How Neoprene Underpins Protective Sports Gear?

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neoprene in Sports Gear: Evolution and Objectives

Neoprene, a synthetic rubber developed in the 1930s, has become a cornerstone material in protective sports gear. Its journey from a laboratory innovation to an essential component in athletic equipment spans nearly a century, marked by continuous advancements and adaptations to meet evolving sports safety requirements.

The evolution of neoprene in sports gear began with its initial application in wetsuits for water sports in the 1950s. Recognizing its unique properties of flexibility, durability, and insulation, manufacturers soon began exploring its potential in other sporting contexts. By the 1970s, neoprene had found its way into various protective gear, including knee braces, elbow pads, and shin guards.

The 1980s and 1990s saw a significant expansion in neoprene's use across multiple sports disciplines. Its shock-absorbing qualities made it ideal for contact sports like football and rugby, while its thermal properties continued to benefit water sports enthusiasts. This period also witnessed the development of more specialized neoprene formulations, tailored to specific sporting needs.

In recent years, the focus has shifted towards enhancing neoprene's performance characteristics. Researchers and manufacturers have been working on improving its breathability, reducing weight, and increasing its resistance to wear and tear. The advent of composite materials has led to the creation of neoprene blends that offer superior protection while maintaining flexibility and comfort.

The primary objective of neoprene in sports gear is to provide effective protection against impacts, abrasions, and environmental factors without compromising an athlete's mobility or performance. This goal drives ongoing research into neoprene's molecular structure and manufacturing processes to optimize its protective qualities.

Another key objective is to improve the sustainability of neoprene production and use in sports gear. With growing environmental concerns, there is a push towards developing eco-friendly alternatives and recycling methods for neoprene products. This aligns with the broader trend of sustainability in the sports industry and responds to consumer demand for more environmentally responsible products.

Looking ahead, the future of neoprene in sports gear is likely to focus on smart integration with wearable technology. The development of neoprene-based gear that can monitor an athlete's vital signs, track performance metrics, or even adapt its properties in real-time to changing conditions represents an exciting frontier in sports technology.

The evolution of neoprene in sports gear began with its initial application in wetsuits for water sports in the 1950s. Recognizing its unique properties of flexibility, durability, and insulation, manufacturers soon began exploring its potential in other sporting contexts. By the 1970s, neoprene had found its way into various protective gear, including knee braces, elbow pads, and shin guards.

The 1980s and 1990s saw a significant expansion in neoprene's use across multiple sports disciplines. Its shock-absorbing qualities made it ideal for contact sports like football and rugby, while its thermal properties continued to benefit water sports enthusiasts. This period also witnessed the development of more specialized neoprene formulations, tailored to specific sporting needs.

In recent years, the focus has shifted towards enhancing neoprene's performance characteristics. Researchers and manufacturers have been working on improving its breathability, reducing weight, and increasing its resistance to wear and tear. The advent of composite materials has led to the creation of neoprene blends that offer superior protection while maintaining flexibility and comfort.

The primary objective of neoprene in sports gear is to provide effective protection against impacts, abrasions, and environmental factors without compromising an athlete's mobility or performance. This goal drives ongoing research into neoprene's molecular structure and manufacturing processes to optimize its protective qualities.

Another key objective is to improve the sustainability of neoprene production and use in sports gear. With growing environmental concerns, there is a push towards developing eco-friendly alternatives and recycling methods for neoprene products. This aligns with the broader trend of sustainability in the sports industry and responds to consumer demand for more environmentally responsible products.

Looking ahead, the future of neoprene in sports gear is likely to focus on smart integration with wearable technology. The development of neoprene-based gear that can monitor an athlete's vital signs, track performance metrics, or even adapt its properties in real-time to changing conditions represents an exciting frontier in sports technology.

Market Analysis: Protective Sports Equipment Demand

The global protective sports equipment market has been experiencing steady growth, driven by increasing awareness of sports safety, rising participation in athletic activities, and technological advancements in protective gear. Neoprene, a versatile synthetic rubber, plays a crucial role in this market, particularly in the production of high-performance protective sports gear.

The demand for protective sports equipment is primarily fueled by the growing popularity of contact sports, extreme sports, and fitness activities. As more individuals engage in these pursuits, the need for effective protection against injuries has become paramount. This trend is further amplified by the rising healthcare costs associated with sports-related injuries, prompting both amateur and professional athletes to invest in quality protective gear.

In recent years, the market has witnessed a shift towards more specialized and sport-specific protective equipment. This trend has led to the development of neoprene-based products tailored for various sports, including surfing, diving, cycling, and contact sports like rugby and American football. The unique properties of neoprene, such as its flexibility, durability, and shock-absorbing capabilities, make it an ideal material for these applications.

The youth sports segment has emerged as a significant driver of market growth. Parents and schools are increasingly prioritizing safety in youth sports, leading to higher adoption rates of protective gear. This demographic shift has created new opportunities for manufacturers to develop neoprene-based products specifically designed for young athletes.

Geographically, North America and Europe dominate the protective sports equipment market, owing to their well-established sports culture and higher disposable incomes. However, emerging economies in Asia-Pacific and Latin America are showing rapid growth potential, driven by increasing sports participation and rising awareness of safety measures.

The COVID-19 pandemic has had a mixed impact on the market. While it initially led to a decline in sports participation and equipment sales, the subsequent focus on personal health and outdoor activities has revitalized demand for protective sports gear. This shift has particularly benefited neoprene-based products, which are often used in individual and outdoor sports.

Looking ahead, the market for protective sports equipment, especially those incorporating neoprene, is expected to continue its growth trajectory. Factors such as technological innovations, increasing health consciousness, and the expansion of sports infrastructure in developing countries are likely to drive this growth. Additionally, the trend towards sustainable and eco-friendly materials presents both challenges and opportunities for neoprene-based products in the protective sports gear market.

The demand for protective sports equipment is primarily fueled by the growing popularity of contact sports, extreme sports, and fitness activities. As more individuals engage in these pursuits, the need for effective protection against injuries has become paramount. This trend is further amplified by the rising healthcare costs associated with sports-related injuries, prompting both amateur and professional athletes to invest in quality protective gear.

In recent years, the market has witnessed a shift towards more specialized and sport-specific protective equipment. This trend has led to the development of neoprene-based products tailored for various sports, including surfing, diving, cycling, and contact sports like rugby and American football. The unique properties of neoprene, such as its flexibility, durability, and shock-absorbing capabilities, make it an ideal material for these applications.

The youth sports segment has emerged as a significant driver of market growth. Parents and schools are increasingly prioritizing safety in youth sports, leading to higher adoption rates of protective gear. This demographic shift has created new opportunities for manufacturers to develop neoprene-based products specifically designed for young athletes.

Geographically, North America and Europe dominate the protective sports equipment market, owing to their well-established sports culture and higher disposable incomes. However, emerging economies in Asia-Pacific and Latin America are showing rapid growth potential, driven by increasing sports participation and rising awareness of safety measures.

The COVID-19 pandemic has had a mixed impact on the market. While it initially led to a decline in sports participation and equipment sales, the subsequent focus on personal health and outdoor activities has revitalized demand for protective sports gear. This shift has particularly benefited neoprene-based products, which are often used in individual and outdoor sports.

Looking ahead, the market for protective sports equipment, especially those incorporating neoprene, is expected to continue its growth trajectory. Factors such as technological innovations, increasing health consciousness, and the expansion of sports infrastructure in developing countries are likely to drive this growth. Additionally, the trend towards sustainable and eco-friendly materials presents both challenges and opportunities for neoprene-based products in the protective sports gear market.

Current Neoprene Technology and Challenges

Neoprene, a synthetic rubber material, has been a cornerstone in protective sports gear for decades. However, the current state of neoprene technology faces several challenges and limitations that necessitate further innovation and development.

One of the primary challenges is the balance between protection and flexibility. While neoprene offers excellent shock absorption and insulation properties, it can sometimes restrict movement, especially in high-performance sports where agility is crucial. Manufacturers are continually striving to develop thinner, more flexible neoprene variants that maintain protective qualities without compromising mobility.

Durability is another area of focus in current neoprene technology. Although neoprene is known for its resilience, repeated stress and exposure to harsh environments can lead to degradation over time. This is particularly problematic in water sports, where constant exposure to saltwater and UV radiation can accelerate wear and tear. Researchers are exploring ways to enhance neoprene's longevity through advanced polymer blends and surface treatments.

Environmental concerns pose a significant challenge to the neoprene industry. Traditional neoprene production involves petroleum-based processes, which have a substantial carbon footprint. There is growing pressure to develop more sustainable alternatives, such as bio-based neoprene or recycled materials, to reduce the environmental impact of protective sports gear manufacturing.

Thermal regulation is an ongoing challenge in neoprene technology. While neoprene provides excellent insulation, it can lead to overheating during intense physical activity. Current research is focused on developing neoprene composites with enhanced breathability and moisture-wicking properties to improve comfort and performance in various temperature conditions.

Customization and fit remain areas for improvement in neoprene-based protective gear. The one-size-fits-all approach is often inadequate for athletes with diverse body types and specific needs. Advanced manufacturing techniques, such as 3D printing and computer-aided design, are being explored to create more personalized and ergonomic neoprene products.

Weight reduction is another key focus in current neoprene technology. Traditional neoprene can be relatively heavy, which can be a disadvantage in sports where every gram counts. Researchers are working on developing lightweight neoprene composites that maintain protective properties while significantly reducing overall weight.

In terms of geographical distribution, neoprene technology development is primarily concentrated in regions with strong sporting goods industries, such as North America, Europe, and parts of Asia. However, there is a growing trend of research collaboration across international borders to address global challenges in neoprene technology.

One of the primary challenges is the balance between protection and flexibility. While neoprene offers excellent shock absorption and insulation properties, it can sometimes restrict movement, especially in high-performance sports where agility is crucial. Manufacturers are continually striving to develop thinner, more flexible neoprene variants that maintain protective qualities without compromising mobility.

Durability is another area of focus in current neoprene technology. Although neoprene is known for its resilience, repeated stress and exposure to harsh environments can lead to degradation over time. This is particularly problematic in water sports, where constant exposure to saltwater and UV radiation can accelerate wear and tear. Researchers are exploring ways to enhance neoprene's longevity through advanced polymer blends and surface treatments.

Environmental concerns pose a significant challenge to the neoprene industry. Traditional neoprene production involves petroleum-based processes, which have a substantial carbon footprint. There is growing pressure to develop more sustainable alternatives, such as bio-based neoprene or recycled materials, to reduce the environmental impact of protective sports gear manufacturing.

Thermal regulation is an ongoing challenge in neoprene technology. While neoprene provides excellent insulation, it can lead to overheating during intense physical activity. Current research is focused on developing neoprene composites with enhanced breathability and moisture-wicking properties to improve comfort and performance in various temperature conditions.

Customization and fit remain areas for improvement in neoprene-based protective gear. The one-size-fits-all approach is often inadequate for athletes with diverse body types and specific needs. Advanced manufacturing techniques, such as 3D printing and computer-aided design, are being explored to create more personalized and ergonomic neoprene products.

Weight reduction is another key focus in current neoprene technology. Traditional neoprene can be relatively heavy, which can be a disadvantage in sports where every gram counts. Researchers are working on developing lightweight neoprene composites that maintain protective properties while significantly reducing overall weight.

In terms of geographical distribution, neoprene technology development is primarily concentrated in regions with strong sporting goods industries, such as North America, Europe, and parts of Asia. However, there is a growing trend of research collaboration across international borders to address global challenges in neoprene technology.

Existing Neoprene Solutions in Protective Sports Gear

01 Composition and synthesis of neoprene

Neoprene is a synthetic rubber produced by polymerization of chloroprene. It is known for its resistance to oil, heat, and weathering. The manufacturing process involves careful control of reaction conditions and may include various additives to enhance specific properties.- Composition and synthesis of neoprene: Neoprene is a synthetic rubber produced by polymerization of chloroprene. Various methods and compositions are used to synthesize neoprene with specific properties, including the use of different catalysts, additives, and polymerization techniques to control the molecular structure and characteristics of the final product.

- Applications of neoprene in protective gear: Neoprene is widely used in the production of protective gear due to its excellent insulation, flexibility, and durability properties. It is commonly used in wetsuits, diving suits, and other water-resistant clothing. The material can be engineered to provide varying levels of thermal insulation and protection against environmental factors.

- Neoprene foam production and properties: Neoprene foam is a versatile material with applications in various industries. The production process involves creating a cellular structure within the neoprene, resulting in a lightweight, flexible, and insulating material. Different techniques are used to control the foam's density, cell structure, and overall properties to suit specific applications.

- Neoprene blends and composites: To enhance its properties or create specialized materials, neoprene is often blended with other polymers or incorporated into composite structures. These blends and composites can improve characteristics such as chemical resistance, flame retardancy, or mechanical strength, expanding the range of applications for neoprene-based materials.

- Testing and quality control of neoprene products: Various testing methods and quality control procedures are employed in the production and assessment of neoprene products. These include physical property tests, chemical analysis, and performance evaluations to ensure the material meets specific standards and requirements for different applications.

02 Applications of neoprene in protective gear

Neoprene is widely used in the production of protective gear such as wetsuits, gloves, and boots. Its flexibility, insulation properties, and resistance to water make it ideal for these applications. The material can be engineered to provide varying levels of thickness and protection based on specific needs.Expand Specific Solutions03 Neoprene foam production and properties

Neoprene foam is a versatile material created by introducing gas bubbles into the neoprene during the manufacturing process. This results in a lightweight, flexible, and insulating material with applications in various industries, including automotive, construction, and sports equipment.Expand Specific Solutions04 Modifications and blends of neoprene

To enhance specific properties, neoprene can be modified or blended with other materials. These modifications can improve characteristics such as flame resistance, chemical resistance, or adhesion properties. The resulting materials find applications in specialized industries and products.Expand Specific Solutions05 Testing and quality control of neoprene products

Various testing methods and quality control procedures are employed to ensure the consistency and performance of neoprene products. These may include physical property tests, chemical analysis, and durability assessments. Standardized testing protocols help maintain product quality across different manufacturing batches and applications.Expand Specific Solutions

Key Players in Neoprene-based Sports Gear Industry

The competitive landscape for neoprene in protective sports gear is characterized by a mature market with steady growth. The global sports protective equipment market, including neoprene-based products, is projected to reach $9.6 billion by 2026, growing at a CAGR of 4.3%. Technologically, neoprene is well-established, with ongoing innovations focused on enhancing performance and sustainability. Key players like NIKE, adidas, and CCM Hockey dominate the market, while specialized manufacturers such as Leatt Corp. and Chestee, Inc. cater to niche segments. The industry is seeing increased competition from eco-friendly alternatives, driving established companies to invest in sustainable neoprene formulations and manufacturing processes.

Reusch International GmbH & Co. KG

Technical Solution: Reusch specializes in neoprene applications for sports gloves and hand protection. Their technology focuses on optimizing grip and dexterity while maintaining protective qualities. Reusch uses a proprietary neoprene blend that incorporates silicone particles for enhanced grip in wet conditions[7]. They have also developed a layered neoprene system for goalkeeper gloves that provides impact protection while allowing finger flexibility. Reusch's latest innovation includes a neoprene-based "smart fabric" that can detect hand movements and provide real-time feedback to athletes[8].

Strengths: Excellent grip properties, specialized hand protection, and innovative smart fabric technology. Weaknesses: Primarily focused on hand gear, limiting application in other protective equipment areas.

adidas International Marketing BV

Technical Solution: Adidas has innovated in neoprene-based sports gear with their Climacool technology. This system incorporates specially engineered neoprene with ventilation channels to improve breathability while maintaining protection. Their neoprene formulation includes microcapsules that release cooling agents when activated by body heat[3]. Adidas has also developed a compression-fit neoprene that provides muscular support and improves blood circulation, enhancing athletic performance[4].

Strengths: Enhanced breathability, active cooling technology, and performance-enhancing compression. Weaknesses: May be less durable than traditional neoprene in high-wear areas.

Core Innovations in Neoprene for Sports Protection

Protective clothing of the femur head during the sports activity

PatentInactiveEP1964484A3

Innovation

- A protective clothing system comprising shaped pieces made of absorbing materials like neoprene, designed to distribute impact away from the femur head, featuring a conic cavity structure that aligns with the femur head, integrated with elastic shorts to absorb and redirect knocks, preventing direct pressure on the joint.

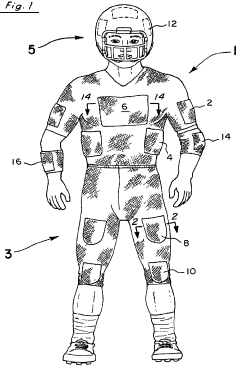

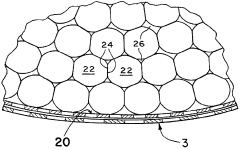

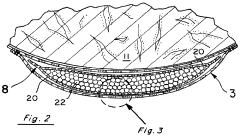

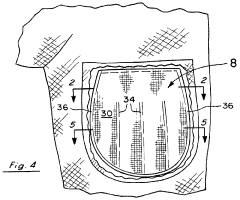

Protective padding for sports gear

PatentInactiveUS6098209A

Innovation

- The use of flexible, porous, inelastic casings overfilled with resilient, elastic beads that compress and rebound to absorb and dissipate impact, while maintaining tension to enhance absorption, and incorporate a pumping effect for breathability and heat dissipation, allowing for integration into various sports gear without compromising mobility.

Environmental Impact of Neoprene Production and Use

The production and use of neoprene in protective sports gear have significant environmental implications that warrant careful consideration. The manufacturing process of neoprene involves the use of petroleum-based chemicals, which contribute to greenhouse gas emissions and potential pollution if not properly managed. The chloroprene rubber production, a key component of neoprene, releases volatile organic compounds (VOCs) and other potentially harmful substances into the atmosphere.

Water pollution is another concern in neoprene production. The manufacturing process requires substantial amounts of water, and without proper treatment, wastewater containing chemical residues can contaminate local water sources. This can have detrimental effects on aquatic ecosystems and potentially impact human health in surrounding communities.

The energy-intensive nature of neoprene production also contributes to its environmental footprint. The high temperatures required for polymerization and vulcanization processes consume significant amounts of energy, often derived from fossil fuels, further adding to the carbon emissions associated with neoprene manufacturing.

During the use phase, neoprene products in sports gear can shed microplastics when subjected to wear and tear. These tiny particles can find their way into water systems and eventually into the oceans, contributing to the growing problem of marine plastic pollution. The durability of neoprene, while beneficial for product longevity, also means that it does not biodegrade easily, potentially persisting in the environment for extended periods.

End-of-life disposal of neoprene products presents additional environmental challenges. Most neoprene items are not biodegradable and are difficult to recycle due to their composite nature, often containing other materials like nylon or polyester. As a result, many neoprene products end up in landfills, where they can take decades or even centuries to decompose.

However, efforts are being made to mitigate the environmental impact of neoprene. Some manufacturers are exploring more sustainable production methods, such as using limestone-based neoprene or incorporating recycled materials. Additionally, research is ongoing to develop bio-based alternatives that could potentially replace traditional petroleum-derived neoprene in certain applications.

The sports industry is also increasingly aware of these environmental concerns and is taking steps to address them. Some companies are implementing take-back programs for used neoprene products, while others are investing in more environmentally friendly manufacturing processes or exploring alternative materials that offer similar protective properties with reduced environmental impact.

Water pollution is another concern in neoprene production. The manufacturing process requires substantial amounts of water, and without proper treatment, wastewater containing chemical residues can contaminate local water sources. This can have detrimental effects on aquatic ecosystems and potentially impact human health in surrounding communities.

The energy-intensive nature of neoprene production also contributes to its environmental footprint. The high temperatures required for polymerization and vulcanization processes consume significant amounts of energy, often derived from fossil fuels, further adding to the carbon emissions associated with neoprene manufacturing.

During the use phase, neoprene products in sports gear can shed microplastics when subjected to wear and tear. These tiny particles can find their way into water systems and eventually into the oceans, contributing to the growing problem of marine plastic pollution. The durability of neoprene, while beneficial for product longevity, also means that it does not biodegrade easily, potentially persisting in the environment for extended periods.

End-of-life disposal of neoprene products presents additional environmental challenges. Most neoprene items are not biodegradable and are difficult to recycle due to their composite nature, often containing other materials like nylon or polyester. As a result, many neoprene products end up in landfills, where they can take decades or even centuries to decompose.

However, efforts are being made to mitigate the environmental impact of neoprene. Some manufacturers are exploring more sustainable production methods, such as using limestone-based neoprene or incorporating recycled materials. Additionally, research is ongoing to develop bio-based alternatives that could potentially replace traditional petroleum-derived neoprene in certain applications.

The sports industry is also increasingly aware of these environmental concerns and is taking steps to address them. Some companies are implementing take-back programs for used neoprene products, while others are investing in more environmentally friendly manufacturing processes or exploring alternative materials that offer similar protective properties with reduced environmental impact.

Safety Standards and Regulations for Sports Protective Gear

Safety standards and regulations play a crucial role in ensuring the effectiveness and reliability of protective sports gear, including those made with neoprene. These standards are developed and enforced by various organizations and governing bodies to minimize the risk of injuries and enhance athlete safety across different sports disciplines.

In the United States, the Consumer Product Safety Commission (CPSC) oversees the safety of sports protective equipment. They have established specific standards for various types of gear, such as bicycle helmets, which must meet the requirements outlined in the CPSC Safety Standard for Bicycle Helmets. Similarly, the American Society for Testing and Materials (ASTM) has developed numerous standards for sports protective equipment, including specifications for materials like neoprene used in these products.

Internationally, the International Organization for Standardization (ISO) has created standards that address the performance and safety requirements for protective equipment in sports. For instance, ISO 13688 provides general requirements for protective clothing, which can be applied to neoprene-based gear. The European Committee for Standardization (CEN) has also established standards such as EN 13277 for protective equipment used in martial arts, many of which incorporate neoprene components.

Sports-specific organizations often have their own set of regulations. For example, the National Operating Committee on Standards for Athletic Equipment (NOCSAE) in the United States develops performance standards for football helmets and other protective equipment. These standards often include requirements for impact absorption and durability, which neoprene-based products must meet.

Compliance with these standards typically involves rigorous testing procedures. For neoprene-based protective gear, this may include tests for tensile strength, tear resistance, and impact absorption. The gear is often subjected to simulated use conditions to ensure it maintains its protective properties over time. Manufacturers must demonstrate that their products meet or exceed these standards before they can be certified for use in official competitions or sold in certain markets.

It's important to note that safety standards are continually evolving as new research emerges and technology advances. Manufacturers of neoprene-based protective gear must stay informed about these changes and adapt their products accordingly. This ongoing process of improvement and compliance helps to ensure that athletes have access to the most effective and reliable protective equipment possible.

In the United States, the Consumer Product Safety Commission (CPSC) oversees the safety of sports protective equipment. They have established specific standards for various types of gear, such as bicycle helmets, which must meet the requirements outlined in the CPSC Safety Standard for Bicycle Helmets. Similarly, the American Society for Testing and Materials (ASTM) has developed numerous standards for sports protective equipment, including specifications for materials like neoprene used in these products.

Internationally, the International Organization for Standardization (ISO) has created standards that address the performance and safety requirements for protective equipment in sports. For instance, ISO 13688 provides general requirements for protective clothing, which can be applied to neoprene-based gear. The European Committee for Standardization (CEN) has also established standards such as EN 13277 for protective equipment used in martial arts, many of which incorporate neoprene components.

Sports-specific organizations often have their own set of regulations. For example, the National Operating Committee on Standards for Athletic Equipment (NOCSAE) in the United States develops performance standards for football helmets and other protective equipment. These standards often include requirements for impact absorption and durability, which neoprene-based products must meet.

Compliance with these standards typically involves rigorous testing procedures. For neoprene-based protective gear, this may include tests for tensile strength, tear resistance, and impact absorption. The gear is often subjected to simulated use conditions to ensure it maintains its protective properties over time. Manufacturers must demonstrate that their products meet or exceed these standards before they can be certified for use in official competitions or sold in certain markets.

It's important to note that safety standards are continually evolving as new research emerges and technology advances. Manufacturers of neoprene-based protective gear must stay informed about these changes and adapt their products accordingly. This ongoing process of improvement and compliance helps to ensure that athletes have access to the most effective and reliable protective equipment possible.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!