How Neoprene Contributes to Automotive Sealing Solutions?

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neoprene in Automotive Sealing: Evolution and Objectives

Neoprene, a synthetic rubber developed by DuPont in 1930, has played a pivotal role in automotive sealing solutions for decades. Its evolution in the automotive industry is closely tied to the advancements in vehicle design and the increasing demands for improved performance, durability, and environmental resistance.

Initially, neoprene was primarily used in general-purpose automotive applications due to its excellent resistance to oil, heat, and weathering. As vehicle designs became more complex and performance requirements more stringent, neoprene's role in automotive sealing expanded significantly. The material's versatility allowed it to be formulated for specific automotive needs, such as enhanced ozone resistance for exterior seals and improved compression set for long-term sealing effectiveness.

The objectives of neoprene in automotive sealing have evolved over time, driven by industry trends and regulatory requirements. Early goals focused on basic functionality and durability. However, as automotive technology advanced, the objectives expanded to include improved noise reduction, better fuel efficiency through reduced air drag, and enhanced safety features.

In recent years, the automotive industry has placed greater emphasis on environmental sustainability and vehicle lightweighting. This shift has led to new objectives for neoprene in automotive sealing, including the development of eco-friendly formulations and the creation of lighter-weight sealing solutions without compromising performance.

The evolution of neoprene in automotive sealing has also been influenced by advancements in manufacturing processes. Improved extrusion and molding techniques have allowed for more complex seal designs, enabling better integration with modern vehicle architectures. Additionally, the development of co-extrusion and over-molding processes has facilitated the creation of multi-material seals that combine neoprene with other elastomers or rigid materials for optimized performance.

Looking forward, the objectives for neoprene in automotive sealing continue to evolve. Key focus areas include enhancing its compatibility with electric and autonomous vehicles, improving its recyclability to support circular economy initiatives, and further optimizing its performance in extreme temperature conditions. Research is also underway to explore nanocomposite formulations of neoprene that could offer superior properties for next-generation automotive sealing solutions.

Initially, neoprene was primarily used in general-purpose automotive applications due to its excellent resistance to oil, heat, and weathering. As vehicle designs became more complex and performance requirements more stringent, neoprene's role in automotive sealing expanded significantly. The material's versatility allowed it to be formulated for specific automotive needs, such as enhanced ozone resistance for exterior seals and improved compression set for long-term sealing effectiveness.

The objectives of neoprene in automotive sealing have evolved over time, driven by industry trends and regulatory requirements. Early goals focused on basic functionality and durability. However, as automotive technology advanced, the objectives expanded to include improved noise reduction, better fuel efficiency through reduced air drag, and enhanced safety features.

In recent years, the automotive industry has placed greater emphasis on environmental sustainability and vehicle lightweighting. This shift has led to new objectives for neoprene in automotive sealing, including the development of eco-friendly formulations and the creation of lighter-weight sealing solutions without compromising performance.

The evolution of neoprene in automotive sealing has also been influenced by advancements in manufacturing processes. Improved extrusion and molding techniques have allowed for more complex seal designs, enabling better integration with modern vehicle architectures. Additionally, the development of co-extrusion and over-molding processes has facilitated the creation of multi-material seals that combine neoprene with other elastomers or rigid materials for optimized performance.

Looking forward, the objectives for neoprene in automotive sealing continue to evolve. Key focus areas include enhancing its compatibility with electric and autonomous vehicles, improving its recyclability to support circular economy initiatives, and further optimizing its performance in extreme temperature conditions. Research is also underway to explore nanocomposite formulations of neoprene that could offer superior properties for next-generation automotive sealing solutions.

Market Demand Analysis for Neoprene-based Automotive Seals

The automotive sealing market has witnessed significant growth in recent years, driven by the increasing demand for high-performance vehicles and the growing emphasis on vehicle comfort and safety. Neoprene-based automotive seals have emerged as a crucial component in this market, offering superior resistance to oil, fuel, and weathering, making them ideal for various automotive applications.

The global automotive sealing market is expected to continue its upward trajectory, with a particular focus on neoprene-based solutions. This growth is primarily attributed to the rising production of vehicles worldwide, especially in emerging economies. Additionally, the increasing consumer preference for quieter and more comfortable rides has led to a surge in demand for high-quality sealing solutions.

Neoprene-based automotive seals find applications in various parts of vehicles, including doors, windows, hoods, and trunks. The versatility of neoprene allows it to be used in both static and dynamic sealing applications, contributing to its widespread adoption in the automotive industry. The material's ability to maintain its properties across a wide temperature range makes it particularly suitable for use in diverse climatic conditions.

The market demand for neoprene-based automotive seals is also driven by stringent regulations regarding vehicle noise reduction and fuel efficiency. As automotive manufacturers strive to meet these standards, the adoption of high-performance sealing solutions becomes increasingly critical. Neoprene's excellent sound-dampening properties and its ability to reduce air and water infiltration contribute to improved vehicle acoustics and aerodynamics.

Furthermore, the growing trend towards electric and hybrid vehicles presents new opportunities for neoprene-based sealing solutions. These vehicles require specialized sealing to protect sensitive electronic components from moisture and contaminants, creating a niche market for advanced neoprene formulations.

The aftermarket segment for neoprene-based automotive seals is also experiencing substantial growth. As vehicles age, the replacement of worn-out seals becomes necessary to maintain optimal performance and safety. This creates a steady demand for neoprene seals in the automotive aftermarket sector.

In terms of regional demand, Asia-Pacific is expected to dominate the market due to the rapid growth of the automotive industry in countries like China and India. North America and Europe also represent significant markets, driven by the presence of major automotive manufacturers and the increasing focus on vehicle quality and performance.

The global automotive sealing market is expected to continue its upward trajectory, with a particular focus on neoprene-based solutions. This growth is primarily attributed to the rising production of vehicles worldwide, especially in emerging economies. Additionally, the increasing consumer preference for quieter and more comfortable rides has led to a surge in demand for high-quality sealing solutions.

Neoprene-based automotive seals find applications in various parts of vehicles, including doors, windows, hoods, and trunks. The versatility of neoprene allows it to be used in both static and dynamic sealing applications, contributing to its widespread adoption in the automotive industry. The material's ability to maintain its properties across a wide temperature range makes it particularly suitable for use in diverse climatic conditions.

The market demand for neoprene-based automotive seals is also driven by stringent regulations regarding vehicle noise reduction and fuel efficiency. As automotive manufacturers strive to meet these standards, the adoption of high-performance sealing solutions becomes increasingly critical. Neoprene's excellent sound-dampening properties and its ability to reduce air and water infiltration contribute to improved vehicle acoustics and aerodynamics.

Furthermore, the growing trend towards electric and hybrid vehicles presents new opportunities for neoprene-based sealing solutions. These vehicles require specialized sealing to protect sensitive electronic components from moisture and contaminants, creating a niche market for advanced neoprene formulations.

The aftermarket segment for neoprene-based automotive seals is also experiencing substantial growth. As vehicles age, the replacement of worn-out seals becomes necessary to maintain optimal performance and safety. This creates a steady demand for neoprene seals in the automotive aftermarket sector.

In terms of regional demand, Asia-Pacific is expected to dominate the market due to the rapid growth of the automotive industry in countries like China and India. North America and Europe also represent significant markets, driven by the presence of major automotive manufacturers and the increasing focus on vehicle quality and performance.

Current State and Challenges in Neoprene Sealing Technology

Neoprene, a synthetic rubber developed in the 1930s, has become a cornerstone in automotive sealing solutions. Its current state in the industry is characterized by widespread adoption due to its excellent resistance to oil, fuel, and weathering. Manufacturers rely on neoprene for various automotive applications, including door seals, window gaskets, and hose connections. The material's ability to maintain flexibility across a wide temperature range (-40°C to 120°C) makes it particularly suitable for the diverse environmental conditions vehicles encounter.

Despite its prevalence, neoprene sealing technology faces several challenges in the automotive sector. One primary concern is the material's relatively high cost compared to some alternative elastomers. This cost factor can impact the overall production expenses of vehicles, especially in the competitive automotive market where manufacturers are constantly seeking cost-effective solutions.

Another significant challenge is the environmental impact of neoprene production and disposal. As the automotive industry shifts towards more sustainable practices, there is growing pressure to find eco-friendly alternatives or improve the recyclability of neoprene seals. The chloroprene rubber used in neoprene production raises environmental concerns due to the potential release of harmful compounds during manufacturing and end-of-life disposal.

Durability under extreme conditions remains an ongoing challenge for neoprene seals. While the material performs well in many scenarios, prolonged exposure to high temperatures, aggressive chemicals, or constant mechanical stress can lead to degradation over time. This is particularly problematic in high-performance vehicles or in regions with extreme climates.

The automotive industry's trend towards lightweight materials to improve fuel efficiency also poses a challenge for neoprene sealing technology. While neoprene offers excellent sealing properties, it is not the lightest material available. Researchers and manufacturers are exploring ways to reduce the weight of neoprene seals without compromising their performance.

Customization and precision manufacturing of neoprene seals present another hurdle. As vehicle designs become more complex and aerodynamic, there is a growing need for seals with intricate shapes and tight tolerances. Achieving these specifications with neoprene can be challenging and may require advancements in manufacturing processes.

Lastly, the integration of smart technologies in vehicles is creating new demands for sealing solutions. There is an emerging need for seals that can accommodate sensors, wiring, and other electronic components while maintaining their protective properties. This convergence of traditional sealing functions with modern vehicle electronics presents both a challenge and an opportunity for innovation in neoprene sealing technology.

Despite its prevalence, neoprene sealing technology faces several challenges in the automotive sector. One primary concern is the material's relatively high cost compared to some alternative elastomers. This cost factor can impact the overall production expenses of vehicles, especially in the competitive automotive market where manufacturers are constantly seeking cost-effective solutions.

Another significant challenge is the environmental impact of neoprene production and disposal. As the automotive industry shifts towards more sustainable practices, there is growing pressure to find eco-friendly alternatives or improve the recyclability of neoprene seals. The chloroprene rubber used in neoprene production raises environmental concerns due to the potential release of harmful compounds during manufacturing and end-of-life disposal.

Durability under extreme conditions remains an ongoing challenge for neoprene seals. While the material performs well in many scenarios, prolonged exposure to high temperatures, aggressive chemicals, or constant mechanical stress can lead to degradation over time. This is particularly problematic in high-performance vehicles or in regions with extreme climates.

The automotive industry's trend towards lightweight materials to improve fuel efficiency also poses a challenge for neoprene sealing technology. While neoprene offers excellent sealing properties, it is not the lightest material available. Researchers and manufacturers are exploring ways to reduce the weight of neoprene seals without compromising their performance.

Customization and precision manufacturing of neoprene seals present another hurdle. As vehicle designs become more complex and aerodynamic, there is a growing need for seals with intricate shapes and tight tolerances. Achieving these specifications with neoprene can be challenging and may require advancements in manufacturing processes.

Lastly, the integration of smart technologies in vehicles is creating new demands for sealing solutions. There is an emerging need for seals that can accommodate sensors, wiring, and other electronic components while maintaining their protective properties. This convergence of traditional sealing functions with modern vehicle electronics presents both a challenge and an opportunity for innovation in neoprene sealing technology.

Existing Neoprene-based Sealing Solutions for Automobiles

01 Neoprene composition and manufacturing

Various compositions and manufacturing methods for neoprene are described, including improvements in the production process and formulations to enhance specific properties such as sealing effectiveness, durability, and chemical resistance.- Neoprene composition and manufacturing: Various methods and compositions for manufacturing neoprene with improved properties for sealing applications. This includes specific formulations, curing processes, and additives to enhance the material's performance in sealing contexts.

- Sealing applications of neoprene: Diverse applications of neoprene in sealing, including its use in automotive, marine, and industrial contexts. This covers specific designs and implementations of neoprene seals for various purposes.

- Neoprene modification for enhanced sealing: Techniques for modifying neoprene to improve its sealing properties. This includes chemical treatments, surface modifications, and the incorporation of other materials to enhance the seal's effectiveness and durability.

- Neoprene sealing in extreme conditions: Specialized neoprene formulations and designs for sealing in extreme temperatures, pressures, or chemical environments. This includes adaptations for high-performance sealing in challenging industrial or environmental conditions.

- Testing and quality control of neoprene seals: Methods and apparatus for testing the quality and performance of neoprene seals. This includes techniques for assessing seal integrity, durability, and effectiveness under various conditions to ensure optimal sealing performance.

02 Sealing applications of neoprene

Neoprene is widely used in sealing applications due to its excellent properties. These applications include gaskets, O-rings, and other sealing components in various industries such as automotive, marine, and construction.Expand Specific Solutions03 Neoprene foam sealing solutions

Neoprene foam is utilized in sealing applications where compressibility and conformability are required. The foam structure provides excellent insulation and cushioning properties, making it suitable for weatherstripping and gap-filling seals.Expand Specific Solutions04 Surface treatment and adhesion of neoprene seals

Various surface treatment methods and adhesive systems are employed to improve the bonding and sealing performance of neoprene. These techniques enhance the material's adhesion to different substrates and increase the overall effectiveness of the seal.Expand Specific Solutions05 Neoprene sealing in extreme environments

Specialized neoprene formulations and designs are developed for sealing applications in extreme environments, such as high-temperature, high-pressure, or chemically aggressive conditions. These solutions ensure the longevity and reliability of seals in challenging industrial settings.Expand Specific Solutions

Key Players in Neoprene and Automotive Sealing Industry

The automotive sealing solutions market, driven by neoprene technology, is in a mature growth phase with steady expansion. The global market size is substantial, reflecting the automotive industry's ongoing demand for high-performance sealing materials. Technologically, neoprene-based solutions are well-established, with companies like Tianjin Pengling Group, Meteor Gummiwerke, and Goodyear Tire & Rubber Co. leading innovation. These firms, along with others such as ExxonMobil Chemical Patents and The Lubrizol Corp., are continually refining neoprene formulations to enhance durability, temperature resistance, and environmental sustainability. The competitive landscape is characterized by a mix of specialized sealing solution providers and diversified chemical companies, all striving to meet the evolving needs of automotive manufacturers for improved performance and efficiency.

Goodyear Tire & Rubber Co.

Technical Solution: Goodyear has developed advanced neoprene-based sealing solutions for automotive applications. Their technology utilizes a proprietary blend of neoprene compounds optimized for durability and weather resistance. The company's sealing systems incorporate multi-layer designs with neoprene as the primary elastomer, enhanced with reinforcing fabrics and specialized coatings. This approach results in seals that maintain flexibility across a wide temperature range (-40°C to 125°C) while resisting degradation from ozone, UV exposure, and automotive fluids[1][3]. Goodyear's neoprene seals also feature self-lubricating properties, reducing friction and wear in dynamic sealing applications such as door and window seals[5].

Strengths: Excellent weather and chemical resistance, wide temperature performance range, and self-lubricating properties. Weaknesses: Higher cost compared to some alternative elastomers, and potential for compression set in static applications.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has pioneered innovative neoprene formulations specifically tailored for automotive sealing applications. Their patented technology focuses on improving the low-temperature flexibility of neoprene while maintaining its inherent resistance to heat, ozone, and oil. The company has developed a cross-linking system that enhances the polymer network structure, resulting in improved compression set resistance and long-term sealing performance[2]. ExxonMobil's neoprene compounds also incorporate nano-scale fillers, which contribute to enhanced tear strength and abrasion resistance, critical for dynamic sealing applications in vehicles[4]. Additionally, they have introduced flame-retardant additives to their neoprene formulations, meeting stringent automotive safety standards[6].

Strengths: Enhanced low-temperature performance, improved compression set resistance, and flame-retardant properties. Weaknesses: Potentially higher production costs due to specialized additives and processing requirements.

Core Innovations in Neoprene Compound Formulations

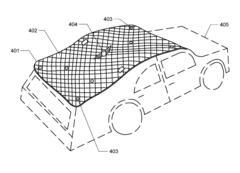

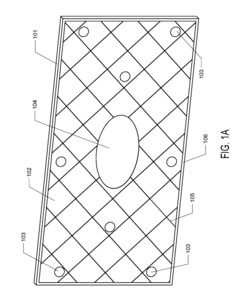

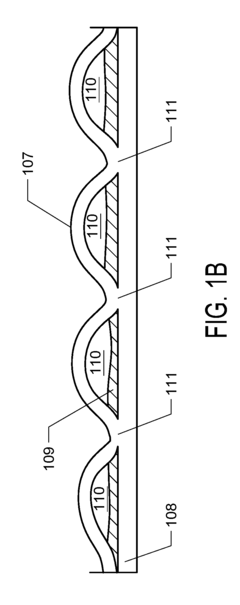

Neoprene Protective Covers for Vehicles and Other Objects

PatentInactiveUS20180170164A1

Innovation

- The use of neoprene material with integrated magnets for vehicle covers, providing a soft, non-scratching, and flame-resistant solution that can be welded for added strength and cushioning, with optional air-filled cells for enhanced padding.

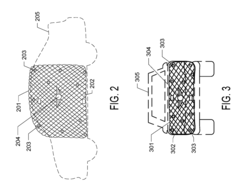

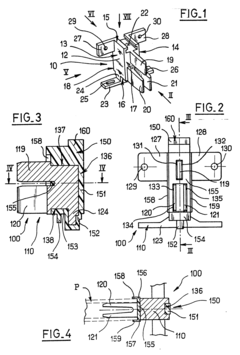

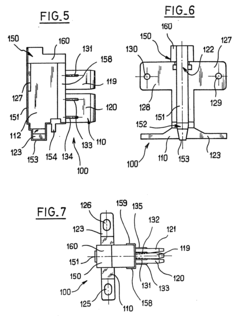

Part for connecting two transversal profiled elements, comprising an integrated seal

PatentInactiveEP0303526A2

Innovation

- Integration of a synthetic elastomer gasket, such as neoprene, overmolded onto the base body of the connecting piece, providing a secure seal that adapts to various weather conditions and temperatures, with a base body made of zamak, ensuring reliable assembly without additional sealing steps.

Environmental Impact and Sustainability of Neoprene Seals

The environmental impact and sustainability of neoprene seals in automotive applications have become increasingly important considerations in recent years. Neoprene, a synthetic rubber, offers excellent sealing properties but also presents challenges in terms of its ecological footprint.

The production of neoprene involves energy-intensive processes and the use of petrochemical feedstocks, contributing to greenhouse gas emissions and resource depletion. However, the automotive industry has been making strides in improving the sustainability of neoprene seals through various initiatives.

One significant area of focus has been the development of more environmentally friendly manufacturing processes for neoprene. Advanced production techniques have been implemented to reduce energy consumption and minimize waste generation during the manufacturing of neoprene seals. Additionally, some manufacturers have explored the use of bio-based alternatives to traditional petrochemical feedstocks, aiming to decrease the carbon footprint of neoprene production.

The durability and longevity of neoprene seals contribute positively to their environmental profile. These seals typically have a long service life, reducing the need for frequent replacements and minimizing waste generation. Furthermore, the excellent sealing properties of neoprene help improve the overall efficiency of vehicles by preventing leaks and maintaining optimal performance, indirectly contributing to reduced fuel consumption and emissions.

End-of-life considerations for neoprene seals have also gained attention. While neoprene is not biodegradable, efforts have been made to improve its recyclability. Advanced recycling technologies are being developed to recover and repurpose neoprene from discarded automotive components, reducing the amount of material sent to landfills.

The automotive industry has been exploring alternative materials with potentially lower environmental impacts. However, neoprene's unique combination of properties, including resistance to oil, fuel, and extreme temperatures, makes it challenging to find suitable replacements that offer comparable performance and durability.

Manufacturers are increasingly adopting life cycle assessment (LCA) approaches to evaluate the overall environmental impact of neoprene seals throughout their entire lifecycle. This holistic view helps identify areas for improvement and guides decision-making towards more sustainable practices.

As environmental regulations become more stringent, the automotive industry continues to invest in research and development to enhance the sustainability of neoprene seals. This includes exploring new formulations, optimizing material usage, and improving end-of-life management strategies. The goal is to strike a balance between maintaining the high performance standards required for automotive applications and minimizing the environmental footprint of neoprene seals.

The production of neoprene involves energy-intensive processes and the use of petrochemical feedstocks, contributing to greenhouse gas emissions and resource depletion. However, the automotive industry has been making strides in improving the sustainability of neoprene seals through various initiatives.

One significant area of focus has been the development of more environmentally friendly manufacturing processes for neoprene. Advanced production techniques have been implemented to reduce energy consumption and minimize waste generation during the manufacturing of neoprene seals. Additionally, some manufacturers have explored the use of bio-based alternatives to traditional petrochemical feedstocks, aiming to decrease the carbon footprint of neoprene production.

The durability and longevity of neoprene seals contribute positively to their environmental profile. These seals typically have a long service life, reducing the need for frequent replacements and minimizing waste generation. Furthermore, the excellent sealing properties of neoprene help improve the overall efficiency of vehicles by preventing leaks and maintaining optimal performance, indirectly contributing to reduced fuel consumption and emissions.

End-of-life considerations for neoprene seals have also gained attention. While neoprene is not biodegradable, efforts have been made to improve its recyclability. Advanced recycling technologies are being developed to recover and repurpose neoprene from discarded automotive components, reducing the amount of material sent to landfills.

The automotive industry has been exploring alternative materials with potentially lower environmental impacts. However, neoprene's unique combination of properties, including resistance to oil, fuel, and extreme temperatures, makes it challenging to find suitable replacements that offer comparable performance and durability.

Manufacturers are increasingly adopting life cycle assessment (LCA) approaches to evaluate the overall environmental impact of neoprene seals throughout their entire lifecycle. This holistic view helps identify areas for improvement and guides decision-making towards more sustainable practices.

As environmental regulations become more stringent, the automotive industry continues to invest in research and development to enhance the sustainability of neoprene seals. This includes exploring new formulations, optimizing material usage, and improving end-of-life management strategies. The goal is to strike a balance between maintaining the high performance standards required for automotive applications and minimizing the environmental footprint of neoprene seals.

Comparative Analysis with Alternative Sealing Materials

Neoprene has established itself as a prominent material in automotive sealing solutions, but it is essential to compare its performance with alternative sealing materials to fully understand its advantages and limitations. This comparative analysis will focus on key properties and characteristics that are crucial for automotive sealing applications.

Rubber-based materials, such as EPDM (Ethylene Propylene Diene Monomer) and silicone rubber, are common alternatives to neoprene in automotive sealing. EPDM offers excellent resistance to weathering, ozone, and UV radiation, making it suitable for exterior sealing applications. It also provides good heat resistance and maintains flexibility at low temperatures. Silicone rubber, on the other hand, excels in extreme temperature conditions, offering superior performance in both high and low-temperature environments.

In terms of durability, neoprene generally outperforms EPDM and silicone rubber. It exhibits better resistance to oil, fuel, and other automotive fluids, which is crucial for engine compartment seals and gaskets. Neoprene also maintains its physical properties over a longer period, resulting in extended service life for automotive seals.

Cost-effectiveness is another important factor to consider. While neoprene may have a higher initial cost compared to EPDM, its longer lifespan and superior performance in harsh environments often result in lower long-term costs. Silicone rubber tends to be more expensive than both neoprene and EPDM, which may limit its use to specialized applications where its unique properties are essential.

Environmental considerations are becoming increasingly important in the automotive industry. In this aspect, EPDM has an advantage as it is more easily recyclable compared to neoprene. However, recent advancements in neoprene recycling technologies are narrowing this gap.

When it comes to processing and manufacturing, neoprene offers good moldability and can be easily formed into complex shapes required for automotive sealing applications. EPDM and silicone rubber also offer good processability, with silicone rubber having the added advantage of being suitable for liquid injection molding, allowing for the production of intricate seal designs.

In conclusion, while neoprene remains a preferred choice for many automotive sealing applications due to its balanced performance across various criteria, alternative materials like EPDM and silicone rubber offer specific advantages in certain areas. The selection of sealing material ultimately depends on the specific requirements of the application, considering factors such as environmental exposure, temperature range, chemical resistance, cost, and manufacturing processes.

Rubber-based materials, such as EPDM (Ethylene Propylene Diene Monomer) and silicone rubber, are common alternatives to neoprene in automotive sealing. EPDM offers excellent resistance to weathering, ozone, and UV radiation, making it suitable for exterior sealing applications. It also provides good heat resistance and maintains flexibility at low temperatures. Silicone rubber, on the other hand, excels in extreme temperature conditions, offering superior performance in both high and low-temperature environments.

In terms of durability, neoprene generally outperforms EPDM and silicone rubber. It exhibits better resistance to oil, fuel, and other automotive fluids, which is crucial for engine compartment seals and gaskets. Neoprene also maintains its physical properties over a longer period, resulting in extended service life for automotive seals.

Cost-effectiveness is another important factor to consider. While neoprene may have a higher initial cost compared to EPDM, its longer lifespan and superior performance in harsh environments often result in lower long-term costs. Silicone rubber tends to be more expensive than both neoprene and EPDM, which may limit its use to specialized applications where its unique properties are essential.

Environmental considerations are becoming increasingly important in the automotive industry. In this aspect, EPDM has an advantage as it is more easily recyclable compared to neoprene. However, recent advancements in neoprene recycling technologies are narrowing this gap.

When it comes to processing and manufacturing, neoprene offers good moldability and can be easily formed into complex shapes required for automotive sealing applications. EPDM and silicone rubber also offer good processability, with silicone rubber having the added advantage of being suitable for liquid injection molding, allowing for the production of intricate seal designs.

In conclusion, while neoprene remains a preferred choice for many automotive sealing applications due to its balanced performance across various criteria, alternative materials like EPDM and silicone rubber offer specific advantages in certain areas. The selection of sealing material ultimately depends on the specific requirements of the application, considering factors such as environmental exposure, temperature range, chemical resistance, cost, and manufacturing processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!