How Muriatic Acid is Used in the Manufacture of Polyvinyl Chloride (PVC)

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVC Manufacturing Overview and Objectives

Polyvinyl Chloride (PVC) is one of the most widely used synthetic plastic materials in the world, with applications ranging from construction to healthcare. The manufacturing process of PVC involves several key steps, with muriatic acid playing a crucial role in its production. This overview aims to provide a comprehensive understanding of PVC manufacturing and the specific objectives related to the use of muriatic acid in this process.

PVC production begins with the polymerization of vinyl chloride monomer (VCM), which is derived from ethylene and chlorine. The polymerization process can be carried out using various methods, including suspension, emulsion, and bulk polymerization. Each method has its advantages and is chosen based on the desired properties of the final PVC product.

Muriatic acid, also known as hydrochloric acid, is primarily used in the production of vinyl chloride monomer, the precursor to PVC. The acid is employed in the oxychlorination process, where ethylene, hydrogen chloride, and oxygen react to form vinyl chloride. This step is critical in ensuring a continuous supply of VCM for PVC production, especially when direct chlorination of ethylene is insufficient to meet demand.

The objectives of using muriatic acid in PVC manufacturing are multifaceted. Firstly, it serves as a key reactant in the production of vinyl chloride monomer, ensuring a stable supply of the primary raw material for PVC. Secondly, the use of muriatic acid allows for the efficient recycling of hydrogen chloride, a byproduct of the direct chlorination process, back into the production cycle. This not only improves the overall efficiency of the manufacturing process but also reduces waste and environmental impact.

Furthermore, the quality of muriatic acid used in PVC production is of utmost importance. High-purity acid is essential to prevent contamination of the final PVC product, which could otherwise lead to degradation of its physical and chemical properties. Therefore, stringent quality control measures are implemented to ensure the acid meets the required specifications.

Another objective in the use of muriatic acid is to optimize the reaction conditions in the oxychlorination process. This involves careful control of temperature, pressure, and catalyst performance to maximize the yield of vinyl chloride monomer while minimizing unwanted side reactions. Advanced process control systems and reactor designs are employed to achieve these goals, contributing to the overall efficiency and sustainability of PVC production.

In conclusion, the use of muriatic acid in PVC manufacturing is a critical aspect of the production process, contributing significantly to the industry's ability to meet the growing global demand for this versatile plastic material. The objectives of its use encompass not only the efficient production of vinyl chloride monomer but also the optimization of the entire manufacturing process, ensuring high-quality output while minimizing environmental impact.

PVC production begins with the polymerization of vinyl chloride monomer (VCM), which is derived from ethylene and chlorine. The polymerization process can be carried out using various methods, including suspension, emulsion, and bulk polymerization. Each method has its advantages and is chosen based on the desired properties of the final PVC product.

Muriatic acid, also known as hydrochloric acid, is primarily used in the production of vinyl chloride monomer, the precursor to PVC. The acid is employed in the oxychlorination process, where ethylene, hydrogen chloride, and oxygen react to form vinyl chloride. This step is critical in ensuring a continuous supply of VCM for PVC production, especially when direct chlorination of ethylene is insufficient to meet demand.

The objectives of using muriatic acid in PVC manufacturing are multifaceted. Firstly, it serves as a key reactant in the production of vinyl chloride monomer, ensuring a stable supply of the primary raw material for PVC. Secondly, the use of muriatic acid allows for the efficient recycling of hydrogen chloride, a byproduct of the direct chlorination process, back into the production cycle. This not only improves the overall efficiency of the manufacturing process but also reduces waste and environmental impact.

Furthermore, the quality of muriatic acid used in PVC production is of utmost importance. High-purity acid is essential to prevent contamination of the final PVC product, which could otherwise lead to degradation of its physical and chemical properties. Therefore, stringent quality control measures are implemented to ensure the acid meets the required specifications.

Another objective in the use of muriatic acid is to optimize the reaction conditions in the oxychlorination process. This involves careful control of temperature, pressure, and catalyst performance to maximize the yield of vinyl chloride monomer while minimizing unwanted side reactions. Advanced process control systems and reactor designs are employed to achieve these goals, contributing to the overall efficiency and sustainability of PVC production.

In conclusion, the use of muriatic acid in PVC manufacturing is a critical aspect of the production process, contributing significantly to the industry's ability to meet the growing global demand for this versatile plastic material. The objectives of its use encompass not only the efficient production of vinyl chloride monomer but also the optimization of the entire manufacturing process, ensuring high-quality output while minimizing environmental impact.

Market Demand Analysis for PVC Products

The global market for Polyvinyl Chloride (PVC) products has shown robust growth in recent years, driven by increasing demand across various industries. PVC's versatility, durability, and cost-effectiveness have made it a preferred material in construction, automotive, healthcare, and consumer goods sectors.

In the construction industry, PVC products such as pipes, fittings, windows, and doors have witnessed substantial demand due to rapid urbanization and infrastructure development worldwide. The automotive sector has also contributed significantly to PVC market growth, with applications in interior components, wire harnesses, and underbody protection.

The healthcare industry has emerged as a key driver for PVC demand, particularly in medical devices, packaging, and disposable products. The COVID-19 pandemic has further accelerated this trend, with increased demand for PVC-based personal protective equipment and medical supplies.

Consumer goods, including packaging materials, household items, and electronics, continue to fuel PVC product demand. The growing e-commerce sector has boosted the need for PVC packaging solutions, while the electronics industry relies on PVC for cable insulation and device casings.

Geographically, Asia-Pacific remains the largest market for PVC products, with China and India leading consumption. The region's rapid industrialization, urbanization, and population growth are expected to sustain this trend. North America and Europe follow, with steady demand in construction and automotive sectors.

Despite the positive market outlook, environmental concerns and regulatory pressures pose challenges to PVC product growth. Increasing awareness of plastic pollution and the push for sustainable alternatives have led to efforts in developing eco-friendly PVC formulations and recycling technologies.

The market is also witnessing a shift towards value-added PVC products, such as specialty grades with enhanced properties for specific applications. This trend is driven by the need for higher performance materials in industries like healthcare and automotive.

In terms of market dynamics, the PVC product industry is characterized by intense competition among key players and regional manufacturers. Price fluctuations of raw materials, particularly ethylene and chlorine, significantly impact market dynamics and profitability.

Looking ahead, the global PVC product market is projected to maintain steady growth, supported by ongoing urbanization, infrastructure development, and technological advancements in PVC formulations. The industry's focus on sustainability and circular economy principles is expected to shape future market trends and product innovations.

In the construction industry, PVC products such as pipes, fittings, windows, and doors have witnessed substantial demand due to rapid urbanization and infrastructure development worldwide. The automotive sector has also contributed significantly to PVC market growth, with applications in interior components, wire harnesses, and underbody protection.

The healthcare industry has emerged as a key driver for PVC demand, particularly in medical devices, packaging, and disposable products. The COVID-19 pandemic has further accelerated this trend, with increased demand for PVC-based personal protective equipment and medical supplies.

Consumer goods, including packaging materials, household items, and electronics, continue to fuel PVC product demand. The growing e-commerce sector has boosted the need for PVC packaging solutions, while the electronics industry relies on PVC for cable insulation and device casings.

Geographically, Asia-Pacific remains the largest market for PVC products, with China and India leading consumption. The region's rapid industrialization, urbanization, and population growth are expected to sustain this trend. North America and Europe follow, with steady demand in construction and automotive sectors.

Despite the positive market outlook, environmental concerns and regulatory pressures pose challenges to PVC product growth. Increasing awareness of plastic pollution and the push for sustainable alternatives have led to efforts in developing eco-friendly PVC formulations and recycling technologies.

The market is also witnessing a shift towards value-added PVC products, such as specialty grades with enhanced properties for specific applications. This trend is driven by the need for higher performance materials in industries like healthcare and automotive.

In terms of market dynamics, the PVC product industry is characterized by intense competition among key players and regional manufacturers. Price fluctuations of raw materials, particularly ethylene and chlorine, significantly impact market dynamics and profitability.

Looking ahead, the global PVC product market is projected to maintain steady growth, supported by ongoing urbanization, infrastructure development, and technological advancements in PVC formulations. The industry's focus on sustainability and circular economy principles is expected to shape future market trends and product innovations.

Muriatic Acid in PVC Production: Current Status and Challenges

The current status of muriatic acid usage in PVC production is characterized by its critical role in the chlorination process of ethylene to produce ethylene dichloride (EDC), a key intermediate in PVC manufacturing. Muriatic acid, also known as hydrochloric acid, is primarily used as a catalyst and reactant in this process, ensuring efficient conversion of ethylene to EDC.

One of the main challenges in the use of muriatic acid for PVC production is its corrosive nature, which necessitates specialized equipment and handling procedures. This corrosiveness can lead to increased maintenance costs and potential safety hazards if not properly managed. Additionally, the storage and transportation of large quantities of muriatic acid pose logistical challenges and environmental concerns.

Another significant challenge is the environmental impact associated with muriatic acid usage. The production and handling of this strong acid can result in emissions of hydrogen chloride gas, which contributes to air pollution and potential acid rain formation. Stringent regulations on emissions and waste management have necessitated the development of more environmentally friendly processes and improved containment systems.

The variability in muriatic acid quality and concentration can also present challenges in maintaining consistent PVC production. Impurities in the acid can affect the final product quality, requiring careful quality control measures and potentially increasing production costs.

Furthermore, the global supply chain for muriatic acid can be subject to fluctuations, impacting availability and pricing for PVC manufacturers. This volatility can be exacerbated by geopolitical factors and changes in industrial demand across various sectors that utilize muriatic acid.

Recent technological advancements have focused on addressing these challenges. Innovations in reactor design and materials have improved resistance to acid corrosion, enhancing equipment longevity and reducing maintenance requirements. Additionally, closed-loop systems and improved recycling techniques have been developed to minimize waste and emissions associated with muriatic acid use in PVC production.

Efforts are also underway to explore alternative catalysts and processes that could reduce or eliminate the need for muriatic acid in PVC manufacturing. These include membrane-based technologies and novel chemical routes that aim to improve efficiency and reduce environmental impact. However, the widespread adoption of these alternatives is still limited due to economic and technical constraints.

One of the main challenges in the use of muriatic acid for PVC production is its corrosive nature, which necessitates specialized equipment and handling procedures. This corrosiveness can lead to increased maintenance costs and potential safety hazards if not properly managed. Additionally, the storage and transportation of large quantities of muriatic acid pose logistical challenges and environmental concerns.

Another significant challenge is the environmental impact associated with muriatic acid usage. The production and handling of this strong acid can result in emissions of hydrogen chloride gas, which contributes to air pollution and potential acid rain formation. Stringent regulations on emissions and waste management have necessitated the development of more environmentally friendly processes and improved containment systems.

The variability in muriatic acid quality and concentration can also present challenges in maintaining consistent PVC production. Impurities in the acid can affect the final product quality, requiring careful quality control measures and potentially increasing production costs.

Furthermore, the global supply chain for muriatic acid can be subject to fluctuations, impacting availability and pricing for PVC manufacturers. This volatility can be exacerbated by geopolitical factors and changes in industrial demand across various sectors that utilize muriatic acid.

Recent technological advancements have focused on addressing these challenges. Innovations in reactor design and materials have improved resistance to acid corrosion, enhancing equipment longevity and reducing maintenance requirements. Additionally, closed-loop systems and improved recycling techniques have been developed to minimize waste and emissions associated with muriatic acid use in PVC production.

Efforts are also underway to explore alternative catalysts and processes that could reduce or eliminate the need for muriatic acid in PVC manufacturing. These include membrane-based technologies and novel chemical routes that aim to improve efficiency and reduce environmental impact. However, the widespread adoption of these alternatives is still limited due to economic and technical constraints.

Muriatic Acid Application Methods in PVC Production

01 Industrial applications of muriatic acid

Muriatic acid, also known as hydrochloric acid, is widely used in various industrial processes. It is employed in metal cleaning and pickling, water treatment, and as a chemical intermediate in the production of other compounds. Its strong acidic properties make it effective for removing rust, scale, and other impurities from metal surfaces.- Production and purification of muriatic acid: Muriatic acid, also known as hydrochloric acid, can be produced and purified through various industrial processes. These methods may involve the reaction of chlorine with hydrogen or the treatment of salt with sulfuric acid. Purification techniques can include distillation or membrane separation to remove impurities and achieve desired concentrations.

- Applications in metal treatment and surface cleaning: Muriatic acid is widely used in metal treatment processes, such as pickling, etching, and surface cleaning. It can effectively remove rust, scale, and other contaminants from metal surfaces. The acid is particularly useful in preparing metal surfaces for further processing, such as painting or plating.

- Use in construction and building materials: Muriatic acid finds applications in the construction industry, particularly in the treatment of concrete and masonry surfaces. It can be used for cleaning, etching, or preparing surfaces for further treatment. The acid is also employed in the production of certain building materials and in the maintenance of swimming pools.

- Environmental and safety considerations: Handling and disposal of muriatic acid require careful consideration of environmental and safety factors. Proper storage, transportation, and use of the acid are essential to prevent accidents and minimize environmental impact. Neutralization techniques and specialized equipment may be necessary for safe handling and disposal.

- Industrial and chemical processing applications: Muriatic acid is a versatile chemical used in various industrial processes. It serves as a reagent in chemical synthesis, pH adjustment, and as a catalyst in certain reactions. The acid is also employed in the production of pharmaceuticals, food additives, and in water treatment processes.

02 Muriatic acid in cleaning and maintenance

Muriatic acid is commonly used in cleaning and maintenance applications. It is effective for removing mineral deposits, stains, and buildup in various settings, including swimming pools, bathrooms, and industrial equipment. Its strong acidic nature allows it to dissolve calcium and other mineral deposits efficiently.Expand Specific Solutions03 Safety and handling of muriatic acid

Due to its corrosive nature, proper safety measures and handling procedures are crucial when working with muriatic acid. This includes using appropriate personal protective equipment, proper storage containers, and following specific disposal guidelines. Dilution and neutralization techniques are often employed to reduce the acid's concentration for safer handling.Expand Specific Solutions04 Environmental considerations and alternatives

The use of muriatic acid can have environmental impacts, leading to research into more environmentally friendly alternatives. Some alternatives include organic acids or less corrosive formulations that can perform similar functions with reduced environmental and safety risks. Proper disposal and treatment of muriatic acid waste are essential to minimize environmental harm.Expand Specific Solutions05 Muriatic acid in chemical processes

Muriatic acid plays a significant role in various chemical processes and reactions. It is used as a catalyst, pH regulator, and reagent in the production of numerous chemicals and materials. Its ability to donate protons makes it valuable in acid-base reactions and in the synthesis of chlorides and other compounds.Expand Specific Solutions

Key Players in PVC and Chemical Industry

The manufacture of Polyvinyl Chloride (PVC) using muriatic acid is a mature technology in the chemical industry, with the market in a consolidation phase. The global PVC market size is substantial, estimated at over $60 billion annually, with steady growth projected. Key players like Reliance Industries, LG Chem, and Wacker Chemie demonstrate the technology's high maturity level through their established production processes and continuous innovation efforts. Companies such as BASF, Braskem, and Formosa Plastics Corp. USA have also made significant investments in PVC production, indicating the industry's stability and ongoing demand. The competitive landscape is characterized by large-scale producers with integrated supply chains, focusing on efficiency improvements and sustainable production methods to maintain market positions.

LG Chem Ltd.

Technical Solution: LG Chem Ltd. utilizes muriatic acid in its PVC production through an advanced membrane-based electrolysis process. This technology produces high-purity hydrogen chloride gas, which is then used in the oxychlorination step of EDC production[2]. LG Chem has also developed a proprietary fluidized bed reactor system for VCM production, which offers improved heat transfer and reaction efficiency compared to traditional fixed-bed reactors[4]. The company's PVC polymerization process incorporates novel initiator systems and suspension stabilizers, resulting in PVC with enhanced thermal stability and processability[6]. Furthermore, LG Chem has implemented a closed-loop recycling system for recovering and purifying unreacted VCM, significantly reducing waste and improving overall process efficiency[8].

Strengths: High-efficiency membrane electrolysis, advanced reactor technology, improved PVC properties. Weaknesses: High capital costs for membrane technology, potential scalability issues for some proprietary processes.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies LLC has developed an innovative process for PVC production using muriatic acid. Their method involves the oxychlorination of ethylene using hydrogen chloride (derived from muriatic acid) and oxygen to produce ethylene dichloride (EDC), a key intermediate in PVC manufacture[1]. This process is integrated with their chlor-alkali operations, allowing for efficient use of by-product hydrogen chloride. The company has also implemented advanced reactor designs and catalysts to improve the conversion efficiency of EDC to vinyl chloride monomer (VCM), the direct precursor to PVC[3]. Additionally, Dow has developed proprietary technology for the polymerization of VCM to PVC, which allows for better control of molecular weight distribution and particle morphology[5].

Strengths: Highly integrated process, efficient use of by-products, advanced catalyst technology. Weaknesses: Dependence on ethylene feedstock, potential environmental concerns related to chlorine chemistry.

Innovations in Muriatic Acid Usage for PVC Manufacturing

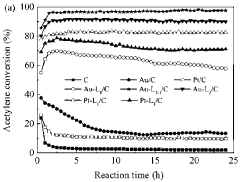

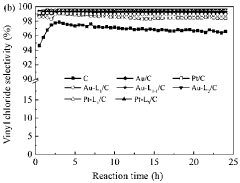

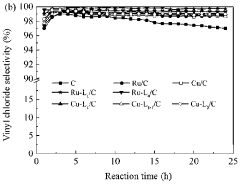

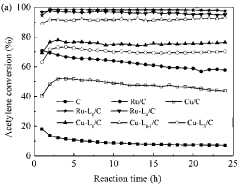

Metal complex catalyst for catalyzing hydrochlorination of acetylene, preparation method and application thereof

PatentActiveZA202203700A

Innovation

- A metal complex catalyst is formed by coordinating central metal atoms (Au, Pt, Ru, or Cu) with organic ligands having an imide structure, which are anchored on activated carbon, preventing loss and agglomeration, and enhancing catalytic activity through unsaturated coordination and hydrogen bonding.

Method of preparing hydrochloric acid from polyvinyl chloride and method of dehydrochlorinating waste polyvinyl chloride

PatentActiveKR1020160137751A

Innovation

- A method involving a dechlorination reaction of waste PVC using a metal oxide or carbon nitride catalyst in a liquid reaction solvent, such as polyethylene glycol or an ionic liquid, to produce hydrochloric acid efficiently and reduce corrosion.

Environmental Impact of Muriatic Acid in PVC Manufacturing

The use of muriatic acid (hydrochloric acid) in the manufacture of polyvinyl chloride (PVC) has significant environmental implications that require careful consideration and management. The production process involves several stages where muriatic acid is utilized, each with potential environmental impacts.

During the initial chlorination of ethylene to produce ethylene dichloride (EDC), muriatic acid is generated as a byproduct. This acid must be carefully handled and neutralized to prevent release into the environment. Improper management can lead to soil and water contamination, potentially harming local ecosystems and human health.

In the oxychlorination process, where ethylene, hydrogen chloride, and oxygen react to produce more EDC, muriatic acid plays a crucial role. However, this process can result in the formation of dioxins, highly toxic compounds that persist in the environment and bioaccumulate in the food chain. Strict emission controls and advanced scrubbing technologies are essential to mitigate these risks.

The thermal cracking of EDC to produce vinyl chloride monomer (VCM) also involves muriatic acid. This step can generate various chlorinated organic compounds, which, if released, can contribute to air pollution and ozone depletion. Proper containment and treatment of these byproducts are critical to minimize environmental impact.

Water pollution is another significant concern in PVC manufacturing. Wastewater from the production process often contains traces of muriatic acid and other chemicals. If not adequately treated, this effluent can alter the pH of water bodies, harm aquatic life, and contaminate drinking water sources. Advanced wastewater treatment systems are necessary to ensure compliance with environmental regulations.

The transportation and storage of muriatic acid for PVC production also pose environmental risks. Accidental spills or leaks during handling can cause localized environmental damage, affecting soil quality and potentially contaminating groundwater. Robust safety protocols and containment measures are essential to prevent such incidents.

Long-term exposure to low levels of muriatic acid emissions from PVC manufacturing facilities can contribute to acid rain formation. This phenomenon can have far-reaching effects on ecosystems, including the acidification of lakes and forests, and the corrosion of buildings and infrastructure.

To address these environmental challenges, the PVC industry has been investing in cleaner technologies and more efficient processes. Closed-loop systems that recycle muriatic acid within the production cycle are becoming more common, reducing the need for fresh acid and minimizing waste. Additionally, the development of alternative production methods that reduce or eliminate the use of muriatic acid is an active area of research, aiming to create more environmentally friendly PVC manufacturing processes.

During the initial chlorination of ethylene to produce ethylene dichloride (EDC), muriatic acid is generated as a byproduct. This acid must be carefully handled and neutralized to prevent release into the environment. Improper management can lead to soil and water contamination, potentially harming local ecosystems and human health.

In the oxychlorination process, where ethylene, hydrogen chloride, and oxygen react to produce more EDC, muriatic acid plays a crucial role. However, this process can result in the formation of dioxins, highly toxic compounds that persist in the environment and bioaccumulate in the food chain. Strict emission controls and advanced scrubbing technologies are essential to mitigate these risks.

The thermal cracking of EDC to produce vinyl chloride monomer (VCM) also involves muriatic acid. This step can generate various chlorinated organic compounds, which, if released, can contribute to air pollution and ozone depletion. Proper containment and treatment of these byproducts are critical to minimize environmental impact.

Water pollution is another significant concern in PVC manufacturing. Wastewater from the production process often contains traces of muriatic acid and other chemicals. If not adequately treated, this effluent can alter the pH of water bodies, harm aquatic life, and contaminate drinking water sources. Advanced wastewater treatment systems are necessary to ensure compliance with environmental regulations.

The transportation and storage of muriatic acid for PVC production also pose environmental risks. Accidental spills or leaks during handling can cause localized environmental damage, affecting soil quality and potentially contaminating groundwater. Robust safety protocols and containment measures are essential to prevent such incidents.

Long-term exposure to low levels of muriatic acid emissions from PVC manufacturing facilities can contribute to acid rain formation. This phenomenon can have far-reaching effects on ecosystems, including the acidification of lakes and forests, and the corrosion of buildings and infrastructure.

To address these environmental challenges, the PVC industry has been investing in cleaner technologies and more efficient processes. Closed-loop systems that recycle muriatic acid within the production cycle are becoming more common, reducing the need for fresh acid and minimizing waste. Additionally, the development of alternative production methods that reduce or eliminate the use of muriatic acid is an active area of research, aiming to create more environmentally friendly PVC manufacturing processes.

Safety Protocols for Handling Muriatic Acid in PVC Production

Safety protocols for handling muriatic acid in PVC production are critical to ensure the well-being of workers and the integrity of the manufacturing process. These protocols encompass a comprehensive set of guidelines and procedures designed to mitigate risks associated with the use of this corrosive substance.

Personal protective equipment (PPE) forms the first line of defense against potential exposure. Workers must wear chemical-resistant gloves, goggles, face shields, and protective clothing when handling muriatic acid. Respiratory protection may also be necessary in areas with inadequate ventilation or where there is a risk of acid vapor inhalation.

Proper storage and handling procedures are essential to prevent accidents and spills. Muriatic acid should be stored in well-ventilated areas, away from incompatible materials and sources of heat. Containers must be clearly labeled and regularly inspected for signs of damage or leakage. Transfer of acid should only be performed using appropriate equipment and techniques to minimize the risk of splashes or spills.

Emergency response protocols must be established and communicated to all personnel. This includes the installation of emergency showers and eyewash stations in strategic locations throughout the facility. Workers should be trained in the proper use of these safety features and in the steps to take in case of accidental exposure or spills.

Ventilation systems play a crucial role in maintaining a safe working environment. Adequate local exhaust ventilation should be installed in areas where muriatic acid is used or stored to remove acid vapors and maintain air quality within acceptable limits. Regular monitoring of air quality and ventilation system performance is necessary to ensure ongoing effectiveness.

Training and education are fundamental components of safety protocols. All personnel involved in handling muriatic acid must receive comprehensive training on its properties, hazards, and safe handling procedures. This training should be regularly updated and reinforced through periodic refresher courses and safety drills.

Spill response procedures should be clearly defined and practiced. This includes the provision of appropriate spill containment and neutralization materials, as well as training in their proper use. Designated spill response teams should be established and equipped to handle potential incidents promptly and effectively.

Regular safety audits and inspections are essential to maintain compliance with safety protocols and identify potential hazards or areas for improvement. These audits should cover all aspects of muriatic acid handling, from storage and transfer to use in the PVC production process.

By implementing and strictly adhering to these safety protocols, PVC manufacturers can significantly reduce the risks associated with muriatic acid handling, ensuring a safer work environment and more reliable production processes.

Personal protective equipment (PPE) forms the first line of defense against potential exposure. Workers must wear chemical-resistant gloves, goggles, face shields, and protective clothing when handling muriatic acid. Respiratory protection may also be necessary in areas with inadequate ventilation or where there is a risk of acid vapor inhalation.

Proper storage and handling procedures are essential to prevent accidents and spills. Muriatic acid should be stored in well-ventilated areas, away from incompatible materials and sources of heat. Containers must be clearly labeled and regularly inspected for signs of damage or leakage. Transfer of acid should only be performed using appropriate equipment and techniques to minimize the risk of splashes or spills.

Emergency response protocols must be established and communicated to all personnel. This includes the installation of emergency showers and eyewash stations in strategic locations throughout the facility. Workers should be trained in the proper use of these safety features and in the steps to take in case of accidental exposure or spills.

Ventilation systems play a crucial role in maintaining a safe working environment. Adequate local exhaust ventilation should be installed in areas where muriatic acid is used or stored to remove acid vapors and maintain air quality within acceptable limits. Regular monitoring of air quality and ventilation system performance is necessary to ensure ongoing effectiveness.

Training and education are fundamental components of safety protocols. All personnel involved in handling muriatic acid must receive comprehensive training on its properties, hazards, and safe handling procedures. This training should be regularly updated and reinforced through periodic refresher courses and safety drills.

Spill response procedures should be clearly defined and practiced. This includes the provision of appropriate spill containment and neutralization materials, as well as training in their proper use. Designated spill response teams should be established and equipped to handle potential incidents promptly and effectively.

Regular safety audits and inspections are essential to maintain compliance with safety protocols and identify potential hazards or areas for improvement. These audits should cover all aspects of muriatic acid handling, from storage and transfer to use in the PVC production process.

By implementing and strictly adhering to these safety protocols, PVC manufacturers can significantly reduce the risks associated with muriatic acid handling, ensuring a safer work environment and more reliable production processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!