How Neoprene Enhances the Versatility of Industrial Gaskets?

AUG 5, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neoprene Gasket Evolution

The evolution of neoprene gaskets represents a significant milestone in the industrial sealing industry. Neoprene, a synthetic rubber developed by DuPont in 1930, quickly gained prominence due to its exceptional properties, including resistance to oil, heat, and weathering. These characteristics made it an ideal material for gasket applications across various industries.

In the early stages of neoprene gasket development, the focus was primarily on improving the material's durability and chemical resistance. Manufacturers experimented with different formulations to enhance its performance in harsh industrial environments. As the technology progressed, the emphasis shifted towards optimizing the manufacturing processes to produce gaskets with more consistent quality and tighter tolerances.

The 1960s and 1970s saw a significant leap in neoprene gasket technology with the introduction of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. These advancements allowed for more precise gasket designs and improved production efficiency. Concurrently, new compounding techniques were developed, enabling the creation of neoprene blends tailored for specific applications, such as high-temperature environments or exposure to aggressive chemicals.

The late 20th century brought about a focus on environmental concerns and energy efficiency. This led to the development of neoprene gaskets with improved compression set resistance and lower outgassing properties, making them suitable for use in sensitive electronic equipment and clean room environments. Additionally, manufacturers began exploring ways to reduce the environmental impact of neoprene production and disposal.

In recent years, the evolution of neoprene gaskets has been driven by the demand for more versatile and high-performance sealing solutions. Advanced manufacturing techniques, such as precision die-cutting and water jet cutting, have enabled the production of complex gasket shapes with tight tolerances. Moreover, the integration of neoprene with other materials, like metal reinforcements or PTFE coatings, has further expanded the application range of these gaskets.

The ongoing research in nanocomposite technology is opening new avenues for neoprene gasket evolution. By incorporating nanoparticles into the neoprene matrix, researchers aim to enhance properties such as thermal conductivity, electrical insulation, and wear resistance. This could potentially lead to a new generation of neoprene gaskets capable of meeting the increasingly demanding requirements of modern industrial applications.

In the early stages of neoprene gasket development, the focus was primarily on improving the material's durability and chemical resistance. Manufacturers experimented with different formulations to enhance its performance in harsh industrial environments. As the technology progressed, the emphasis shifted towards optimizing the manufacturing processes to produce gaskets with more consistent quality and tighter tolerances.

The 1960s and 1970s saw a significant leap in neoprene gasket technology with the introduction of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. These advancements allowed for more precise gasket designs and improved production efficiency. Concurrently, new compounding techniques were developed, enabling the creation of neoprene blends tailored for specific applications, such as high-temperature environments or exposure to aggressive chemicals.

The late 20th century brought about a focus on environmental concerns and energy efficiency. This led to the development of neoprene gaskets with improved compression set resistance and lower outgassing properties, making them suitable for use in sensitive electronic equipment and clean room environments. Additionally, manufacturers began exploring ways to reduce the environmental impact of neoprene production and disposal.

In recent years, the evolution of neoprene gaskets has been driven by the demand for more versatile and high-performance sealing solutions. Advanced manufacturing techniques, such as precision die-cutting and water jet cutting, have enabled the production of complex gasket shapes with tight tolerances. Moreover, the integration of neoprene with other materials, like metal reinforcements or PTFE coatings, has further expanded the application range of these gaskets.

The ongoing research in nanocomposite technology is opening new avenues for neoprene gasket evolution. By incorporating nanoparticles into the neoprene matrix, researchers aim to enhance properties such as thermal conductivity, electrical insulation, and wear resistance. This could potentially lead to a new generation of neoprene gaskets capable of meeting the increasingly demanding requirements of modern industrial applications.

Industrial Demand Analysis

The industrial demand for neoprene-enhanced gaskets has seen significant growth in recent years, driven by the material's unique properties and versatility across various sectors. Neoprene, a synthetic rubber known for its excellent resistance to oil, heat, and weathering, has become a preferred choice for industrial gasket applications.

In the oil and gas industry, neoprene gaskets are increasingly sought after due to their ability to withstand harsh environments and maintain seal integrity under extreme pressures and temperatures. The sector's expansion, particularly in offshore drilling and exploration, has fueled the demand for high-performance sealing solutions, with neoprene gaskets playing a crucial role in preventing leaks and ensuring operational safety.

The automotive industry represents another major market for neoprene gaskets. As vehicle manufacturers strive for improved fuel efficiency and reduced emissions, the need for lightweight yet durable sealing components has grown. Neoprene gaskets offer an excellent balance of weight reduction and performance, contributing to their increased adoption in engine compartments, transmission systems, and other critical areas.

Chemical processing plants have also contributed to the rising demand for neoprene gaskets. The material's resistance to a wide range of chemicals makes it ideal for use in pipelines, reactors, and storage tanks. As the chemical industry continues to expand and diversify, the need for reliable sealing solutions capable of handling corrosive substances has intensified, further driving the demand for neoprene-enhanced gaskets.

The HVAC (Heating, Ventilation, and Air Conditioning) sector has emerged as a significant consumer of neoprene gaskets. With increasing emphasis on energy efficiency and indoor air quality, HVAC systems require robust sealing solutions to prevent air leakage and maintain optimal performance. Neoprene gaskets' ability to withstand temperature fluctuations and resist degradation from UV exposure makes them particularly suitable for these applications.

In the food and beverage industry, neoprene gaskets have gained traction due to their compliance with food safety regulations and resistance to oils and fats. The material's non-toxic nature and ability to maintain its properties in both hot and cold environments have made it a preferred choice for sealing applications in processing equipment, storage tanks, and packaging machinery.

The marine industry has also contributed to the growing demand for neoprene gaskets. Their excellent resistance to saltwater, UV radiation, and ozone makes them ideal for use in shipbuilding, offshore platforms, and marine equipment. As global trade and maritime activities continue to expand, the need for durable and reliable sealing solutions in marine environments has increased correspondingly.

In the oil and gas industry, neoprene gaskets are increasingly sought after due to their ability to withstand harsh environments and maintain seal integrity under extreme pressures and temperatures. The sector's expansion, particularly in offshore drilling and exploration, has fueled the demand for high-performance sealing solutions, with neoprene gaskets playing a crucial role in preventing leaks and ensuring operational safety.

The automotive industry represents another major market for neoprene gaskets. As vehicle manufacturers strive for improved fuel efficiency and reduced emissions, the need for lightweight yet durable sealing components has grown. Neoprene gaskets offer an excellent balance of weight reduction and performance, contributing to their increased adoption in engine compartments, transmission systems, and other critical areas.

Chemical processing plants have also contributed to the rising demand for neoprene gaskets. The material's resistance to a wide range of chemicals makes it ideal for use in pipelines, reactors, and storage tanks. As the chemical industry continues to expand and diversify, the need for reliable sealing solutions capable of handling corrosive substances has intensified, further driving the demand for neoprene-enhanced gaskets.

The HVAC (Heating, Ventilation, and Air Conditioning) sector has emerged as a significant consumer of neoprene gaskets. With increasing emphasis on energy efficiency and indoor air quality, HVAC systems require robust sealing solutions to prevent air leakage and maintain optimal performance. Neoprene gaskets' ability to withstand temperature fluctuations and resist degradation from UV exposure makes them particularly suitable for these applications.

In the food and beverage industry, neoprene gaskets have gained traction due to their compliance with food safety regulations and resistance to oils and fats. The material's non-toxic nature and ability to maintain its properties in both hot and cold environments have made it a preferred choice for sealing applications in processing equipment, storage tanks, and packaging machinery.

The marine industry has also contributed to the growing demand for neoprene gaskets. Their excellent resistance to saltwater, UV radiation, and ozone makes them ideal for use in shipbuilding, offshore platforms, and marine equipment. As global trade and maritime activities continue to expand, the need for durable and reliable sealing solutions in marine environments has increased correspondingly.

Neoprene Gasket Challenges

Despite the numerous advantages of neoprene gaskets in industrial applications, several challenges persist in their development and implementation. One of the primary issues is the material's susceptibility to degradation when exposed to certain chemicals and extreme temperatures. While neoprene exhibits good resistance to many substances, prolonged contact with strong oxidizing agents, aromatic hydrocarbons, or chlorinated solvents can lead to deterioration, compromising the gasket's integrity and performance.

Temperature fluctuations pose another significant challenge for neoprene gaskets. Although they generally perform well within a temperature range of -40°C to 120°C, extreme heat or cold can cause the material to become brittle or lose its elasticity. This limitation restricts their use in high-temperature industrial processes or cryogenic applications, necessitating the development of specialized formulations or alternative materials for such environments.

The compression set of neoprene gaskets is another area of concern. Over time and under constant pressure, neoprene may experience permanent deformation, reducing its ability to maintain an effective seal. This issue is particularly problematic in applications requiring long-term, stable sealing performance, such as in pressure vessels or fluid handling systems.

Neoprene's electrical conductivity presents both advantages and challenges. While its conductive properties make it suitable for certain electrical applications, they can also limit its use in scenarios where electrical insulation is crucial. Balancing these properties to meet diverse industrial needs remains an ongoing challenge for manufacturers and engineers.

The manufacturing process of neoprene gaskets also faces challenges in achieving consistent quality and precise dimensions. Variations in raw material composition, curing conditions, and molding techniques can lead to inconsistencies in the final product's properties. Ensuring uniformity across large production batches while maintaining tight tolerances is essential for critical industrial applications but remains a complex task.

Environmental concerns and regulatory pressures add another layer of complexity to neoprene gasket production. The chloroprene rubber used in neoprene manufacturing has been subject to scrutiny due to potential environmental and health impacts. Developing more sustainable production methods and exploring eco-friendly alternatives without compromising performance is an ongoing challenge for the industry.

Lastly, the cost-effectiveness of neoprene gaskets in comparison to newer, high-performance elastomers is a persistent issue. As industries demand increasingly specialized sealing solutions, balancing the cost-benefit ratio of neoprene against more advanced but expensive materials becomes crucial for manufacturers and end-users alike.

Temperature fluctuations pose another significant challenge for neoprene gaskets. Although they generally perform well within a temperature range of -40°C to 120°C, extreme heat or cold can cause the material to become brittle or lose its elasticity. This limitation restricts their use in high-temperature industrial processes or cryogenic applications, necessitating the development of specialized formulations or alternative materials for such environments.

The compression set of neoprene gaskets is another area of concern. Over time and under constant pressure, neoprene may experience permanent deformation, reducing its ability to maintain an effective seal. This issue is particularly problematic in applications requiring long-term, stable sealing performance, such as in pressure vessels or fluid handling systems.

Neoprene's electrical conductivity presents both advantages and challenges. While its conductive properties make it suitable for certain electrical applications, they can also limit its use in scenarios where electrical insulation is crucial. Balancing these properties to meet diverse industrial needs remains an ongoing challenge for manufacturers and engineers.

The manufacturing process of neoprene gaskets also faces challenges in achieving consistent quality and precise dimensions. Variations in raw material composition, curing conditions, and molding techniques can lead to inconsistencies in the final product's properties. Ensuring uniformity across large production batches while maintaining tight tolerances is essential for critical industrial applications but remains a complex task.

Environmental concerns and regulatory pressures add another layer of complexity to neoprene gasket production. The chloroprene rubber used in neoprene manufacturing has been subject to scrutiny due to potential environmental and health impacts. Developing more sustainable production methods and exploring eco-friendly alternatives without compromising performance is an ongoing challenge for the industry.

Lastly, the cost-effectiveness of neoprene gaskets in comparison to newer, high-performance elastomers is a persistent issue. As industries demand increasingly specialized sealing solutions, balancing the cost-benefit ratio of neoprene against more advanced but expensive materials becomes crucial for manufacturers and end-users alike.

Current Neoprene Solutions

01 Chemical resistance and durability

Neoprene gaskets exhibit excellent resistance to various chemicals, oils, and weathering conditions. This makes them suitable for use in harsh environments and applications requiring long-term durability. The material's ability to withstand degradation from exposure to different substances contributes to its versatility in industrial and automotive settings.- Chemical resistance and durability: Neoprene gaskets exhibit excellent resistance to various chemicals, oils, and weathering conditions. This makes them highly versatile for use in diverse industrial applications, including automotive, marine, and chemical processing industries. Their durability and ability to maintain properties under harsh conditions contribute to their widespread use.

- Temperature range adaptability: Neoprene gaskets can function effectively across a wide range of temperatures, from very low to moderately high. This temperature versatility allows them to be used in various environments and applications, such as refrigeration systems, automotive engines, and industrial machinery, where temperature fluctuations are common.

- Compression set resistance: Neoprene gaskets demonstrate good compression set resistance, meaning they can maintain their shape and sealing properties even after prolonged periods of compression. This characteristic makes them suitable for applications requiring long-term sealing performance, such as in construction, automotive, and industrial equipment.

- Flexibility and conformability: The inherent flexibility of neoprene allows gaskets made from this material to conform well to irregular surfaces and accommodate slight misalignments. This property enhances their sealing effectiveness in various applications, including electrical enclosures, HVAC systems, and marine equipment, where perfect surface matching may be challenging.

- Customization and fabrication ease: Neoprene gaskets can be easily customized and fabricated into various shapes, sizes, and profiles. This versatility in manufacturing allows for the creation of specialized gaskets for unique applications across different industries. The material can be molded, extruded, or die-cut to meet specific requirements, making it adaptable to a wide range of sealing needs.

02 Temperature range and flexibility

Neoprene gaskets maintain their flexibility and sealing properties across a wide temperature range. This characteristic allows them to be used in applications involving both high and low temperatures, making them versatile for various industrial and automotive uses. The material's ability to remain pliable in different temperature conditions enhances its sealing effectiveness.Expand Specific Solutions03 Compression set resistance

Neoprene gaskets demonstrate good compression set resistance, allowing them to maintain their shape and sealing properties even after prolonged periods of compression. This quality makes them suitable for applications requiring long-term sealing performance and contributes to their versatility in various industries.Expand Specific Solutions04 Customization and formulation

Neoprene can be formulated and customized to meet specific application requirements. By adjusting the composition and manufacturing process, neoprene gaskets can be tailored to achieve desired properties such as hardness, tensile strength, and elongation. This adaptability enhances their versatility across different industries and applications.Expand Specific Solutions05 Vibration and noise dampening

Neoprene gaskets possess excellent vibration and noise dampening properties. This characteristic makes them suitable for applications where reducing vibration transmission and noise is crucial, such as in automotive and industrial machinery. The material's ability to absorb vibrations contributes to its versatility in various engineering applications.Expand Specific Solutions

Key Gasket Manufacturers

The market for neoprene-enhanced industrial gaskets is in a growth phase, driven by increasing demand for versatile sealing solutions across various industries. The global market size is estimated to be in the billions, with steady expansion projected due to neoprene's unique properties. Technologically, neoprene gaskets are mature but continue to evolve, with companies like W. L. Gore & Associates, Parker-Hannifin, and Freudenberg-NOK Sealing Technologies leading innovation. These firms, along with others like ExxonMobil Chemical and Goodyear, are investing in R&D to improve neoprene formulations and manufacturing processes, enhancing gasket performance in extreme conditions and expanding applications across automotive, aerospace, and industrial sectors.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has developed advanced neoprene-based gasket materials that enhance industrial sealing performance. Their proprietary technology combines neoprene with expanded PTFE to create a hybrid material that offers superior chemical resistance and flexibility[1]. This composite gasket material maintains its sealing properties under extreme temperature and pressure conditions, making it ideal for use in chemical processing and oil refinery applications[2]. Gore's neoprene-enhanced gaskets also feature a unique surface texture that improves conformability to flange surfaces, reducing the risk of leaks in critical industrial systems[3].

Strengths: Excellent chemical resistance, high temperature tolerance, and improved conformability. Weaknesses: Potentially higher cost compared to standard neoprene gaskets, and may require specialized installation techniques.

Parker-Hannifin Corp.

Technical Solution: Parker-Hannifin has innovated in the field of neoprene-based industrial gaskets by developing a proprietary compound that enhances the material's resistance to compression set. Their advanced neoprene formulation incorporates nano-scale reinforcing agents that significantly improve the gasket's ability to maintain a tight seal over extended periods[4]. This technology is particularly beneficial in applications with frequent thermal cycling or vibration. Parker's neoprene gaskets also feature a self-lubricating surface treatment that reduces friction during installation and removal, extending the overall lifespan of the sealing system[5]. The company has further enhanced the versatility of their neoprene gaskets by introducing a range of custom-engineered profiles that optimize sealing performance for specific industrial applications[6].

Strengths: Excellent compression set resistance, improved longevity, and application-specific designs. Weaknesses: May be more expensive than standard neoprene gaskets, and could require specialized handling during installation.

Neoprene Gasket Innovations

gaskets

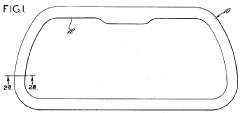

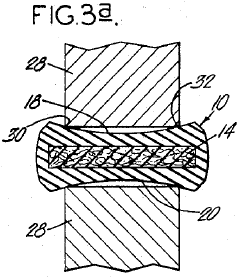

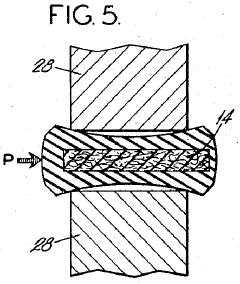

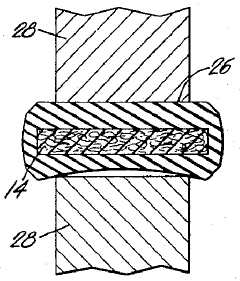

PatentInactiveUS3729205A

Innovation

- A gasket design featuring a fibrous insert with thick rubber coatings on upper and lower surfaces for sealing and thin coatings on edges, produced using a mold with an auto-setting neoprene latex compound, providing improved sealing integrity and resistance to creep and oil penetration.

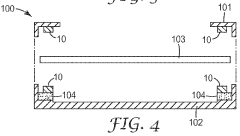

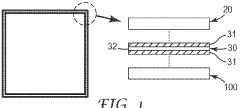

Gasket and display apparatus using the same

PatentWO2010033708A2

Innovation

- A gasket with a support layer, a blocking pad layer made of an acrylic polymer resin composition comprising a urethane acrylate oligomer, a first acrylic monomer with a lower glass transition temperature, and a second acrylic monomer with a higher glass transition temperature, along with a filler, and an adhesive layer, which provides improved cushion and anti-slip properties without the need for separate adhesives.

Environmental Impact

The environmental impact of neoprene in industrial gaskets is a crucial consideration in today's sustainability-focused industrial landscape. Neoprene, a synthetic rubber, offers significant advantages in terms of durability and versatility, but its production and disposal processes raise important environmental concerns.

The manufacturing of neoprene involves the use of petroleum-based chemicals, which contribute to carbon emissions and potential environmental pollution. The production process requires substantial energy inputs, further increasing its carbon footprint. However, the long-lasting nature of neoprene gaskets can offset some of these impacts by reducing the frequency of replacement and, consequently, the overall material consumption over time.

In terms of disposal, neoprene presents challenges due to its non-biodegradable nature. When neoprene gaskets reach the end of their lifecycle, they often end up in landfills, where they can persist for extended periods. This longevity in the environment raises concerns about long-term ecological effects and the accumulation of synthetic materials in ecosystems.

Despite these challenges, recent advancements in recycling technologies have shown promise for mitigating the environmental impact of neoprene. Some innovative processes can break down neoprene into its component materials, allowing for the recovery and reuse of valuable resources. These recycling methods, while still in development, offer potential pathways for reducing the environmental footprint of neoprene gaskets.

The use of neoprene in industrial gaskets also contributes to environmental protection in certain applications. Its excellent resistance to chemicals, oils, and extreme temperatures makes it an effective sealant in potentially hazardous industrial environments. This property helps prevent leaks and spills of harmful substances, thereby protecting soil and water resources from contamination.

Furthermore, the versatility of neoprene allows for the creation of custom-fit gaskets that provide superior sealing performance. This enhanced sealing efficiency can lead to improved energy efficiency in industrial processes, potentially reducing overall energy consumption and associated environmental impacts.

In conclusion, while the production and disposal of neoprene gaskets pose environmental challenges, their durability, versatility, and potential for recycling offer opportunities for mitigating these impacts. As industries continue to prioritize sustainability, ongoing research and development in eco-friendly alternatives and improved recycling technologies will be crucial in balancing the performance benefits of neoprene with environmental considerations.

The manufacturing of neoprene involves the use of petroleum-based chemicals, which contribute to carbon emissions and potential environmental pollution. The production process requires substantial energy inputs, further increasing its carbon footprint. However, the long-lasting nature of neoprene gaskets can offset some of these impacts by reducing the frequency of replacement and, consequently, the overall material consumption over time.

In terms of disposal, neoprene presents challenges due to its non-biodegradable nature. When neoprene gaskets reach the end of their lifecycle, they often end up in landfills, where they can persist for extended periods. This longevity in the environment raises concerns about long-term ecological effects and the accumulation of synthetic materials in ecosystems.

Despite these challenges, recent advancements in recycling technologies have shown promise for mitigating the environmental impact of neoprene. Some innovative processes can break down neoprene into its component materials, allowing for the recovery and reuse of valuable resources. These recycling methods, while still in development, offer potential pathways for reducing the environmental footprint of neoprene gaskets.

The use of neoprene in industrial gaskets also contributes to environmental protection in certain applications. Its excellent resistance to chemicals, oils, and extreme temperatures makes it an effective sealant in potentially hazardous industrial environments. This property helps prevent leaks and spills of harmful substances, thereby protecting soil and water resources from contamination.

Furthermore, the versatility of neoprene allows for the creation of custom-fit gaskets that provide superior sealing performance. This enhanced sealing efficiency can lead to improved energy efficiency in industrial processes, potentially reducing overall energy consumption and associated environmental impacts.

In conclusion, while the production and disposal of neoprene gaskets pose environmental challenges, their durability, versatility, and potential for recycling offer opportunities for mitigating these impacts. As industries continue to prioritize sustainability, ongoing research and development in eco-friendly alternatives and improved recycling technologies will be crucial in balancing the performance benefits of neoprene with environmental considerations.

Cost-Benefit Analysis

The cost-benefit analysis of incorporating neoprene into industrial gaskets reveals significant advantages that justify its widespread adoption. Initially, the upfront costs of neoprene gaskets may be higher compared to traditional materials like rubber or cork. However, the long-term benefits far outweigh this initial investment.

Neoprene gaskets offer superior durability and resistance to various environmental factors, including chemicals, oils, and extreme temperatures. This enhanced resilience translates into extended service life, reducing the frequency of replacements and associated maintenance costs. In industrial settings where downtime is costly, the reliability of neoprene gaskets contributes to improved operational efficiency and reduced production interruptions.

The versatility of neoprene allows for its use across a wide range of applications, from automotive to aerospace industries. This adaptability reduces the need for multiple specialized gasket materials, simplifying inventory management and potentially lowering overall procurement costs. Furthermore, neoprene's excellent sealing properties ensure better containment of fluids and gases, minimizing leakage-related losses and enhancing safety standards.

From an environmental perspective, the durability of neoprene gaskets contributes to reduced waste generation over time. While the initial production of neoprene may have a higher environmental impact compared to some alternatives, its longevity offsets this by reducing the frequency of replacement and disposal.

The cost savings associated with neoprene gaskets extend beyond direct material expenses. Improved sealing efficiency can lead to energy savings in systems where maintaining pressure or temperature is critical. Additionally, the reduced risk of leaks and failures contributes to lower potential liability costs and improved workplace safety.

When considering labor costs, the ease of installation and removal of neoprene gaskets, coupled with their longer service life, results in reduced man-hours spent on maintenance and replacement activities. This efficiency can lead to significant labor cost savings over the lifecycle of industrial equipment.

While the initial investment in neoprene gaskets may be higher, the total cost of ownership analysis demonstrates clear long-term economic benefits. The combination of extended service life, reduced maintenance requirements, improved operational efficiency, and enhanced safety features positions neoprene as a cost-effective solution for industrial gasket applications.

Neoprene gaskets offer superior durability and resistance to various environmental factors, including chemicals, oils, and extreme temperatures. This enhanced resilience translates into extended service life, reducing the frequency of replacements and associated maintenance costs. In industrial settings where downtime is costly, the reliability of neoprene gaskets contributes to improved operational efficiency and reduced production interruptions.

The versatility of neoprene allows for its use across a wide range of applications, from automotive to aerospace industries. This adaptability reduces the need for multiple specialized gasket materials, simplifying inventory management and potentially lowering overall procurement costs. Furthermore, neoprene's excellent sealing properties ensure better containment of fluids and gases, minimizing leakage-related losses and enhancing safety standards.

From an environmental perspective, the durability of neoprene gaskets contributes to reduced waste generation over time. While the initial production of neoprene may have a higher environmental impact compared to some alternatives, its longevity offsets this by reducing the frequency of replacement and disposal.

The cost savings associated with neoprene gaskets extend beyond direct material expenses. Improved sealing efficiency can lead to energy savings in systems where maintaining pressure or temperature is critical. Additionally, the reduced risk of leaks and failures contributes to lower potential liability costs and improved workplace safety.

When considering labor costs, the ease of installation and removal of neoprene gaskets, coupled with their longer service life, results in reduced man-hours spent on maintenance and replacement activities. This efficiency can lead to significant labor cost savings over the lifecycle of industrial equipment.

While the initial investment in neoprene gaskets may be higher, the total cost of ownership analysis demonstrates clear long-term economic benefits. The combination of extended service life, reduced maintenance requirements, improved operational efficiency, and enhanced safety features positions neoprene as a cost-effective solution for industrial gasket applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!