How to Accelerate Perovskite Scale-Up Without Compromising Lifetime: Process Controls

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite Scale-Up Challenges and Objectives

Perovskite solar cells have emerged as a promising technology in the field of photovoltaics, offering high efficiency and low-cost manufacturing potential. However, the scale-up of perovskite solar cells from laboratory-scale devices to commercial-scale modules presents significant challenges that need to be addressed to realize their full potential in the renewable energy market.

The primary objective of accelerating perovskite scale-up without compromising lifetime is to develop robust and reliable manufacturing processes that can produce high-performance, large-area perovskite solar modules with long-term stability. This goal requires overcoming several key technical hurdles and optimizing various process controls throughout the fabrication chain.

One of the main challenges in perovskite scale-up is maintaining uniform film quality over large areas. As the active layer size increases, issues such as thickness variations, defect formation, and compositional inhomogeneities become more pronounced, potentially leading to reduced efficiency and stability. Addressing these challenges requires precise control of deposition parameters, including temperature, precursor composition, and environmental conditions.

Another critical objective is to develop scalable deposition techniques that are compatible with high-throughput manufacturing. While spin-coating is widely used for small-scale devices, alternative methods such as slot-die coating, blade coating, or spray deposition need to be optimized for large-area fabrication without compromising the optoelectronic properties of the perovskite layer.

Ensuring long-term stability is paramount in the scale-up process. Perovskite materials are known to be sensitive to moisture, oxygen, and thermal stress, which can lead to rapid degradation. Developing effective encapsulation strategies and identifying stable perovskite compositions that can withstand real-world operating conditions are crucial objectives in the scale-up efforts.

Process reproducibility and yield are also key challenges that need to be addressed. Achieving consistent performance across multiple batches and minimizing device-to-device variations are essential for commercial viability. This requires implementing robust quality control measures and developing in-line monitoring techniques to ensure uniformity throughout the production process.

Furthermore, the integration of perovskite modules into existing photovoltaic systems and infrastructure presents additional challenges. Compatibility with standard module designs, interconnection technologies, and balance-of-system components needs to be considered to facilitate seamless adoption of perovskite technology in the solar energy market.

In summary, the main objectives in accelerating perovskite scale-up while maintaining device lifetime focus on developing scalable fabrication processes, enhancing material stability, improving uniformity over large areas, and ensuring reproducibility in high-volume manufacturing. Addressing these challenges through careful process control and innovative engineering solutions is crucial for the successful commercialization of perovskite solar technology.

The primary objective of accelerating perovskite scale-up without compromising lifetime is to develop robust and reliable manufacturing processes that can produce high-performance, large-area perovskite solar modules with long-term stability. This goal requires overcoming several key technical hurdles and optimizing various process controls throughout the fabrication chain.

One of the main challenges in perovskite scale-up is maintaining uniform film quality over large areas. As the active layer size increases, issues such as thickness variations, defect formation, and compositional inhomogeneities become more pronounced, potentially leading to reduced efficiency and stability. Addressing these challenges requires precise control of deposition parameters, including temperature, precursor composition, and environmental conditions.

Another critical objective is to develop scalable deposition techniques that are compatible with high-throughput manufacturing. While spin-coating is widely used for small-scale devices, alternative methods such as slot-die coating, blade coating, or spray deposition need to be optimized for large-area fabrication without compromising the optoelectronic properties of the perovskite layer.

Ensuring long-term stability is paramount in the scale-up process. Perovskite materials are known to be sensitive to moisture, oxygen, and thermal stress, which can lead to rapid degradation. Developing effective encapsulation strategies and identifying stable perovskite compositions that can withstand real-world operating conditions are crucial objectives in the scale-up efforts.

Process reproducibility and yield are also key challenges that need to be addressed. Achieving consistent performance across multiple batches and minimizing device-to-device variations are essential for commercial viability. This requires implementing robust quality control measures and developing in-line monitoring techniques to ensure uniformity throughout the production process.

Furthermore, the integration of perovskite modules into existing photovoltaic systems and infrastructure presents additional challenges. Compatibility with standard module designs, interconnection technologies, and balance-of-system components needs to be considered to facilitate seamless adoption of perovskite technology in the solar energy market.

In summary, the main objectives in accelerating perovskite scale-up while maintaining device lifetime focus on developing scalable fabrication processes, enhancing material stability, improving uniformity over large areas, and ensuring reproducibility in high-volume manufacturing. Addressing these challenges through careful process control and innovative engineering solutions is crucial for the successful commercialization of perovskite solar technology.

Market Demand for Scalable Perovskite Solar Cells

The market demand for scalable perovskite solar cells has been growing rapidly in recent years, driven by the increasing global focus on renewable energy and the unique advantages of perovskite technology. Perovskite solar cells offer the potential for high efficiency, low-cost production, and versatile applications, making them an attractive option for both large-scale solar farms and building-integrated photovoltaics.

The global solar energy market is projected to reach significant growth in the coming years, with perovskite solar cells expected to play a crucial role in this expansion. As traditional silicon-based solar cells approach their theoretical efficiency limits, perovskite technology presents an opportunity to surpass these limitations and achieve higher power conversion efficiencies at a lower cost.

One of the key drivers of market demand for scalable perovskite solar cells is their potential for integration into flexible and lightweight products. This opens up new applications in portable electronics, wearable devices, and building materials that were previously challenging for conventional solar technologies. The ability to produce perovskite solar cells using low-temperature, solution-based processes also contributes to their scalability and cost-effectiveness.

The automotive industry has shown increasing interest in perovskite solar cells for integration into electric vehicles, potentially extending their range and reducing charging requirements. This represents a significant market opportunity as the electric vehicle sector continues to grow globally.

However, the market demand for scalable perovskite solar cells is tempered by concerns over their long-term stability and durability. Addressing these challenges through improved process controls and materials engineering is crucial for widespread commercial adoption. Investors and industry stakeholders are closely monitoring advancements in perovskite technology, with expectations that overcoming stability issues will unlock substantial market potential.

Government policies and incentives supporting renewable energy adoption are also driving market demand for scalable perovskite solar cells. Many countries have set ambitious targets for solar energy deployment, creating a favorable environment for innovative technologies that can contribute to these goals.

As research and development efforts continue to improve the performance and stability of perovskite solar cells, the market demand is expected to accelerate. The ability to scale up production while maintaining or enhancing device lifetime will be a critical factor in meeting this growing demand and establishing perovskite technology as a major player in the global solar energy market.

The global solar energy market is projected to reach significant growth in the coming years, with perovskite solar cells expected to play a crucial role in this expansion. As traditional silicon-based solar cells approach their theoretical efficiency limits, perovskite technology presents an opportunity to surpass these limitations and achieve higher power conversion efficiencies at a lower cost.

One of the key drivers of market demand for scalable perovskite solar cells is their potential for integration into flexible and lightweight products. This opens up new applications in portable electronics, wearable devices, and building materials that were previously challenging for conventional solar technologies. The ability to produce perovskite solar cells using low-temperature, solution-based processes also contributes to their scalability and cost-effectiveness.

The automotive industry has shown increasing interest in perovskite solar cells for integration into electric vehicles, potentially extending their range and reducing charging requirements. This represents a significant market opportunity as the electric vehicle sector continues to grow globally.

However, the market demand for scalable perovskite solar cells is tempered by concerns over their long-term stability and durability. Addressing these challenges through improved process controls and materials engineering is crucial for widespread commercial adoption. Investors and industry stakeholders are closely monitoring advancements in perovskite technology, with expectations that overcoming stability issues will unlock substantial market potential.

Government policies and incentives supporting renewable energy adoption are also driving market demand for scalable perovskite solar cells. Many countries have set ambitious targets for solar energy deployment, creating a favorable environment for innovative technologies that can contribute to these goals.

As research and development efforts continue to improve the performance and stability of perovskite solar cells, the market demand is expected to accelerate. The ability to scale up production while maintaining or enhancing device lifetime will be a critical factor in meeting this growing demand and establishing perovskite technology as a major player in the global solar energy market.

Current State and Limitations of Perovskite Fabrication

Perovskite solar cells have shown remarkable progress in recent years, with laboratory-scale devices achieving power conversion efficiencies exceeding 25%. However, the transition from small-scale laboratory production to large-scale industrial manufacturing presents significant challenges. The current state of perovskite fabrication is characterized by a delicate balance between efficiency, stability, and scalability.

One of the primary limitations in perovskite fabrication is the lack of standardized, reproducible manufacturing processes. Laboratory-scale production often relies on spin-coating techniques, which are not suitable for large-scale production. Alternative deposition methods such as slot-die coating, blade coating, and spray coating are being explored, but each comes with its own set of challenges in maintaining film uniformity and quality across larger areas.

The stability of perovskite materials remains a critical concern. Perovskites are sensitive to moisture, oxygen, and heat, which can lead to rapid degradation of the solar cell performance. Current fabrication processes often struggle to create encapsulation methods that effectively protect the perovskite layer without compromising device efficiency or increasing production costs significantly.

Another limitation is the use of toxic lead-based materials in most high-performance perovskite solar cells. While efforts are underway to develop lead-free alternatives, these typically show lower efficiencies and stability compared to their lead-based counterparts. This presents a significant challenge for large-scale production, as environmental and safety regulations may limit the use of lead-containing materials in commercial applications.

The choice of hole-transport materials (HTMs) and electron-transport materials (ETMs) also poses challenges in scaling up perovskite solar cell production. Many high-performance devices use expensive or unstable materials that are not suitable for commercial-scale manufacturing. Finding cost-effective, stable, and scalable alternatives for these charge transport layers is crucial for successful industrialization.

Quality control and process monitoring present additional hurdles in perovskite fabrication. The performance of perovskite solar cells is highly sensitive to small variations in composition, crystallization conditions, and layer thicknesses. Developing robust in-line monitoring techniques and feedback control systems to ensure consistent quality across large-area substrates is essential for successful scale-up.

Lastly, the long-term stability and degradation mechanisms of perovskite solar cells are not yet fully understood. This knowledge gap hampers the development of accelerated aging tests and reliable lifetime predictions, which are crucial for commercial viability and consumer confidence in the technology.

One of the primary limitations in perovskite fabrication is the lack of standardized, reproducible manufacturing processes. Laboratory-scale production often relies on spin-coating techniques, which are not suitable for large-scale production. Alternative deposition methods such as slot-die coating, blade coating, and spray coating are being explored, but each comes with its own set of challenges in maintaining film uniformity and quality across larger areas.

The stability of perovskite materials remains a critical concern. Perovskites are sensitive to moisture, oxygen, and heat, which can lead to rapid degradation of the solar cell performance. Current fabrication processes often struggle to create encapsulation methods that effectively protect the perovskite layer without compromising device efficiency or increasing production costs significantly.

Another limitation is the use of toxic lead-based materials in most high-performance perovskite solar cells. While efforts are underway to develop lead-free alternatives, these typically show lower efficiencies and stability compared to their lead-based counterparts. This presents a significant challenge for large-scale production, as environmental and safety regulations may limit the use of lead-containing materials in commercial applications.

The choice of hole-transport materials (HTMs) and electron-transport materials (ETMs) also poses challenges in scaling up perovskite solar cell production. Many high-performance devices use expensive or unstable materials that are not suitable for commercial-scale manufacturing. Finding cost-effective, stable, and scalable alternatives for these charge transport layers is crucial for successful industrialization.

Quality control and process monitoring present additional hurdles in perovskite fabrication. The performance of perovskite solar cells is highly sensitive to small variations in composition, crystallization conditions, and layer thicknesses. Developing robust in-line monitoring techniques and feedback control systems to ensure consistent quality across large-area substrates is essential for successful scale-up.

Lastly, the long-term stability and degradation mechanisms of perovskite solar cells are not yet fully understood. This knowledge gap hampers the development of accelerated aging tests and reliable lifetime predictions, which are crucial for commercial viability and consumer confidence in the technology.

Existing Process Control Solutions for Perovskite Scale-Up

01 Composition modifications for improved stability

Various compositional modifications can be made to perovskite materials to enhance their stability and lifetime. These include incorporating specific additives, dopants, or using mixed-cation or mixed-halide perovskites. Such modifications can help reduce defects, improve crystallinity, and increase resistance to environmental factors like moisture and heat.- Composition modifications for improved stability: Various compositional modifications can be made to perovskite materials to enhance their stability and lifetime. These include incorporating specific additives, dopants, or using mixed-cation or mixed-halide perovskites. Such modifications can help mitigate issues like ion migration and phase segregation, leading to improved long-term performance of perovskite-based devices.

- Encapsulation and protective layers: Implementing effective encapsulation techniques and protective layers can significantly extend the lifetime of perovskite devices. This may involve using moisture-resistant barriers, UV-blocking layers, or advanced sealing methods to protect the perovskite material from environmental factors that contribute to degradation.

- Interface engineering: Optimizing the interfaces between the perovskite layer and adjacent layers in a device structure can improve stability and lifetime. This includes developing charge transport layers with better compatibility, reducing interfacial defects, and enhancing charge extraction efficiency to minimize stress on the perovskite layer during operation.

- Fabrication process optimization: Refining the fabrication process of perovskite materials and devices can lead to improved lifetime. This may involve optimizing crystallization conditions, developing new deposition techniques, or implementing post-treatment processes that enhance the structural stability and reduce defects in the perovskite layer.

- Advanced characterization and lifetime prediction: Developing and utilizing advanced characterization techniques and predictive models can help in understanding degradation mechanisms and predicting the lifetime of perovskite devices. This includes in-situ monitoring methods, accelerated aging tests, and machine learning approaches for analyzing complex degradation patterns and optimizing device designs for longevity.

02 Encapsulation and protective layers

Implementing effective encapsulation techniques and protective layers can significantly extend the lifetime of perovskite devices. This may involve using hydrophobic materials, barrier films, or multi-layer encapsulation strategies to shield the perovskite from moisture, oxygen, and other degradation factors.Expand Specific Solutions03 Interface engineering

Optimizing the interfaces between the perovskite layer and adjacent layers in devices can improve stability and longevity. This includes developing novel charge transport materials, passivation layers, and buffer layers that enhance charge extraction while minimizing interfacial degradation.Expand Specific Solutions04 Fabrication process optimization

Refining the fabrication process of perovskite materials and devices can lead to improved stability. This may involve optimizing deposition methods, annealing conditions, and crystallization processes to achieve high-quality, defect-free perovskite films with enhanced long-term stability.Expand Specific Solutions05 In-situ healing and self-repair mechanisms

Developing perovskite materials with in-situ healing or self-repair capabilities can help maintain device performance over time. This may involve incorporating specific additives or designing the perovskite structure to allow for spontaneous defect healing or ion migration that counteracts degradation processes.Expand Specific Solutions

Key Players in Perovskite Solar Cell Industry

The perovskite solar cell industry is in a rapid growth phase, with significant market potential as the technology matures. The global market for perovskite solar cells is projected to expand substantially in the coming years, driven by increasing demand for renewable energy solutions. Key players like LONGi Green Energy, Energy Materials Corp., and Hanwha Solutions are investing heavily in research and development to overcome stability and scalability challenges. Universities and research institutions, including King Abdullah University of Science & Technology and Shanghai Jiao Tong University, are collaborating with industry partners to accelerate commercialization. While the technology is still evolving, recent advancements in manufacturing processes and materials engineering by companies like Caelux and Wuxi UtmoLight Technology are bringing perovskite solar cells closer to widespread commercial adoption.

King Abdullah University of Science & Technology

Technical Solution: King Abdullah University of Science & Technology (KAUST) has developed a novel approach to accelerate perovskite scale-up while maintaining device lifetime. Their method involves a two-step deposition process, combining solution processing and vapor deposition techniques. This hybrid approach allows for precise control over the perovskite crystal formation and film morphology. KAUST researchers have implemented in-situ monitoring systems to optimize the deposition parameters in real-time, ensuring consistent film quality across large areas[1]. They have also developed a passivation strategy using organic molecules to reduce defects at grain boundaries, which significantly improves the stability of the perovskite layer[2]. Additionally, KAUST has pioneered the use of machine learning algorithms to predict optimal process conditions based on environmental factors and substrate properties, further enhancing scalability and reproducibility[3].

Strengths: Advanced process control techniques, innovative hybrid deposition method, and integration of AI for optimization. Weaknesses: Potential high costs associated with sophisticated equipment and the need for highly skilled operators.

Caelux Corp.

Technical Solution: Caelux Corporation has developed a proprietary manufacturing process for perovskite solar cells that addresses both scalability and lifetime concerns. Their approach utilizes a continuous roll-to-roll fabrication technique, which allows for high-throughput production of perovskite modules. Caelux has implemented precise environmental controls throughout the manufacturing process, including temperature, humidity, and atmospheric composition regulation[4]. They have also developed a unique encapsulation method that significantly enhances the moisture resistance of the perovskite layer, addressing one of the primary degradation pathways[5]. Caelux's process incorporates in-line quality control measures, such as spectroscopic analysis and electrical characterization, to ensure consistent performance across large-area modules. Furthermore, they have implemented a data-driven feedback loop to continuously optimize process parameters based on real-time production data and long-term performance metrics[6].

Strengths: High-throughput roll-to-roll processing, advanced encapsulation technology, and data-driven process optimization. Weaknesses: Potential challenges in maintaining uniform film quality over large areas and the need for specialized equipment.

Core Innovations in Perovskite Stability Enhancement

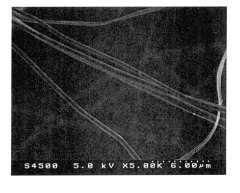

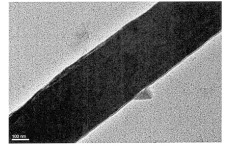

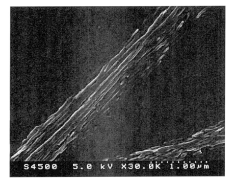

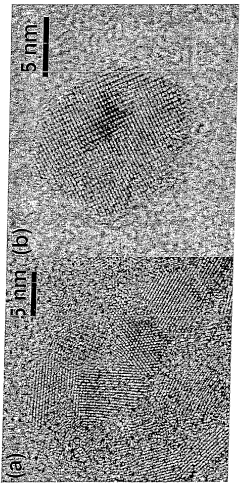

Structure-controlled metal halide crystals and perovskite compound crystals

PatentInactiveJPWO2016167285A1

Innovation

- The development of nanofiber-like metal halides and perovskite compound crystals with uniform crystal sizes arranged in one dimension, and fibrous aggregates and film-like bodies, achieved through methods such as electrospinning and vapor treatment, allowing controlled crystal structure formation.

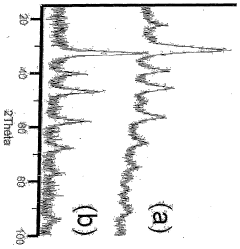

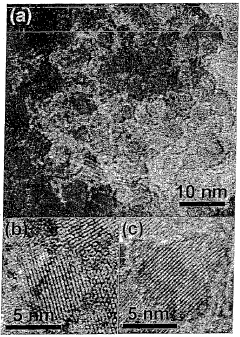

Production of perovskite particles

PatentWO2005021426A1

Innovation

- A method involving the dissolution of metals in anhydrous solvents and reaction with metal alkoxides at elevated temperatures, eliminating the need for ligands and organic additives, producing perovskite particles with high crystallinity and purity without water, acids, or bases, achieving sizes less than 50 nm.

Environmental Impact of Perovskite Solar Cell Manufacturing

The environmental impact of perovskite solar cell manufacturing is a critical consideration as the technology moves towards large-scale commercialization. Perovskite solar cells offer promising efficiency and cost advantages, but their production processes raise concerns about potential ecological consequences.

One of the primary environmental challenges in perovskite manufacturing is the use of lead-based compounds. While the amount of lead used is relatively small, proper handling and disposal are essential to prevent contamination of soil and water resources. Researchers are exploring lead-free alternatives, such as tin-based perovskites, to mitigate this issue.

The solvents used in perovskite production, including dimethylformamide (DMF) and dimethyl sulfoxide (DMSO), pose another environmental concern. These organic solvents are toxic and can contribute to air and water pollution if not properly managed. Efforts are underway to develop greener solvent alternatives or solvent-free deposition methods to reduce the environmental footprint.

Energy consumption during the manufacturing process is another factor to consider. While perovskite solar cells generally require less energy-intensive production compared to traditional silicon-based cells, optimizing energy efficiency in large-scale manufacturing remains crucial for minimizing carbon emissions.

The stability and longevity of perovskite solar cells also impact their overall environmental profile. Improving the durability of these cells is essential to reduce the frequency of replacement and associated waste generation. Ongoing research focuses on enhancing the stability of perovskite materials and developing effective encapsulation techniques.

Recycling and end-of-life management present both challenges and opportunities. Developing efficient recycling processes for perovskite solar cells can help recover valuable materials and reduce waste. However, the complex composition of these cells requires innovative recycling technologies to be developed and implemented at scale.

As perovskite technology advances, life cycle assessments (LCAs) are becoming increasingly important. These comprehensive analyses help quantify the environmental impacts throughout the entire life cycle of perovskite solar cells, from raw material extraction to disposal or recycling. LCAs provide valuable insights for identifying areas of improvement and guiding sustainable manufacturing practices.

One of the primary environmental challenges in perovskite manufacturing is the use of lead-based compounds. While the amount of lead used is relatively small, proper handling and disposal are essential to prevent contamination of soil and water resources. Researchers are exploring lead-free alternatives, such as tin-based perovskites, to mitigate this issue.

The solvents used in perovskite production, including dimethylformamide (DMF) and dimethyl sulfoxide (DMSO), pose another environmental concern. These organic solvents are toxic and can contribute to air and water pollution if not properly managed. Efforts are underway to develop greener solvent alternatives or solvent-free deposition methods to reduce the environmental footprint.

Energy consumption during the manufacturing process is another factor to consider. While perovskite solar cells generally require less energy-intensive production compared to traditional silicon-based cells, optimizing energy efficiency in large-scale manufacturing remains crucial for minimizing carbon emissions.

The stability and longevity of perovskite solar cells also impact their overall environmental profile. Improving the durability of these cells is essential to reduce the frequency of replacement and associated waste generation. Ongoing research focuses on enhancing the stability of perovskite materials and developing effective encapsulation techniques.

Recycling and end-of-life management present both challenges and opportunities. Developing efficient recycling processes for perovskite solar cells can help recover valuable materials and reduce waste. However, the complex composition of these cells requires innovative recycling technologies to be developed and implemented at scale.

As perovskite technology advances, life cycle assessments (LCAs) are becoming increasingly important. These comprehensive analyses help quantify the environmental impacts throughout the entire life cycle of perovskite solar cells, from raw material extraction to disposal or recycling. LCAs provide valuable insights for identifying areas of improvement and guiding sustainable manufacturing practices.

Economic Feasibility of Scaled Perovskite Production

The economic feasibility of scaled perovskite production is a critical factor in determining the viability of perovskite solar cells as a competitive alternative to traditional photovoltaic technologies. As the industry moves towards large-scale manufacturing, several key economic considerations come into play.

Production costs are a primary concern in scaling up perovskite solar cell manufacturing. The materials used in perovskite production, such as lead and organic precursors, are relatively inexpensive compared to traditional silicon-based solar cells. However, the processing and fabrication costs can be significant, particularly when considering the need for precise control over environmental conditions during production.

Capital expenditure for setting up large-scale manufacturing facilities is another crucial economic factor. While perovskite solar cells can potentially be produced using existing manufacturing infrastructure with some modifications, significant investments may be required to establish dedicated production lines that can maintain the necessary quality and consistency at scale.

The efficiency and stability of perovskite solar cells play a vital role in their economic viability. Higher efficiency translates to more power output per unit area, potentially reducing the overall cost per watt. However, the challenge lies in maintaining high efficiency while scaling up production, as larger area devices often suffer from performance losses.

Lifetime and durability of perovskite solar modules are critical for their economic feasibility. Longer-lasting modules provide better return on investment for end-users, making them more competitive in the market. Improving the stability and longevity of perovskite solar cells without significantly increasing production costs is a key challenge that directly impacts their economic viability.

Market demand and competition from established technologies also influence the economic feasibility of scaled perovskite production. As production scales up, economies of scale can help reduce costs, but this must be balanced against the need to capture market share from incumbent technologies that benefit from decades of optimization and established supply chains.

Regulatory factors and environmental considerations can impact the economic landscape for perovskite solar cells. Potential restrictions on lead usage or requirements for end-of-life recycling may introduce additional costs that need to be factored into the overall economic assessment.

In conclusion, while perovskite solar cells show promise for cost-effective large-scale production, several economic challenges must be addressed to ensure their feasibility. Balancing production costs, efficiency, stability, and market factors will be crucial in determining the success of scaled perovskite production in the competitive solar energy landscape.

Production costs are a primary concern in scaling up perovskite solar cell manufacturing. The materials used in perovskite production, such as lead and organic precursors, are relatively inexpensive compared to traditional silicon-based solar cells. However, the processing and fabrication costs can be significant, particularly when considering the need for precise control over environmental conditions during production.

Capital expenditure for setting up large-scale manufacturing facilities is another crucial economic factor. While perovskite solar cells can potentially be produced using existing manufacturing infrastructure with some modifications, significant investments may be required to establish dedicated production lines that can maintain the necessary quality and consistency at scale.

The efficiency and stability of perovskite solar cells play a vital role in their economic viability. Higher efficiency translates to more power output per unit area, potentially reducing the overall cost per watt. However, the challenge lies in maintaining high efficiency while scaling up production, as larger area devices often suffer from performance losses.

Lifetime and durability of perovskite solar modules are critical for their economic feasibility. Longer-lasting modules provide better return on investment for end-users, making them more competitive in the market. Improving the stability and longevity of perovskite solar cells without significantly increasing production costs is a key challenge that directly impacts their economic viability.

Market demand and competition from established technologies also influence the economic feasibility of scaled perovskite production. As production scales up, economies of scale can help reduce costs, but this must be balanced against the need to capture market share from incumbent technologies that benefit from decades of optimization and established supply chains.

Regulatory factors and environmental considerations can impact the economic landscape for perovskite solar cells. Potential restrictions on lead usage or requirements for end-of-life recycling may introduce additional costs that need to be factored into the overall economic assessment.

In conclusion, while perovskite solar cells show promise for cost-effective large-scale production, several economic challenges must be addressed to ensure their feasibility. Balancing production costs, efficiency, stability, and market factors will be crucial in determining the success of scaled perovskite production in the competitive solar energy landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!