How Neoprene Enhances the Next-Gen Transportation Gear?

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neoprene in Transport: Evolution and Objectives

Neoprene, a synthetic rubber developed in the 1930s, has played a significant role in the evolution of transportation gear. Initially created as an oil-resistant alternative to natural rubber, neoprene quickly found its way into various applications due to its unique properties. The material's journey in transportation began with its use in automotive components, such as hoses and gaskets, where its resistance to oil, heat, and weathering proved invaluable.

As transportation technologies advanced, so did the applications of neoprene. The material's versatility allowed it to adapt to the changing needs of the industry, from aerospace to marine transport. In the aviation sector, neoprene became crucial for fuel tank linings and insulation materials, contributing to improved safety and efficiency in aircraft design.

The objectives for neoprene in next-generation transportation gear are multifaceted. Primarily, there is a focus on enhancing the material's performance characteristics to meet the increasingly demanding requirements of modern vehicles. This includes improving its thermal stability, reducing weight without compromising strength, and extending its durability under extreme conditions.

Another key objective is to align neoprene's development with sustainability goals. As environmental concerns take center stage in the transportation industry, researchers are exploring ways to make neoprene more eco-friendly. This involves developing bio-based alternatives and improving recycling processes for neoprene products at the end of their lifecycle.

In the automotive sector, the evolution of neoprene aims to support the transition to electric and hybrid vehicles. This includes developing specialized formulations that can withstand the unique challenges posed by electric powertrains, such as enhanced electromagnetic shielding properties and improved thermal management capabilities.

For marine applications, the focus is on creating neoprene variants that offer superior resistance to saltwater and marine organisms, extending the lifespan of underwater components and reducing maintenance needs. In aerospace, research is directed towards ultra-lightweight neoprene composites that can withstand the extreme temperature fluctuations and pressure changes experienced during flight.

The future trajectory of neoprene in transportation gear is closely tied to advancements in material science and nanotechnology. By incorporating nanomaterials and smart polymers, researchers aim to develop neoprene-based products with self-healing properties, adaptive insulation, and even energy-harvesting capabilities. These innovations could revolutionize the way transportation equipment is designed and maintained, leading to safer, more efficient, and more sustainable vehicles across all modes of transport.

As transportation technologies advanced, so did the applications of neoprene. The material's versatility allowed it to adapt to the changing needs of the industry, from aerospace to marine transport. In the aviation sector, neoprene became crucial for fuel tank linings and insulation materials, contributing to improved safety and efficiency in aircraft design.

The objectives for neoprene in next-generation transportation gear are multifaceted. Primarily, there is a focus on enhancing the material's performance characteristics to meet the increasingly demanding requirements of modern vehicles. This includes improving its thermal stability, reducing weight without compromising strength, and extending its durability under extreme conditions.

Another key objective is to align neoprene's development with sustainability goals. As environmental concerns take center stage in the transportation industry, researchers are exploring ways to make neoprene more eco-friendly. This involves developing bio-based alternatives and improving recycling processes for neoprene products at the end of their lifecycle.

In the automotive sector, the evolution of neoprene aims to support the transition to electric and hybrid vehicles. This includes developing specialized formulations that can withstand the unique challenges posed by electric powertrains, such as enhanced electromagnetic shielding properties and improved thermal management capabilities.

For marine applications, the focus is on creating neoprene variants that offer superior resistance to saltwater and marine organisms, extending the lifespan of underwater components and reducing maintenance needs. In aerospace, research is directed towards ultra-lightweight neoprene composites that can withstand the extreme temperature fluctuations and pressure changes experienced during flight.

The future trajectory of neoprene in transportation gear is closely tied to advancements in material science and nanotechnology. By incorporating nanomaterials and smart polymers, researchers aim to develop neoprene-based products with self-healing properties, adaptive insulation, and even energy-harvesting capabilities. These innovations could revolutionize the way transportation equipment is designed and maintained, leading to safer, more efficient, and more sustainable vehicles across all modes of transport.

Market Demand Analysis for Neoprene-Enhanced Gear

The market demand for neoprene-enhanced transportation gear has been steadily increasing in recent years, driven by the growing need for durable, versatile, and high-performance materials in the transportation industry. Neoprene, a synthetic rubber known for its excellent resistance to water, oil, and weathering, has found widespread applications in various transportation sectors, including automotive, marine, aerospace, and personal mobility.

In the automotive industry, neoprene-enhanced gear is gaining traction due to its ability to withstand extreme temperatures and provide superior insulation. The material is increasingly used in gaskets, seals, and hoses, contributing to improved vehicle performance and longevity. As electric vehicles continue to gain market share, the demand for neoprene-based components in battery insulation and thermal management systems is expected to rise significantly.

The marine sector represents another substantial market for neoprene-enhanced gear. With its exceptional water resistance and durability, neoprene is extensively used in boat covers, fenders, and personal flotation devices. The growing recreational boating industry and the expansion of commercial maritime activities are driving the demand for neoprene-based products in this sector.

In the aerospace industry, neoprene's unique properties make it an ideal material for various applications, including insulation, vibration dampening, and sealing. As the aerospace sector continues to innovate and develop more advanced aircraft, the demand for high-performance materials like neoprene is expected to increase.

The personal mobility market, encompassing bicycles, e-scooters, and other micro-mobility solutions, is also contributing to the growing demand for neoprene-enhanced gear. Neoprene is widely used in protective gear, such as knee pads and gloves, as well as in weather-resistant accessories for these vehicles.

Market analysts project that the global neoprene market will experience substantial growth in the coming years, with a significant portion of this growth attributed to transportation-related applications. The increasing focus on sustainability and environmental concerns is also driving innovation in neoprene production, with manufacturers developing eco-friendly alternatives to traditional neoprene.

As urbanization continues and the need for efficient transportation solutions grows, the demand for neoprene-enhanced gear is expected to expand further. The material's versatility, durability, and performance characteristics position it as a key component in the development of next-generation transportation equipment and accessories.

In the automotive industry, neoprene-enhanced gear is gaining traction due to its ability to withstand extreme temperatures and provide superior insulation. The material is increasingly used in gaskets, seals, and hoses, contributing to improved vehicle performance and longevity. As electric vehicles continue to gain market share, the demand for neoprene-based components in battery insulation and thermal management systems is expected to rise significantly.

The marine sector represents another substantial market for neoprene-enhanced gear. With its exceptional water resistance and durability, neoprene is extensively used in boat covers, fenders, and personal flotation devices. The growing recreational boating industry and the expansion of commercial maritime activities are driving the demand for neoprene-based products in this sector.

In the aerospace industry, neoprene's unique properties make it an ideal material for various applications, including insulation, vibration dampening, and sealing. As the aerospace sector continues to innovate and develop more advanced aircraft, the demand for high-performance materials like neoprene is expected to increase.

The personal mobility market, encompassing bicycles, e-scooters, and other micro-mobility solutions, is also contributing to the growing demand for neoprene-enhanced gear. Neoprene is widely used in protective gear, such as knee pads and gloves, as well as in weather-resistant accessories for these vehicles.

Market analysts project that the global neoprene market will experience substantial growth in the coming years, with a significant portion of this growth attributed to transportation-related applications. The increasing focus on sustainability and environmental concerns is also driving innovation in neoprene production, with manufacturers developing eco-friendly alternatives to traditional neoprene.

As urbanization continues and the need for efficient transportation solutions grows, the demand for neoprene-enhanced gear is expected to expand further. The material's versatility, durability, and performance characteristics position it as a key component in the development of next-generation transportation equipment and accessories.

Current Neoprene Applications and Challenges

Neoprene, a synthetic rubber with exceptional properties, has found widespread applications in the transportation industry. Its current uses span across various sectors, including automotive, marine, and aerospace. In automotive applications, neoprene is commonly used in gaskets, seals, and hoses due to its resistance to oil, fuel, and extreme temperatures. It plays a crucial role in maintaining the integrity of engine components and preventing leaks.

In marine transportation, neoprene is utilized in the production of wetsuits, drysuits, and other protective gear for water-based activities. Its excellent insulation properties and resistance to saltwater make it an ideal material for these applications. Additionally, neoprene is used in boat fenders, dock bumpers, and marine hoses, providing durability and protection against impacts and harsh marine environments.

The aerospace industry also benefits from neoprene's unique characteristics. It is used in aircraft seals, gaskets, and vibration dampening components, contributing to the overall safety and performance of aircraft. Neoprene's ability to withstand extreme temperatures and maintain flexibility in various conditions makes it valuable in this sector.

Despite its widespread use, neoprene faces several challenges in next-generation transportation applications. One significant challenge is its environmental impact. Traditional neoprene production involves the use of chloroprene, a potentially harmful chemical. As sustainability becomes increasingly important in the transportation industry, there is a growing need for more eco-friendly alternatives or production methods.

Another challenge is the weight of neoprene components. While neoprene offers excellent durability and resistance properties, it can contribute to the overall weight of vehicles or aircraft. In an era where fuel efficiency and reduced emissions are paramount, there is a demand for lighter materials that can match or exceed neoprene's performance characteristics.

Durability in extreme conditions remains an ongoing challenge. While neoprene performs well in many environments, there is a constant push for materials that can withstand even more severe conditions, particularly in aerospace and high-performance automotive applications. Researchers are exploring ways to enhance neoprene's properties or develop hybrid materials that combine its benefits with those of other advanced materials.

Lastly, the cost of neoprene production and its potential supply chain vulnerabilities pose challenges for widespread adoption in next-generation transportation gear. As the demand for advanced materials grows, there is a need for more cost-effective production methods and a diversified supply chain to ensure consistent availability for manufacturers.

In marine transportation, neoprene is utilized in the production of wetsuits, drysuits, and other protective gear for water-based activities. Its excellent insulation properties and resistance to saltwater make it an ideal material for these applications. Additionally, neoprene is used in boat fenders, dock bumpers, and marine hoses, providing durability and protection against impacts and harsh marine environments.

The aerospace industry also benefits from neoprene's unique characteristics. It is used in aircraft seals, gaskets, and vibration dampening components, contributing to the overall safety and performance of aircraft. Neoprene's ability to withstand extreme temperatures and maintain flexibility in various conditions makes it valuable in this sector.

Despite its widespread use, neoprene faces several challenges in next-generation transportation applications. One significant challenge is its environmental impact. Traditional neoprene production involves the use of chloroprene, a potentially harmful chemical. As sustainability becomes increasingly important in the transportation industry, there is a growing need for more eco-friendly alternatives or production methods.

Another challenge is the weight of neoprene components. While neoprene offers excellent durability and resistance properties, it can contribute to the overall weight of vehicles or aircraft. In an era where fuel efficiency and reduced emissions are paramount, there is a demand for lighter materials that can match or exceed neoprene's performance characteristics.

Durability in extreme conditions remains an ongoing challenge. While neoprene performs well in many environments, there is a constant push for materials that can withstand even more severe conditions, particularly in aerospace and high-performance automotive applications. Researchers are exploring ways to enhance neoprene's properties or develop hybrid materials that combine its benefits with those of other advanced materials.

Lastly, the cost of neoprene production and its potential supply chain vulnerabilities pose challenges for widespread adoption in next-generation transportation gear. As the demand for advanced materials grows, there is a need for more cost-effective production methods and a diversified supply chain to ensure consistent availability for manufacturers.

Existing Neoprene Solutions in Transportation

01 Composition and synthesis of neoprene

Neoprene is a synthetic rubber produced by polymerization of chloroprene. Various methods and compositions are used to synthesize neoprene with specific properties, including the use of different catalysts, additives, and polymerization techniques.- Composition and synthesis of neoprene: Neoprene is a synthetic rubber produced by polymerization of chloroprene. Various methods and compositions are used to synthesize neoprene with specific properties, including the use of different catalysts, additives, and polymerization techniques to control the molecular structure and characteristics of the final product.

- Applications of neoprene in protective gear: Neoprene is widely used in the production of protective gear due to its excellent insulation, flexibility, and durability properties. It is commonly used in wetsuits, diving suits, and other water-resistant clothing. Neoprene-based materials are also used in safety equipment and protective wear for various industries.

- Neoprene foam and cellular structures: Neoprene can be processed into foam or cellular structures, which enhance its insulation and cushioning properties. These foams are used in various applications, including padding, gaskets, and seals. Different techniques are employed to create neoprene foams with specific densities and cell structures for various end-uses.

- Neoprene blends and composites: Neoprene is often blended with other materials or used in composite structures to enhance its properties or create materials with specific characteristics. These blends and composites can improve strength, chemical resistance, or other properties for specialized applications in industries such as automotive, construction, and aerospace.

- Neoprene processing and manufacturing techniques: Various processing and manufacturing techniques are used to produce neoprene products with specific shapes, sizes, and properties. These include extrusion, molding, calendering, and vulcanization processes. Advanced manufacturing methods are continually developed to improve the efficiency and quality of neoprene production.

02 Applications of neoprene in protective gear

Neoprene is widely used in the production of protective gear such as wetsuits, gloves, and other equipment due to its excellent insulation properties, flexibility, and resistance to water and chemicals.Expand Specific Solutions03 Neoprene foam production and properties

Neoprene foam is produced through various foaming processes, resulting in a material with unique properties such as buoyancy, thermal insulation, and shock absorption. Different techniques are used to control the foam's cell structure and density.Expand Specific Solutions04 Neoprene in adhesive and sealant applications

Neoprene-based adhesives and sealants are developed for various industrial applications, offering strong bonding properties, chemical resistance, and durability in harsh environments.Expand Specific Solutions05 Modifications and blends of neoprene

Neoprene is often modified or blended with other materials to enhance its properties or create new materials with specific characteristics. This includes the development of neoprene composites, nanocomposites, and blends with other polymers.Expand Specific Solutions

Key Players in Neoprene and Transport Industries

The competition landscape for neoprene in next-generation transportation gear is evolving rapidly, with the industry in a growth phase. The market size is expanding as demand for high-performance materials in transportation increases. Technologically, neoprene applications are advancing, with companies like ExxonMobil Chemical Patents, DuPont de Nemours, and Tosoh Corp leading innovation. These firms, along with others like Tianjin Pengling Group and Zhuzhou Times New Materials Technology, are developing specialized neoprene formulations for automotive and aerospace applications. The technology's maturity varies across different transportation sectors, with automotive applications being more established while aerospace and high-speed rail uses are still emerging.

Denka Corp.

Technical Solution: Denka Corporation has been at the forefront of neoprene innovation for next-generation transportation gear. Their research focuses on developing high-performance neoprene compounds that offer enhanced chemical resistance and durability. Denka's advanced neoprene formulations incorporate proprietary cross-linking technologies, resulting in materials with improved heat resistance and mechanical properties[7]. These innovations have led to the creation of neoprene-based components for fuel systems, engine mounts, and transmission seals that can withstand the harsh conditions in modern vehicles[9]. Denka has also been exploring the use of their advanced neoprene in electric vehicle applications, particularly for battery insulation and thermal management systems[11].

Strengths: Specialized expertise in neoprene chemistry, strong focus on high-performance applications, and adaptability to emerging transportation technologies. Weaknesses: Potential limitations in scaling production and higher material costs.

NOK Corp.

Technical Solution: NOK Corporation has developed innovative neoprene-based solutions for next-generation transportation gear, focusing on sealing and vibration control applications. Their research has led to the creation of advanced neoprene compounds with improved ozone resistance and low-temperature flexibility, crucial for automotive and aerospace applications[8]. NOK's neoprene technologies include specialized formulations for dynamic sealing in electric vehicle powertrains, offering enhanced durability and reduced friction[10]. The company has also developed neoprene-based materials with self-lubricating properties, which can significantly extend the lifespan of various vehicle components[12].

Strengths: Specialized in sealing and vibration control applications, strong presence in automotive and aerospace industries, and focus on performance-enhancing properties. Weaknesses: Potential limitations in broader material applications beyond sealing and vibration control.

Innovative Neoprene Technologies for Transport

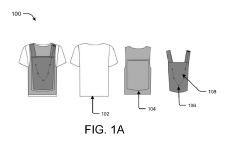

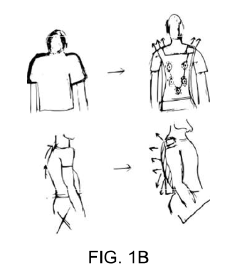

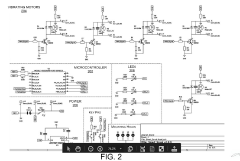

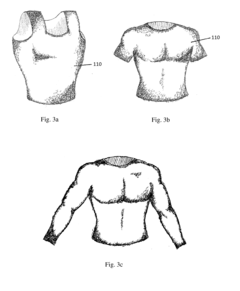

Smart scrubs with posture correction

PatentPendingIN202341056831A

Innovation

- A smart wearable garment with a cotton outer layer, an organic cotton spandex inner layer, and a posture control unit composed of neoprene and silicone rubber, featuring vibratory motors with adjustable frequencies powered by a rechargeable battery, integrated into the garment for seamless wear and extended use.

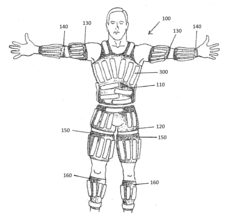

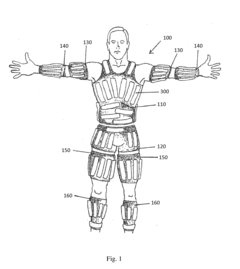

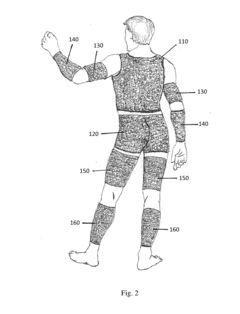

Exoskeleton system

PatentInactiveUS20150264984A1

Innovation

- An exoskeleton system with a plush outer surface and hook and loop fasteners allowing attachment of devices and weights on any body part, combined with a multilayer construction for compressive support and protection, enabling customizable resistance training and protection during high-impact activities.

Environmental Impact of Neoprene in Transportation

The environmental impact of neoprene in transportation is a critical consideration as the material gains prominence in next-generation gear. Neoprene, a synthetic rubber, offers numerous benefits for transportation applications, but its production and disposal processes raise environmental concerns.

Neoprene manufacturing involves the use of petroleum-based chemicals, which contribute to greenhouse gas emissions and resource depletion. The production process releases volatile organic compounds (VOCs) and other pollutants, potentially affecting air quality in surrounding areas. Additionally, the energy-intensive nature of neoprene production further increases its carbon footprint.

Water pollution is another significant concern associated with neoprene manufacturing. The process generates wastewater containing harmful chemicals, which, if not properly treated, can contaminate local water sources and ecosystems. This poses risks to aquatic life and human health in affected areas.

Despite these challenges, advancements in production techniques are mitigating some of neoprene's environmental impacts. Closed-loop manufacturing systems and improved filtration technologies are reducing emissions and wastewater contamination. Some manufacturers are also exploring bio-based alternatives to traditional petroleum-derived neoprene, aiming to decrease reliance on fossil fuels.

The durability of neoprene contributes to its environmental profile in transportation applications. Its resistance to wear, tear, and environmental factors extends the lifespan of transportation gear, potentially reducing the need for frequent replacements and associated resource consumption. This longevity can offset some of the environmental costs associated with its production.

End-of-life considerations for neoprene products present both challenges and opportunities. While neoprene is not biodegradable, it can be recycled through specialized processes. However, the current infrastructure for neoprene recycling is limited, leading to a significant portion of used neoprene products ending up in landfills or incineration facilities.

Efforts are underway to improve neoprene's recyclability and develop more efficient recycling processes. Some companies are implementing take-back programs for used neoprene products, ensuring proper recycling and reducing waste. Research into chemical recycling methods shows promise for breaking down neoprene into its constituent materials, potentially enabling closed-loop recycling systems.

As the transportation industry continues to adopt neoprene-enhanced gear, balancing its performance benefits with environmental considerations becomes crucial. Ongoing research and development focus on improving production efficiency, exploring sustainable alternatives, and enhancing end-of-life management to minimize neoprene's environmental footprint in transportation applications.

Neoprene manufacturing involves the use of petroleum-based chemicals, which contribute to greenhouse gas emissions and resource depletion. The production process releases volatile organic compounds (VOCs) and other pollutants, potentially affecting air quality in surrounding areas. Additionally, the energy-intensive nature of neoprene production further increases its carbon footprint.

Water pollution is another significant concern associated with neoprene manufacturing. The process generates wastewater containing harmful chemicals, which, if not properly treated, can contaminate local water sources and ecosystems. This poses risks to aquatic life and human health in affected areas.

Despite these challenges, advancements in production techniques are mitigating some of neoprene's environmental impacts. Closed-loop manufacturing systems and improved filtration technologies are reducing emissions and wastewater contamination. Some manufacturers are also exploring bio-based alternatives to traditional petroleum-derived neoprene, aiming to decrease reliance on fossil fuels.

The durability of neoprene contributes to its environmental profile in transportation applications. Its resistance to wear, tear, and environmental factors extends the lifespan of transportation gear, potentially reducing the need for frequent replacements and associated resource consumption. This longevity can offset some of the environmental costs associated with its production.

End-of-life considerations for neoprene products present both challenges and opportunities. While neoprene is not biodegradable, it can be recycled through specialized processes. However, the current infrastructure for neoprene recycling is limited, leading to a significant portion of used neoprene products ending up in landfills or incineration facilities.

Efforts are underway to improve neoprene's recyclability and develop more efficient recycling processes. Some companies are implementing take-back programs for used neoprene products, ensuring proper recycling and reducing waste. Research into chemical recycling methods shows promise for breaking down neoprene into its constituent materials, potentially enabling closed-loop recycling systems.

As the transportation industry continues to adopt neoprene-enhanced gear, balancing its performance benefits with environmental considerations becomes crucial. Ongoing research and development focus on improving production efficiency, exploring sustainable alternatives, and enhancing end-of-life management to minimize neoprene's environmental footprint in transportation applications.

Safety Standards for Neoprene-Enhanced Transport Equipment

The safety standards for neoprene-enhanced transport equipment are crucial in ensuring the reliability and effectiveness of next-generation transportation gear. These standards encompass a wide range of considerations, from material properties to performance requirements under various conditions.

Neoprene, a synthetic rubber known for its excellent resistance to oil, heat, and weathering, has become increasingly popular in transportation applications. As such, safety standards have been developed to address its unique characteristics when used in transport equipment.

One of the primary safety considerations is the fire resistance of neoprene-enhanced gear. Standards typically require that neoprene components meet specific flame retardancy tests, such as the UL 94 vertical burn test or ASTM D635. These tests evaluate the material's ability to self-extinguish and resist flame spread, crucial factors in transportation safety.

Durability and wear resistance are also key aspects of safety standards for neoprene-enhanced transport equipment. Accelerated aging tests, such as those outlined in ASTM D573, are used to assess the long-term performance of neoprene components under various environmental conditions. These tests help ensure that the material maintains its protective properties throughout the equipment's intended lifespan.

Chemical resistance is another critical factor addressed by safety standards. Neoprene's resistance to oils, fuels, and other chemicals commonly encountered in transportation environments is evaluated using standardized testing methods like ASTM D471. This ensures that neoprene-enhanced equipment maintains its integrity when exposed to potentially harmful substances.

Safety standards also focus on the mechanical properties of neoprene-enhanced transport gear. Tensile strength, elongation, and tear resistance are typically assessed using methods such as ASTM D412 and ASTM D624. These tests help guarantee that the equipment can withstand the stresses and strains associated with transportation applications.

Environmental considerations play a significant role in modern safety standards. Regulations often require that neoprene-enhanced transport equipment meet specific criteria for recyclability and environmental impact. This may include standards for the use of eco-friendly additives and manufacturing processes that minimize harmful emissions.

Lastly, safety standards for neoprene-enhanced transport equipment often incorporate requirements for quality control and traceability. Manufacturers may be required to implement rigorous testing and documentation procedures to ensure consistency and reliability in their products. This helps maintain high safety standards across the industry and facilitates rapid identification and resolution of any potential issues.

Neoprene, a synthetic rubber known for its excellent resistance to oil, heat, and weathering, has become increasingly popular in transportation applications. As such, safety standards have been developed to address its unique characteristics when used in transport equipment.

One of the primary safety considerations is the fire resistance of neoprene-enhanced gear. Standards typically require that neoprene components meet specific flame retardancy tests, such as the UL 94 vertical burn test or ASTM D635. These tests evaluate the material's ability to self-extinguish and resist flame spread, crucial factors in transportation safety.

Durability and wear resistance are also key aspects of safety standards for neoprene-enhanced transport equipment. Accelerated aging tests, such as those outlined in ASTM D573, are used to assess the long-term performance of neoprene components under various environmental conditions. These tests help ensure that the material maintains its protective properties throughout the equipment's intended lifespan.

Chemical resistance is another critical factor addressed by safety standards. Neoprene's resistance to oils, fuels, and other chemicals commonly encountered in transportation environments is evaluated using standardized testing methods like ASTM D471. This ensures that neoprene-enhanced equipment maintains its integrity when exposed to potentially harmful substances.

Safety standards also focus on the mechanical properties of neoprene-enhanced transport gear. Tensile strength, elongation, and tear resistance are typically assessed using methods such as ASTM D412 and ASTM D624. These tests help guarantee that the equipment can withstand the stresses and strains associated with transportation applications.

Environmental considerations play a significant role in modern safety standards. Regulations often require that neoprene-enhanced transport equipment meet specific criteria for recyclability and environmental impact. This may include standards for the use of eco-friendly additives and manufacturing processes that minimize harmful emissions.

Lastly, safety standards for neoprene-enhanced transport equipment often incorporate requirements for quality control and traceability. Manufacturers may be required to implement rigorous testing and documentation procedures to ensure consistency and reliability in their products. This helps maintain high safety standards across the industry and facilitates rapid identification and resolution of any potential issues.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!