What Is Thermal Cycling Tolerance for Perovskite Modules — Test Methods & Acceptance Criteria

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite Module Thermal Cycling Background

Perovskite solar cells have emerged as a promising technology in the field of photovoltaics, offering high efficiency and low-cost manufacturing potential. However, their long-term stability and durability under real-world operating conditions remain significant challenges. Thermal cycling, which involves repeated exposure to varying temperatures, is a critical factor affecting the performance and lifespan of perovskite modules.

The thermal cycling tolerance of perovskite modules refers to their ability to withstand temperature fluctuations without significant degradation in performance or structural integrity. This tolerance is crucial for ensuring the reliability and longevity of perovskite-based solar panels in diverse environmental conditions. The temperature variations experienced by solar modules can be substantial, ranging from sub-zero temperatures during cold nights to high temperatures exceeding 80°C under direct sunlight.

Thermal cycling can induce various degradation mechanisms in perovskite modules. These include phase transitions within the perovskite material, ion migration, interfacial delamination, and thermal expansion mismatches between different layers of the module. Such phenomena can lead to performance losses, reduced power output, and ultimately, module failure.

To address these challenges, researchers and manufacturers have been developing test methods and acceptance criteria to evaluate the thermal cycling tolerance of perovskite modules. These tests aim to simulate real-world temperature fluctuations and assess the modules' ability to maintain their performance and structural integrity over time.

Standard test protocols typically involve subjecting perovskite modules to repeated temperature cycles, often ranging from -40°C to +85°C, with specified ramp rates and dwell times at extreme temperatures. The number of cycles can vary, but common standards require hundreds or even thousands of cycles to evaluate long-term stability.

During and after thermal cycling tests, various parameters are monitored to assess the modules' performance. These include power conversion efficiency, fill factor, open-circuit voltage, and short-circuit current. Additionally, visual inspections and imaging techniques are employed to detect physical changes such as delamination, cracking, or discoloration.

Acceptance criteria for thermal cycling tolerance are typically based on the degree of performance degradation observed after a specified number of cycles. For example, a common criterion might require that the module retains at least 90% of its initial power output after 200 thermal cycles. However, as the perovskite technology is still evolving, standardized acceptance criteria are still being developed and refined by industry stakeholders and regulatory bodies.

The thermal cycling tolerance of perovskite modules refers to their ability to withstand temperature fluctuations without significant degradation in performance or structural integrity. This tolerance is crucial for ensuring the reliability and longevity of perovskite-based solar panels in diverse environmental conditions. The temperature variations experienced by solar modules can be substantial, ranging from sub-zero temperatures during cold nights to high temperatures exceeding 80°C under direct sunlight.

Thermal cycling can induce various degradation mechanisms in perovskite modules. These include phase transitions within the perovskite material, ion migration, interfacial delamination, and thermal expansion mismatches between different layers of the module. Such phenomena can lead to performance losses, reduced power output, and ultimately, module failure.

To address these challenges, researchers and manufacturers have been developing test methods and acceptance criteria to evaluate the thermal cycling tolerance of perovskite modules. These tests aim to simulate real-world temperature fluctuations and assess the modules' ability to maintain their performance and structural integrity over time.

Standard test protocols typically involve subjecting perovskite modules to repeated temperature cycles, often ranging from -40°C to +85°C, with specified ramp rates and dwell times at extreme temperatures. The number of cycles can vary, but common standards require hundreds or even thousands of cycles to evaluate long-term stability.

During and after thermal cycling tests, various parameters are monitored to assess the modules' performance. These include power conversion efficiency, fill factor, open-circuit voltage, and short-circuit current. Additionally, visual inspections and imaging techniques are employed to detect physical changes such as delamination, cracking, or discoloration.

Acceptance criteria for thermal cycling tolerance are typically based on the degree of performance degradation observed after a specified number of cycles. For example, a common criterion might require that the module retains at least 90% of its initial power output after 200 thermal cycles. However, as the perovskite technology is still evolving, standardized acceptance criteria are still being developed and refined by industry stakeholders and regulatory bodies.

Market Demand Analysis

The market demand for perovskite solar modules with high thermal cycling tolerance is rapidly growing, driven by the increasing adoption of solar energy and the need for more durable and efficient photovoltaic technologies. As the global solar industry continues to expand, there is a pressing requirement for solar modules that can withstand extreme temperature fluctuations without significant performance degradation.

Perovskite solar cells have emerged as a promising alternative to traditional silicon-based photovoltaics due to their potential for high efficiency and low-cost manufacturing. However, their commercial viability heavily depends on their ability to maintain performance under real-world conditions, including thermal cycling. This has created a substantial market demand for perovskite modules with enhanced thermal cycling tolerance.

The utility-scale solar sector, in particular, has shown keen interest in perovskite technology with improved thermal stability. Large-scale solar installations often experience significant temperature variations between day and night, as well as seasonal changes. Modules that can withstand these thermal cycles without substantial efficiency loss or physical degradation are highly sought after by solar farm developers and operators.

Building-integrated photovoltaics (BIPV) represent another growing market segment where thermal cycling tolerance is crucial. As architects and builders increasingly incorporate solar panels into building designs, the demand for aesthetically pleasing and durable perovskite modules that can withstand the thermal stresses of being part of a building's envelope is rising.

The automotive industry has also expressed interest in perovskite solar technology for integration into electric vehicles. Here, thermal cycling tolerance is essential due to the extreme temperature variations vehicles may experience in different climates and seasons. Perovskite modules that can maintain performance under these conditions could open up new applications in vehicle-integrated photovoltaics.

Developing countries with extreme climates present a significant market opportunity for thermally stable perovskite modules. These regions often have high solar potential but also face challenges related to temperature fluctuations. Robust perovskite modules could help accelerate solar adoption in these markets, addressing both energy needs and durability concerns.

The aerospace industry is another sector showing interest in perovskite solar technology with enhanced thermal cycling tolerance. Satellites and other space-based applications require solar cells that can withstand the extreme temperature cycles experienced in orbit. Perovskite modules meeting these stringent requirements could potentially disrupt the current space solar cell market.

Perovskite solar cells have emerged as a promising alternative to traditional silicon-based photovoltaics due to their potential for high efficiency and low-cost manufacturing. However, their commercial viability heavily depends on their ability to maintain performance under real-world conditions, including thermal cycling. This has created a substantial market demand for perovskite modules with enhanced thermal cycling tolerance.

The utility-scale solar sector, in particular, has shown keen interest in perovskite technology with improved thermal stability. Large-scale solar installations often experience significant temperature variations between day and night, as well as seasonal changes. Modules that can withstand these thermal cycles without substantial efficiency loss or physical degradation are highly sought after by solar farm developers and operators.

Building-integrated photovoltaics (BIPV) represent another growing market segment where thermal cycling tolerance is crucial. As architects and builders increasingly incorporate solar panels into building designs, the demand for aesthetically pleasing and durable perovskite modules that can withstand the thermal stresses of being part of a building's envelope is rising.

The automotive industry has also expressed interest in perovskite solar technology for integration into electric vehicles. Here, thermal cycling tolerance is essential due to the extreme temperature variations vehicles may experience in different climates and seasons. Perovskite modules that can maintain performance under these conditions could open up new applications in vehicle-integrated photovoltaics.

Developing countries with extreme climates present a significant market opportunity for thermally stable perovskite modules. These regions often have high solar potential but also face challenges related to temperature fluctuations. Robust perovskite modules could help accelerate solar adoption in these markets, addressing both energy needs and durability concerns.

The aerospace industry is another sector showing interest in perovskite solar technology with enhanced thermal cycling tolerance. Satellites and other space-based applications require solar cells that can withstand the extreme temperature cycles experienced in orbit. Perovskite modules meeting these stringent requirements could potentially disrupt the current space solar cell market.

Current Challenges

Perovskite solar modules face significant challenges in thermal cycling tolerance, which is crucial for their long-term stability and commercial viability. One of the primary issues is the intrinsic instability of perovskite materials under thermal stress. When exposed to temperature fluctuations, perovskite crystals can undergo phase transitions, leading to structural changes that negatively impact their photovoltaic performance.

The lack of standardized test methods for thermal cycling tolerance presents another major challenge. Unlike traditional silicon-based solar panels, which have well-established testing protocols, perovskite modules require specialized procedures that account for their unique material properties and degradation mechanisms. This absence of standardization makes it difficult to compare results across different research groups and manufacturers, hindering progress in the field.

Interfacial degradation between the perovskite layer and adjacent transport layers is a critical concern during thermal cycling. Temperature variations can cause differential thermal expansion, leading to delamination and the formation of defects at these interfaces. These defects act as recombination centers, reducing the overall efficiency of the solar module.

The encapsulation of perovskite modules poses another significant challenge in thermal cycling tolerance. Current encapsulation materials and techniques may not provide adequate protection against moisture ingress and thermal stress simultaneously. Developing encapsulation strategies that can withstand repeated thermal cycling while maintaining a hermetic seal is essential for improving module durability.

Scalability of thermal cycling tolerance from small laboratory cells to large-area modules remains a substantial hurdle. Techniques that work well for small-scale devices often face complications when applied to larger modules, particularly in maintaining uniform thermal distribution and stress management across the entire module area.

The development of accelerated aging tests that accurately predict long-term thermal cycling performance is another critical challenge. Current test methods may not fully capture the complex degradation mechanisms that occur over extended periods in real-world conditions. Establishing correlations between accelerated tests and actual field performance is crucial for reliable product development and certification.

Lastly, the acceptance criteria for thermal cycling tolerance in perovskite modules are still evolving. Determining appropriate pass/fail thresholds that balance performance requirements with practical manufacturing constraints is an ongoing challenge. These criteria must consider not only initial efficiency drop but also long-term degradation rates and potential recovery mechanisms unique to perovskite materials.

The lack of standardized test methods for thermal cycling tolerance presents another major challenge. Unlike traditional silicon-based solar panels, which have well-established testing protocols, perovskite modules require specialized procedures that account for their unique material properties and degradation mechanisms. This absence of standardization makes it difficult to compare results across different research groups and manufacturers, hindering progress in the field.

Interfacial degradation between the perovskite layer and adjacent transport layers is a critical concern during thermal cycling. Temperature variations can cause differential thermal expansion, leading to delamination and the formation of defects at these interfaces. These defects act as recombination centers, reducing the overall efficiency of the solar module.

The encapsulation of perovskite modules poses another significant challenge in thermal cycling tolerance. Current encapsulation materials and techniques may not provide adequate protection against moisture ingress and thermal stress simultaneously. Developing encapsulation strategies that can withstand repeated thermal cycling while maintaining a hermetic seal is essential for improving module durability.

Scalability of thermal cycling tolerance from small laboratory cells to large-area modules remains a substantial hurdle. Techniques that work well for small-scale devices often face complications when applied to larger modules, particularly in maintaining uniform thermal distribution and stress management across the entire module area.

The development of accelerated aging tests that accurately predict long-term thermal cycling performance is another critical challenge. Current test methods may not fully capture the complex degradation mechanisms that occur over extended periods in real-world conditions. Establishing correlations between accelerated tests and actual field performance is crucial for reliable product development and certification.

Lastly, the acceptance criteria for thermal cycling tolerance in perovskite modules are still evolving. Determining appropriate pass/fail thresholds that balance performance requirements with practical manufacturing constraints is an ongoing challenge. These criteria must consider not only initial efficiency drop but also long-term degradation rates and potential recovery mechanisms unique to perovskite materials.

Existing Test Methods

01 Thermal management systems for perovskite modules

Implementing advanced thermal management systems can improve the thermal cycling tolerance of perovskite modules. These systems may include heat sinks, cooling channels, or phase change materials to regulate temperature fluctuations and prevent thermal stress-induced degradation of the perovskite layer.- Thermal management systems for perovskite modules: Implementing effective thermal management systems can improve the thermal cycling tolerance of perovskite modules. These systems may include heat dissipation mechanisms, temperature control devices, and thermal insulation materials to regulate and stabilize the temperature of the modules during operation and environmental fluctuations.

- Encapsulation techniques for perovskite modules: Advanced encapsulation methods can enhance the thermal cycling tolerance of perovskite modules by protecting the sensitive perovskite material from environmental stresses. These techniques may involve the use of specialized sealants, barrier layers, and protective coatings to minimize thermal expansion and contraction effects.

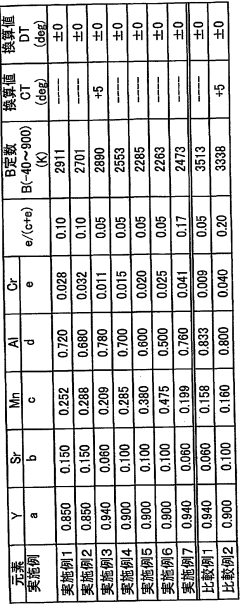

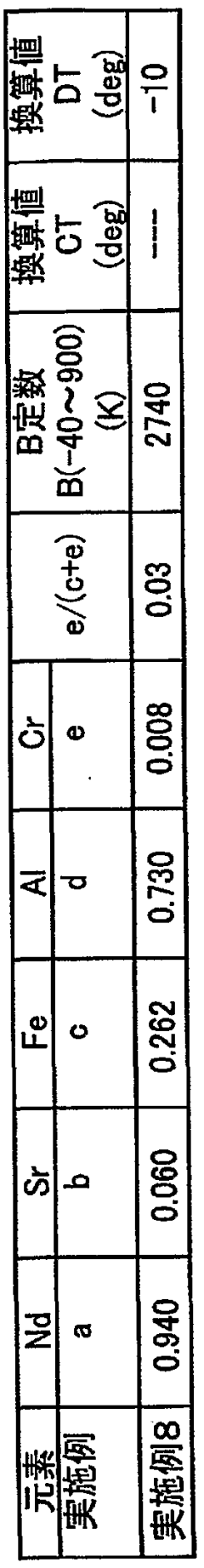

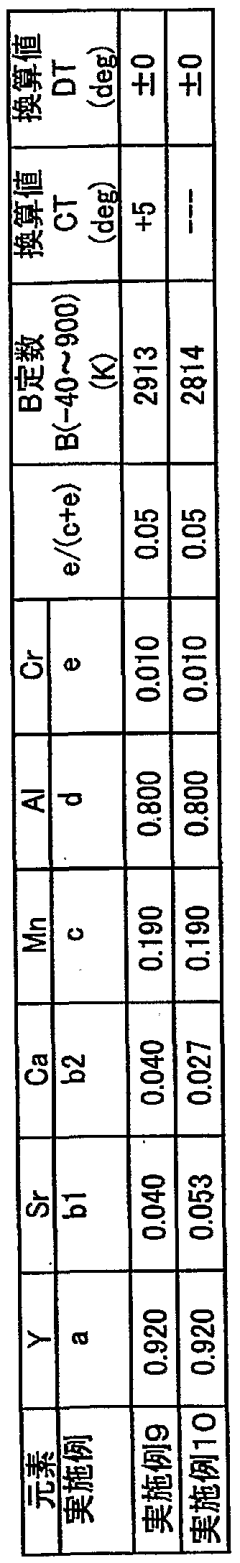

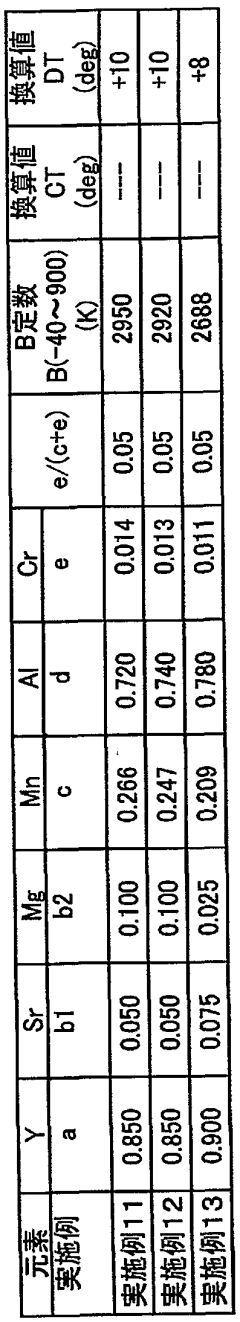

- Material composition optimization for thermal stability: Optimizing the composition of perovskite materials and associated layers can improve their inherent thermal stability. This may involve incorporating additives, dopants, or modifying the crystal structure to enhance resistance to thermal cycling and reduce degradation under temperature fluctuations.

- Stress-relief mechanisms in module design: Incorporating stress-relief mechanisms into the module design can mitigate the effects of thermal cycling. This may include flexible substrates, buffer layers, or structural elements that accommodate thermal expansion and contraction, reducing mechanical stress on the perovskite layer.

- Testing and characterization methods for thermal cycling tolerance: Developing and implementing advanced testing and characterization methods can help assess and improve the thermal cycling tolerance of perovskite modules. These methods may include accelerated aging tests, in-situ monitoring techniques, and thermal imaging to identify weak points and optimize module design for enhanced thermal stability.

02 Encapsulation techniques for improved thermal stability

Developing effective encapsulation methods can enhance the thermal cycling tolerance of perovskite modules. This may involve using moisture-resistant and thermally stable materials to protect the perovskite layer from environmental factors and temperature variations, thereby maintaining long-term performance.Expand Specific Solutions03 Compositional engineering of perovskite materials

Modifying the composition of perovskite materials can improve their thermal stability and cycling tolerance. This may include incorporating additives, dopants, or using mixed-cation perovskites to enhance the material's resistance to temperature-induced phase transitions and degradation.Expand Specific Solutions04 Interface engineering for improved thermal resilience

Optimizing the interfaces between the perovskite layer and adjacent layers in the module can enhance thermal cycling tolerance. This may involve developing buffer layers or modifying surface treatments to reduce thermal stress and improve adhesion between layers during temperature fluctuations.Expand Specific Solutions05 Testing and characterization methods for thermal cycling

Developing standardized testing protocols and advanced characterization techniques can help assess and improve the thermal cycling tolerance of perovskite modules. This may include accelerated aging tests, in-situ monitoring of material properties during thermal cycling, and non-destructive evaluation methods to identify potential failure modes.Expand Specific Solutions

Key Industry Players

The thermal cycling tolerance for perovskite modules is an emerging area of research in the rapidly evolving solar energy sector. The market is in its early growth stage, with significant potential for expansion as perovskite technology matures. Current market size is relatively small but expected to grow substantially in the coming years. Technologically, the field is still developing, with companies like Murata Manufacturing, TDK Electronics, and Trina Solar leading research efforts. These firms are working to improve the stability and durability of perovskite modules under thermal stress, a critical factor for commercial viability. As the technology progresses, standardized test methods and acceptance criteria are being established to ensure consistent performance and reliability across the industry.

Forschungszentrum Jülich GmbH

Technical Solution: Forschungszentrum Jülich has developed sophisticated thermal cycling protocols for perovskite solar modules. Their approach combines thermal shock testing (-40°C to 85°C) with controlled humidity exposure (85% RH) to simulate real-world conditions[5]. They utilize custom-built environmental chambers capable of rapid temperature and humidity changes. Jülich's testing includes in-situ electrical characterization and time-resolved photoluminescence measurements to track degradation mechanisms. Their acceptance criteria are based on statistical analysis of performance data, requiring 95% confidence that power loss will not exceed 10% after the equivalent of 25 years of thermal cycling[6].

Strengths: Cutting-edge research facilities, holistic approach to degradation studies. Weaknesses: Academic focus may not fully align with industry manufacturing needs.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The CEA has developed a comprehensive thermal cycling tolerance assessment for perovskite modules. Their method combines standard IEC 61215 thermal cycling (-40°C to 85°C, 200 cycles) with additional high-temperature storage tests at 85°C for extended periods[9]. They utilize specially designed climate chambers with precise temperature and humidity control. The CEA's approach includes regular intervallic testing of electrical parameters and detailed materials analysis using techniques such as Raman spectroscopy and X-ray photoelectron spectroscopy. Their acceptance criteria are based on a multi-parameter degradation model that considers both performance loss and materials changes, with a target of less than 10% power loss after the equivalent of 25 years of operation[10].

Strengths: Combination of standardized and advanced testing methods, detailed materials analysis. Weaknesses: Time-intensive testing protocol may slow down product development cycles.

Core Thermal Cycling Innovations

Perovskite materials for high temperature and high performance actuators and transducers

PatentInactiveUS6685849B2

Innovation

- A new family of perovskite solid solutions with the formula (1-x)BiMeO3-xPbTiO3, where Me is a suitably sized cation such as scandium, indium, or yttrium, combining crystallographic engineering with tolerance factor relationships to create high-temperature piezoelectric materials with a morphotropic phase boundary between rhombohedral and tetragonal phases, exceeding the temperature constraints of PZT-based materials.

Sintered electroconductive oxide, thermister element using sintered electroconductive oxide, and temperature sensor using thermister element

PatentWO2006109792A1

Innovation

- A conductive oxide sintered body with a perovskite phase, composed of specific group elements, is developed, allowing for a temperature gradient constant adjustment within 2000-3000K, ensuring stable resistance value changes across the desired temperature range by optimizing the composition and firing conditions.

Regulatory Framework

The regulatory framework surrounding thermal cycling tolerance for perovskite modules is still evolving, as this technology is relatively new compared to traditional silicon-based photovoltaics. However, several key standards and guidelines are emerging to address the unique characteristics of perovskite solar cells.

The International Electrotechnical Commission (IEC) is at the forefront of developing standards for perovskite solar technology. The IEC Technical Committee 82 (TC 82) is working on adapting existing photovoltaic standards to include perovskite-specific requirements. One of the most relevant standards under development is IEC 63209, which focuses on extended-stress testing of photovoltaic modules.

In the United States, the National Renewable Energy Laboratory (NREL) has been instrumental in developing test protocols for perovskite solar cells. Their research has led to the proposal of modified damp heat and thermal cycling tests that take into account the unique degradation mechanisms of perovskite materials.

The European Commission's Joint Research Centre (JRC) has also been active in this area, publishing guidelines for the assessment of perovskite solar cell stability. These guidelines recommend specific test conditions and durations for thermal cycling, which are more stringent than those for traditional silicon modules.

In China, the National Institute of Metrology (NIM) has been working on establishing measurement standards for perovskite solar cells, including protocols for thermal cycling tests. Their efforts are aimed at ensuring consistency and comparability of test results across different laboratories.

The International Summit on Organic and Hybrid Photovoltaics Stability (ISOS) has proposed a set of protocols specifically for perovskite solar cells, including thermal cycling tests. These protocols, known as ISOS-P, are gaining recognition in the scientific community and are being considered for incorporation into formal standards.

While not specifically focused on thermal cycling, the IEC 61215 standard for terrestrial photovoltaic modules provides a foundation for testing procedures that are being adapted for perovskite technology. The thermal cycling test described in this standard (TC200) is being used as a starting point for developing perovskite-specific protocols.

As the technology matures, it is expected that more comprehensive and specific regulations will be developed. Industry stakeholders, research institutions, and regulatory bodies are collaborating to establish a robust framework that ensures the reliability and performance of perovskite modules under various environmental conditions, including thermal cycling.

The International Electrotechnical Commission (IEC) is at the forefront of developing standards for perovskite solar technology. The IEC Technical Committee 82 (TC 82) is working on adapting existing photovoltaic standards to include perovskite-specific requirements. One of the most relevant standards under development is IEC 63209, which focuses on extended-stress testing of photovoltaic modules.

In the United States, the National Renewable Energy Laboratory (NREL) has been instrumental in developing test protocols for perovskite solar cells. Their research has led to the proposal of modified damp heat and thermal cycling tests that take into account the unique degradation mechanisms of perovskite materials.

The European Commission's Joint Research Centre (JRC) has also been active in this area, publishing guidelines for the assessment of perovskite solar cell stability. These guidelines recommend specific test conditions and durations for thermal cycling, which are more stringent than those for traditional silicon modules.

In China, the National Institute of Metrology (NIM) has been working on establishing measurement standards for perovskite solar cells, including protocols for thermal cycling tests. Their efforts are aimed at ensuring consistency and comparability of test results across different laboratories.

The International Summit on Organic and Hybrid Photovoltaics Stability (ISOS) has proposed a set of protocols specifically for perovskite solar cells, including thermal cycling tests. These protocols, known as ISOS-P, are gaining recognition in the scientific community and are being considered for incorporation into formal standards.

While not specifically focused on thermal cycling, the IEC 61215 standard for terrestrial photovoltaic modules provides a foundation for testing procedures that are being adapted for perovskite technology. The thermal cycling test described in this standard (TC200) is being used as a starting point for developing perovskite-specific protocols.

As the technology matures, it is expected that more comprehensive and specific regulations will be developed. Industry stakeholders, research institutions, and regulatory bodies are collaborating to establish a robust framework that ensures the reliability and performance of perovskite modules under various environmental conditions, including thermal cycling.

Environmental Impact Assessment

The environmental impact of perovskite solar modules, particularly in relation to their thermal cycling tolerance, is a critical consideration in the development and deployment of this emerging photovoltaic technology. As perovskite solar cells gain traction in the renewable energy sector, it is essential to assess their potential environmental effects throughout their lifecycle.

Thermal cycling tolerance directly influences the longevity and performance of perovskite modules, which in turn affects their environmental footprint. Modules with poor thermal cycling tolerance may degrade more rapidly, necessitating more frequent replacements and potentially increasing waste generation. Conversely, modules with high thermal cycling tolerance can maintain their efficiency for longer periods, reducing the need for replacements and minimizing environmental impact.

The manufacturing process of perovskite solar modules involves the use of various materials, some of which may have environmental implications. Lead-based perovskites, for instance, raise concerns about potential lead leaching into the environment. However, ongoing research is focused on developing lead-free alternatives to mitigate these risks. The thermal cycling tolerance of these alternative materials must be carefully evaluated to ensure they meet both environmental and performance standards.

Energy consumption during the production of perovskite modules is another important factor to consider. The relatively low processing temperatures required for perovskite fabrication compared to traditional silicon solar cells could potentially reduce energy inputs and associated carbon emissions. However, the impact of thermal cycling tolerance testing on overall energy consumption during manufacturing and quality control processes should be assessed.

End-of-life considerations for perovskite modules are crucial in evaluating their full environmental impact. The recyclability and proper disposal of modules that have reached the end of their operational life due to thermal cycling degradation or other factors must be addressed. Developing efficient recycling processes for perovskite modules, including the recovery of valuable materials, can significantly reduce their environmental footprint.

The potential for perovskite modules to contribute to reduced greenhouse gas emissions through clean energy generation must be weighed against their lifecycle environmental impacts. Improved thermal cycling tolerance can enhance the overall positive environmental impact of perovskite technology by extending module lifespan and maintaining high efficiency over time.

Thermal cycling tolerance directly influences the longevity and performance of perovskite modules, which in turn affects their environmental footprint. Modules with poor thermal cycling tolerance may degrade more rapidly, necessitating more frequent replacements and potentially increasing waste generation. Conversely, modules with high thermal cycling tolerance can maintain their efficiency for longer periods, reducing the need for replacements and minimizing environmental impact.

The manufacturing process of perovskite solar modules involves the use of various materials, some of which may have environmental implications. Lead-based perovskites, for instance, raise concerns about potential lead leaching into the environment. However, ongoing research is focused on developing lead-free alternatives to mitigate these risks. The thermal cycling tolerance of these alternative materials must be carefully evaluated to ensure they meet both environmental and performance standards.

Energy consumption during the production of perovskite modules is another important factor to consider. The relatively low processing temperatures required for perovskite fabrication compared to traditional silicon solar cells could potentially reduce energy inputs and associated carbon emissions. However, the impact of thermal cycling tolerance testing on overall energy consumption during manufacturing and quality control processes should be assessed.

End-of-life considerations for perovskite modules are crucial in evaluating their full environmental impact. The recyclability and proper disposal of modules that have reached the end of their operational life due to thermal cycling degradation or other factors must be addressed. Developing efficient recycling processes for perovskite modules, including the recovery of valuable materials, can significantly reduce their environmental footprint.

The potential for perovskite modules to contribute to reduced greenhouse gas emissions through clean energy generation must be weighed against their lifecycle environmental impacts. Improved thermal cycling tolerance can enhance the overall positive environmental impact of perovskite technology by extending module lifespan and maintaining high efficiency over time.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!