How Neoprene Upgrades Protective Industrial Apparel?

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neoprene in Protective Gear: Evolution and Objectives

Neoprene, a synthetic rubber developed in the 1930s, has revolutionized protective industrial apparel over the decades. Initially created as an oil-resistant alternative to natural rubber, neoprene's unique properties have made it a cornerstone in the evolution of safety gear across various industries.

The journey of neoprene in protective gear began with its application in chemical-resistant gloves and boots. Its resistance to oils, solvents, and chemicals, coupled with its flexibility and durability, quickly made it a preferred material in hazardous work environments. As industrial safety standards evolved, so did the applications of neoprene in protective apparel.

In the 1950s and 1960s, neoprene found its way into diving suits, showcasing its excellent insulation properties and water resistance. This breakthrough led to the development of more specialized protective gear for maritime industries and emergency response teams. The material's ability to maintain flexibility in extreme temperatures further expanded its use in firefighting equipment and cold storage protective wear.

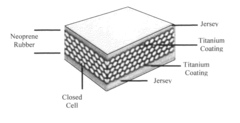

The 1970s and 1980s saw neoprene's integration into more sophisticated multi-layer protective garments. Manufacturers began combining neoprene with other materials to enhance its protective qualities while addressing comfort issues. This period marked the beginning of ergonomic considerations in protective gear design, with neoprene playing a crucial role in creating more user-friendly apparel.

As environmental and occupational safety regulations became more stringent in the 1990s and 2000s, neoprene-based protective gear underwent further refinements. Innovations in manufacturing processes led to the development of lighter, more breathable neoprene fabrics without compromising on protection. This era also saw the introduction of neoprene composites, offering improved resistance to specific hazards while maintaining the material's core benefits.

The current objectives in neoprene-based protective gear focus on sustainability, enhanced performance, and smart integration. Researchers are exploring bio-based alternatives to traditional neoprene production, aiming to reduce the environmental impact. There's also a push towards developing neoprene formulations with improved chemical resistance and flame-retardant properties.

Another key goal is the integration of smart technologies into neoprene-based protective apparel. This includes embedding sensors for real-time monitoring of environmental conditions and the wearer's physiological state. The future of neoprene in protective gear lies in its ability to adapt to these emerging technologies while maintaining its fundamental protective qualities.

The journey of neoprene in protective gear began with its application in chemical-resistant gloves and boots. Its resistance to oils, solvents, and chemicals, coupled with its flexibility and durability, quickly made it a preferred material in hazardous work environments. As industrial safety standards evolved, so did the applications of neoprene in protective apparel.

In the 1950s and 1960s, neoprene found its way into diving suits, showcasing its excellent insulation properties and water resistance. This breakthrough led to the development of more specialized protective gear for maritime industries and emergency response teams. The material's ability to maintain flexibility in extreme temperatures further expanded its use in firefighting equipment and cold storage protective wear.

The 1970s and 1980s saw neoprene's integration into more sophisticated multi-layer protective garments. Manufacturers began combining neoprene with other materials to enhance its protective qualities while addressing comfort issues. This period marked the beginning of ergonomic considerations in protective gear design, with neoprene playing a crucial role in creating more user-friendly apparel.

As environmental and occupational safety regulations became more stringent in the 1990s and 2000s, neoprene-based protective gear underwent further refinements. Innovations in manufacturing processes led to the development of lighter, more breathable neoprene fabrics without compromising on protection. This era also saw the introduction of neoprene composites, offering improved resistance to specific hazards while maintaining the material's core benefits.

The current objectives in neoprene-based protective gear focus on sustainability, enhanced performance, and smart integration. Researchers are exploring bio-based alternatives to traditional neoprene production, aiming to reduce the environmental impact. There's also a push towards developing neoprene formulations with improved chemical resistance and flame-retardant properties.

Another key goal is the integration of smart technologies into neoprene-based protective apparel. This includes embedding sensors for real-time monitoring of environmental conditions and the wearer's physiological state. The future of neoprene in protective gear lies in its ability to adapt to these emerging technologies while maintaining its fundamental protective qualities.

Market Demand Analysis for Advanced Protective Apparel

The market demand for advanced protective industrial apparel has been experiencing significant growth, driven by increasing awareness of workplace safety, stringent regulations, and the need for enhanced protection in various industries. Neoprene, a versatile synthetic rubber, has emerged as a key material in upgrading protective gear, offering improved performance and comfort.

In the industrial sector, there is a growing demand for protective apparel that can withstand harsh environments while providing flexibility and durability. Neoprene-based protective gear addresses these requirements, leading to increased adoption across industries such as manufacturing, construction, oil and gas, and chemical processing. The material's resistance to oils, chemicals, and extreme temperatures makes it particularly suitable for hazardous work environments.

The global personal protective equipment (PPE) market, which includes advanced protective apparel, has been expanding rapidly. This growth is attributed to the rising focus on worker safety and the implementation of stringent safety regulations across various regions. Industries are increasingly recognizing the long-term benefits of investing in high-quality protective gear, including reduced workplace injuries and improved productivity.

Neoprene's unique properties have positioned it as a preferred material for upgrading protective industrial apparel. Its ability to provide insulation, flexibility, and resistance to various environmental factors has led to its incorporation in a wide range of protective gear, including gloves, suits, and footwear. This versatility has expanded the market potential for neoprene-based protective apparel across diverse industrial applications.

The COVID-19 pandemic has further accelerated the demand for advanced protective apparel, with increased emphasis on personal safety and hygiene. This has led to a surge in demand for neoprene-based protective gear in healthcare and related industries, expanding the market beyond traditional industrial sectors.

Technological advancements in neoprene manufacturing and processing have enabled the development of more sophisticated protective apparel. These innovations have resulted in lighter, more comfortable, and more effective protective gear, further driving market demand. The integration of smart technologies and wearable sensors into neoprene-based protective apparel is also emerging as a trend, offering enhanced monitoring and safety features.

The market for neoprene-upgraded protective industrial apparel is expected to continue its growth trajectory in the coming years. Factors such as increasing industrialization in developing countries, growing awareness of workplace safety, and the continuous evolution of safety standards are likely to sustain this demand. Additionally, the rising focus on sustainability has led to the development of eco-friendly neoprene alternatives, potentially opening new market segments for environmentally conscious consumers and industries.

In the industrial sector, there is a growing demand for protective apparel that can withstand harsh environments while providing flexibility and durability. Neoprene-based protective gear addresses these requirements, leading to increased adoption across industries such as manufacturing, construction, oil and gas, and chemical processing. The material's resistance to oils, chemicals, and extreme temperatures makes it particularly suitable for hazardous work environments.

The global personal protective equipment (PPE) market, which includes advanced protective apparel, has been expanding rapidly. This growth is attributed to the rising focus on worker safety and the implementation of stringent safety regulations across various regions. Industries are increasingly recognizing the long-term benefits of investing in high-quality protective gear, including reduced workplace injuries and improved productivity.

Neoprene's unique properties have positioned it as a preferred material for upgrading protective industrial apparel. Its ability to provide insulation, flexibility, and resistance to various environmental factors has led to its incorporation in a wide range of protective gear, including gloves, suits, and footwear. This versatility has expanded the market potential for neoprene-based protective apparel across diverse industrial applications.

The COVID-19 pandemic has further accelerated the demand for advanced protective apparel, with increased emphasis on personal safety and hygiene. This has led to a surge in demand for neoprene-based protective gear in healthcare and related industries, expanding the market beyond traditional industrial sectors.

Technological advancements in neoprene manufacturing and processing have enabled the development of more sophisticated protective apparel. These innovations have resulted in lighter, more comfortable, and more effective protective gear, further driving market demand. The integration of smart technologies and wearable sensors into neoprene-based protective apparel is also emerging as a trend, offering enhanced monitoring and safety features.

The market for neoprene-upgraded protective industrial apparel is expected to continue its growth trajectory in the coming years. Factors such as increasing industrialization in developing countries, growing awareness of workplace safety, and the continuous evolution of safety standards are likely to sustain this demand. Additionally, the rising focus on sustainability has led to the development of eco-friendly neoprene alternatives, potentially opening new market segments for environmentally conscious consumers and industries.

Current State and Challenges in Industrial Protective Clothing

The current state of industrial protective clothing is characterized by a continuous evolution towards enhanced safety, comfort, and functionality. Neoprene, a synthetic rubber material, has emerged as a significant player in upgrading protective apparel across various industries. Its unique properties, including chemical resistance, flexibility, and durability, have made it a preferred choice for many applications.

In recent years, there has been a growing demand for protective clothing that can withstand harsh industrial environments while maintaining worker comfort. Neoprene-based apparel has addressed this need by offering superior protection against chemicals, oils, and extreme temperatures. The material's ability to maintain its properties across a wide temperature range has made it particularly valuable in industries such as oil and gas, manufacturing, and chemical processing.

Despite these advancements, the industrial protective clothing sector faces several challenges. One of the primary concerns is the balance between protection and breathability. While neoprene offers excellent barrier properties, it can lead to heat stress in workers due to limited air permeability. Manufacturers are actively researching ways to incorporate ventilation systems or develop neoprene blends that allow better air circulation without compromising protective qualities.

Another challenge lies in the customization of protective apparel for specific industry needs. Different sectors require varying levels of protection against different hazards, necessitating the development of specialized neoprene formulations. This has led to increased research and development costs as companies strive to create tailored solutions for diverse industrial applications.

The durability of protective clothing remains a critical issue, particularly in high-wear environments. While neoprene demonstrates good resistance to abrasion and tearing, there is an ongoing effort to enhance its longevity further. This includes exploring new coating technologies and reinforcement techniques to extend the lifespan of neoprene-based protective gear.

Environmental concerns also pose a significant challenge to the industry. The production and disposal of neoprene-based products have raised sustainability issues. Manufacturers are under pressure to develop more eco-friendly alternatives or improve the recyclability of neoprene materials without compromising their protective properties.

Lastly, the regulatory landscape for industrial protective clothing is becoming increasingly complex. Compliance with evolving safety standards and regulations across different regions requires continuous adaptation of neoprene-based apparel. This necessitates ongoing testing and certification processes, adding to the overall cost and complexity of product development in the industrial protective clothing sector.

In recent years, there has been a growing demand for protective clothing that can withstand harsh industrial environments while maintaining worker comfort. Neoprene-based apparel has addressed this need by offering superior protection against chemicals, oils, and extreme temperatures. The material's ability to maintain its properties across a wide temperature range has made it particularly valuable in industries such as oil and gas, manufacturing, and chemical processing.

Despite these advancements, the industrial protective clothing sector faces several challenges. One of the primary concerns is the balance between protection and breathability. While neoprene offers excellent barrier properties, it can lead to heat stress in workers due to limited air permeability. Manufacturers are actively researching ways to incorporate ventilation systems or develop neoprene blends that allow better air circulation without compromising protective qualities.

Another challenge lies in the customization of protective apparel for specific industry needs. Different sectors require varying levels of protection against different hazards, necessitating the development of specialized neoprene formulations. This has led to increased research and development costs as companies strive to create tailored solutions for diverse industrial applications.

The durability of protective clothing remains a critical issue, particularly in high-wear environments. While neoprene demonstrates good resistance to abrasion and tearing, there is an ongoing effort to enhance its longevity further. This includes exploring new coating technologies and reinforcement techniques to extend the lifespan of neoprene-based protective gear.

Environmental concerns also pose a significant challenge to the industry. The production and disposal of neoprene-based products have raised sustainability issues. Manufacturers are under pressure to develop more eco-friendly alternatives or improve the recyclability of neoprene materials without compromising their protective properties.

Lastly, the regulatory landscape for industrial protective clothing is becoming increasingly complex. Compliance with evolving safety standards and regulations across different regions requires continuous adaptation of neoprene-based apparel. This necessitates ongoing testing and certification processes, adding to the overall cost and complexity of product development in the industrial protective clothing sector.

Existing Neoprene Applications in Protective Industrial Wear

01 Neoprene composition and manufacturing

Various methods and compositions for manufacturing neoprene with improved properties are described. These include specific formulations, polymerization techniques, and additives to enhance the material's performance and durability.- Neoprene composition and manufacturing: Various methods and compositions for manufacturing neoprene with improved properties are described. These include specific formulations, polymerization techniques, and additives to enhance the material's performance and durability.

- Protective gear made from neoprene: Neoprene is used in the production of various protective gear items, including wetsuits, gloves, and other equipment. These applications leverage neoprene's insulating and flexible properties to provide protection in different environments.

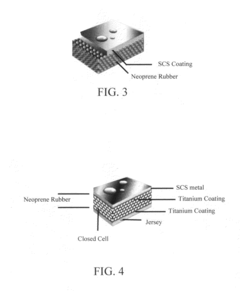

- Neoprene surface treatments and coatings: Surface treatments and coatings are applied to neoprene to enhance its protective properties. These treatments can improve water resistance, durability, and other performance characteristics of neoprene-based products.

- Neoprene in specialized applications: Neoprene is utilized in specialized applications that require specific protective properties. These include uses in automotive, aerospace, and industrial settings where the material's unique characteristics provide essential protection.

- Neoprene blends and composites: Neoprene is combined with other materials to create blends and composites with enhanced protective properties. These combinations can improve strength, chemical resistance, or other specific characteristics needed for particular applications.

02 Protective gear made from neoprene

Neoprene is used in the production of various protective gear items, including wetsuits, gloves, and other equipment. These applications take advantage of neoprene's flexibility, insulation properties, and resistance to water and chemicals.Expand Specific Solutions03 Neoprene coatings and treatments

Techniques for applying neoprene coatings or treatments to various substrates are presented. These methods aim to improve the protective properties of materials or objects by utilizing neoprene's characteristics.Expand Specific Solutions04 Neoprene in automotive applications

Neoprene is utilized in automotive components for protection against heat, vibration, and environmental factors. This includes applications in seals, gaskets, and other parts requiring durability and resistance to various conditions.Expand Specific Solutions05 Neoprene foam and insulation

Methods for producing and using neoprene foam for insulation and protective purposes are described. These applications take advantage of neoprene's closed-cell structure, which provides excellent thermal insulation and impact resistance.Expand Specific Solutions

Key Players in Neoprene and Industrial Apparel Manufacturing

The neoprene protective industrial apparel market is in a growth phase, driven by increasing demand for safety equipment across various industries. The global market size is estimated to be in the billions, with steady annual growth projected. Technologically, neoprene applications are evolving, with companies like Tianjin Pengling Group and Anhui Zhongding Sealing Parts leading in automotive rubber products. Academic institutions such as Beijing University of Chemical Technology and East China University of Science & Technology are contributing to material advancements. Companies like Compania Miguel Caballero and Honeywell International are innovating in specialized protective gear, while research institutes like China Academy of Railway Sciences are exploring neoprene applications in transportation. The industry is characterized by ongoing R&D efforts to enhance neoprene's properties and expand its applications in protective apparel.

East China University of Science & Technology

Technical Solution: Researchers at East China University of Science & Technology have made significant advancements in neoprene technology for industrial protective apparel. Their work focuses on improving the material's performance through novel synthesis methods and surface modifications. The university has developed a new polymerization technique that results in neoprene with a more uniform molecular weight distribution, leading to improved overall mechanical properties[9]. Additionally, they have pioneered a surface grafting method that enhances neoprene's resistance to oil and organic solvents without compromising its flexibility. This modified neoprene shows a 50% increase in oil repellency compared to standard neoprene[10]. The university's research also extends to the development of neoprene-based smart materials that can change properties in response to environmental stimuli, potentially revolutionizing adaptive protective gear.

Strengths: Cutting-edge research in neoprene synthesis and modification, potential for smart and adaptive materials. Weaknesses: Technologies may still be in early stages of development, requiring further testing and scaling for industrial application.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced neoprene-based protective apparel using their proprietary Spectra® fiber technology. This innovative approach combines neoprene's flexibility and chemical resistance with Spectra's high strength-to-weight ratio. The resulting material offers enhanced cut and puncture resistance while maintaining comfort and dexterity. Honeywell's neoprene composites incorporate nano-additives to improve thermal stability and flame retardancy[1]. Their latest designs feature multi-layer constructions with neoprene as a key component, providing superior protection against a wide range of industrial hazards including chemicals, heat, and abrasion[3].

Strengths: Superior protection against multiple hazards, improved comfort, and flexibility. Weaknesses: Potentially higher cost due to advanced materials and manufacturing processes.

Core Innovations in Neoprene-based Protective Technologies

Anti-microbial compounds used in garments for water based activities

PatentInactiveUS20100205709A1

Innovation

- Incorporating colloidal or nanosized metals such as silver, platinum, palladium, and other metals into the insulation materials to create an antimicrobial barrier that inhibits bacterial and fungal growth, combined with polymers like polychloroprene, Hypalon, and polyurethanes, which are effective in reducing infection risk.

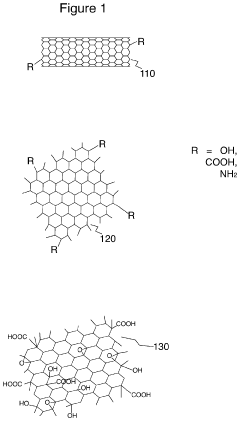

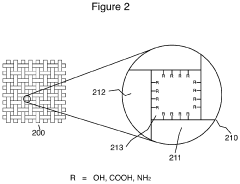

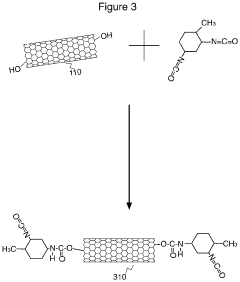

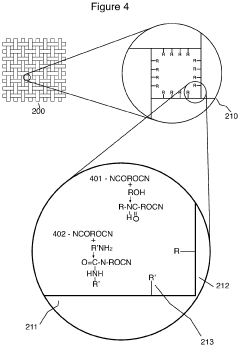

Fabric reinforced with carbon nanostructures to improve mechanical performance

PatentActiveUS20220081808A1

Innovation

- The integration of covalently bonded carbon nanostructured materials, such as graphene, graphene oxide, and carbon nanotubes, into high-strength fibers to create a hierarchal entangled structure that enhances fiber entanglement and mechanical properties, including inter-laminar shear strength, through functionalization and chemical bonding.

Safety Standards and Regulations for Protective Workwear

Safety standards and regulations play a crucial role in ensuring the effectiveness and reliability of protective industrial apparel, including those incorporating neoprene materials. These standards are established by various national and international organizations to provide guidelines for manufacturers, employers, and workers in maintaining workplace safety.

One of the primary regulatory bodies in this field is the Occupational Safety and Health Administration (OSHA) in the United States. OSHA sets forth specific requirements for personal protective equipment (PPE) in different industries, including those utilizing neoprene-based protective gear. These regulations cover aspects such as chemical resistance, flame retardancy, and durability of protective clothing.

The European Union has its own set of standards, known as the EN (European Norm) standards, which are developed by the European Committee for Standardization (CEN). These standards provide detailed specifications for protective clothing, including those made with neoprene, and cover various aspects such as chemical protection (EN 14605), heat and flame protection (EN ISO 11612), and high-visibility clothing (EN ISO 20471).

Internationally, the International Organization for Standardization (ISO) develops and publishes standards that are widely recognized and adopted globally. ISO standards relevant to neoprene-based protective apparel include ISO 16602 for chemical protective clothing and ISO 11612 for heat and flame protection.

In addition to these overarching regulatory bodies, specific industries often have their own standards and regulations. For instance, the National Fire Protection Association (NFPA) in the United States sets standards for firefighting gear, which may incorporate neoprene components.

Compliance with these safety standards and regulations is typically demonstrated through rigorous testing and certification processes. Third-party testing laboratories conduct various tests to evaluate the performance of protective apparel against specific hazards. These tests may include chemical permeation resistance, flame spread rate, heat transfer performance, and durability under different environmental conditions.

Manufacturers of neoprene-based protective apparel must ensure their products meet or exceed these standards to be considered compliant and suitable for use in industrial settings. This often involves ongoing research and development to improve the properties of neoprene and its integration into protective clothing systems.

As technology and workplace hazards evolve, safety standards and regulations are periodically reviewed and updated. This ensures that protective apparel, including those utilizing neoprene, continues to provide adequate protection against emerging risks. Manufacturers and employers must stay informed about these changes to maintain compliance and ensure worker safety.

One of the primary regulatory bodies in this field is the Occupational Safety and Health Administration (OSHA) in the United States. OSHA sets forth specific requirements for personal protective equipment (PPE) in different industries, including those utilizing neoprene-based protective gear. These regulations cover aspects such as chemical resistance, flame retardancy, and durability of protective clothing.

The European Union has its own set of standards, known as the EN (European Norm) standards, which are developed by the European Committee for Standardization (CEN). These standards provide detailed specifications for protective clothing, including those made with neoprene, and cover various aspects such as chemical protection (EN 14605), heat and flame protection (EN ISO 11612), and high-visibility clothing (EN ISO 20471).

Internationally, the International Organization for Standardization (ISO) develops and publishes standards that are widely recognized and adopted globally. ISO standards relevant to neoprene-based protective apparel include ISO 16602 for chemical protective clothing and ISO 11612 for heat and flame protection.

In addition to these overarching regulatory bodies, specific industries often have their own standards and regulations. For instance, the National Fire Protection Association (NFPA) in the United States sets standards for firefighting gear, which may incorporate neoprene components.

Compliance with these safety standards and regulations is typically demonstrated through rigorous testing and certification processes. Third-party testing laboratories conduct various tests to evaluate the performance of protective apparel against specific hazards. These tests may include chemical permeation resistance, flame spread rate, heat transfer performance, and durability under different environmental conditions.

Manufacturers of neoprene-based protective apparel must ensure their products meet or exceed these standards to be considered compliant and suitable for use in industrial settings. This often involves ongoing research and development to improve the properties of neoprene and its integration into protective clothing systems.

As technology and workplace hazards evolve, safety standards and regulations are periodically reviewed and updated. This ensures that protective apparel, including those utilizing neoprene, continues to provide adequate protection against emerging risks. Manufacturers and employers must stay informed about these changes to maintain compliance and ensure worker safety.

Environmental Impact of Neoprene in Industrial Applications

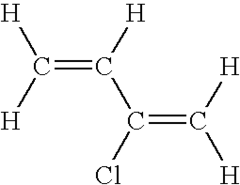

The environmental impact of neoprene in industrial applications is a critical consideration as the material's usage in protective apparel continues to grow. Neoprene, a synthetic rubber, offers excellent resistance to chemicals, oils, and weathering, making it ideal for industrial protective gear. However, its production and disposal processes raise significant environmental concerns.

The manufacturing of neoprene involves the use of petroleum-based chemicals, which contribute to greenhouse gas emissions and resource depletion. The production process releases chloroprene, a potentially harmful compound, into the environment. This has led to increased scrutiny from environmental agencies and calls for more sustainable production methods.

During its use phase, neoprene demonstrates remarkable durability, which can be seen as an environmental advantage. The longevity of neoprene-based protective apparel reduces the need for frequent replacements, potentially lowering the overall environmental footprint of industrial gear over time. However, this durability becomes problematic at the end of the product's life cycle.

Neoprene's resistance to degradation makes it challenging to dispose of in an environmentally friendly manner. Traditional landfilling is not an ideal solution, as neoprene can take centuries to decompose, contributing to long-term soil and water pollution. Incineration of neoprene waste can release toxic fumes, including hydrogen chloride and other harmful substances.

Recycling neoprene presents both opportunities and challenges. While technically possible, the process is complex and not widely implemented on a large scale. Some innovative companies have begun developing closed-loop recycling systems for neoprene products, but these efforts are still in their early stages and not yet economically viable for widespread adoption.

The water-intensive nature of neoprene production also raises concerns about water scarcity and pollution. The manufacturing process requires significant amounts of water for cooling and washing, potentially straining local water resources in production areas. Additionally, wastewater from neoprene factories may contain pollutants that require careful treatment before release.

As environmental awareness grows, there is increasing pressure on manufacturers to develop more sustainable alternatives to traditional neoprene. Bio-based neoprene substitutes, derived from renewable resources like plant oils, are being researched and developed. These alternatives aim to reduce the carbon footprint and environmental impact associated with neoprene production while maintaining its protective properties.

In conclusion, while neoprene offers significant benefits in industrial protective apparel, its environmental impact throughout its lifecycle remains a concern. Balancing the material's protective qualities with environmental sustainability is a key challenge for the industry moving forward. Continued research into eco-friendly production methods, improved recycling technologies, and sustainable alternatives will be crucial in mitigating the environmental impact of neoprene in industrial applications.

The manufacturing of neoprene involves the use of petroleum-based chemicals, which contribute to greenhouse gas emissions and resource depletion. The production process releases chloroprene, a potentially harmful compound, into the environment. This has led to increased scrutiny from environmental agencies and calls for more sustainable production methods.

During its use phase, neoprene demonstrates remarkable durability, which can be seen as an environmental advantage. The longevity of neoprene-based protective apparel reduces the need for frequent replacements, potentially lowering the overall environmental footprint of industrial gear over time. However, this durability becomes problematic at the end of the product's life cycle.

Neoprene's resistance to degradation makes it challenging to dispose of in an environmentally friendly manner. Traditional landfilling is not an ideal solution, as neoprene can take centuries to decompose, contributing to long-term soil and water pollution. Incineration of neoprene waste can release toxic fumes, including hydrogen chloride and other harmful substances.

Recycling neoprene presents both opportunities and challenges. While technically possible, the process is complex and not widely implemented on a large scale. Some innovative companies have begun developing closed-loop recycling systems for neoprene products, but these efforts are still in their early stages and not yet economically viable for widespread adoption.

The water-intensive nature of neoprene production also raises concerns about water scarcity and pollution. The manufacturing process requires significant amounts of water for cooling and washing, potentially straining local water resources in production areas. Additionally, wastewater from neoprene factories may contain pollutants that require careful treatment before release.

As environmental awareness grows, there is increasing pressure on manufacturers to develop more sustainable alternatives to traditional neoprene. Bio-based neoprene substitutes, derived from renewable resources like plant oils, are being researched and developed. These alternatives aim to reduce the carbon footprint and environmental impact associated with neoprene production while maintaining its protective properties.

In conclusion, while neoprene offers significant benefits in industrial protective apparel, its environmental impact throughout its lifecycle remains a concern. Balancing the material's protective qualities with environmental sustainability is a key challenge for the industry moving forward. Continued research into eco-friendly production methods, improved recycling technologies, and sustainable alternatives will be crucial in mitigating the environmental impact of neoprene in industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!