Perovskite Solar Cell Stability Roadmap 2025: From R&D to Certification

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite Stability Challenges and Objectives

Perovskite solar cells have emerged as a promising technology in the field of photovoltaics, offering high efficiency and low-cost manufacturing potential. However, the stability of these devices remains a significant challenge, hindering their widespread commercialization. The Perovskite Solar Cell Stability Roadmap 2025 aims to address these challenges and establish a clear path from research and development to certification.

The primary objective of this roadmap is to improve the long-term stability of perovskite solar cells, ensuring they can maintain their high performance over extended periods under various environmental conditions. This includes enhancing resistance to moisture, heat, light, and oxygen exposure, which are known to degrade perovskite materials rapidly.

One of the key challenges is the intrinsic instability of the perovskite crystal structure. The organic-inorganic hybrid nature of perovskites makes them susceptible to phase transitions and ion migration, leading to performance degradation. Addressing this issue requires innovative approaches in material engineering and device architecture.

Another critical objective is to develop standardized testing protocols for assessing the stability of perovskite solar cells. Currently, there is a lack of consensus on testing methodologies, making it difficult to compare results across different research groups and evaluate progress accurately. The roadmap aims to establish uniform testing procedures that simulate real-world conditions and accelerated aging processes.

Improving the encapsulation techniques for perovskite solar modules is also a crucial goal. Effective encapsulation can significantly enhance the device's resistance to environmental factors and extend its operational lifetime. This involves developing new materials and processes that can provide a robust barrier against moisture and oxygen ingress while maintaining optical transparency and flexibility.

The roadmap also focuses on addressing the scalability of stable perovskite solar cells. While high efficiencies have been achieved in small-scale laboratory devices, translating these results to large-area modules while maintaining stability remains challenging. Developing manufacturing processes that can produce stable, high-performance perovskite solar panels at scale is a key objective.

Furthermore, the roadmap aims to explore and mitigate potential environmental and health concerns associated with perovskite materials, particularly those containing lead. Developing lead-free alternatives or ensuring proper encapsulation and end-of-life management for lead-containing devices is crucial for the technology's long-term sustainability and market acceptance.

By addressing these challenges and objectives, the Perovskite Solar Cell Stability Roadmap 2025 seeks to accelerate the transition of perovskite solar technology from laboratory research to commercial certification and widespread deployment. This ambitious goal requires collaborative efforts from academia, industry, and regulatory bodies to overcome the stability hurdles and unlock the full potential of perovskite photovoltaics.

The primary objective of this roadmap is to improve the long-term stability of perovskite solar cells, ensuring they can maintain their high performance over extended periods under various environmental conditions. This includes enhancing resistance to moisture, heat, light, and oxygen exposure, which are known to degrade perovskite materials rapidly.

One of the key challenges is the intrinsic instability of the perovskite crystal structure. The organic-inorganic hybrid nature of perovskites makes them susceptible to phase transitions and ion migration, leading to performance degradation. Addressing this issue requires innovative approaches in material engineering and device architecture.

Another critical objective is to develop standardized testing protocols for assessing the stability of perovskite solar cells. Currently, there is a lack of consensus on testing methodologies, making it difficult to compare results across different research groups and evaluate progress accurately. The roadmap aims to establish uniform testing procedures that simulate real-world conditions and accelerated aging processes.

Improving the encapsulation techniques for perovskite solar modules is also a crucial goal. Effective encapsulation can significantly enhance the device's resistance to environmental factors and extend its operational lifetime. This involves developing new materials and processes that can provide a robust barrier against moisture and oxygen ingress while maintaining optical transparency and flexibility.

The roadmap also focuses on addressing the scalability of stable perovskite solar cells. While high efficiencies have been achieved in small-scale laboratory devices, translating these results to large-area modules while maintaining stability remains challenging. Developing manufacturing processes that can produce stable, high-performance perovskite solar panels at scale is a key objective.

Furthermore, the roadmap aims to explore and mitigate potential environmental and health concerns associated with perovskite materials, particularly those containing lead. Developing lead-free alternatives or ensuring proper encapsulation and end-of-life management for lead-containing devices is crucial for the technology's long-term sustainability and market acceptance.

By addressing these challenges and objectives, the Perovskite Solar Cell Stability Roadmap 2025 seeks to accelerate the transition of perovskite solar technology from laboratory research to commercial certification and widespread deployment. This ambitious goal requires collaborative efforts from academia, industry, and regulatory bodies to overcome the stability hurdles and unlock the full potential of perovskite photovoltaics.

Market Analysis for Stable Perovskite Solar Cells

The market for stable perovskite solar cells is poised for significant growth as the technology matures and addresses key stability challenges. Perovskite solar cells have garnered substantial attention due to their potential for high efficiency, low-cost production, and versatile applications. However, long-term stability issues have been a major hurdle in their commercialization.

Recent advancements in perovskite stability have sparked renewed interest from both established solar manufacturers and new entrants. The global solar photovoltaic market, valued at $52.5 billion in 2018, is projected to reach $333.7 billion by 2026, with perovskite technology expected to capture an increasing share.

The demand for stable perovskite solar cells is driven by several factors. First, the push for renewable energy sources to combat climate change has created a favorable policy environment for solar technologies. Second, the potential for high-efficiency, lightweight, and flexible solar panels opens up new applications in building-integrated photovoltaics and portable electronics.

Market segmentation for stable perovskite solar cells includes utility-scale solar farms, residential and commercial rooftop installations, and niche applications such as space solar cells and indoor light harvesting. The utility-scale segment is expected to dominate in terms of volume, while niche applications may offer higher margins.

Geographically, China, the United States, and Europe are anticipated to be the largest markets for stable perovskite solar cells. China, in particular, has shown strong commitment to solar energy deployment and has the manufacturing capacity to scale up production rapidly.

The competitive landscape is evolving, with both established solar companies and startups investing in perovskite technology. Key players include Oxford PV, Saule Technologies, and Microquanta Semiconductor. Traditional silicon solar cell manufacturers are also exploring perovskite-silicon tandem cells to boost efficiency.

Market adoption of stable perovskite solar cells will depend on achieving certified stability standards and demonstrating long-term field performance. The industry is working towards meeting IEC 61215 certification requirements, which will be crucial for market acceptance and bankability of perovskite-based products.

In conclusion, the market for stable perovskite solar cells shows promising growth potential, driven by technological advancements, favorable policies, and the need for high-efficiency, cost-effective solar solutions. As stability issues are addressed and certification milestones are achieved, perovskite technology is expected to gain significant market share in the coming years.

Recent advancements in perovskite stability have sparked renewed interest from both established solar manufacturers and new entrants. The global solar photovoltaic market, valued at $52.5 billion in 2018, is projected to reach $333.7 billion by 2026, with perovskite technology expected to capture an increasing share.

The demand for stable perovskite solar cells is driven by several factors. First, the push for renewable energy sources to combat climate change has created a favorable policy environment for solar technologies. Second, the potential for high-efficiency, lightweight, and flexible solar panels opens up new applications in building-integrated photovoltaics and portable electronics.

Market segmentation for stable perovskite solar cells includes utility-scale solar farms, residential and commercial rooftop installations, and niche applications such as space solar cells and indoor light harvesting. The utility-scale segment is expected to dominate in terms of volume, while niche applications may offer higher margins.

Geographically, China, the United States, and Europe are anticipated to be the largest markets for stable perovskite solar cells. China, in particular, has shown strong commitment to solar energy deployment and has the manufacturing capacity to scale up production rapidly.

The competitive landscape is evolving, with both established solar companies and startups investing in perovskite technology. Key players include Oxford PV, Saule Technologies, and Microquanta Semiconductor. Traditional silicon solar cell manufacturers are also exploring perovskite-silicon tandem cells to boost efficiency.

Market adoption of stable perovskite solar cells will depend on achieving certified stability standards and demonstrating long-term field performance. The industry is working towards meeting IEC 61215 certification requirements, which will be crucial for market acceptance and bankability of perovskite-based products.

In conclusion, the market for stable perovskite solar cells shows promising growth potential, driven by technological advancements, favorable policies, and the need for high-efficiency, cost-effective solar solutions. As stability issues are addressed and certification milestones are achieved, perovskite technology is expected to gain significant market share in the coming years.

Current State and Hurdles in Perovskite Stability

Perovskite solar cells have shown remarkable progress in recent years, with power conversion efficiencies now exceeding 25%. However, stability remains a critical challenge hindering their commercial viability. The current state of perovskite stability is characterized by significant improvements in laboratory settings, but long-term operational stability under real-world conditions remains elusive.

One of the primary hurdles in perovskite stability is the material's sensitivity to environmental factors. Moisture, oxygen, heat, and light exposure can all contribute to rapid degradation of the perovskite structure. This degradation manifests as phase segregation, ion migration, and interfacial defects, leading to a decline in device performance over time.

Encapsulation techniques have been developed to mitigate environmental degradation, but they often fall short in providing comprehensive protection. The challenge lies in developing encapsulation methods that are both effective and cost-efficient for large-scale production.

Another significant hurdle is the intrinsic instability of certain perovskite compositions. While mixed-cation and mixed-halide perovskites have shown improved stability, they often come at the cost of reduced efficiency or increased complexity in fabrication processes. Balancing stability and performance remains a key challenge for researchers.

The scalability of stable perovskite solar cells presents another major obstacle. Techniques that yield highly stable devices in small-scale laboratory settings often face difficulties when scaled up to industrially relevant sizes. This scaling issue is compounded by the need for uniform deposition and the potential for defect formation in larger area devices.

Standardization of stability testing protocols is also a critical challenge. The lack of universally accepted testing procedures makes it difficult to compare stability results across different research groups and assess progress in the field. This hinders the development of a clear roadmap for improving perovskite stability.

Lastly, the use of lead in most high-performance perovskite solar cells raises environmental and regulatory concerns. While lead-free alternatives are being explored, they currently lag behind in terms of efficiency and stability. Developing stable, high-performance lead-free perovskites remains a significant challenge for the field.

In conclusion, while substantial progress has been made in improving perovskite stability, significant hurdles remain in achieving the long-term operational stability required for commercial viability. Overcoming these challenges will require concerted efforts in materials engineering, device architecture optimization, and standardization of testing protocols.

One of the primary hurdles in perovskite stability is the material's sensitivity to environmental factors. Moisture, oxygen, heat, and light exposure can all contribute to rapid degradation of the perovskite structure. This degradation manifests as phase segregation, ion migration, and interfacial defects, leading to a decline in device performance over time.

Encapsulation techniques have been developed to mitigate environmental degradation, but they often fall short in providing comprehensive protection. The challenge lies in developing encapsulation methods that are both effective and cost-efficient for large-scale production.

Another significant hurdle is the intrinsic instability of certain perovskite compositions. While mixed-cation and mixed-halide perovskites have shown improved stability, they often come at the cost of reduced efficiency or increased complexity in fabrication processes. Balancing stability and performance remains a key challenge for researchers.

The scalability of stable perovskite solar cells presents another major obstacle. Techniques that yield highly stable devices in small-scale laboratory settings often face difficulties when scaled up to industrially relevant sizes. This scaling issue is compounded by the need for uniform deposition and the potential for defect formation in larger area devices.

Standardization of stability testing protocols is also a critical challenge. The lack of universally accepted testing procedures makes it difficult to compare stability results across different research groups and assess progress in the field. This hinders the development of a clear roadmap for improving perovskite stability.

Lastly, the use of lead in most high-performance perovskite solar cells raises environmental and regulatory concerns. While lead-free alternatives are being explored, they currently lag behind in terms of efficiency and stability. Developing stable, high-performance lead-free perovskites remains a significant challenge for the field.

In conclusion, while substantial progress has been made in improving perovskite stability, significant hurdles remain in achieving the long-term operational stability required for commercial viability. Overcoming these challenges will require concerted efforts in materials engineering, device architecture optimization, and standardization of testing protocols.

Existing Solutions for Improving Perovskite Stability

01 Compositional engineering for stability enhancement

Improving the stability of perovskite solar cells through careful compositional engineering of the perovskite material. This involves optimizing the ratio of different cations and anions in the perovskite structure to enhance its resistance to environmental factors such as moisture, heat, and light exposure.- Compositional engineering for stability enhancement: Improving the stability of perovskite solar cells through careful selection and modification of the perovskite material composition. This includes incorporating mixed cations or halides, doping with specific elements, or using additives to enhance the structural and chemical stability of the perovskite layer.

- Encapsulation and barrier layers: Developing effective encapsulation techniques and barrier layers to protect perovskite solar cells from environmental factors such as moisture and oxygen. This involves the use of hydrophobic materials, multi-layer encapsulation strategies, or advanced sealing methods to improve long-term stability.

- Interface engineering: Optimizing the interfaces between different layers in perovskite solar cells to enhance stability. This includes developing novel charge transport materials, passivation layers, or buffer layers that can improve charge extraction while protecting the perovskite layer from degradation.

- Defect passivation and grain boundary engineering: Implementing strategies to passivate defects and engineer grain boundaries within the perovskite layer. This can involve the use of specific additives, post-treatment processes, or growth control techniques to reduce recombination sites and improve overall stability.

- Thermal stability enhancement: Developing methods to improve the thermal stability of perovskite solar cells. This includes the use of thermally stable materials, heat-resistant additives, or structural modifications that can withstand higher operating temperatures and thermal cycling without significant degradation.

02 Encapsulation and protective layers

Implementing effective encapsulation techniques and incorporating protective layers to shield the perovskite material from external degradation factors. This may include the use of hydrophobic materials, barrier films, or multi-layer encapsulation strategies to prevent moisture ingress and enhance long-term stability.Expand Specific Solutions03 Interface engineering

Optimizing the interfaces between different layers in the perovskite solar cell structure to improve stability. This involves developing novel charge transport materials, buffer layers, and surface treatments that enhance charge extraction while minimizing interfacial degradation and ion migration.Expand Specific Solutions04 Defect passivation and grain boundary engineering

Implementing strategies to passivate defects and engineer grain boundaries within the perovskite layer. This includes the use of additives, post-treatment processes, and crystallization control techniques to reduce the density of defects and improve the overall stability of the perovskite material.Expand Specific Solutions05 Tandem and multi-junction architectures

Developing tandem and multi-junction solar cell architectures that incorporate perovskite materials to enhance overall stability and efficiency. This approach combines perovskite layers with other photovoltaic materials to create more robust and efficient devices that can better withstand environmental stresses.Expand Specific Solutions

Key Players in Perovskite Solar Cell Industry

The perovskite solar cell stability landscape is evolving rapidly as the technology approaches commercialization. The industry is in a transitional phase, moving from R&D to early commercialization, with market size projected to grow significantly by 2025. While technical challenges remain, major players like Oxford University Innovation, Energy Materials Corp., and Trina Solar are making strides in improving stability and scalability. Universities and research institutions continue to play a crucial role in advancing the fundamental science, collaborating closely with industry partners to accelerate development and certification processes. The technology's maturity is progressing, but further work is needed to meet long-term stability requirements for widespread adoption.

Trina Solar Co., Ltd.

Technical Solution: Trina Solar Co., Ltd. has made significant progress in improving the stability of perovskite solar cells for commercial applications. Their approach combines material innovation with advanced manufacturing techniques. Trina Solar has developed a proprietary perovskite composition that incorporates multiple cations and halides, optimized for both efficiency and stability[10]. They have also implemented a low-temperature solution processing method that allows for better control of film morphology and reduces thermal stress during fabrication[11]. Furthermore, Trina Solar has pioneered an advanced encapsulation technology using flexible barrier films and edge sealants, which significantly enhances the moisture resistance and operational lifetime of their perovskite modules[12]. The company has also focused on scalable deposition techniques, such as slot-die coating, to ensure the stability improvements can be translated to large-area production.

Strengths: Optimized perovskite composition, scalable manufacturing processes, advanced encapsulation technology. Weaknesses: Potential higher production costs, challenges in achieving uniform performance across large areas.

Zhejiang Jinko Solar Co. Ltd.

Technical Solution: Zhejiang Jinko Solar Co. Ltd. has made substantial advancements in perovskite solar cell stability, focusing on both material engineering and device architecture. Their approach includes the development of a multi-component perovskite system that incorporates formamidinium, methylammonium, and cesium cations, along with iodide and bromide anions, to enhance structural stability and reduce phase segregation[13]. Jinko Solar has also implemented a novel interface engineering strategy, using functionalized fullerene derivatives as an electron transport layer, which improves charge extraction and reduces interfacial recombination[14]. Additionally, they have developed a hybrid tandem structure, combining perovskite top cells with silicon bottom cells, which not only increases efficiency but also improves overall stability by reducing the stress on the perovskite layer[15]. The company has also invested in advanced manufacturing processes, including the use of anti-solvent engineering and controlled crystallization techniques, to ensure consistent film quality and stability across large-area modules.

Strengths: Multi-component perovskite system, advanced interface engineering, hybrid tandem structure. Weaknesses: Increased complexity in manufacturing, potential higher material costs.

Core Innovations in Perovskite Stability Research

Solar cell

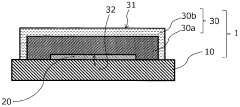

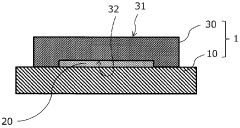

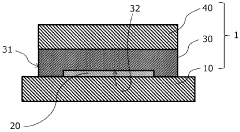

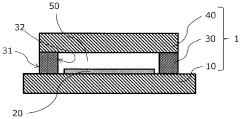

PatentWO2023132135A1

Innovation

- A solar cell structure with a first sealing portion containing a water vapor concentration adjusting material and a second sealing portion with lower water vapor permeability, controlling the water vapor concentration in the sealed space to an optimal range (100 ppm to 5000 ppm) to prevent moisture reaction with the perovskite compound and improve conductivity.

Solar cell

PatentWO2023132135A1

Innovation

- A solar cell structure with a first sealing portion containing a water vapor concentration adjusting material and a second sealing portion with lower water vapor permeability, controlling the water vapor concentration in the sealed space to an optimal range (100 ppm to 5000 ppm) to prevent moisture reaction with the perovskite compound and improve conductivity.

Certification Standards for Perovskite Solar Cells

Certification standards for perovskite solar cells are crucial for ensuring the reliability and performance of this emerging technology. As the industry moves towards commercialization, standardized testing and certification processes become increasingly important to build trust among consumers and investors.

The International Electrotechnical Commission (IEC) is at the forefront of developing certification standards for perovskite solar cells. The IEC Technical Committee 82 (TC 82) is responsible for creating and updating standards for photovoltaic systems, including perovskite technology. Their work focuses on establishing uniform test methods and performance criteria that can be applied across different manufacturers and regions.

One of the key challenges in developing certification standards for perovskite solar cells is addressing their unique stability issues. Unlike traditional silicon-based solar cells, perovskites are more susceptible to degradation from environmental factors such as moisture, heat, and light exposure. As a result, certification standards must include rigorous stability testing protocols that accurately reflect real-world conditions and long-term performance.

The IEC 61215 series of standards, which covers terrestrial photovoltaic modules, is being adapted to include specific requirements for perovskite solar cells. This includes modifications to existing tests and the introduction of new procedures tailored to perovskite technology. For example, enhanced damp heat testing and light-soaking protocols are being developed to assess the stability of perovskite modules under various environmental stresses.

In addition to stability testing, certification standards for perovskite solar cells must also address safety concerns. The IEC 61730 standard, which focuses on photovoltaic module safety qualification, is being updated to include specific requirements for perovskite technology. This includes assessing potential risks associated with lead-containing perovskite materials and ensuring proper encapsulation to prevent environmental contamination.

As the perovskite solar cell industry matures, certification standards will continue to evolve. Collaborative efforts between research institutions, industry players, and standardization bodies are essential to develop comprehensive and effective certification processes. These standards will play a crucial role in accelerating the commercialization of perovskite solar cells and ensuring their long-term success in the global renewable energy market.

The International Electrotechnical Commission (IEC) is at the forefront of developing certification standards for perovskite solar cells. The IEC Technical Committee 82 (TC 82) is responsible for creating and updating standards for photovoltaic systems, including perovskite technology. Their work focuses on establishing uniform test methods and performance criteria that can be applied across different manufacturers and regions.

One of the key challenges in developing certification standards for perovskite solar cells is addressing their unique stability issues. Unlike traditional silicon-based solar cells, perovskites are more susceptible to degradation from environmental factors such as moisture, heat, and light exposure. As a result, certification standards must include rigorous stability testing protocols that accurately reflect real-world conditions and long-term performance.

The IEC 61215 series of standards, which covers terrestrial photovoltaic modules, is being adapted to include specific requirements for perovskite solar cells. This includes modifications to existing tests and the introduction of new procedures tailored to perovskite technology. For example, enhanced damp heat testing and light-soaking protocols are being developed to assess the stability of perovskite modules under various environmental stresses.

In addition to stability testing, certification standards for perovskite solar cells must also address safety concerns. The IEC 61730 standard, which focuses on photovoltaic module safety qualification, is being updated to include specific requirements for perovskite technology. This includes assessing potential risks associated with lead-containing perovskite materials and ensuring proper encapsulation to prevent environmental contamination.

As the perovskite solar cell industry matures, certification standards will continue to evolve. Collaborative efforts between research institutions, industry players, and standardization bodies are essential to develop comprehensive and effective certification processes. These standards will play a crucial role in accelerating the commercialization of perovskite solar cells and ensuring their long-term success in the global renewable energy market.

Environmental Impact of Perovskite Solar Technology

Perovskite solar cells have emerged as a promising technology in the renewable energy sector, offering high efficiency and low-cost production. However, their environmental impact throughout the lifecycle must be carefully considered as the technology advances towards commercialization. The production of perovskite solar cells involves the use of lead-based compounds, which raises concerns about potential environmental contamination and health risks. While the amount of lead used is relatively small, proper handling and disposal protocols are crucial to mitigate these risks.

The manufacturing process of perovskite solar cells also requires the use of organic solvents, which can contribute to air pollution and pose health hazards if not managed properly. As the industry scales up, it is essential to develop and implement sustainable manufacturing practices that minimize the release of harmful chemicals into the environment. This includes exploring alternative, less toxic materials and improving solvent recycling techniques.

End-of-life management is another critical aspect of the environmental impact of perovskite solar technology. Unlike traditional silicon-based solar panels, perovskite cells have a shorter lifespan due to stability issues. This could potentially lead to increased electronic waste if not addressed through improved recycling and disposal methods. Research into efficient recycling processes for perovskite solar cells is ongoing, with the aim of recovering valuable materials and reducing the overall environmental footprint.

The energy payback time and carbon footprint of perovskite solar cells are generally favorable compared to traditional photovoltaic technologies. Their simpler manufacturing process and potential for high efficiency contribute to a lower overall environmental impact during the use phase. However, the long-term stability issues currently faced by perovskite cells could offset some of these benefits if frequent replacements are required.

Water consumption in the production of perovskite solar cells is relatively low compared to silicon-based technologies, which is advantageous in water-stressed regions. However, the potential for lead leaching into water systems in the event of damage or improper disposal remains a concern that must be addressed through robust encapsulation techniques and stringent safety standards.

As the technology progresses towards large-scale deployment, life cycle assessments (LCAs) are becoming increasingly important to quantify the environmental impacts accurately. These assessments will help guide the development of more sustainable materials and processes, ensuring that perovskite solar technology can deliver on its promise of clean energy without introducing new environmental challenges.

The manufacturing process of perovskite solar cells also requires the use of organic solvents, which can contribute to air pollution and pose health hazards if not managed properly. As the industry scales up, it is essential to develop and implement sustainable manufacturing practices that minimize the release of harmful chemicals into the environment. This includes exploring alternative, less toxic materials and improving solvent recycling techniques.

End-of-life management is another critical aspect of the environmental impact of perovskite solar technology. Unlike traditional silicon-based solar panels, perovskite cells have a shorter lifespan due to stability issues. This could potentially lead to increased electronic waste if not addressed through improved recycling and disposal methods. Research into efficient recycling processes for perovskite solar cells is ongoing, with the aim of recovering valuable materials and reducing the overall environmental footprint.

The energy payback time and carbon footprint of perovskite solar cells are generally favorable compared to traditional photovoltaic technologies. Their simpler manufacturing process and potential for high efficiency contribute to a lower overall environmental impact during the use phase. However, the long-term stability issues currently faced by perovskite cells could offset some of these benefits if frequent replacements are required.

Water consumption in the production of perovskite solar cells is relatively low compared to silicon-based technologies, which is advantageous in water-stressed regions. However, the potential for lead leaching into water systems in the event of damage or improper disposal remains a concern that must be addressed through robust encapsulation techniques and stringent safety standards.

As the technology progresses towards large-scale deployment, life cycle assessments (LCAs) are becoming increasingly important to quantify the environmental impacts accurately. These assessments will help guide the development of more sustainable materials and processes, ensuring that perovskite solar technology can deliver on its promise of clean energy without introducing new environmental challenges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!