China and India.

Despite the positive market outlook, challenges such as high production costs and competition from alternative materials may impact the growth of the polysulfone market. Manufacturers are focusing on research and development to improve production efficiency and expand the material's applications, which could help mitigate these challenges and drive further market growth.

In the healthcare sector, polysulfone has gained traction due to its biocompatibility and ability to withstand sterilization processes. The material is widely used in medical devices, surgical instruments, and dialysis membranes. With the global healthcare industry expanding, particularly in emerging economies, the demand for polysulfone in this sector is expected to continue its upward trajectory.

The aerospace and automotive industries have also contributed to the growth of the polysulfone market. The material's lightweight properties, combined with its high strength-to-weight ratio, make it ideal for replacing metal components in aircraft and vehicles. As manufacturers strive to improve fuel efficiency and reduce emissions, the adoption of polysulfone in these industries is likely to increase.

In the electronics sector, polysulfone's excellent electrical insulation properties and dimensional stability have led to its use in various components, including connectors, circuit boards, and housings for electronic devices. The rapid growth of the electronics industry, particularly in Asia-Pacific regions, has further boosted the demand for polysulfone.

The water treatment industry represents another significant market for polysulfone products. The material's resistance to chlorine and other chemicals makes it suitable for use in filtration membranes and water purification systems. As global water scarcity concerns grow and regulations on water quality become more stringent, the demand for polysulfone in this sector is expected to rise.

Geographically, North America and Europe have been the traditional strongholds for polysulfone consumption, primarily due to their well-established healthcare and aerospace industries. However, the Asia-Pacific region is emerging as a key growth market, driven by rapid industrialization, increasing healthcare expenditure, and growing automotive production in countries like China and India.

Despite the positive market outlook, challenges such as high production costs and competition from alternative materials may impact the growth of the polysulfone market. Manufacturers are focusing on research and development to improve production efficiency and expand the material's applications, which could help mitigate these challenges and drive further market growth.

Current Muriatic Acid Usage in Polysulfone Production

Muriatic acid, also known as hydrochloric acid, plays a crucial role in the production of polysulfone, a high-performance thermoplastic. The current usage of muriatic acid in polysulfone manufacturing primarily revolves around its application as a catalyst and reactant in the polymerization process.

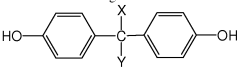

In the initial stages of polysulfone production, muriatic acid is used to catalyze the condensation reaction between bisphenol A and 4,4'-dichlorodiphenyl sulfone. This reaction is fundamental to the formation of the polymer backbone. The acid acts as a proton donor, facilitating the nucleophilic aromatic substitution that occurs during polymerization.

The concentration of muriatic acid used in this process is typically maintained between 35% and 37%. This specific range ensures optimal reactivity while minimizing potential side reactions or degradation of the forming polymer chains. The acid is carefully metered into the reaction vessel under controlled conditions to maintain the desired pH level throughout the polymerization process.

Temperature control is critical when using muriatic acid in polysulfone production. The reaction is typically carried out at temperatures ranging from 150°C to 180°C. At these elevated temperatures, the acid catalyzes the polymerization more efficiently, but care must be taken to prevent excessive degradation of the polymer or unwanted side reactions.

Another important aspect of muriatic acid usage in polysulfone manufacturing is its role in end-group control. By adjusting the acid concentration and reaction conditions, manufacturers can influence the molecular weight distribution and end-group functionality of the resulting polymer. This level of control is essential for tailoring the properties of the final polysulfone product to meet specific application requirements.

Post-polymerization, muriatic acid is also utilized in the purification process of polysulfone. It aids in removing residual monomers and oligomers, thereby improving the purity and performance characteristics of the final product. This purification step typically involves washing the polymer with dilute acid solutions followed by thorough rinsing to neutralize any remaining acid.

In recent years, there has been a focus on optimizing the use of muriatic acid in polysulfone production to enhance efficiency and reduce environmental impact. This includes developing more precise dosing systems, implementing closed-loop acid recovery processes, and exploring alternative catalysts that may offer similar performance with reduced environmental concerns.

In the initial stages of polysulfone production, muriatic acid is used to catalyze the condensation reaction between bisphenol A and 4,4'-dichlorodiphenyl sulfone. This reaction is fundamental to the formation of the polymer backbone. The acid acts as a proton donor, facilitating the nucleophilic aromatic substitution that occurs during polymerization.

The concentration of muriatic acid used in this process is typically maintained between 35% and 37%. This specific range ensures optimal reactivity while minimizing potential side reactions or degradation of the forming polymer chains. The acid is carefully metered into the reaction vessel under controlled conditions to maintain the desired pH level throughout the polymerization process.

Temperature control is critical when using muriatic acid in polysulfone production. The reaction is typically carried out at temperatures ranging from 150°C to 180°C. At these elevated temperatures, the acid catalyzes the polymerization more efficiently, but care must be taken to prevent excessive degradation of the polymer or unwanted side reactions.

Another important aspect of muriatic acid usage in polysulfone manufacturing is its role in end-group control. By adjusting the acid concentration and reaction conditions, manufacturers can influence the molecular weight distribution and end-group functionality of the resulting polymer. This level of control is essential for tailoring the properties of the final polysulfone product to meet specific application requirements.

Post-polymerization, muriatic acid is also utilized in the purification process of polysulfone. It aids in removing residual monomers and oligomers, thereby improving the purity and performance characteristics of the final product. This purification step typically involves washing the polymer with dilute acid solutions followed by thorough rinsing to neutralize any remaining acid.

In recent years, there has been a focus on optimizing the use of muriatic acid in polysulfone production to enhance efficiency and reduce environmental impact. This includes developing more precise dosing systems, implementing closed-loop acid recovery processes, and exploring alternative catalysts that may offer similar performance with reduced environmental concerns.

Muriatic Acid-Based Polysulfone Production Methods

01 Production and purification of muriatic acid

Muriatic acid, also known as hydrochloric acid, can be produced and purified through various industrial processes. These methods often involve the reaction of chlorine with hydrogen or the treatment of salt (sodium chloride) with sulfuric acid. Purification techniques may include distillation or membrane separation to remove impurities and achieve desired concentrations.- Production and purification of muriatic acid: Muriatic acid, also known as hydrochloric acid, can be produced and purified through various industrial processes. These methods often involve the reaction of chlorine with hydrogen or the treatment of chloride salts with sulfuric acid. Purification techniques may include distillation or membrane separation to remove impurities and achieve desired concentrations.

- Applications in metal treatment and surface cleaning: Muriatic acid is widely used in metal treatment processes, such as pickling, etching, and surface cleaning. It effectively removes rust, scale, and other contaminants from metal surfaces, preparing them for further processing or coating. The acid's strong reactivity makes it suitable for various industrial cleaning applications.

- Use in water treatment and pH adjustment: Muriatic acid plays a crucial role in water treatment processes, particularly in pH adjustment. It is used to neutralize alkaline water, control scale formation in cooling systems, and maintain optimal pH levels in swimming pools. The acid's ability to effectively lower pH makes it valuable in various water treatment applications.

- Safety measures and handling precautions: Due to its corrosive nature, proper safety measures and handling precautions are essential when working with muriatic acid. This includes using appropriate personal protective equipment, ensuring proper ventilation, and following specific storage and transportation guidelines. Safety protocols often involve neutralization procedures and spill containment measures.

- Environmental considerations and waste management: The use and disposal of muriatic acid require careful consideration of environmental impacts. Proper waste management techniques, such as neutralization and treatment before disposal, are necessary to minimize environmental harm. Recycling and recovery methods may be employed to reduce waste and improve sustainability in industrial processes involving muriatic acid.

02 Applications in metal treatment and surface cleaning

Muriatic acid is widely used in metal treatment processes, such as pickling, etching, and surface cleaning. It effectively removes rust, scale, and other contaminants from metal surfaces, preparing them for further processing or coating. The acid's strong reactivity makes it suitable for various industrial cleaning applications.Expand Specific Solutions03 Use in construction and building materials

In the construction industry, muriatic acid is utilized for cleaning masonry, concrete, and other building materials. It can remove efflorescence, mortar residues, and stains from surfaces. Additionally, it is used in the production of certain construction materials and in the treatment of swimming pool water to maintain proper pH levels.Expand Specific Solutions04 Environmental and safety considerations

Handling and disposal of muriatic acid require careful consideration of environmental and safety factors. Proper storage, transportation, and use of protective equipment are essential to prevent accidents and minimize environmental impact. Neutralization techniques and specialized disposal methods are often employed to manage waste acid safely.Expand Specific Solutions05 Alternative applications and formulations

Beyond its traditional uses, muriatic acid finds applications in various industries. It can be used in the production of pharmaceuticals, food processing, and water treatment. Modified formulations or combinations with other chemicals may enhance its effectiveness or create specialized products for specific applications.Expand Specific Solutions

Key Players in Polysulfone and Chemical Industries

The market for polysulfone manufacturing using muriatic acid is in a mature stage, with established players and well-defined processes. The global market size for polysulfone is estimated to be in the range of $1-2 billion, with steady growth projected. Technologically, the process is well-developed, with companies like BASF Corp., Solvay Advanced Polymers LLC, and Sumitomo Chemical Co., Ltd. leading the way in innovation and production. These firms have extensive experience in polymer chemistry and industrial-scale manufacturing, giving them a competitive edge. However, emerging players such as Kingfa Sci. & Tech. Co., Ltd. and Wanhua Chemical Group Co., Ltd. are also making strides in this field, potentially disrupting the market with new formulations or more efficient production methods.

BASF Corp.

Technical Solution: BASF Corp. has developed an innovative process for manufacturing polysulfone using muriatic acid (hydrochloric acid) as a key reagent. Their method involves the condensation reaction between bisphenol A and 4,4'-dichlorodiphenyl sulfone in the presence of potassium carbonate and muriatic acid[1]. The muriatic acid plays a crucial role in maintaining the pH balance and promoting the polymerization reaction. BASF's process incorporates a unique solvent system that enhances the solubility of reactants and improves the molecular weight distribution of the final polymer[2]. Additionally, they have implemented a continuous flow reactor design that allows for better control of reaction conditions and increased production efficiency[3].

Strengths: Improved reaction control, enhanced polymer properties, and increased production efficiency. Weaknesses: Potential corrosion issues due to muriatic acid use, requiring specialized equipment and safety measures.

Sumitomo Chemical Co., Ltd.

Technical Solution: Sumitomo Chemical Co., Ltd. has developed an innovative approach to polysulfone manufacture using muriatic acid as both a reactant and a catalyst. Their process involves a one-pot synthesis method where muriatic acid is used to generate the reactive intermediates of bisphenol A and 4,4'-dichlorodiphenyl sulfone in situ[7]. This approach reduces the number of steps in the manufacturing process and improves overall efficiency. Sumitomo's method also incorporates a unique phase-transfer catalyst system that enhances the reaction rate and allows for milder reaction conditions[8]. Additionally, they have implemented a sophisticated acid recovery system that enables the reuse of muriatic acid, significantly reducing raw material costs and environmental impact[9].

Strengths: Simplified manufacturing process, improved reaction efficiency, and reduced environmental impact. Weaknesses: Potential challenges in controlling the reaction due to the dual role of muriatic acid, which may affect product consistency.

Innovations in Muriatic Acid Application for Polysulfone

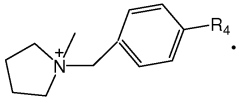

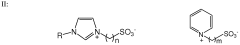

Method for preparing polysulfone

PatentActiveJP2014530266A

Innovation

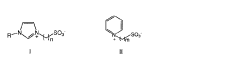

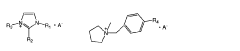

- A method using mixed ionic liquids as solvents for the preparation of polysulfones, involving a one-pot two-step process that includes reacting bisphenol monomers with salt-forming agents in the presence of mixed ionic liquids to form bisphenolates, followed by condensation polymerization, which significantly reduces reaction time and increases molecular weight.

Process for preparing polysulfone

PatentWO2013041062A1

Innovation

- A process using a composite ionic liquid as the solvent for reacting bisphenol monomers with a salt forming agent to form bisphenolate, followed by polycondensation with 4,4'-dihalodiphenyl sulfone, significantly shortening reaction times and improving molecular weight.

Environmental Impact of Muriatic Acid in Manufacturing

The use of muriatic acid (hydrochloric acid) in the manufacture of polysulfone has significant environmental implications that require careful consideration and management. The production process involves the use of this strong acid, which can pose risks to both the environment and human health if not properly handled and disposed of.

One of the primary environmental concerns is the potential for acid runoff and contamination of water sources. Muriatic acid, if released into aquatic ecosystems, can drastically alter pH levels, leading to harmful effects on aquatic life and biodiversity. This acidification can disrupt entire food chains and cause long-term ecological damage. To mitigate this risk, manufacturing facilities must implement robust containment systems and wastewater treatment processes to neutralize and safely dispose of acid-containing effluents.

Air pollution is another significant environmental impact associated with the use of muriatic acid in polysulfone production. The volatile nature of the acid can lead to the release of hydrogen chloride gas, which contributes to air quality degradation and can cause respiratory issues in both humans and animals. Proper ventilation systems and air scrubbers are essential to minimize these emissions and protect the surrounding environment and communities.

The transportation and storage of muriatic acid also present environmental risks. Accidental spills during transport or leaks from storage tanks can result in soil contamination and groundwater pollution. This necessitates stringent safety protocols, including proper containment measures, regular inspections, and emergency response plans to quickly address any potential leaks or spills.

Furthermore, the production of muriatic acid itself has upstream environmental impacts. The chlor-alkali process, commonly used to manufacture hydrochloric acid, consumes significant amounts of energy and can result in mercury emissions if older production methods are employed. This underscores the importance of considering the entire life cycle of the acid when assessing its environmental footprint in polysulfone manufacturing.

To address these environmental challenges, manufacturers are increasingly adopting cleaner production techniques and exploring alternative processes that reduce or eliminate the use of muriatic acid. This includes the development of less hazardous catalysts and the implementation of closed-loop systems that minimize waste and emissions. Additionally, some companies are investing in green chemistry initiatives to find more environmentally friendly alternatives to traditional acid-based processes in polymer production.

Regulatory compliance plays a crucial role in managing the environmental impact of muriatic acid use. Stringent environmental regulations govern the handling, storage, and disposal of hazardous chemicals, including muriatic acid. Manufacturers must adhere to these regulations, which often require comprehensive environmental management systems, regular monitoring, and reporting of emissions and waste.

One of the primary environmental concerns is the potential for acid runoff and contamination of water sources. Muriatic acid, if released into aquatic ecosystems, can drastically alter pH levels, leading to harmful effects on aquatic life and biodiversity. This acidification can disrupt entire food chains and cause long-term ecological damage. To mitigate this risk, manufacturing facilities must implement robust containment systems and wastewater treatment processes to neutralize and safely dispose of acid-containing effluents.

Air pollution is another significant environmental impact associated with the use of muriatic acid in polysulfone production. The volatile nature of the acid can lead to the release of hydrogen chloride gas, which contributes to air quality degradation and can cause respiratory issues in both humans and animals. Proper ventilation systems and air scrubbers are essential to minimize these emissions and protect the surrounding environment and communities.

The transportation and storage of muriatic acid also present environmental risks. Accidental spills during transport or leaks from storage tanks can result in soil contamination and groundwater pollution. This necessitates stringent safety protocols, including proper containment measures, regular inspections, and emergency response plans to quickly address any potential leaks or spills.

Furthermore, the production of muriatic acid itself has upstream environmental impacts. The chlor-alkali process, commonly used to manufacture hydrochloric acid, consumes significant amounts of energy and can result in mercury emissions if older production methods are employed. This underscores the importance of considering the entire life cycle of the acid when assessing its environmental footprint in polysulfone manufacturing.

To address these environmental challenges, manufacturers are increasingly adopting cleaner production techniques and exploring alternative processes that reduce or eliminate the use of muriatic acid. This includes the development of less hazardous catalysts and the implementation of closed-loop systems that minimize waste and emissions. Additionally, some companies are investing in green chemistry initiatives to find more environmentally friendly alternatives to traditional acid-based processes in polymer production.

Regulatory compliance plays a crucial role in managing the environmental impact of muriatic acid use. Stringent environmental regulations govern the handling, storage, and disposal of hazardous chemicals, including muriatic acid. Manufacturers must adhere to these regulations, which often require comprehensive environmental management systems, regular monitoring, and reporting of emissions and waste.

Safety Protocols for Muriatic Acid Handling

The safe handling of muriatic acid (hydrochloric acid) is paramount in the manufacture of polysulfone. Strict safety protocols must be implemented to protect workers and the environment from the corrosive and hazardous nature of this chemical.

Personal protective equipment (PPE) is the first line of defense. Workers must wear chemical-resistant gloves, goggles, face shields, and protective clothing when handling muriatic acid. Respiratory protection may also be necessary, depending on the concentration and potential for vapor exposure.

Proper storage and containment are critical. Muriatic acid should be stored in corrosion-resistant containers in well-ventilated areas, away from incompatible materials. Secondary containment systems should be in place to prevent spills from spreading. Regular inspections of storage areas and containers are essential to identify potential leaks or damage.

Handling and transfer procedures must be carefully designed and followed. Use of closed systems and proper ventilation is crucial to minimize exposure. Transfer operations should be conducted in designated areas with spill containment measures. Pumps and transfer equipment must be compatible with the acid's corrosive properties.

Emergency response planning is vital. Eyewash stations and safety showers must be readily accessible in all areas where muriatic acid is used or stored. Spill response kits should be available, and workers must be trained in their use. Clear evacuation procedures should be established and regularly practiced.

Worker training is a cornerstone of safety protocols. All personnel involved in handling muriatic acid must receive comprehensive training on its hazards, proper handling techniques, PPE use, and emergency procedures. Regular refresher training should be conducted to maintain awareness and competence.

Environmental considerations are also crucial. Proper disposal methods for waste acid and contaminated materials must be implemented. Neutralization procedures should be in place for small spills, while larger incidents may require specialized cleanup teams.

Monitoring and documentation are essential components of safety protocols. Regular air quality monitoring should be conducted to ensure exposure limits are not exceeded. Detailed records of acid usage, storage, and any incidents should be maintained for regulatory compliance and continuous improvement of safety measures.

Implementation of engineering controls, such as closed systems, local exhaust ventilation, and automated handling equipment, can significantly reduce the risk of exposure. These should be regularly inspected and maintained to ensure optimal performance.

Finally, a culture of safety must be fostered throughout the organization. This includes encouraging reporting of near-misses and potential hazards, conducting regular safety audits, and continuously reviewing and updating safety protocols based on industry best practices and lessons learned.

Personal protective equipment (PPE) is the first line of defense. Workers must wear chemical-resistant gloves, goggles, face shields, and protective clothing when handling muriatic acid. Respiratory protection may also be necessary, depending on the concentration and potential for vapor exposure.

Proper storage and containment are critical. Muriatic acid should be stored in corrosion-resistant containers in well-ventilated areas, away from incompatible materials. Secondary containment systems should be in place to prevent spills from spreading. Regular inspections of storage areas and containers are essential to identify potential leaks or damage.

Handling and transfer procedures must be carefully designed and followed. Use of closed systems and proper ventilation is crucial to minimize exposure. Transfer operations should be conducted in designated areas with spill containment measures. Pumps and transfer equipment must be compatible with the acid's corrosive properties.

Emergency response planning is vital. Eyewash stations and safety showers must be readily accessible in all areas where muriatic acid is used or stored. Spill response kits should be available, and workers must be trained in their use. Clear evacuation procedures should be established and regularly practiced.

Worker training is a cornerstone of safety protocols. All personnel involved in handling muriatic acid must receive comprehensive training on its hazards, proper handling techniques, PPE use, and emergency procedures. Regular refresher training should be conducted to maintain awareness and competence.

Environmental considerations are also crucial. Proper disposal methods for waste acid and contaminated materials must be implemented. Neutralization procedures should be in place for small spills, while larger incidents may require specialized cleanup teams.

Monitoring and documentation are essential components of safety protocols. Regular air quality monitoring should be conducted to ensure exposure limits are not exceeded. Detailed records of acid usage, storage, and any incidents should be maintained for regulatory compliance and continuous improvement of safety measures.

Implementation of engineering controls, such as closed systems, local exhaust ventilation, and automated handling equipment, can significantly reduce the risk of exposure. These should be regularly inspected and maintained to ensure optimal performance.

Finally, a culture of safety must be fostered throughout the organization. This includes encouraging reporting of near-misses and potential hazards, conducting regular safety audits, and continuously reviewing and updating safety protocols based on industry best practices and lessons learned.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!